Methane Pyrolysis: Cost-Effectiveness Analysis.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Background and Objectives

Methane pyrolysis represents a significant technological advancement in hydrogen production, offering a cleaner alternative to traditional steam methane reforming (SMR) processes. The technology has evolved considerably since its conceptual development in the mid-20th century, with substantial progress occurring in the last two decades as global focus on decarbonization has intensified. The fundamental principle involves thermal decomposition of methane (CH₄) into hydrogen (H₂) and solid carbon, without producing carbon dioxide emissions that characterize conventional hydrogen production methods.

The evolution of methane pyrolysis technology has followed several distinct phases, beginning with laboratory-scale experiments in the 1960s, advancing through pilot demonstrations in the 1990s, and now entering early commercial implementation in the 2020s. Recent technological breakthroughs in catalyst development, reactor design, and process integration have significantly improved conversion efficiencies and operational stability, making methane pyrolysis increasingly viable for industrial application.

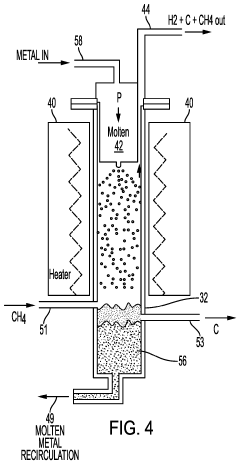

Current technological trends indicate a growing emphasis on molten metal reactors, particularly those utilizing liquid metals such as tin, nickel, and copper-based alloys. Parallel development paths include plasma-assisted pyrolysis and advanced thermal reactors with specialized carbon separation mechanisms. These innovations address historical challenges related to carbon deposition, catalyst deactivation, and energy intensity that previously limited commercial adoption.

The primary objective of methane pyrolysis cost-effectiveness analysis is to establish economic viability benchmarks against conventional hydrogen production methods while accounting for carbon pricing scenarios. Specific technical goals include achieving hydrogen production costs below $2/kg, carbon conversion efficiencies exceeding 95%, and continuous operation periods of 1000+ hours without significant performance degradation.

Secondary objectives encompass the development of value chains for solid carbon byproducts, which can potentially serve as revenue streams in carbon fiber, construction materials, or advanced materials applications. This dual-product approach represents a paradigm shift in hydrogen economics, potentially transforming carbon from waste product to valuable commodity.

The technology aims to bridge the gap between current fossil-based hydrogen production and fully renewable electrolysis methods, providing a transitional pathway that can utilize existing natural gas infrastructure while dramatically reducing associated emissions. As such, methane pyrolysis represents a critical enabling technology for near-term decarbonization efforts across multiple industrial sectors, including ammonia production, refining, and emerging applications in steel manufacturing and synthetic fuel production.

The evolution of methane pyrolysis technology has followed several distinct phases, beginning with laboratory-scale experiments in the 1960s, advancing through pilot demonstrations in the 1990s, and now entering early commercial implementation in the 2020s. Recent technological breakthroughs in catalyst development, reactor design, and process integration have significantly improved conversion efficiencies and operational stability, making methane pyrolysis increasingly viable for industrial application.

Current technological trends indicate a growing emphasis on molten metal reactors, particularly those utilizing liquid metals such as tin, nickel, and copper-based alloys. Parallel development paths include plasma-assisted pyrolysis and advanced thermal reactors with specialized carbon separation mechanisms. These innovations address historical challenges related to carbon deposition, catalyst deactivation, and energy intensity that previously limited commercial adoption.

The primary objective of methane pyrolysis cost-effectiveness analysis is to establish economic viability benchmarks against conventional hydrogen production methods while accounting for carbon pricing scenarios. Specific technical goals include achieving hydrogen production costs below $2/kg, carbon conversion efficiencies exceeding 95%, and continuous operation periods of 1000+ hours without significant performance degradation.

Secondary objectives encompass the development of value chains for solid carbon byproducts, which can potentially serve as revenue streams in carbon fiber, construction materials, or advanced materials applications. This dual-product approach represents a paradigm shift in hydrogen economics, potentially transforming carbon from waste product to valuable commodity.

The technology aims to bridge the gap between current fossil-based hydrogen production and fully renewable electrolysis methods, providing a transitional pathway that can utilize existing natural gas infrastructure while dramatically reducing associated emissions. As such, methane pyrolysis represents a critical enabling technology for near-term decarbonization efforts across multiple industrial sectors, including ammonia production, refining, and emerging applications in steel manufacturing and synthetic fuel production.

Market Demand for Carbon-Neutral Hydrogen

The global hydrogen market is experiencing a significant shift towards carbon-neutral production methods, with carbon-neutral hydrogen emerging as a critical component in the transition to a low-carbon economy. Current market demand for hydrogen stands at approximately 70 million tonnes annually, primarily used in industrial applications such as ammonia production, petroleum refining, and methanol synthesis. However, nearly 95% of this hydrogen is produced through carbon-intensive methods like steam methane reforming (SMR), which generates substantial CO2 emissions.

Market analysis indicates rapidly growing demand for carbon-neutral hydrogen across multiple sectors. The transportation sector represents one of the most promising growth areas, with fuel cell electric vehicles (FCEVs) gaining traction in heavy-duty transport, long-haul trucking, and public transportation where battery limitations become apparent. Major automotive manufacturers including Toyota, Hyundai, and Honda have made significant investments in hydrogen fuel cell technology.

The industrial sector presents another substantial market opportunity, particularly in hard-to-abate industries such as steel manufacturing, where hydrogen can replace coal in direct reduction processes. Companies like SSAB, ArcelorMittal, and ThyssenKrupp have initiated pilot projects using hydrogen for steel production, signaling a potential market disruption in this carbon-intensive industry.

Energy storage applications represent a third major demand driver, with hydrogen increasingly viewed as a solution for long-duration energy storage to complement intermittent renewable energy sources. Several utility-scale projects are underway in Europe, Australia, and Japan, demonstrating hydrogen's role in grid stabilization and seasonal energy storage.

Market forecasts project carbon-neutral hydrogen demand to reach 400-500 million tonnes annually by 2050, representing a market value exceeding $700 billion. This growth trajectory is supported by increasingly ambitious national hydrogen strategies, with over 30 countries having published dedicated roadmaps and investment plans totaling more than $300 billion through 2030.

Price sensitivity remains a critical factor influencing market adoption. Current carbon-neutral hydrogen production costs range from $3-8/kg, significantly higher than conventional hydrogen at $1-2/kg. However, analysis suggests that methane pyrolysis could potentially deliver hydrogen at $1.5-3/kg, positioning it competitively against other low-carbon production methods while offering the advantage of solid carbon co-production.

Regulatory frameworks are evolving to support market development, with carbon pricing mechanisms, renewable energy mandates, and sector-specific decarbonization targets creating favorable conditions for carbon-neutral hydrogen adoption. The EU's Hydrogen Strategy and similar initiatives in Japan, South Korea, and Australia are establishing clear market signals that are accelerating investment in production capacity and infrastructure development.

Market analysis indicates rapidly growing demand for carbon-neutral hydrogen across multiple sectors. The transportation sector represents one of the most promising growth areas, with fuel cell electric vehicles (FCEVs) gaining traction in heavy-duty transport, long-haul trucking, and public transportation where battery limitations become apparent. Major automotive manufacturers including Toyota, Hyundai, and Honda have made significant investments in hydrogen fuel cell technology.

The industrial sector presents another substantial market opportunity, particularly in hard-to-abate industries such as steel manufacturing, where hydrogen can replace coal in direct reduction processes. Companies like SSAB, ArcelorMittal, and ThyssenKrupp have initiated pilot projects using hydrogen for steel production, signaling a potential market disruption in this carbon-intensive industry.

Energy storage applications represent a third major demand driver, with hydrogen increasingly viewed as a solution for long-duration energy storage to complement intermittent renewable energy sources. Several utility-scale projects are underway in Europe, Australia, and Japan, demonstrating hydrogen's role in grid stabilization and seasonal energy storage.

Market forecasts project carbon-neutral hydrogen demand to reach 400-500 million tonnes annually by 2050, representing a market value exceeding $700 billion. This growth trajectory is supported by increasingly ambitious national hydrogen strategies, with over 30 countries having published dedicated roadmaps and investment plans totaling more than $300 billion through 2030.

Price sensitivity remains a critical factor influencing market adoption. Current carbon-neutral hydrogen production costs range from $3-8/kg, significantly higher than conventional hydrogen at $1-2/kg. However, analysis suggests that methane pyrolysis could potentially deliver hydrogen at $1.5-3/kg, positioning it competitively against other low-carbon production methods while offering the advantage of solid carbon co-production.

Regulatory frameworks are evolving to support market development, with carbon pricing mechanisms, renewable energy mandates, and sector-specific decarbonization targets creating favorable conditions for carbon-neutral hydrogen adoption. The EU's Hydrogen Strategy and similar initiatives in Japan, South Korea, and Australia are establishing clear market signals that are accelerating investment in production capacity and infrastructure development.

Technical Challenges in Methane Pyrolysis

Methane pyrolysis faces several significant technical challenges that currently limit its widespread commercial adoption. The primary obstacle is the high energy requirement for breaking the strong carbon-hydrogen bonds in methane molecules. This process typically demands temperatures exceeding 700°C, resulting in substantial energy consumption that impacts overall cost-effectiveness and carbon footprint unless renewable energy sources are utilized.

Catalyst deactivation presents another major challenge. Most catalytic systems for methane pyrolysis suffer from carbon deposition on active sites, leading to rapid performance degradation. While metal catalysts (particularly nickel, iron, and cobalt) show promising activity, they require frequent regeneration or replacement, adding operational complexity and costs. Novel catalyst designs incorporating support materials like alumina or silica have shown improved stability but still face longevity issues in industrial settings.

Reactor design and scaling represent significant engineering hurdles. Current reactor configurations struggle with efficient heat transfer, uniform temperature distribution, and continuous carbon removal. Fluidized bed reactors offer advantages for heat transfer but face challenges with particle agglomeration and carbon separation. Molten metal reactors provide excellent heat transfer and facilitate carbon separation but introduce corrosion concerns and metal loss issues.

Carbon management constitutes another critical challenge. The solid carbon produced during pyrolysis must be continuously removed to prevent reactor clogging and catalyst deactivation. While this carbon potentially represents a valuable by-product, developing efficient separation, collection, and purification systems remains technically demanding. The quality and morphology of the carbon (amorphous, graphitic, or nanostructured) significantly impacts its market value and applications.

Process integration and system optimization present complex engineering challenges. Balancing reaction kinetics, heat management, and product separation requires sophisticated control systems. Additionally, the intermittent nature of renewable energy sources complicates the design of continuously operating pyrolysis systems, necessitating innovative approaches to energy storage and process flexibility.

Economic viability remains constrained by high capital expenditure requirements. Current reactor materials must withstand extreme temperatures and potentially corrosive environments, driving up equipment costs. The trade-off between conversion efficiency, energy consumption, and operational stability creates a complex optimization problem that has not been fully resolved at commercial scale.

Catalyst deactivation presents another major challenge. Most catalytic systems for methane pyrolysis suffer from carbon deposition on active sites, leading to rapid performance degradation. While metal catalysts (particularly nickel, iron, and cobalt) show promising activity, they require frequent regeneration or replacement, adding operational complexity and costs. Novel catalyst designs incorporating support materials like alumina or silica have shown improved stability but still face longevity issues in industrial settings.

Reactor design and scaling represent significant engineering hurdles. Current reactor configurations struggle with efficient heat transfer, uniform temperature distribution, and continuous carbon removal. Fluidized bed reactors offer advantages for heat transfer but face challenges with particle agglomeration and carbon separation. Molten metal reactors provide excellent heat transfer and facilitate carbon separation but introduce corrosion concerns and metal loss issues.

Carbon management constitutes another critical challenge. The solid carbon produced during pyrolysis must be continuously removed to prevent reactor clogging and catalyst deactivation. While this carbon potentially represents a valuable by-product, developing efficient separation, collection, and purification systems remains technically demanding. The quality and morphology of the carbon (amorphous, graphitic, or nanostructured) significantly impacts its market value and applications.

Process integration and system optimization present complex engineering challenges. Balancing reaction kinetics, heat management, and product separation requires sophisticated control systems. Additionally, the intermittent nature of renewable energy sources complicates the design of continuously operating pyrolysis systems, necessitating innovative approaches to energy storage and process flexibility.

Economic viability remains constrained by high capital expenditure requirements. Current reactor materials must withstand extreme temperatures and potentially corrosive environments, driving up equipment costs. The trade-off between conversion efficiency, energy consumption, and operational stability creates a complex optimization problem that has not been fully resolved at commercial scale.

Current Methane Pyrolysis Process Solutions

01 Economic viability of methane pyrolysis processes

Methane pyrolysis offers a cost-effective approach to hydrogen production compared to traditional methods. The economic viability is enhanced by the production of solid carbon as a valuable by-product, which can offset operational costs. Various analyses demonstrate favorable economics when considering factors such as carbon pricing, reduced CO2 emissions, and integration with existing energy infrastructure. The process becomes particularly competitive when carbon capture requirements are factored into conventional hydrogen production methods.- Economic viability of methane pyrolysis processes: Methane pyrolysis offers a cost-effective approach to hydrogen production compared to traditional methods, with economic analyses showing favorable returns on investment. The process generates valuable carbon byproducts that can offset operational costs. Various economic models demonstrate that methane pyrolysis can be commercially viable when implemented at industrial scale, particularly when carbon credits or environmental incentives are factored into the financial calculations.

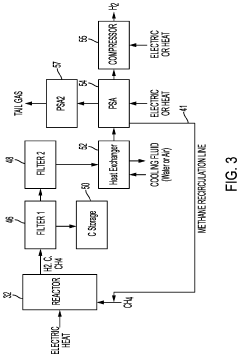

- Technological innovations reducing pyrolysis costs: Recent technological advancements have significantly improved the cost-effectiveness of methane pyrolysis. These innovations include novel reactor designs, improved catalysts that operate at lower temperatures, and more efficient heating methods. Continuous flow systems and modular designs have reduced capital expenditures while increasing throughput. Enhanced heat recovery systems and process integration techniques have further decreased operational expenses, making methane pyrolysis increasingly competitive with conventional hydrogen production methods.

- Carbon byproduct valorization enhancing economic returns: The solid carbon produced during methane pyrolysis can be processed into high-value materials such as carbon black, carbon nanotubes, and graphene, significantly improving the overall economics of the process. Various purification and post-processing techniques have been developed to enhance the quality and market value of these carbon byproducts. The integration of carbon valorization pathways into methane pyrolysis operations creates additional revenue streams that can transform the economics from marginally profitable to highly lucrative.

- Energy efficiency improvements in pyrolysis systems: Energy consumption represents a major cost factor in methane pyrolysis. Recent developments have focused on improving energy efficiency through better thermal management, alternative heating methods such as microwave or plasma-assisted pyrolysis, and process intensification techniques. Renewable energy integration and waste heat recovery systems have been implemented to reduce operational costs. These energy efficiency improvements directly translate to lower production costs for hydrogen and carbon, enhancing the overall cost-effectiveness of methane pyrolysis.

- Comparative economic analysis with competing hydrogen production methods: Economic analyses comparing methane pyrolysis with other hydrogen production methods such as steam methane reforming (SMR) and electrolysis show distinct advantages in certain scenarios. While SMR with carbon capture remains competitive in regions with low natural gas prices, methane pyrolysis offers lower capital costs and avoids expensive carbon capture infrastructure. Compared to electrolysis, methane pyrolysis typically requires less energy input per unit of hydrogen produced. These comparative advantages make methane pyrolysis particularly attractive in regions with moderate energy costs and environmental regulations on carbon emissions.

02 Technological innovations reducing pyrolysis costs

Recent technological innovations have significantly improved the cost-effectiveness of methane pyrolysis. These include advanced reactor designs that enhance heat transfer efficiency, catalytic systems that lower activation energy requirements, and process intensification techniques that increase throughput. Molten metal reactors and plasma-assisted pyrolysis represent breakthrough technologies that operate at lower temperatures while maintaining high conversion rates, thereby reducing energy consumption and operational expenses.Expand Specific Solutions03 Energy integration and efficiency improvements

Energy integration strategies significantly enhance the cost-effectiveness of methane pyrolysis operations. By recovering waste heat from the high-temperature pyrolysis process and utilizing it elsewhere in the system, overall energy consumption can be reduced by up to 30%. Advanced heat exchangers, thermal energy storage systems, and process optimization techniques contribute to improved energy efficiency. Additionally, integration with renewable energy sources for process heating can further reduce operational costs and environmental impact.Expand Specific Solutions04 Carbon valorization and market opportunities

The solid carbon produced during methane pyrolysis represents a significant economic opportunity that enhances overall process cost-effectiveness. Depending on purity and structure, this carbon can be marketed as carbon black for rubber manufacturing, as graphite for electrodes, or as advanced carbon nanomaterials for high-value applications. The development of specialized carbon products from pyrolysis can generate revenue streams that substantially improve the economic viability of the process, potentially making hydrogen production cost-neutral or even profitable.Expand Specific Solutions05 Comparative economic analysis with competing technologies

Economic analyses comparing methane pyrolysis with competing hydrogen production technologies demonstrate its cost advantages under specific conditions. While steam methane reforming with carbon capture remains competitive in regions with low natural gas prices, methane pyrolysis becomes increasingly favorable as carbon pricing increases. The absence of CO2 separation and storage requirements provides a significant cost advantage. Additionally, methane pyrolysis offers lower capital intensity compared to electrolysis and can be deployed at smaller scales, making it suitable for distributed hydrogen production scenarios.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Methane pyrolysis technology is currently in the early commercialization phase, with a growing market expected to reach significant scale as hydrogen demand increases globally. The competitive landscape features established energy companies like Shell, Linde, and SINOPEC alongside innovative startups such as Molten Industries developing cost-effective solutions. Technical maturity varies across approaches, with thermal, catalytic, and plasma-based methods at different readiness levels. Research institutions (PARC, Dalian University of Technology) collaborate with industry leaders (BASF, UOP LLC) to overcome efficiency and scaling challenges. The technology's advancement is accelerated by strategic partnerships between petrochemical giants (China Petroleum & Chemical Corp.) and specialized engineering firms (GTI Energy), focusing on reducing carbon emissions while maintaining economic viability in hydrogen production.

BASF Corp.

Technical Solution: BASF has developed an advanced methane pyrolysis process utilizing their proprietary structured carbon catalyst system. Their technology operates at temperatures between 900-1100°C in a fixed-bed reactor configuration that maximizes surface area contact between methane and the catalyst. BASF's approach employs a regenerative thermal management system that recovers waste heat, reducing overall energy consumption by approximately 20% compared to conventional pyrolysis methods. Economic analysis shows hydrogen production costs ranging from $1.80-2.30/kg, with the potential to decrease to $1.50/kg at scale. The process achieves methane conversion rates of 70-80% with hydrogen purity of 98% before purification steps. BASF's carbon management system produces high-quality carbon nanostructures that can be marketed to specialty materials sectors, potentially generating $0.50-0.70 in revenue per kg of hydrogen produced, improving the overall economics of the process.

Strengths: Energy-efficient thermal management, production of high-value carbon nanostructures, and integration potential with existing chemical production infrastructure. Weaknesses: Catalyst deactivation requiring periodic regeneration, higher capital intensity than conventional hydrogen production, and sensitivity to feed gas composition variations.

GTI Energy

Technical Solution: GTI Energy has developed a methane pyrolysis technology called the H2/C Process that utilizes a novel fluidized bed reactor design with specialized carbon-based catalysts. Their system operates at moderate temperatures (800-950°C) and achieves methane conversion rates of 65-75%. The process employs a continuous catalyst regeneration system that maintains activity while allowing for uninterrupted operation. GTI's economic assessment indicates hydrogen production costs of $1.90-2.40/kg, with potential for reduction to $1.70/kg with scale optimization. Their approach integrates with existing natural gas infrastructure, allowing for deployment at various points in the gas value chain. The technology produces a unique form of structured carbon that has applications in construction materials and soil amendment, potentially offsetting 20-30% of production costs. GTI has operated a 100 kg/day pilot facility since 2020 and is currently designing a 1 ton/day demonstration plant in partnership with several industrial gas companies.

Strengths: Lower temperature operation than competing technologies, integration with existing natural gas infrastructure, and continuous catalyst regeneration capability. Weaknesses: Lower single-pass conversion efficiency requiring gas recycling, more complex reactor design with moving parts, and less developed market for the specific carbon morphology produced.

Critical Patents and Innovations in Pyrolysis

High throughput methane pyrolysis reactor for low-cost hydrogen production

PatentActiveUS11981563B2

Innovation

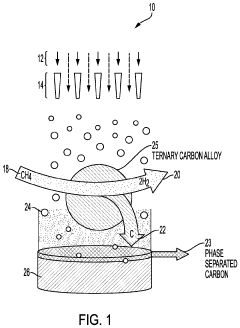

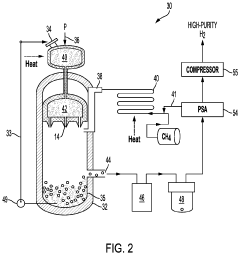

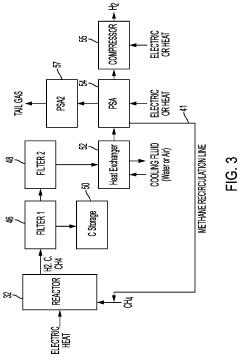

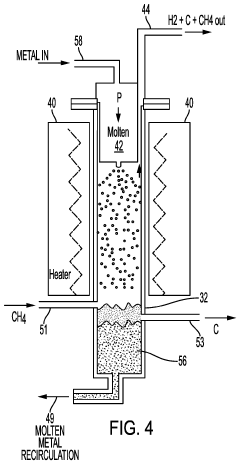

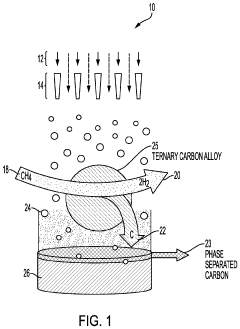

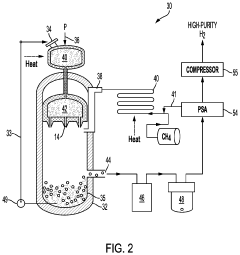

- A liquid mist reactor system using catalytically active molten alloys to decompose hydrocarbons into hydrogen and solid carbon, with a reactor design that enhances catalyst surface area and gas hourly space velocity, allowing for high reactor utilization and efficient carbon separation.

High throughput methane pyrolysis reactor for low-cost hydrogen production

PatentActiveUS11964867B2

Innovation

- A liquid mist reactor design utilizing a catalytically active liquid catalyst to increase surface area and improve pyrolysis kinetics, allowing for high reactor vessel utilization and efficient hydrogen production, with a reactor configuration that includes a reservoir, nozzles for mist distribution, a heat source, separator, and filters for product separation.

Economic Viability and ROI Analysis

The economic viability of methane pyrolysis hinges on several critical factors that determine its commercial feasibility compared to conventional hydrogen production methods. Current cost analyses indicate that methane pyrolysis requires an initial capital investment ranging from $800-1,200 per kW of hydrogen production capacity, positioning it between steam methane reforming (SMR) with carbon capture ($600-900/kW) and electrolysis ($1,000-1,500/kW). This capital expenditure structure creates a distinct middle-ground position for pyrolysis technologies in the hydrogen production landscape.

Operational expenditure calculations reveal that methane pyrolysis can achieve hydrogen production costs between $1.50-2.50/kg, depending on natural gas prices, scale of operation, and technological maturity. When carbon pricing mechanisms are factored in, the comparative advantage of pyrolysis becomes more pronounced, as it avoids approximately 85-95% of CO2 emissions associated with traditional SMR processes without requiring additional carbon capture infrastructure.

Return on investment (ROI) projections demonstrate variable timelines based on deployment scenarios. Small-scale distributed systems typically show payback periods of 5-7 years, while larger centralized facilities can achieve ROI within 3-5 years when operating at optimal capacity. These projections assume carbon credit valuations of $30-50 per ton of CO2 avoided, which significantly enhances the economic case for pyrolysis technologies.

Sensitivity analysis reveals that methane pyrolysis economics are most vulnerable to fluctuations in natural gas prices, with each $1/MMBtu increase in natural gas cost translating to approximately $0.30-0.40/kg increase in hydrogen production costs. This creates regional variability in economic viability, with regions enjoying low natural gas prices offering more favorable conditions for implementation.

The value proposition extends beyond direct hydrogen production costs when considering the solid carbon co-product. High-grade carbon black produced through advanced pyrolysis processes can command market prices of $1,000-2,500 per ton, potentially offsetting 15-30% of operational costs. However, this benefit remains contingent on developing consistent carbon quality and establishing reliable market channels for these materials.

Lifecycle economic assessment indicates that methane pyrolysis achieves cost parity with conventional SMR when carbon prices exceed approximately $40-60 per ton CO2-equivalent, or when natural gas prices remain below $3.50/MMBtu. These threshold points represent critical economic triggers that would accelerate market adoption of pyrolysis technologies across various industrial applications.

Operational expenditure calculations reveal that methane pyrolysis can achieve hydrogen production costs between $1.50-2.50/kg, depending on natural gas prices, scale of operation, and technological maturity. When carbon pricing mechanisms are factored in, the comparative advantage of pyrolysis becomes more pronounced, as it avoids approximately 85-95% of CO2 emissions associated with traditional SMR processes without requiring additional carbon capture infrastructure.

Return on investment (ROI) projections demonstrate variable timelines based on deployment scenarios. Small-scale distributed systems typically show payback periods of 5-7 years, while larger centralized facilities can achieve ROI within 3-5 years when operating at optimal capacity. These projections assume carbon credit valuations of $30-50 per ton of CO2 avoided, which significantly enhances the economic case for pyrolysis technologies.

Sensitivity analysis reveals that methane pyrolysis economics are most vulnerable to fluctuations in natural gas prices, with each $1/MMBtu increase in natural gas cost translating to approximately $0.30-0.40/kg increase in hydrogen production costs. This creates regional variability in economic viability, with regions enjoying low natural gas prices offering more favorable conditions for implementation.

The value proposition extends beyond direct hydrogen production costs when considering the solid carbon co-product. High-grade carbon black produced through advanced pyrolysis processes can command market prices of $1,000-2,500 per ton, potentially offsetting 15-30% of operational costs. However, this benefit remains contingent on developing consistent carbon quality and establishing reliable market channels for these materials.

Lifecycle economic assessment indicates that methane pyrolysis achieves cost parity with conventional SMR when carbon prices exceed approximately $40-60 per ton CO2-equivalent, or when natural gas prices remain below $3.50/MMBtu. These threshold points represent critical economic triggers that would accelerate market adoption of pyrolysis technologies across various industrial applications.

Environmental Impact and Carbon Footprint Assessment

Methane pyrolysis represents a significant advancement in hydrogen production with substantially lower environmental impacts compared to conventional methods. The process directly decomposes methane into hydrogen and solid carbon, eliminating CO2 emissions that characterize traditional steam methane reforming (SMR) processes. When powered by renewable energy sources, methane pyrolysis can achieve near-zero greenhouse gas emissions, positioning it as a potentially transformative technology for clean hydrogen production.

The carbon footprint assessment of methane pyrolysis reveals impressive environmental credentials. Life cycle analyses indicate that methane pyrolysis produces approximately 85-90% fewer CO2 emissions per kilogram of hydrogen compared to SMR without carbon capture. Even when compared to SMR with carbon capture and storage (CCS), pyrolysis maintains a 40-50% advantage in emissions reduction, primarily due to the elimination of CO2 as a byproduct and reduced energy requirements.

Methane leakage represents a critical environmental consideration for pyrolysis systems. As methane has a global warming potential 28-36 times that of CO2 over a 100-year period, even small leakage rates (1-3%) can significantly impact the overall environmental benefits. Advanced monitoring systems and stringent operational protocols are essential to minimize fugitive emissions throughout the supply chain.

The solid carbon byproduct from methane pyrolysis offers additional environmental advantages through carbon sequestration. Unlike gaseous CO2 from conventional processes, which requires expensive capture and storage infrastructure, solid carbon is immediately sequestered in a stable form. This carbon can potentially be utilized in various applications including construction materials, soil amendments, and advanced materials manufacturing, creating a circular economy approach that further enhances environmental benefits.

Water consumption represents another environmental advantage of methane pyrolysis. The process requires significantly less water than SMR or electrolysis, reducing pressure on water resources. This aspect is particularly valuable in water-stressed regions where hydrogen production might otherwise compete with agricultural or municipal water needs.

Land use impacts of methane pyrolysis facilities are generally favorable compared to other clean energy technologies. The compact nature of pyrolysis plants results in a smaller physical footprint compared to renewable hydrogen production methods that rely on extensive solar or wind installations. This efficiency in land use minimizes habitat disruption and allows for more flexible facility siting options.

Regional environmental benefits vary based on implementation context. In areas with high natural gas production but limited renewable energy infrastructure, methane pyrolysis offers an immediate pathway to reduce emissions from hydrogen production while longer-term renewable transitions occur. This transitional capability makes pyrolysis particularly valuable in the medium-term decarbonization strategy for industrial hydrogen applications.

The carbon footprint assessment of methane pyrolysis reveals impressive environmental credentials. Life cycle analyses indicate that methane pyrolysis produces approximately 85-90% fewer CO2 emissions per kilogram of hydrogen compared to SMR without carbon capture. Even when compared to SMR with carbon capture and storage (CCS), pyrolysis maintains a 40-50% advantage in emissions reduction, primarily due to the elimination of CO2 as a byproduct and reduced energy requirements.

Methane leakage represents a critical environmental consideration for pyrolysis systems. As methane has a global warming potential 28-36 times that of CO2 over a 100-year period, even small leakage rates (1-3%) can significantly impact the overall environmental benefits. Advanced monitoring systems and stringent operational protocols are essential to minimize fugitive emissions throughout the supply chain.

The solid carbon byproduct from methane pyrolysis offers additional environmental advantages through carbon sequestration. Unlike gaseous CO2 from conventional processes, which requires expensive capture and storage infrastructure, solid carbon is immediately sequestered in a stable form. This carbon can potentially be utilized in various applications including construction materials, soil amendments, and advanced materials manufacturing, creating a circular economy approach that further enhances environmental benefits.

Water consumption represents another environmental advantage of methane pyrolysis. The process requires significantly less water than SMR or electrolysis, reducing pressure on water resources. This aspect is particularly valuable in water-stressed regions where hydrogen production might otherwise compete with agricultural or municipal water needs.

Land use impacts of methane pyrolysis facilities are generally favorable compared to other clean energy technologies. The compact nature of pyrolysis plants results in a smaller physical footprint compared to renewable hydrogen production methods that rely on extensive solar or wind installations. This efficiency in land use minimizes habitat disruption and allows for more flexible facility siting options.

Regional environmental benefits vary based on implementation context. In areas with high natural gas production but limited renewable energy infrastructure, methane pyrolysis offers an immediate pathway to reduce emissions from hydrogen production while longer-term renewable transitions occur. This transitional capability makes pyrolysis particularly valuable in the medium-term decarbonization strategy for industrial hydrogen applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!