Measure GDI Engine Fuel Consumption Using Real Tests

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Fuel Efficiency Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, representing one of the most important advancements in internal combustion engine design. First introduced commercially in the late 1990s, GDI engines have become increasingly prevalent due to their potential for improved fuel efficiency and reduced emissions compared to traditional port fuel injection systems. The fundamental principle behind GDI involves injecting fuel directly into the combustion chamber at high pressure, allowing for more precise control of the combustion process.

The evolution of GDI technology has been driven by increasingly stringent global emissions regulations and consumer demand for improved fuel economy without sacrificing performance. Early GDI systems faced challenges related to particulate emissions and carbon buildup, but continuous refinements in injection strategies, combustion chamber design, and electronic control systems have addressed many of these initial concerns.

Current market trends indicate that GDI engines now power approximately 60% of new passenger vehicles in developed markets, with this percentage expected to increase further as manufacturers seek to meet future efficiency standards. The technology has proven particularly valuable when combined with other efficiency-enhancing technologies such as turbocharging, variable valve timing, and cylinder deactivation.

The primary objective of measuring GDI engine fuel consumption through real tests is to bridge the significant gap between laboratory-certified fuel economy figures and real-world performance. This discrepancy has become a critical issue for both regulatory bodies and consumers, with studies indicating differences of up to 40% between official figures and actual on-road consumption in some cases.

Real-world testing aims to develop more accurate methodologies that account for variables such as ambient conditions, driving behaviors, traffic patterns, and vehicle loading that are not fully represented in standardized laboratory tests. By establishing reliable real-world measurement protocols, stakeholders can better understand the true efficiency characteristics of GDI engines across diverse operating conditions.

Additional objectives include identifying specific operating conditions where GDI technology offers the greatest efficiency advantages, quantifying the impact of different driving styles on fuel consumption, and developing more sophisticated engine management strategies that can optimize fuel delivery based on real-world usage patterns rather than idealized test cycles.

The ultimate goal is to create a comprehensive framework for evaluating GDI engine fuel efficiency that combines laboratory precision with real-world relevance, thereby providing manufacturers, regulators, and consumers with more transparent and actionable information about vehicle performance and environmental impact.

The evolution of GDI technology has been driven by increasingly stringent global emissions regulations and consumer demand for improved fuel economy without sacrificing performance. Early GDI systems faced challenges related to particulate emissions and carbon buildup, but continuous refinements in injection strategies, combustion chamber design, and electronic control systems have addressed many of these initial concerns.

Current market trends indicate that GDI engines now power approximately 60% of new passenger vehicles in developed markets, with this percentage expected to increase further as manufacturers seek to meet future efficiency standards. The technology has proven particularly valuable when combined with other efficiency-enhancing technologies such as turbocharging, variable valve timing, and cylinder deactivation.

The primary objective of measuring GDI engine fuel consumption through real tests is to bridge the significant gap between laboratory-certified fuel economy figures and real-world performance. This discrepancy has become a critical issue for both regulatory bodies and consumers, with studies indicating differences of up to 40% between official figures and actual on-road consumption in some cases.

Real-world testing aims to develop more accurate methodologies that account for variables such as ambient conditions, driving behaviors, traffic patterns, and vehicle loading that are not fully represented in standardized laboratory tests. By establishing reliable real-world measurement protocols, stakeholders can better understand the true efficiency characteristics of GDI engines across diverse operating conditions.

Additional objectives include identifying specific operating conditions where GDI technology offers the greatest efficiency advantages, quantifying the impact of different driving styles on fuel consumption, and developing more sophisticated engine management strategies that can optimize fuel delivery based on real-world usage patterns rather than idealized test cycles.

The ultimate goal is to create a comprehensive framework for evaluating GDI engine fuel efficiency that combines laboratory precision with real-world relevance, thereby providing manufacturers, regulators, and consumers with more transparent and actionable information about vehicle performance and environmental impact.

Market Demand for Accurate Fuel Consumption Measurement

The global automotive industry is witnessing a significant shift towards more fuel-efficient vehicles, driven by stringent emission regulations, rising fuel costs, and growing environmental consciousness among consumers. This has created a substantial market demand for accurate fuel consumption measurement technologies, particularly for Gasoline Direct Injection (GDI) engines which have gained popularity due to their improved efficiency and performance characteristics.

According to recent market research, the global automotive fuel efficiency testing market was valued at approximately $180 million in 2022 and is projected to grow at a CAGR of 6.8% through 2030. This growth is primarily fueled by regulatory pressures, with major markets including the European Union, United States, China, and Japan implementing increasingly stringent fuel economy standards that require precise measurement methodologies.

Vehicle manufacturers are facing mounting pressure to provide accurate fuel consumption figures that reflect real-world driving conditions rather than laboratory-optimized results. The "emissions gap" scandal that affected several major automotive manufacturers has intensified scrutiny from regulatory bodies and consumers alike, creating demand for more transparent and accurate testing procedures that can reliably measure GDI engine fuel consumption under actual driving conditions.

Fleet operators represent another significant market segment driving demand for accurate fuel consumption measurement. With fuel costs accounting for approximately 30% of total fleet operating expenses, even marginal improvements in fuel efficiency can translate to substantial cost savings. Fleet managers increasingly require precise, real-world fuel consumption data to optimize vehicle selection, maintenance schedules, and driver training programs.

The aftermarket sector has also emerged as a growing market for fuel consumption measurement technologies. Performance tuning shops, independent repair facilities, and DIY enthusiasts seek affordable yet accurate tools to verify the effectiveness of modifications and repairs on fuel efficiency. This segment values portable, user-friendly measurement solutions that can provide reliable data without requiring specialized technical expertise.

Consumer advocacy groups and environmental organizations constitute another market driver, as they increasingly demand transparency in advertised fuel economy figures. These organizations frequently conduct independent testing to verify manufacturer claims, creating demand for standardized real-world measurement methodologies that can be consistently applied across different vehicle models and driving conditions.

The insurance industry has begun exploring usage-based insurance models that incorporate actual driving behavior and vehicle efficiency metrics, potentially creating a new market application for accurate fuel consumption measurement technologies that can integrate with telematics systems.

According to recent market research, the global automotive fuel efficiency testing market was valued at approximately $180 million in 2022 and is projected to grow at a CAGR of 6.8% through 2030. This growth is primarily fueled by regulatory pressures, with major markets including the European Union, United States, China, and Japan implementing increasingly stringent fuel economy standards that require precise measurement methodologies.

Vehicle manufacturers are facing mounting pressure to provide accurate fuel consumption figures that reflect real-world driving conditions rather than laboratory-optimized results. The "emissions gap" scandal that affected several major automotive manufacturers has intensified scrutiny from regulatory bodies and consumers alike, creating demand for more transparent and accurate testing procedures that can reliably measure GDI engine fuel consumption under actual driving conditions.

Fleet operators represent another significant market segment driving demand for accurate fuel consumption measurement. With fuel costs accounting for approximately 30% of total fleet operating expenses, even marginal improvements in fuel efficiency can translate to substantial cost savings. Fleet managers increasingly require precise, real-world fuel consumption data to optimize vehicle selection, maintenance schedules, and driver training programs.

The aftermarket sector has also emerged as a growing market for fuel consumption measurement technologies. Performance tuning shops, independent repair facilities, and DIY enthusiasts seek affordable yet accurate tools to verify the effectiveness of modifications and repairs on fuel efficiency. This segment values portable, user-friendly measurement solutions that can provide reliable data without requiring specialized technical expertise.

Consumer advocacy groups and environmental organizations constitute another market driver, as they increasingly demand transparency in advertised fuel economy figures. These organizations frequently conduct independent testing to verify manufacturer claims, creating demand for standardized real-world measurement methodologies that can be consistently applied across different vehicle models and driving conditions.

The insurance industry has begun exploring usage-based insurance models that incorporate actual driving behavior and vehicle efficiency metrics, potentially creating a new market application for accurate fuel consumption measurement technologies that can integrate with telematics systems.

Current State and Challenges in GDI Fuel Testing

Gasoline Direct Injection (GDI) technology has become the dominant fuel delivery system in modern internal combustion engines, offering improved fuel efficiency and reduced emissions. However, accurately measuring fuel consumption in real-world conditions remains a significant challenge. Current testing methodologies vary widely across regions and manufacturers, creating inconsistencies in reported fuel economy figures.

Laboratory-based testing protocols such as the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and the Environmental Protection Agency (EPA) cycles attempt to standardize measurements, but they often fail to capture the complexity of real-world driving conditions. This discrepancy between laboratory results and actual performance has led to consumer skepticism and regulatory scrutiny, particularly following emissions scandals in the automotive industry.

The technical challenges in GDI fuel consumption testing are multifaceted. First, the high-pressure fuel injection systems (operating at 200-300 bar) create measurement complexities not present in port fuel injection systems. The precise timing and quantity of fuel delivery are difficult to monitor without specialized equipment that can operate under these extreme pressures without affecting system performance.

Temperature variations significantly impact GDI fuel consumption measurements. Cold-start conditions, which represent a substantial portion of real-world driving scenarios, show markedly different consumption patterns compared to fully warmed engines. Current testing protocols often underrepresent these transitional operational states, leading to optimistic consumption figures.

Another major challenge is the integration of advanced driver assistance systems (ADAS) and their impact on fuel consumption. These systems, which are increasingly common in modern vehicles, can significantly alter driving patterns and energy management, yet standardized methodologies for accounting for their effects remain underdeveloped.

Data acquisition systems for real-world testing face limitations in bandwidth, storage capacity, and power requirements. The need for non-intrusive measurement techniques that don't alter vehicle performance presents additional technical hurdles. Current portable emissions measurement systems (PEMS) add weight and aerodynamic drag, potentially skewing results.

Regulatory frameworks worldwide are evolving toward more stringent real-world testing requirements, but harmonization remains elusive. The European Real Driving Emissions (RDE) regulations represent progress but still face implementation challenges and technological limitations in measurement accuracy.

The gap between laboratory and real-world measurements continues to average 20-40% according to recent studies, highlighting the urgent need for more sophisticated testing methodologies that can accurately capture the complex interactions between driver behavior, environmental conditions, and vehicle systems in GDI engines.

Laboratory-based testing protocols such as the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and the Environmental Protection Agency (EPA) cycles attempt to standardize measurements, but they often fail to capture the complexity of real-world driving conditions. This discrepancy between laboratory results and actual performance has led to consumer skepticism and regulatory scrutiny, particularly following emissions scandals in the automotive industry.

The technical challenges in GDI fuel consumption testing are multifaceted. First, the high-pressure fuel injection systems (operating at 200-300 bar) create measurement complexities not present in port fuel injection systems. The precise timing and quantity of fuel delivery are difficult to monitor without specialized equipment that can operate under these extreme pressures without affecting system performance.

Temperature variations significantly impact GDI fuel consumption measurements. Cold-start conditions, which represent a substantial portion of real-world driving scenarios, show markedly different consumption patterns compared to fully warmed engines. Current testing protocols often underrepresent these transitional operational states, leading to optimistic consumption figures.

Another major challenge is the integration of advanced driver assistance systems (ADAS) and their impact on fuel consumption. These systems, which are increasingly common in modern vehicles, can significantly alter driving patterns and energy management, yet standardized methodologies for accounting for their effects remain underdeveloped.

Data acquisition systems for real-world testing face limitations in bandwidth, storage capacity, and power requirements. The need for non-intrusive measurement techniques that don't alter vehicle performance presents additional technical hurdles. Current portable emissions measurement systems (PEMS) add weight and aerodynamic drag, potentially skewing results.

Regulatory frameworks worldwide are evolving toward more stringent real-world testing requirements, but harmonization remains elusive. The European Real Driving Emissions (RDE) regulations represent progress but still face implementation challenges and technological limitations in measurement accuracy.

The gap between laboratory and real-world measurements continues to average 20-40% according to recent studies, highlighting the urgent need for more sophisticated testing methodologies that can accurately capture the complex interactions between driver behavior, environmental conditions, and vehicle systems in GDI engines.

Existing GDI Fuel Consumption Measurement Methodologies

01 Fuel injection optimization techniques

Various techniques for optimizing fuel injection in GDI engines can significantly reduce fuel consumption. These include precise control of injection timing, pressure, and spray pattern to ensure optimal combustion. Advanced injection strategies such as multiple injections per cycle and variable injection pressure can improve fuel atomization and mixing with air, leading to more complete combustion and reduced fuel consumption.- Fuel injection optimization techniques: Various techniques for optimizing fuel injection in GDI engines can significantly reduce fuel consumption. These include precise control of injection timing, pressure, and spray pattern to ensure optimal combustion. Advanced injection strategies such as multiple injections per cycle and variable injection pressure can improve fuel atomization and mixing with air, leading to more complete combustion and reduced fuel consumption.

- Engine control systems for fuel efficiency: Sophisticated engine control systems play a crucial role in managing GDI engine fuel consumption. These systems utilize various sensors and algorithms to monitor engine parameters and adjust operating conditions in real-time. Advanced control strategies can optimize air-fuel ratio, ignition timing, and valve timing based on driving conditions, resulting in improved fuel economy while maintaining performance and emissions compliance.

- Combustion chamber design improvements: Innovations in combustion chamber design can enhance the fuel efficiency of GDI engines. Optimized piston crown shapes, intake port configurations, and cylinder head designs promote better air-fuel mixing and more complete combustion. These design improvements can reduce wall wetting, minimize quenching effects, and create ideal turbulence patterns that contribute to lower fuel consumption and reduced emissions.

- Thermal management solutions: Effective thermal management systems can significantly impact GDI engine fuel consumption. Technologies that optimize engine operating temperature, reduce friction losses, and manage heat distribution can improve combustion efficiency. Advanced cooling systems, thermal barrier coatings, and heat recovery mechanisms help maintain ideal operating temperatures under various conditions, contributing to better fuel economy and engine longevity.

- Integration with hybrid and start-stop systems: Combining GDI technology with hybrid powertrains or start-stop systems can further reduce overall fuel consumption. These integrated approaches leverage the efficiency benefits of GDI engines while adding capabilities like engine shutdown during idle, regenerative braking, and electric assist during acceleration. The synergistic effect of these technologies can significantly improve fuel economy in various driving conditions, particularly in urban environments.

02 Engine control systems for fuel efficiency

Sophisticated engine control systems play a crucial role in managing GDI engine fuel consumption. These systems utilize sensors and electronic control units to monitor and adjust various engine parameters in real-time. By implementing advanced algorithms for fuel-air mixture control, ignition timing, and throttle management, these control systems can optimize engine operation under various driving conditions to minimize fuel consumption while maintaining performance.Expand Specific Solutions03 Combustion chamber design improvements

Innovations in combustion chamber design can enhance the fuel efficiency of GDI engines. Optimized piston crown shapes, intake port configurations, and combustion chamber geometries promote better air-fuel mixing and more complete combustion. These design improvements can reduce wall wetting, minimize quenching effects, and create ideal turbulence patterns, all contributing to reduced fuel consumption and improved thermal efficiency.Expand Specific Solutions04 Turbocharging and downsizing strategies

Combining GDI technology with turbocharging and engine downsizing offers significant fuel consumption benefits. Smaller displacement engines with turbochargers can deliver equivalent power to larger naturally aspirated engines while consuming less fuel. The precise fuel control of GDI systems complements turbocharging by allowing for optimized air-fuel ratios across a wide range of operating conditions, resulting in improved thermal efficiency and reduced fuel consumption.Expand Specific Solutions05 Thermal management and friction reduction

Effective thermal management systems and friction reduction technologies can further enhance GDI engine fuel efficiency. Advanced cooling systems that maintain optimal operating temperatures, low-friction coatings for engine components, and improved lubricants all contribute to reduced mechanical losses. By minimizing energy losses due to friction and optimizing thermal conditions for combustion, these technologies help decrease overall fuel consumption in GDI engines.Expand Specific Solutions

Key Industry Players in Engine Testing Equipment

The fuel consumption measurement landscape for GDI engines is evolving rapidly, currently transitioning from early adoption to mainstream implementation. The market is expanding significantly as automotive manufacturers prioritize fuel efficiency to meet stringent emissions regulations. Technologically, the field shows varying maturity levels across competitors. Hyundai Motor and Kia lead with advanced real-world testing methodologies, while Ford Global Technologies and Honda Motor focus on integrating testing with vehicle development cycles. HORIBA Instruments and HORIBA MIRA provide specialized measurement equipment, establishing industry standards. Oil companies like Shell, Repsol, and Petróleo Brasileiro contribute fuel formulation expertise. Academic institutions including Beijing Institute of Technology and Jiangsu University are advancing theoretical frameworks, creating a competitive ecosystem balancing commercial applications with research innovation.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an advanced real-world testing methodology for GDI engine fuel consumption that integrates vehicle-to-infrastructure (V2I) communication with traditional measurement techniques. Their system employs high-precision Coriolis flow meters installed in-line with the fuel delivery system, capable of measuring instantaneous fuel flow rates with minimal pressure drop impact on engine performance. Hyundai's approach incorporates road gradient detection and compensation algorithms that isolate the effects of elevation changes on GDI fuel consumption patterns. Their methodology includes specialized testing protocols for various injection strategies (single vs. multiple injections per cycle) to optimize real-world efficiency. Hyundai has implemented a driver behavior modeling system that standardizes the human factor in consumption testing, using robotic driving systems that replicate consistent acceleration and braking patterns. Their approach also features comparative analysis between different GDI engine generations and conventional port fuel injection systems under identical real-world conditions, providing valuable benchmarking data for technology advancement assessment.

Strengths: Hyundai's V2I integration provides contextual data that helps isolate environmental factors affecting consumption. Their specialized injection strategy testing offers insights into optimizing GDI operation for real-world conditions. Weaknesses: The V2I system requires specialized infrastructure that limits testing to equipped regions. The complex test apparatus necessitates significant vehicle modification that may impact normal operating characteristics.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive real-world testing methodology for GDI engine fuel consumption measurement that combines portable emissions measurement systems (PEMS) with advanced data analytics. Their approach utilizes on-board diagnostics (OBD) integration with real-time fuel flow meters to capture actual consumption data across various driving conditions. Ford's system incorporates compensation algorithms that account for temperature variations, fuel quality differences, and altitude changes that affect GDI engine performance. The company has implemented a standardized test protocol that includes urban, highway, and mixed driving cycles with controlled ambient conditions monitoring. Ford's methodology also features machine learning algorithms that analyze the correlation between laboratory testing and real-world performance, allowing for predictive modeling of fuel consumption under various conditions not directly tested. Their system can detect and isolate the impact of specific GDI technologies such as direct injection timing, spray patterns, and turbocharging effects on overall fuel economy.

Strengths: Ford's methodology provides exceptional real-world accuracy through comprehensive data collection across diverse driving conditions. Their machine learning integration enables predictive modeling beyond test conditions. Weaknesses: The system requires expensive specialized equipment and extensive testing time, making it less accessible for smaller research entities. The complexity of data analysis demands significant computational resources.

Critical Test Protocols and Standards Analysis

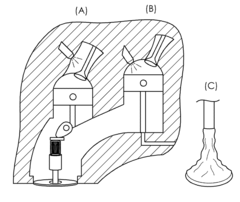

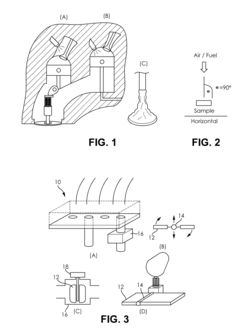

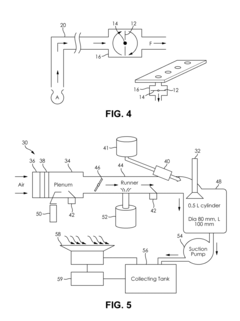

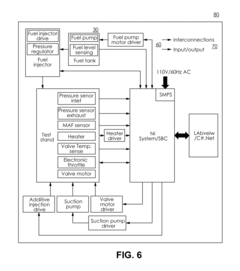

Evaluation of the delivery and effectiveness of engine performance chemicals and products

PatentActiveUS20170114716A1

Innovation

- A method and system for evaluating the delivery and effectiveness of engine performance chemicals and products for reducing intake valve deposits, utilizing a controlled environment with simulated engine conditions to quantify improvements, including adjustable parameters like air-fuel ratio, temperature, and oscillation frequency, and employing three approaches to introduce cleaners: airstream addition, suction-based distribution, and fuel additive application.

Fuel additives and formulations for improving performance of gasoline direct injection engines

PatentWO2022140533A1

Innovation

- A novel fuel additive composition comprising an acylated detergent, a Mannich detergent, and a polyether/polyetheramine, which reduces carbonaceous deposits in both PFI and GDI engines by preventing or removing deposits, thereby improving engine performance and reducing emissions.

Environmental Regulations Impact on Testing Requirements

Environmental regulations worldwide have significantly evolved over the past decade, creating a complex framework that directly impacts fuel consumption testing requirements for GDI (Gasoline Direct Injection) engines. The European Union's implementation of Euro 6d standards has established stringent Real Driving Emissions (RDE) testing protocols that require manufacturers to demonstrate compliance under actual driving conditions rather than solely in laboratory settings. These regulations have shifted testing paradigms from controlled environments to real-world scenarios, necessitating more sophisticated measurement methodologies.

The United States Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have similarly tightened their regulatory frameworks, introducing supplemental testing procedures that evaluate fuel consumption across diverse driving patterns and environmental conditions. These regulations specifically target the discrepancies between laboratory and real-world performance that became evident during various emissions scandals in the automotive industry.

Asian markets, particularly China with its China 6 standards, have adopted comparable approaches that emphasize real-world testing conditions. The global regulatory convergence toward real-driving assessments has fundamentally altered how manufacturers must approach fuel consumption measurement for GDI engines, requiring more comprehensive data collection across variable conditions.

Temperature requirements present particular challenges for GDI engine testing, as regulations now mandate performance verification across extreme temperature ranges (-7°C to 35°C in European RDE tests). This expanded environmental testing window has revealed significant variations in fuel consumption patterns that were previously undetected in standard laboratory conditions, particularly regarding cold-start efficiency and thermal management strategies.

Altitude considerations have also been incorporated into modern testing requirements, with regulations requiring performance validation at elevations up to 1,300 meters. This has exposed additional challenges for GDI systems, as fuel atomization and combustion characteristics change significantly with atmospheric pressure variations, directly impacting consumption measurements.

The regulatory focus on particulate emissions has further complicated GDI engine testing, as these engines typically produce higher particulate matter than port fuel injection alternatives. This has necessitated the development of more precise measurement techniques that can simultaneously track fuel consumption and emissions output, particularly during transient operating conditions where GDI engines may exhibit efficiency fluctuations.

The cumulative effect of these evolving regulations has been a fundamental shift toward testing methodologies that capture real-world variability while maintaining measurement precision. Manufacturers must now develop testing protocols that account for environmental factors previously considered outside standard test parameters, creating both challenges and opportunities for innovation in measurement technologies.

The United States Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have similarly tightened their regulatory frameworks, introducing supplemental testing procedures that evaluate fuel consumption across diverse driving patterns and environmental conditions. These regulations specifically target the discrepancies between laboratory and real-world performance that became evident during various emissions scandals in the automotive industry.

Asian markets, particularly China with its China 6 standards, have adopted comparable approaches that emphasize real-world testing conditions. The global regulatory convergence toward real-driving assessments has fundamentally altered how manufacturers must approach fuel consumption measurement for GDI engines, requiring more comprehensive data collection across variable conditions.

Temperature requirements present particular challenges for GDI engine testing, as regulations now mandate performance verification across extreme temperature ranges (-7°C to 35°C in European RDE tests). This expanded environmental testing window has revealed significant variations in fuel consumption patterns that were previously undetected in standard laboratory conditions, particularly regarding cold-start efficiency and thermal management strategies.

Altitude considerations have also been incorporated into modern testing requirements, with regulations requiring performance validation at elevations up to 1,300 meters. This has exposed additional challenges for GDI systems, as fuel atomization and combustion characteristics change significantly with atmospheric pressure variations, directly impacting consumption measurements.

The regulatory focus on particulate emissions has further complicated GDI engine testing, as these engines typically produce higher particulate matter than port fuel injection alternatives. This has necessitated the development of more precise measurement techniques that can simultaneously track fuel consumption and emissions output, particularly during transient operating conditions where GDI engines may exhibit efficiency fluctuations.

The cumulative effect of these evolving regulations has been a fundamental shift toward testing methodologies that capture real-world variability while maintaining measurement precision. Manufacturers must now develop testing protocols that account for environmental factors previously considered outside standard test parameters, creating both challenges and opportunities for innovation in measurement technologies.

Data Acquisition and Processing Technologies

The acquisition and processing of data in GDI engine fuel consumption measurement requires sophisticated technologies to ensure accuracy and reliability. Modern data acquisition systems for engine testing typically incorporate multiple sensor arrays that simultaneously capture various parameters including fuel flow rates, air-fuel ratios, exhaust gas composition, engine speed, load conditions, and ambient environmental factors. These systems operate at high sampling frequencies, often exceeding 1 kHz, to capture transient phenomena that significantly impact fuel consumption measurements.

Real-time data acquisition hardware from manufacturers such as National Instruments, Siemens, and AVL provides the foundation for these measurement systems, offering multi-channel capabilities with high-precision analog-to-digital converters that minimize signal noise and quantization errors. These systems typically achieve measurement accuracies within ±0.1% for critical parameters, essential for detecting the subtle efficiency improvements in modern GDI engines.

Signal conditioning represents a critical component in the measurement chain, with specialized hardware implementing anti-aliasing filters, amplification circuits, and isolation mechanisms to protect sensitive measurement equipment from engine-generated electromagnetic interference. Advanced signal processing algorithms further enhance data quality through adaptive filtering techniques that can distinguish between actual performance variations and measurement artifacts.

For fuel consumption specifically, Coriolis flow meters have emerged as the gold standard, offering direct mass flow measurement with accuracies approaching ±0.1% of reading across the wide dynamic range required for GDI engine testing. These are complemented by carbon balance methods using exhaust gas analyzers that provide independent verification of consumption figures.

Data processing technologies have evolved significantly, with specialized software platforms integrating statistical analysis tools, machine learning algorithms for pattern recognition, and automated calibration procedures. These systems can compensate for sensor drift, identify outliers, and apply correction factors based on reference measurements. Cloud-based processing solutions now enable the handling of massive datasets generated during extended test campaigns, facilitating collaborative analysis across distributed research teams.

Real-time visualization tools provide engineers with immediate feedback during testing, allowing for on-the-fly test procedure adjustments. Post-processing capabilities include cycle-averaging techniques, frequency domain analysis, and correlation studies that reveal relationships between operating parameters and fuel efficiency outcomes.

Real-time data acquisition hardware from manufacturers such as National Instruments, Siemens, and AVL provides the foundation for these measurement systems, offering multi-channel capabilities with high-precision analog-to-digital converters that minimize signal noise and quantization errors. These systems typically achieve measurement accuracies within ±0.1% for critical parameters, essential for detecting the subtle efficiency improvements in modern GDI engines.

Signal conditioning represents a critical component in the measurement chain, with specialized hardware implementing anti-aliasing filters, amplification circuits, and isolation mechanisms to protect sensitive measurement equipment from engine-generated electromagnetic interference. Advanced signal processing algorithms further enhance data quality through adaptive filtering techniques that can distinguish between actual performance variations and measurement artifacts.

For fuel consumption specifically, Coriolis flow meters have emerged as the gold standard, offering direct mass flow measurement with accuracies approaching ±0.1% of reading across the wide dynamic range required for GDI engine testing. These are complemented by carbon balance methods using exhaust gas analyzers that provide independent verification of consumption figures.

Data processing technologies have evolved significantly, with specialized software platforms integrating statistical analysis tools, machine learning algorithms for pattern recognition, and automated calibration procedures. These systems can compensate for sensor drift, identify outliers, and apply correction factors based on reference measurements. Cloud-based processing solutions now enable the handling of massive datasets generated during extended test campaigns, facilitating collaborative analysis across distributed research teams.

Real-time visualization tools provide engineers with immediate feedback during testing, allowing for on-the-fly test procedure adjustments. Post-processing capabilities include cycle-averaging techniques, frequency domain analysis, and correlation studies that reveal relationships between operating parameters and fuel efficiency outcomes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!