Measure WOLED Lifespan in High-Use Environments

SEP 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED Lifespan Technology Background and Objectives

White Organic Light-Emitting Diodes (WOLEDs) have emerged as a revolutionary technology in the display and lighting industries since their initial development in the late 1980s. The evolution of WOLED technology has been characterized by significant improvements in efficiency, color quality, and manufacturing processes. However, lifespan remains a critical challenge, particularly in high-use environments where devices operate continuously or under harsh conditions.

The technical trajectory of WOLEDs shows a clear progression from simple single-layer devices to complex multi-layer structures incorporating various emissive materials. Early WOLEDs suffered from rapid degradation, with lifespans measured in hundreds of hours. Modern iterations have extended this to tens of thousands of hours under standard conditions, but performance in high-use scenarios continues to lag behind industry requirements.

Current industry standards typically measure WOLED lifespan as the time taken for luminance to decrease to 50% or 70% of initial brightness (L50 or L70). However, these measurements are predominantly conducted under controlled laboratory conditions that fail to replicate real-world high-use environments, creating a significant gap between specified and actual performance metrics.

The primary degradation mechanisms in WOLEDs include chemical decomposition of organic materials, electrode deterioration, and interfacial instability. These processes accelerate dramatically under conditions of elevated temperature, high humidity, continuous operation, and high brightness settings—precisely the conditions found in many commercial and industrial applications.

The technical objectives of this research are multifaceted. First, to develop standardized methodologies for measuring WOLED lifespan that accurately reflect performance in high-use environments. Second, to identify the specific failure modes and degradation pathways that dominate under these conditions. Third, to establish predictive models that can reliably extrapolate long-term performance from accelerated testing protocols.

Beyond measurement, we aim to understand the fundamental physical and chemical processes that limit WOLED longevity in demanding applications. This includes investigating the impact of thermal cycling, humidity fluctuations, and variable power loads on device stability. The ultimate goal is to bridge the gap between laboratory testing and real-world performance, enabling more accurate lifespan predictions and informing the development of more robust WOLED technologies.

The technological evolution in this field is trending toward novel material systems, advanced encapsulation techniques, and hybrid device architectures that promise enhanced stability. By establishing reliable measurement protocols for high-use environments, this research will provide critical feedback to guide these development efforts and accelerate the adoption of WOLEDs in demanding applications.

The technical trajectory of WOLEDs shows a clear progression from simple single-layer devices to complex multi-layer structures incorporating various emissive materials. Early WOLEDs suffered from rapid degradation, with lifespans measured in hundreds of hours. Modern iterations have extended this to tens of thousands of hours under standard conditions, but performance in high-use scenarios continues to lag behind industry requirements.

Current industry standards typically measure WOLED lifespan as the time taken for luminance to decrease to 50% or 70% of initial brightness (L50 or L70). However, these measurements are predominantly conducted under controlled laboratory conditions that fail to replicate real-world high-use environments, creating a significant gap between specified and actual performance metrics.

The primary degradation mechanisms in WOLEDs include chemical decomposition of organic materials, electrode deterioration, and interfacial instability. These processes accelerate dramatically under conditions of elevated temperature, high humidity, continuous operation, and high brightness settings—precisely the conditions found in many commercial and industrial applications.

The technical objectives of this research are multifaceted. First, to develop standardized methodologies for measuring WOLED lifespan that accurately reflect performance in high-use environments. Second, to identify the specific failure modes and degradation pathways that dominate under these conditions. Third, to establish predictive models that can reliably extrapolate long-term performance from accelerated testing protocols.

Beyond measurement, we aim to understand the fundamental physical and chemical processes that limit WOLED longevity in demanding applications. This includes investigating the impact of thermal cycling, humidity fluctuations, and variable power loads on device stability. The ultimate goal is to bridge the gap between laboratory testing and real-world performance, enabling more accurate lifespan predictions and informing the development of more robust WOLED technologies.

The technological evolution in this field is trending toward novel material systems, advanced encapsulation techniques, and hybrid device architectures that promise enhanced stability. By establishing reliable measurement protocols for high-use environments, this research will provide critical feedback to guide these development efforts and accelerate the adoption of WOLEDs in demanding applications.

Market Demand Analysis for Durable WOLED Solutions

The WOLED (White Organic Light-Emitting Diode) market has experienced significant growth in recent years, driven by increasing demand for high-quality displays in various electronic devices. Market research indicates that the global OLED market is projected to reach $48.8 billion by 2026, with WOLED technology representing a substantial segment of this market. The durability of WOLED displays has emerged as a critical factor influencing consumer purchasing decisions, particularly in high-use environments such as retail, transportation, healthcare, and industrial settings.

In retail environments, digital signage operates continuously for extended periods, often exceeding 16 hours daily. Market surveys reveal that retailers are willing to pay a premium of 15-20% for display solutions that demonstrate proven longevity, as replacement costs and downtime significantly impact operational expenses. Similarly, transportation hubs require displays that can withstand 24/7 operation while maintaining consistent brightness and color accuracy throughout their operational lifespan.

The healthcare sector presents unique demands for WOLED durability, with medical displays requiring exceptional reliability and consistent performance. Hospital environments typically operate displays for 12+ hours daily, with critical monitoring systems running continuously. Market analysis shows that healthcare institutions prioritize display solutions with documented lifespan metrics and predictable degradation patterns to ensure patient safety and diagnostic accuracy.

Corporate and educational sectors represent another significant market segment, with conference rooms and classrooms utilizing display technology for 8-10 hours daily. These environments demand displays that maintain performance despite frequent power cycles and varying content types. Survey data indicates that procurement decisions increasingly incorporate total cost of ownership calculations, where display lifespan directly impacts return on investment metrics.

Consumer electronics manufacturers have identified display longevity as a key differentiator in premium product segments. Smartphones and tablets with demonstrably longer-lasting displays command higher market prices and enjoy stronger brand loyalty. This trend is particularly evident in regions with high device usage rates, such as East Asia and North America.

Market forecasts predict that demand for verifiable lifespan metrics will intensify as WOLED technology expands into emerging applications such as automotive displays, wearable devices, and smart home interfaces. These applications expose displays to challenging environmental conditions including temperature fluctuations, humidity variations, and vibration—factors that accelerate display degradation and necessitate robust lifespan testing methodologies.

Industry stakeholders increasingly require standardized testing protocols that accurately predict real-world performance in high-use scenarios. This demand has created market opportunities for testing equipment manufacturers and certification services that can provide objective lifespan assessments under accelerated aging conditions that simulate actual usage patterns.

In retail environments, digital signage operates continuously for extended periods, often exceeding 16 hours daily. Market surveys reveal that retailers are willing to pay a premium of 15-20% for display solutions that demonstrate proven longevity, as replacement costs and downtime significantly impact operational expenses. Similarly, transportation hubs require displays that can withstand 24/7 operation while maintaining consistent brightness and color accuracy throughout their operational lifespan.

The healthcare sector presents unique demands for WOLED durability, with medical displays requiring exceptional reliability and consistent performance. Hospital environments typically operate displays for 12+ hours daily, with critical monitoring systems running continuously. Market analysis shows that healthcare institutions prioritize display solutions with documented lifespan metrics and predictable degradation patterns to ensure patient safety and diagnostic accuracy.

Corporate and educational sectors represent another significant market segment, with conference rooms and classrooms utilizing display technology for 8-10 hours daily. These environments demand displays that maintain performance despite frequent power cycles and varying content types. Survey data indicates that procurement decisions increasingly incorporate total cost of ownership calculations, where display lifespan directly impacts return on investment metrics.

Consumer electronics manufacturers have identified display longevity as a key differentiator in premium product segments. Smartphones and tablets with demonstrably longer-lasting displays command higher market prices and enjoy stronger brand loyalty. This trend is particularly evident in regions with high device usage rates, such as East Asia and North America.

Market forecasts predict that demand for verifiable lifespan metrics will intensify as WOLED technology expands into emerging applications such as automotive displays, wearable devices, and smart home interfaces. These applications expose displays to challenging environmental conditions including temperature fluctuations, humidity variations, and vibration—factors that accelerate display degradation and necessitate robust lifespan testing methodologies.

Industry stakeholders increasingly require standardized testing protocols that accurately predict real-world performance in high-use scenarios. This demand has created market opportunities for testing equipment manufacturers and certification services that can provide objective lifespan assessments under accelerated aging conditions that simulate actual usage patterns.

Current WOLED Durability Challenges in High-Use Settings

White Organic Light-Emitting Diodes (WOLEDs) face significant durability challenges in high-use environments that limit their widespread adoption in commercial and industrial applications. One of the primary issues is the differential aging of the organic materials that produce different colors. Blue emitters typically degrade faster than red and green counterparts, leading to color shift over time and reducing the overall lifespan of the display. This uneven degradation becomes particularly problematic in environments where displays operate continuously for extended periods.

Temperature fluctuations in high-use settings further exacerbate WOLED degradation. When operating in environments with temperatures exceeding 40°C, the organic materials experience accelerated molecular breakdown, significantly shortening device lifetime. Conversely, extremely cold environments can cause physical stress on the organic layers, leading to delamination and catastrophic failure of the display structure.

Humidity presents another critical challenge for WOLED durability. The encapsulation technologies currently employed in commercial WOLEDs provide insufficient protection against moisture ingress during prolonged exposure to humid environments. Water molecules that penetrate the device react with the electron transport layers and emissive materials, creating non-emissive "dark spots" that progressively expand and diminish display performance.

Continuous high-brightness operation, often required in commercial signage and automotive displays, induces accelerated degradation through increased current density. This leads to joule heating within the device and promotes the formation of trap states that reduce charge carrier mobility and quantum efficiency. Studies indicate that operating WOLEDs at 1000 nits continuously can reduce their effective lifespan by 40-60% compared to standard usage patterns.

UV exposure in outdoor or brightly lit indoor environments catalyzes photochemical reactions within the organic layers. These reactions break down the molecular structures responsible for light emission, particularly affecting blue phosphorescent materials. Current UV filtering approaches add cost and complexity while reducing overall luminous efficacy.

Mechanical stress poses a significant challenge for flexible WOLED implementations. Repeated bending or vibration in high-use environments creates microfractures in the thin film layers and deteriorates the interfaces between organic and electrode layers. This is particularly problematic in automotive and industrial control panel applications where vibration is constant.

Electrical stress from power fluctuations and static discharge events common in industrial environments can create localized hot spots that permanently damage WOLED pixels. Current protection circuitry adds complexity and cost while not fully mitigating these risks in harsh operating conditions.

These durability challenges collectively limit WOLED application in mission-critical environments where display longevity is essential. Addressing these issues requires interdisciplinary approaches combining materials science, device engineering, and advanced manufacturing techniques.

Temperature fluctuations in high-use settings further exacerbate WOLED degradation. When operating in environments with temperatures exceeding 40°C, the organic materials experience accelerated molecular breakdown, significantly shortening device lifetime. Conversely, extremely cold environments can cause physical stress on the organic layers, leading to delamination and catastrophic failure of the display structure.

Humidity presents another critical challenge for WOLED durability. The encapsulation technologies currently employed in commercial WOLEDs provide insufficient protection against moisture ingress during prolonged exposure to humid environments. Water molecules that penetrate the device react with the electron transport layers and emissive materials, creating non-emissive "dark spots" that progressively expand and diminish display performance.

Continuous high-brightness operation, often required in commercial signage and automotive displays, induces accelerated degradation through increased current density. This leads to joule heating within the device and promotes the formation of trap states that reduce charge carrier mobility and quantum efficiency. Studies indicate that operating WOLEDs at 1000 nits continuously can reduce their effective lifespan by 40-60% compared to standard usage patterns.

UV exposure in outdoor or brightly lit indoor environments catalyzes photochemical reactions within the organic layers. These reactions break down the molecular structures responsible for light emission, particularly affecting blue phosphorescent materials. Current UV filtering approaches add cost and complexity while reducing overall luminous efficacy.

Mechanical stress poses a significant challenge for flexible WOLED implementations. Repeated bending or vibration in high-use environments creates microfractures in the thin film layers and deteriorates the interfaces between organic and electrode layers. This is particularly problematic in automotive and industrial control panel applications where vibration is constant.

Electrical stress from power fluctuations and static discharge events common in industrial environments can create localized hot spots that permanently damage WOLED pixels. Current protection circuitry adds complexity and cost while not fully mitigating these risks in harsh operating conditions.

These durability challenges collectively limit WOLED application in mission-critical environments where display longevity is essential. Addressing these issues requires interdisciplinary approaches combining materials science, device engineering, and advanced manufacturing techniques.

Current Measurement Methodologies for WOLED Longevity

01 Material composition for improved WOLED lifespan

The lifespan of White Organic Light-Emitting Diodes (WOLEDs) can be significantly improved through careful selection of organic materials and dopants. Specific combinations of host materials and phosphorescent dopants can reduce degradation mechanisms and enhance operational stability. These compositions often include optimized ratios of red, green, and blue emitting materials to maintain color balance throughout the device lifetime while minimizing differential aging of the various emissive components.- Material composition for improved WOLED lifespan: Specific material compositions can significantly enhance the lifespan of White Organic Light-Emitting Diodes. These include optimized combinations of host materials, dopants, and transport layers that reduce degradation mechanisms. Advanced phosphorescent and fluorescent emitters with improved stability contribute to longer operational lifetimes. The selection of materials with compatible energy levels and appropriate molecular structures minimizes stress during operation and prevents premature aging of the device.

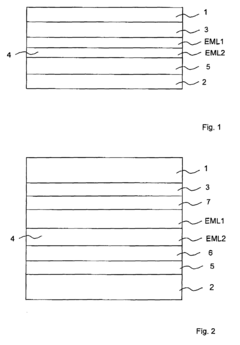

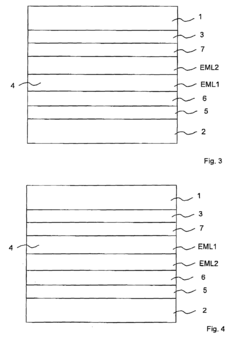

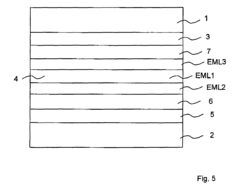

- Multi-layer structure design for WOLED longevity: The arrangement and design of multiple layers in WOLED devices significantly impact their operational lifespan. Optimized layer thicknesses and interfaces between electron transport layers, hole transport layers, and emission layers can reduce current density and heat generation. Tandem structures with multiple emission units connected by charge generation layers distribute operational stress and extend device lifetime. Buffer layers and carefully engineered transition zones between different functional layers prevent degradation mechanisms at interfaces.

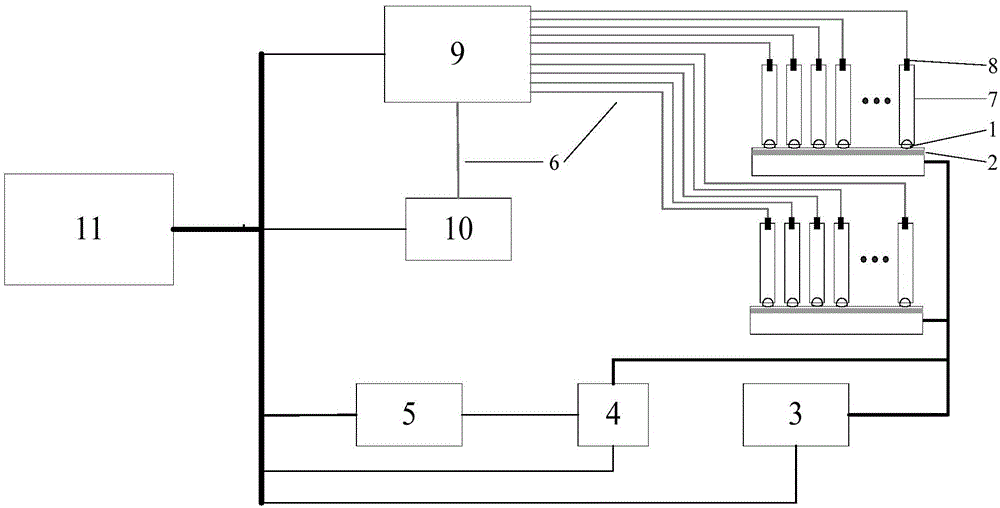

- Driving method and current control for extending WOLED lifespan: Specialized driving methods and current control techniques can significantly extend WOLED operational lifetimes. Pulse-width modulation and adaptive brightness control reduce thermal stress during operation. Current distribution optimization prevents localized degradation in high-brightness areas. Compensation algorithms that adjust driving parameters based on usage history and temperature conditions maintain consistent performance over time. These approaches minimize degradation mechanisms related to current flow and charge carrier imbalances.

- Thermal management solutions for WOLED longevity: Effective thermal management is crucial for extending WOLED lifespan as heat accelerates degradation mechanisms. Heat dissipation structures integrated into device architecture reduce operating temperatures. Thermally conductive substrates and encapsulation materials help distribute and remove heat from emission layers. Temperature sensors and feedback systems that adjust brightness based on thermal conditions prevent overheating. These thermal management approaches significantly slow down temperature-dependent degradation processes that limit device lifetime.

- Encapsulation and barrier technologies for WOLED protection: Advanced encapsulation and barrier technologies protect WOLED devices from environmental factors that accelerate degradation. Multi-layer barrier films with alternating organic and inorganic layers prevent moisture and oxygen penetration. Edge sealing techniques eliminate ingress pathways around device perimeters. Self-healing encapsulation materials can repair minor damage to protective barriers. These protection strategies shield sensitive organic materials from external degradation factors, significantly extending operational lifetimes under real-world conditions.

02 Device structure optimization for WOLED longevity

The structural design of WOLEDs plays a crucial role in determining their operational lifespan. Multi-layer architectures with optimized thickness of transport layers, buffer layers, and carefully positioned emission zones can distribute electrical stress more evenly throughout the device. Tandem structures with multiple emission units connected by charge generation layers allow for lower current density operation at equivalent brightness, significantly extending device lifetime. Specialized electrode configurations and encapsulation techniques further protect against environmental degradation factors.Expand Specific Solutions03 Driving method innovations for extending WOLED lifespan

Novel driving schemes can substantially extend WOLED operational lifetime by reducing electrical stress on the organic materials. Techniques such as pulse-width modulation, constant-current driving, and compensation algorithms that account for device aging help maintain consistent performance over time. Advanced driving methods also include temperature-dependent current adjustment and pixel-specific compensation to ensure uniform aging across display panels, preventing localized degradation that can lead to image retention or burn-in effects.Expand Specific Solutions04 Thermal management solutions for WOLED longevity

Effective thermal management is essential for maximizing WOLED lifespan, as elevated operating temperatures accelerate degradation mechanisms in organic materials. Innovative heat dissipation structures, including specialized substrates with high thermal conductivity, integrated heat sinks, and thermally conductive adhesives help maintain lower operating temperatures. Some designs incorporate temperature sensors and adaptive brightness control systems that automatically adjust power consumption based on device temperature to prevent thermal stress during operation.Expand Specific Solutions05 Encapsulation and barrier technologies for WOLED protection

Advanced encapsulation and barrier technologies are critical for protecting WOLEDs from environmental factors that accelerate degradation. Multi-layer thin film encapsulation with alternating organic and inorganic layers provides effective moisture and oxygen barriers while maintaining flexibility. Some solutions employ getter materials that actively absorb contaminants within the sealed device. Edge sealing techniques and specialized adhesives further enhance protection against environmental ingress, significantly extending the operational lifetime of WOLEDs in various applications and environmental conditions.Expand Specific Solutions

Key Industry Players in WOLED Durability Research

The WOLED lifespan measurement in high-use environments market is currently in a growth phase, with increasing adoption in commercial and consumer electronics sectors. The global OLED market is projected to reach approximately $48 billion by 2023, with WOLED technology gaining significant traction. Technologically, the field shows varying maturity levels across players. Universal Display Corporation and Samsung Display lead with advanced phosphorescent OLED materials and testing methodologies, while BOE Technology and Shenzhen China Star Optoelectronics are rapidly advancing their capabilities. Academic institutions like University of Southern California and University of Michigan contribute fundamental research, while specialized companies such as Hangzhou Everfine Photo-e-info focus on measurement instrumentation. Nitto Denko and Merck Patent GmbH provide essential materials, creating a diverse ecosystem of innovation across the WOLED lifespan assessment landscape.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has pioneered a comprehensive WOLED lifespan measurement system specifically for high-use environments. Their approach combines real-time monitoring with accelerated aging protocols to accurately predict panel degradation. Samsung's methodology employs specialized optical measurement equipment that captures minute changes in luminance, color coordinates, and power efficiency during continuous operation[3]. Their system incorporates environmental chambers that simulate various usage conditions including temperature cycling (between -20°C and 85°C), humidity variation (10-95% RH), and UV exposure to replicate outdoor applications. Samsung has developed proprietary algorithms that correlate accelerated test data with real-world performance, enabling accurate lifespan predictions from shorter test periods. Their testing protocol includes periodic measurement of pixel-level luminance uniformity, allowing for identification of specific degradation mechanisms in different panel regions. Samsung's system also monitors electrical parameters during aging to detect changes in driving voltage requirements, which serve as early indicators of material degradation before visible brightness loss occurs[4].

Strengths: Extensive manufacturing infrastructure allowing for large-scale validation of test results, vertical integration providing control over both materials and device architecture, and established presence in consumer electronics enabling real-world data collection. Weaknesses: Proprietary testing methodologies that may not align with industry standards, and focus primarily on consumer electronics environments rather than specialized industrial applications.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has developed an advanced scientific framework for measuring and predicting WOLED lifespan in demanding operational environments. Their approach combines fundamental materials science with innovative measurement techniques to understand degradation mechanisms at the molecular level. Michigan's research utilizes in-situ spectroscopic analysis during device operation, allowing real-time monitoring of chemical changes within the organic layers as degradation occurs[9]. Their methodology incorporates transient electroluminescence measurements with sub-microsecond resolution, enabling separation of different degradation pathways based on their characteristic timescales. The university has pioneered the use of isotopically labeled OLED materials that can be tracked through mass spectrometry during device aging, providing direct evidence of specific chemical degradation products. Their measurement system includes variable-temperature testing capabilities (from -40°C to 120°C) that help establish activation energies for different degradation mechanisms, enabling more accurate extrapolation to normal operating conditions. Michigan researchers have developed mathematical models that account for multiple simultaneous degradation mechanisms, providing more accurate lifetime predictions than traditional stretched-exponential approaches[10]. Their work includes correlation studies between accelerated laboratory tests and real-world device performance in various high-stress applications, continuously refining the acceleration factors used for lifetime predictions.

Strengths: Deep scientific understanding of fundamental degradation mechanisms, access to advanced analytical instrumentation not typically available in industrial settings, and academic approach that prioritizes publication of methodologies. Weaknesses: Potential gap between laboratory research and commercial implementation, and possible focus on scientific understanding rather than standardized testing protocols for manufacturing.

Critical Patents and Research in WOLED Lifespan Extension

Light emitting element

PatentInactiveEP1705727A1

Innovation

- A light-emitting component with a fluorescent emitter in the blue or blue-green spectral range and a phosphorescent emitter in another spectral range, where the triplet energy of the fluorescent emitter is higher than that of the phosphorescent emitter, allowing for efficient energy transfer and extended lifespan by utilizing triplet excitons for light emission.

Accelerated on-line test system for service life of LED

PatentActiveCN105021968A

Innovation

- A lightweight automated LED life-acceleration online test system is designed. It uses a PID heater for precise temperature control, combines the spectral method to calculate the junction temperature, conducts electrical characteristics testing through an electrical matrix switch and a test source meter, and establishes a light decay and color life model. , realizing all-round testing and real-time monitoring of photoelectric, color and heat characteristics.

Environmental Impact Factors on WOLED Performance

The environmental conditions in which White Organic Light-Emitting Diodes (WOLEDs) operate significantly influence their performance and longevity. Temperature stands as one of the most critical factors affecting WOLED lifespan. Research indicates that operating temperatures exceeding 40°C can accelerate degradation mechanisms within the organic layers, potentially reducing lifespan by 20-30% compared to operation at standard room temperature (25°C). Conversely, extremely low temperatures may cause thermal stress during power cycles, leading to delamination issues at material interfaces.

Humidity represents another crucial environmental variable. WOLEDs are inherently sensitive to moisture ingress, which can trigger chemical reactions with the electron transport layers and cathode materials. High-humidity environments (>60% RH) have been documented to accelerate dark spot formation and edge degradation, particularly in displays with compromised encapsulation. Advanced barrier technologies incorporating alternating inorganic/organic layers have demonstrated significant improvements, reducing moisture permeation rates to below 10^-6 g/m²/day.

Light exposure, particularly UV radiation, catalyzes photochemical degradation processes within WOLED structures. Studies have shown that continuous exposure to ambient UV light can accelerate color shift phenomena and reduce luminance efficiency by up to 15% over extended periods. This effect becomes particularly pronounced in outdoor digital signage applications and automotive displays where solar exposure is unavoidable.

Atmospheric contaminants present additional challenges for WOLED performance. Sulfur-containing compounds, volatile organic compounds (VOCs), and particulate matter can interact with both the encapsulation materials and the active layers. Laboratory analyses have demonstrated that even low concentrations (parts per billion) of certain airborne contaminants can initiate localized degradation mechanisms, manifesting as non-uniform brightness and color rendering across the display surface.

Mechanical stress factors, including vibration and impact forces, affect WOLED durability in high-use environments such as industrial control panels and transportation displays. Continuous vibration can gradually compromise the integrity of internal interfaces, while sudden impacts may create microfractures in rigid components. Flexible WOLED technologies incorporating elastomeric substrates have shown improved resilience to mechanical stressors, maintaining performance metrics after exposure to repeated bending cycles (>10,000 cycles at 10mm radius).

Electrical environment factors, particularly power quality issues like voltage fluctuations and transient spikes, can significantly impact WOLED driver circuits and consequently affect display performance. Installations in environments with unstable power supplies have exhibited accelerated differential aging between pixel elements, resulting in permanent image retention phenomena.

Humidity represents another crucial environmental variable. WOLEDs are inherently sensitive to moisture ingress, which can trigger chemical reactions with the electron transport layers and cathode materials. High-humidity environments (>60% RH) have been documented to accelerate dark spot formation and edge degradation, particularly in displays with compromised encapsulation. Advanced barrier technologies incorporating alternating inorganic/organic layers have demonstrated significant improvements, reducing moisture permeation rates to below 10^-6 g/m²/day.

Light exposure, particularly UV radiation, catalyzes photochemical degradation processes within WOLED structures. Studies have shown that continuous exposure to ambient UV light can accelerate color shift phenomena and reduce luminance efficiency by up to 15% over extended periods. This effect becomes particularly pronounced in outdoor digital signage applications and automotive displays where solar exposure is unavoidable.

Atmospheric contaminants present additional challenges for WOLED performance. Sulfur-containing compounds, volatile organic compounds (VOCs), and particulate matter can interact with both the encapsulation materials and the active layers. Laboratory analyses have demonstrated that even low concentrations (parts per billion) of certain airborne contaminants can initiate localized degradation mechanisms, manifesting as non-uniform brightness and color rendering across the display surface.

Mechanical stress factors, including vibration and impact forces, affect WOLED durability in high-use environments such as industrial control panels and transportation displays. Continuous vibration can gradually compromise the integrity of internal interfaces, while sudden impacts may create microfractures in rigid components. Flexible WOLED technologies incorporating elastomeric substrates have shown improved resilience to mechanical stressors, maintaining performance metrics after exposure to repeated bending cycles (>10,000 cycles at 10mm radius).

Electrical environment factors, particularly power quality issues like voltage fluctuations and transient spikes, can significantly impact WOLED driver circuits and consequently affect display performance. Installations in environments with unstable power supplies have exhibited accelerated differential aging between pixel elements, resulting in permanent image retention phenomena.

Standardization Requirements for WOLED Lifespan Testing

The standardization of WOLED lifespan testing methodologies represents a critical need in the rapidly evolving display technology landscape. Current testing protocols exhibit significant variations across manufacturers, research institutions, and industry bodies, creating challenges in comparing performance data and establishing reliable benchmarks for high-use environments. These inconsistencies undermine consumer confidence and hinder technological advancement in the WOLED sector.

A comprehensive standardization framework must address multiple testing parameters simultaneously. Temperature and humidity controls during testing require precise specification, as WOLED degradation mechanisms are highly sensitive to environmental conditions. Testing conducted at 23±2°C with 50±5% relative humidity has emerged as a potential baseline, though additional profiles for extreme conditions should be included to simulate diverse real-world scenarios.

Luminance measurement protocols present another standardization challenge. The industry currently lacks consensus on whether constant current or constant brightness testing methodologies more accurately reflect real-world usage patterns. Each approach yields different lifespan projections, with constant brightness testing typically providing more conservative estimates relevant to high-use applications where display luminance must remain consistent over time.

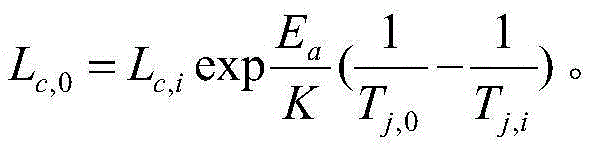

Acceleration factors for expedited testing demand rigorous validation and standardization. Current practices often employ elevated temperature and current density to accelerate degradation, but the mathematical models correlating accelerated results to normal operating conditions vary significantly between organizations. A unified approach to acceleration factors would enable more reliable extrapolation of long-term performance from shorter test durations.

Endpoint definitions require particular attention in standardization efforts. The conventional LT50 (time to 50% luminance reduction) metric may be insufficient for high-use environments where even modest luminance degradation impacts functionality. Supplementary metrics such as color shift tolerance (Δu'v' ≤ 0.04) and uniformity degradation should be incorporated into standardized testing protocols.

Cycle testing represents another critical area requiring standardization. High-use environments frequently involve on-off cycling that can accelerate degradation through thermal stress and interfacial phenomena. Standardized protocols should specify cycle frequency, duration, and environmental transitions to ensure test results accurately predict field performance.

A comprehensive standardization framework must address multiple testing parameters simultaneously. Temperature and humidity controls during testing require precise specification, as WOLED degradation mechanisms are highly sensitive to environmental conditions. Testing conducted at 23±2°C with 50±5% relative humidity has emerged as a potential baseline, though additional profiles for extreme conditions should be included to simulate diverse real-world scenarios.

Luminance measurement protocols present another standardization challenge. The industry currently lacks consensus on whether constant current or constant brightness testing methodologies more accurately reflect real-world usage patterns. Each approach yields different lifespan projections, with constant brightness testing typically providing more conservative estimates relevant to high-use applications where display luminance must remain consistent over time.

Acceleration factors for expedited testing demand rigorous validation and standardization. Current practices often employ elevated temperature and current density to accelerate degradation, but the mathematical models correlating accelerated results to normal operating conditions vary significantly between organizations. A unified approach to acceleration factors would enable more reliable extrapolation of long-term performance from shorter test durations.

Endpoint definitions require particular attention in standardization efforts. The conventional LT50 (time to 50% luminance reduction) metric may be insufficient for high-use environments where even modest luminance degradation impacts functionality. Supplementary metrics such as color shift tolerance (Δu'v' ≤ 0.04) and uniformity degradation should be incorporated into standardized testing protocols.

Cycle testing represents another critical area requiring standardization. High-use environments frequently involve on-off cycling that can accelerate degradation through thermal stress and interfacial phenomena. Standardized protocols should specify cycle frequency, duration, and environmental transitions to ensure test results accurately predict field performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!