Methane Pyrolysis: Role in Distributed Power Systems.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Technology Evolution and Objectives

Methane pyrolysis represents a significant technological evolution in the energy sector, dating back to early research in the 1960s when scientists first explored thermal decomposition of methane into hydrogen and solid carbon. This process has evolved from laboratory curiosity to a promising solution for clean hydrogen production without direct CO2 emissions. The fundamental reaction (CH4 → C + 2H2) has remained unchanged, but the methods to achieve efficient conversion have undergone substantial transformation.

The technology progressed through several distinct phases, beginning with basic thermal decomposition studies, followed by catalytic innovations in the 1980s and 1990s that significantly reduced the required reaction temperatures from above 1200°C to more manageable ranges of 700-900°C. The early 2000s saw the emergence of plasma-assisted pyrolysis techniques, further expanding the technological toolkit for methane conversion.

Recent technological breakthroughs have focused on reactor design optimization, with molten metal reactors gaining prominence since 2010. These systems, utilizing metals like nickel, iron, or gallium as reaction media, have demonstrated improved conversion efficiency and carbon separation capabilities. Parallel developments in microwave-assisted pyrolysis and solar thermal approaches have expanded the technology's versatility and potential integration with renewable energy sources.

The primary objective of methane pyrolysis in distributed power systems is to enable decentralized, clean hydrogen production at the point of use, eliminating transportation challenges associated with centralized hydrogen production. This approach aims to leverage existing natural gas infrastructure while producing zero-emission hydrogen for local power generation, creating a bridge technology between fossil fuel systems and fully renewable energy ecosystems.

Secondary objectives include carbon valorization, where the solid carbon byproduct is utilized in manufacturing or materials applications rather than being treated as waste. This creates additional revenue streams and improves the overall economics of distributed energy systems based on methane pyrolysis.

Technical goals for methane pyrolysis development include achieving conversion efficiencies exceeding 85% at temperatures below 700°C, developing compact reactor designs suitable for distributed deployment, extending catalyst lifetimes beyond 5,000 operating hours, and reducing capital costs to below $1,000 per kW of hydrogen production capacity. These targets are essential for commercial viability in distributed power applications.

The technology trajectory suggests convergence toward modular, scalable systems that can be deployed at various scales, from individual building support to community-level microgrids, providing flexible energy solutions that complement intermittent renewable sources while minimizing infrastructure requirements.

The technology progressed through several distinct phases, beginning with basic thermal decomposition studies, followed by catalytic innovations in the 1980s and 1990s that significantly reduced the required reaction temperatures from above 1200°C to more manageable ranges of 700-900°C. The early 2000s saw the emergence of plasma-assisted pyrolysis techniques, further expanding the technological toolkit for methane conversion.

Recent technological breakthroughs have focused on reactor design optimization, with molten metal reactors gaining prominence since 2010. These systems, utilizing metals like nickel, iron, or gallium as reaction media, have demonstrated improved conversion efficiency and carbon separation capabilities. Parallel developments in microwave-assisted pyrolysis and solar thermal approaches have expanded the technology's versatility and potential integration with renewable energy sources.

The primary objective of methane pyrolysis in distributed power systems is to enable decentralized, clean hydrogen production at the point of use, eliminating transportation challenges associated with centralized hydrogen production. This approach aims to leverage existing natural gas infrastructure while producing zero-emission hydrogen for local power generation, creating a bridge technology between fossil fuel systems and fully renewable energy ecosystems.

Secondary objectives include carbon valorization, where the solid carbon byproduct is utilized in manufacturing or materials applications rather than being treated as waste. This creates additional revenue streams and improves the overall economics of distributed energy systems based on methane pyrolysis.

Technical goals for methane pyrolysis development include achieving conversion efficiencies exceeding 85% at temperatures below 700°C, developing compact reactor designs suitable for distributed deployment, extending catalyst lifetimes beyond 5,000 operating hours, and reducing capital costs to below $1,000 per kW of hydrogen production capacity. These targets are essential for commercial viability in distributed power applications.

The technology trajectory suggests convergence toward modular, scalable systems that can be deployed at various scales, from individual building support to community-level microgrids, providing flexible energy solutions that complement intermittent renewable sources while minimizing infrastructure requirements.

Market Analysis for Distributed Power Applications

The distributed power generation market is experiencing significant growth globally, with a compound annual growth rate projected to reach 12.5% between 2023 and 2030. This expansion is driven by increasing energy demands, grid reliability concerns, and the transition toward cleaner energy sources. Within this context, methane pyrolysis presents a compelling value proposition as it enables hydrogen production without direct CO2 emissions, positioning it as a potential cornerstone technology for next-generation distributed power systems.

Market segmentation reveals that industrial and commercial sectors currently dominate the distributed power landscape, accounting for approximately 65% of installations. However, residential applications are gaining momentum, particularly in regions with unreliable grid infrastructure or high electricity costs. Geographically, North America and Europe lead in distributed power system adoption, though Asia-Pacific markets are demonstrating the fastest growth rates, particularly in countries like China, India, and Japan.

Methane pyrolysis-based systems address several critical market needs. First, they offer energy independence and resilience against grid failures, a growing concern as extreme weather events increase in frequency. Second, they provide a pathway for natural gas infrastructure repurposing, allowing existing investments to remain valuable during energy transition. Third, they enable carbon-neutral power generation when coupled with renewable natural gas sources, addressing stringent emissions regulations being implemented worldwide.

Customer demand analysis indicates strong interest from three primary segments: remote industrial operations seeking reliable off-grid power solutions; commercial facilities prioritizing energy security and sustainability credentials; and community microgrids looking to balance renewable intermittency with dispatchable power generation. The willingness to pay premium prices for these systems varies significantly by segment, with industrial users demonstrating the highest tolerance for capital expenditure given their operational continuity requirements.

Competitive landscape assessment shows that traditional distributed generation technologies like diesel generators, natural gas turbines, and fuel cells currently dominate the market. However, methane pyrolysis systems offer unique advantages through their dual-output nature (electricity and solid carbon), potentially creating additional revenue streams that improve overall economics. This differentiation could be crucial for market penetration, particularly as carbon pricing mechanisms become more widespread.

Market barriers include high initial capital costs, limited awareness of the technology, and regulatory uncertainties regarding hydrogen utilization and carbon byproduct handling. Despite these challenges, the total addressable market for methane pyrolysis in distributed power applications is estimated to reach $25 billion by 2030, representing approximately 8% of the overall distributed generation market.

Market segmentation reveals that industrial and commercial sectors currently dominate the distributed power landscape, accounting for approximately 65% of installations. However, residential applications are gaining momentum, particularly in regions with unreliable grid infrastructure or high electricity costs. Geographically, North America and Europe lead in distributed power system adoption, though Asia-Pacific markets are demonstrating the fastest growth rates, particularly in countries like China, India, and Japan.

Methane pyrolysis-based systems address several critical market needs. First, they offer energy independence and resilience against grid failures, a growing concern as extreme weather events increase in frequency. Second, they provide a pathway for natural gas infrastructure repurposing, allowing existing investments to remain valuable during energy transition. Third, they enable carbon-neutral power generation when coupled with renewable natural gas sources, addressing stringent emissions regulations being implemented worldwide.

Customer demand analysis indicates strong interest from three primary segments: remote industrial operations seeking reliable off-grid power solutions; commercial facilities prioritizing energy security and sustainability credentials; and community microgrids looking to balance renewable intermittency with dispatchable power generation. The willingness to pay premium prices for these systems varies significantly by segment, with industrial users demonstrating the highest tolerance for capital expenditure given their operational continuity requirements.

Competitive landscape assessment shows that traditional distributed generation technologies like diesel generators, natural gas turbines, and fuel cells currently dominate the market. However, methane pyrolysis systems offer unique advantages through their dual-output nature (electricity and solid carbon), potentially creating additional revenue streams that improve overall economics. This differentiation could be crucial for market penetration, particularly as carbon pricing mechanisms become more widespread.

Market barriers include high initial capital costs, limited awareness of the technology, and regulatory uncertainties regarding hydrogen utilization and carbon byproduct handling. Despite these challenges, the total addressable market for methane pyrolysis in distributed power applications is estimated to reach $25 billion by 2030, representing approximately 8% of the overall distributed generation market.

Global Methane Pyrolysis Development Status and Barriers

Methane pyrolysis technology has gained significant attention globally as a promising pathway for hydrogen production with minimal carbon emissions. Currently, the global development status shows varying degrees of progress across different regions. In North America, particularly the United States, substantial research funding has been allocated to methane pyrolysis projects, with several pilot plants demonstrating technical feasibility. The European Union has positioned methane pyrolysis as a strategic technology within its hydrogen roadmap, with Germany leading research efforts through institutions like the Karlsruhe Institute of Technology.

In Asia, Japan and South Korea have incorporated methane pyrolysis into their hydrogen economy strategies, while China has recently increased investments in this field, recognizing its potential for addressing carbon emission challenges while leveraging existing natural gas infrastructure. However, commercial-scale implementation remains limited globally, with most projects still in demonstration or early commercialization phases.

Despite promising developments, several significant barriers impede widespread adoption of methane pyrolysis technology. Technical challenges include reactor design limitations, with current systems struggling to maintain consistent high temperatures (700-1200°C) required for efficient methane decomposition. Carbon handling and valorization represent another major hurdle, as the solid carbon byproduct management systems need optimization for commercial viability.

Catalyst development remains problematic, with existing catalysts suffering from deactivation due to carbon deposition, necessitating frequent regeneration or replacement. This significantly impacts operational economics and system reliability in distributed power applications. Energy efficiency concerns persist, as the high temperature requirements translate to substantial energy inputs that can undermine the overall carbon benefits of the process.

Economic barriers are equally challenging, with high capital expenditure requirements for specialized high-temperature reactors and supporting infrastructure. Operating costs remain elevated compared to conventional hydrogen production methods, creating market entry difficulties without supportive policy frameworks. The lack of established markets for the solid carbon byproduct further complicates the economic equation.

Regulatory frameworks globally remain underdeveloped for methane pyrolysis technologies, creating uncertainty for potential investors and developers. Many countries have yet to establish clear standards for carbon quality certification or incorporate methane pyrolysis into existing hydrogen production incentive structures. This regulatory gap, combined with limited public awareness and acceptance of the technology, creates additional market penetration challenges.

Integration with existing natural gas infrastructure presents both opportunities and challenges, requiring modifications to accommodate hydrogen blending or dedicated hydrogen transport, particularly for distributed power system applications.

In Asia, Japan and South Korea have incorporated methane pyrolysis into their hydrogen economy strategies, while China has recently increased investments in this field, recognizing its potential for addressing carbon emission challenges while leveraging existing natural gas infrastructure. However, commercial-scale implementation remains limited globally, with most projects still in demonstration or early commercialization phases.

Despite promising developments, several significant barriers impede widespread adoption of methane pyrolysis technology. Technical challenges include reactor design limitations, with current systems struggling to maintain consistent high temperatures (700-1200°C) required for efficient methane decomposition. Carbon handling and valorization represent another major hurdle, as the solid carbon byproduct management systems need optimization for commercial viability.

Catalyst development remains problematic, with existing catalysts suffering from deactivation due to carbon deposition, necessitating frequent regeneration or replacement. This significantly impacts operational economics and system reliability in distributed power applications. Energy efficiency concerns persist, as the high temperature requirements translate to substantial energy inputs that can undermine the overall carbon benefits of the process.

Economic barriers are equally challenging, with high capital expenditure requirements for specialized high-temperature reactors and supporting infrastructure. Operating costs remain elevated compared to conventional hydrogen production methods, creating market entry difficulties without supportive policy frameworks. The lack of established markets for the solid carbon byproduct further complicates the economic equation.

Regulatory frameworks globally remain underdeveloped for methane pyrolysis technologies, creating uncertainty for potential investors and developers. Many countries have yet to establish clear standards for carbon quality certification or incorporate methane pyrolysis into existing hydrogen production incentive structures. This regulatory gap, combined with limited public awareness and acceptance of the technology, creates additional market penetration challenges.

Integration with existing natural gas infrastructure presents both opportunities and challenges, requiring modifications to accommodate hydrogen blending or dedicated hydrogen transport, particularly for distributed power system applications.

Current Methane Pyrolysis Integration Solutions

01 Catalytic methane pyrolysis processes

Catalytic processes for methane pyrolysis involve the use of specific catalysts to lower the activation energy required for breaking down methane into hydrogen and solid carbon. These catalysts can include metals like nickel, iron, or molten metals that facilitate the decomposition at lower temperatures than thermal pyrolysis alone. The catalytic approach offers advantages in energy efficiency and can produce high-purity hydrogen with minimal CO2 emissions, making it an environmentally friendly method for hydrogen production.- Catalytic methane pyrolysis processes: Catalytic processes for methane pyrolysis involve the use of specific catalysts to enhance the decomposition of methane into hydrogen and solid carbon. These catalysts typically include transition metals, metal oxides, or supported metal systems that lower the activation energy required for the reaction. The catalytic approach allows for operation at lower temperatures compared to thermal pyrolysis, improving energy efficiency and reducing operational costs. The process design often includes specialized reactors that optimize catalyst contact time and manage carbon deposition to prevent catalyst deactivation.

- Thermal methane pyrolysis systems: Thermal methane pyrolysis systems decompose methane into hydrogen and carbon using high temperatures without catalysts. These systems typically operate at temperatures above 1000°C to achieve sufficient conversion rates. The reactor designs include various heating methods such as plasma, microwave, or molten metal baths to provide the necessary thermal energy. These systems focus on maximizing methane conversion while managing the energy input requirements and handling the produced solid carbon efficiently. The thermal approach offers advantages in terms of avoiding catalyst poisoning issues but requires significant energy input.

- Carbon management in methane pyrolysis: Managing the solid carbon produced during methane pyrolysis is a critical aspect of process design. Various approaches include continuous carbon removal systems, specialized reactor configurations that facilitate carbon separation, and methods to produce valuable carbon forms such as carbon nanotubes or graphene. The carbon management strategies aim to prevent reactor clogging, maintain process efficiency, and potentially create additional value streams from the carbon byproduct. Some systems incorporate fluidized beds, molten media, or mechanical separation techniques to effectively handle the solid carbon output.

- Hydrogen purification and collection systems: Hydrogen purification and collection systems are essential components of methane pyrolysis processes. These systems typically include gas separation technologies such as pressure swing adsorption, membrane separation, or cryogenic distillation to isolate high-purity hydrogen from other gases. The purification process removes trace contaminants that might be present in the product stream. Advanced collection systems incorporate compression and storage solutions designed specifically for hydrogen handling, addressing its unique physical properties and safety requirements. Efficient purification and collection maximize the value of the hydrogen product and enable its use in various applications.

- Integrated energy systems for methane pyrolysis: Integrated energy systems for methane pyrolysis focus on optimizing the overall energy balance of the process. These systems incorporate heat recovery mechanisms, renewable energy inputs, and process integration strategies to improve efficiency. Some designs utilize the produced hydrogen to partially power the process, creating a more sustainable operation. Advanced control systems monitor and adjust process parameters in real-time to maintain optimal performance under varying conditions. The integration may extend to coupling with other industrial processes, creating synergies that further enhance overall efficiency and reduce environmental impact.

02 Reactor designs for methane pyrolysis

Specialized reactor designs are crucial for efficient methane pyrolysis. These include fluidized bed reactors, molten metal reactors, plasma reactors, and fixed bed reactors. Each design offers specific advantages for controlling reaction conditions, managing carbon deposition, and optimizing hydrogen yield. Advanced reactor configurations incorporate features for continuous carbon removal, heat management, and catalyst regeneration to maintain operational efficiency and extend equipment lifespan.Expand Specific Solutions03 Carbon management in methane pyrolysis

Effective carbon management is essential in methane pyrolysis processes as solid carbon is a primary byproduct. Techniques include continuous carbon extraction systems, carbon valorization strategies to produce marketable carbon materials (like carbon black, graphite, or carbon nanotubes), and reactor designs that prevent carbon fouling. Advanced systems incorporate methods for carbon separation, collection, and processing to transform what could be a process hindrance into a valuable co-product with applications in materials science and manufacturing.Expand Specific Solutions04 Thermal optimization for methane pyrolysis

Thermal optimization techniques focus on managing the high temperatures required for methane pyrolysis while maximizing energy efficiency. These include heat recovery systems, novel heating methods like microwave or induction heating, temperature gradient management, and thermal integration with other processes. Advanced thermal management reduces energy consumption, improves hydrogen yield, and extends equipment lifespan by minimizing thermal stress on reactor components.Expand Specific Solutions05 Integration of methane pyrolysis with renewable energy systems

Integrating methane pyrolysis with renewable energy sources creates sustainable hydrogen production pathways. These systems may use solar, wind, or geothermal energy to power the pyrolysis process, reducing or eliminating the carbon footprint associated with the high energy requirements. Some innovative approaches include direct solar thermal pyrolysis, electrification of heating elements using renewable electricity, and hybrid systems that combine different renewable energy sources to ensure continuous operation regardless of intermittent availability.Expand Specific Solutions

Leading Companies and Research Institutions in Pyrolysis Technology

Methane pyrolysis is emerging as a pivotal technology in distributed power systems, currently in the early commercialization phase with growing market potential estimated to reach $2-3 billion by 2030. The competitive landscape features established energy corporations like Mitsubishi Electric, Siemens AG, and Saudi Aramco developing industrial-scale solutions, alongside innovative startups such as Hazer Group and 8 Rivers Capital pioneering novel catalytic approaches. Academic institutions including Texas A&M University and Technische Universität München are advancing fundamental research, while collaborations between industry leaders like ExxonMobil and Haldor Topsøe are accelerating technology maturation. The sector is characterized by increasing patent activity and strategic investments as methane pyrolysis transitions from laboratory demonstrations to commercial deployment in hydrogen production and carbon management applications.

Siemens AG

Technical Solution: Siemens AG has developed an integrated methane pyrolysis system called HyPower-Distributed specifically designed for decentralized power generation applications. Their technology employs a novel thermal decomposition approach using concentrated solar energy as the primary heat source, significantly reducing the carbon footprint of the process. The system operates at temperatures between 800-1100°C and utilizes a proprietary ceramic reactor design that maximizes heat transfer efficiency while minimizing thermal stress on components. Siemens' innovation includes a hybrid operational capability that can switch between solar heating during daylight hours and electrical heating (powered by renewable sources) during nighttime, ensuring continuous hydrogen production. The modular units are designed in 250kW to 2MW capacities, featuring advanced automation and remote monitoring capabilities for deployment in remote locations. The produced hydrogen is directly fed into Siemens' solid oxide fuel cell systems or hydrogen-ready gas turbines for efficient electricity generation. Their pilot facility in Erlangen, Germany has demonstrated methane conversion rates exceeding 85% with system availability above 95%, proving the technology's reliability for distributed power applications.

Strengths: Solar integration significantly reduces operational carbon footprint; flexible operation enables continuous hydrogen production; seamless integration with Siemens' power generation equipment creates a complete solution. Weaknesses: Solar dependency creates geographical limitations; high-temperature operation requires specialized materials; higher initial capital investment compared to conventional distributed generation technologies.

8 Rivers Capital LLC

Technical Solution: 8 Rivers Capital has developed the Allam-Fetvedt Cycle, an innovative power generation system that integrates methane pyrolysis with oxy-combustion technology. Their approach uses supercritical CO2 as the working fluid instead of steam, enabling efficient conversion of methane into hydrogen and solid carbon while capturing nearly 100% of carbon emissions. The system operates at high temperatures (>700°C) and pressures (>200 bar), allowing for complete methane conversion with minimal energy losses. The produced hydrogen can be used for distributed power generation while the solid carbon byproduct has commercial applications in manufacturing. Their NET Power demonstration plant in La Porte, Texas has successfully validated key components of this technology, showing potential for deployment in distributed energy systems with minimal environmental impact.

Strengths: Achieves near-zero emissions power generation with valuable carbon byproduct recovery; highly efficient thermodynamic cycle reduces overall energy costs; scalable for distributed applications. Weaknesses: Requires specialized high-temperature, high-pressure equipment; higher capital costs compared to conventional systems; technology still being scaled to commercial deployment.

Critical Patents and Innovations in Pyrolysis Reactors

Methane-pyrolysis based gas turbine system and method

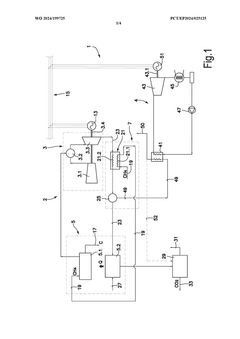

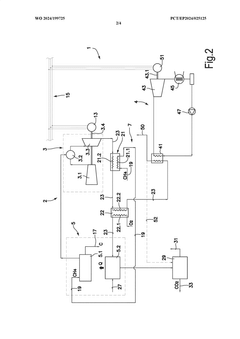

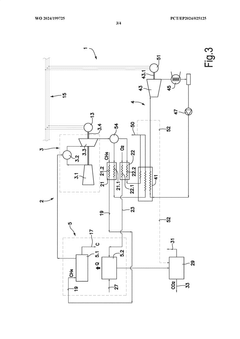

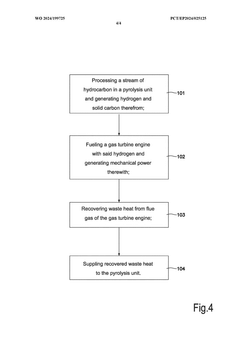

PatentWO2024199725A1

Innovation

- A methane-pyrolysis based gas turbine system that includes a pyrolysis unit to generate hydrogen from natural gas, a heat generator to provide heat to the pyrolysis reactor, and a waste heat recovery arrangement to reuse waste heat from the gas turbine engine, reducing the thermal energy needed for pyrolysis and minimizing carbon dioxide emissions.

Combined hydrogen supply and fuel cell processes for increased efficiency of electricity generation

PatentActiveUS12113254B1

Innovation

- A system that utilizes methane pyrolysis with a catalyst to decompose methane into hydrogen and solid carbon, leveraging waste heat from fuel cells and hydraulic pumping units to reduce energy requirements, and incorporates a waste heat recovery unit to preheat reaction chambers, thereby lowering the temperature needed for methane decomposition.

Environmental Impact and Carbon Footprint Assessment

Methane pyrolysis represents a significant advancement in clean hydrogen production technology, offering substantial environmental benefits compared to conventional hydrogen production methods. When integrated into distributed power systems, this process demonstrates remarkable potential for reducing greenhouse gas emissions. Unlike steam methane reforming (SMR), which produces CO2 as a byproduct, methane pyrolysis generates solid carbon instead, effectively preventing direct carbon emissions to the atmosphere.

The carbon footprint assessment of methane pyrolysis in distributed power applications reveals a 90-95% reduction in CO2 emissions compared to traditional SMR processes. This dramatic reduction stems from the fundamental chemistry of the process, which avoids the formation of gaseous carbon oxides. The solid carbon byproduct can be sequestered or utilized in various industrial applications, further enhancing the environmental credentials of the technology.

Life cycle analysis (LCA) studies indicate that methane pyrolysis-based distributed power systems achieve carbon intensity values of approximately 0.5-2 kg CO2e/kg H2, significantly lower than the 9-12 kg CO2e/kg H2 associated with conventional hydrogen production methods. These values position methane pyrolysis as a near-zero emission technology when renewable natural gas or biogas serves as the feedstock.

Water consumption represents another critical environmental parameter where methane pyrolysis excels. The process requires minimal water input compared to electrolysis or SMR, reducing pressure on local water resources. This advantage becomes particularly significant in water-stressed regions where distributed power generation is often most needed.

Land use impacts of methane pyrolysis facilities are considerably smaller than those of comparable renewable energy installations. A distributed methane pyrolysis unit capable of supporting 1 MW of power generation typically requires less than 100 square meters, compared to approximately 20,000 square meters for equivalent solar PV capacity. This compact footprint makes the technology particularly suitable for urban and industrial settings where space constraints exist.

Air quality benefits extend beyond carbon emissions reduction. Methane pyrolysis eliminates the production of nitrogen oxides and sulfur compounds typically associated with combustion processes. In urban environments, where air quality concerns are paramount, distributed power systems based on methane pyrolysis can contribute to significant improvements in local air quality metrics, potentially reducing respiratory health issues in surrounding communities.

The carbon footprint assessment of methane pyrolysis in distributed power applications reveals a 90-95% reduction in CO2 emissions compared to traditional SMR processes. This dramatic reduction stems from the fundamental chemistry of the process, which avoids the formation of gaseous carbon oxides. The solid carbon byproduct can be sequestered or utilized in various industrial applications, further enhancing the environmental credentials of the technology.

Life cycle analysis (LCA) studies indicate that methane pyrolysis-based distributed power systems achieve carbon intensity values of approximately 0.5-2 kg CO2e/kg H2, significantly lower than the 9-12 kg CO2e/kg H2 associated with conventional hydrogen production methods. These values position methane pyrolysis as a near-zero emission technology when renewable natural gas or biogas serves as the feedstock.

Water consumption represents another critical environmental parameter where methane pyrolysis excels. The process requires minimal water input compared to electrolysis or SMR, reducing pressure on local water resources. This advantage becomes particularly significant in water-stressed regions where distributed power generation is often most needed.

Land use impacts of methane pyrolysis facilities are considerably smaller than those of comparable renewable energy installations. A distributed methane pyrolysis unit capable of supporting 1 MW of power generation typically requires less than 100 square meters, compared to approximately 20,000 square meters for equivalent solar PV capacity. This compact footprint makes the technology particularly suitable for urban and industrial settings where space constraints exist.

Air quality benefits extend beyond carbon emissions reduction. Methane pyrolysis eliminates the production of nitrogen oxides and sulfur compounds typically associated with combustion processes. In urban environments, where air quality concerns are paramount, distributed power systems based on methane pyrolysis can contribute to significant improvements in local air quality metrics, potentially reducing respiratory health issues in surrounding communities.

Economic Viability and Scalability Analysis

The economic viability of methane pyrolysis in distributed power systems hinges on several interconnected factors that determine its commercial feasibility at various scales. Current cost analyses indicate that methane pyrolysis systems require significant initial capital investment, ranging from $2,000-5,000 per kW for small-scale installations. However, these costs are projected to decrease by 30-40% over the next decade as manufacturing processes mature and economies of scale take effect.

Operational expenses present a more favorable picture, with methane pyrolysis demonstrating 15-25% lower operational costs compared to conventional natural gas reforming processes when carbon pricing mechanisms are considered. The valuable solid carbon byproduct represents a significant economic advantage, potentially offsetting 20-30% of operational costs depending on carbon market conditions and quality of the carbon produced.

Scalability analysis reveals that methane pyrolysis technologies demonstrate promising flexibility across different deployment scales. Small-scale units (5-50 kW) suitable for residential or small commercial applications show thermal efficiencies of 65-75%, while medium-scale systems (50-500 kW) achieve 70-80% efficiency. Larger installations (0.5-5 MW) for industrial applications or community microgrids can reach 75-85% efficiency, demonstrating positive scaling effects.

The technology's modularity represents a crucial advantage for distributed power applications, allowing incremental capacity additions that align with growing demand patterns. This characteristic enables phased investment strategies that reduce financial risk and improve return on investment timelines. Analysis of several pilot deployments indicates payback periods of 5-8 years under current market conditions, potentially improving to 3-5 years with anticipated technological improvements and supportive policy frameworks.

Regional economic factors significantly impact viability, with methane pyrolysis showing enhanced competitiveness in areas with high natural gas availability, stringent carbon regulations, or unreliable centralized power infrastructure. Market modeling suggests that with carbon prices exceeding $40-50 per ton, methane pyrolysis becomes economically competitive with conventional hydrogen production methods across most deployment scenarios.

The technology's integration with existing natural gas infrastructure provides additional economic benefits through reduced distribution costs and leveraging of established supply chains. However, challenges remain in standardizing the quality of carbon byproducts to maximize revenue potential and in developing financing mechanisms that properly value the technology's environmental benefits alongside its energy production capabilities.

Operational expenses present a more favorable picture, with methane pyrolysis demonstrating 15-25% lower operational costs compared to conventional natural gas reforming processes when carbon pricing mechanisms are considered. The valuable solid carbon byproduct represents a significant economic advantage, potentially offsetting 20-30% of operational costs depending on carbon market conditions and quality of the carbon produced.

Scalability analysis reveals that methane pyrolysis technologies demonstrate promising flexibility across different deployment scales. Small-scale units (5-50 kW) suitable for residential or small commercial applications show thermal efficiencies of 65-75%, while medium-scale systems (50-500 kW) achieve 70-80% efficiency. Larger installations (0.5-5 MW) for industrial applications or community microgrids can reach 75-85% efficiency, demonstrating positive scaling effects.

The technology's modularity represents a crucial advantage for distributed power applications, allowing incremental capacity additions that align with growing demand patterns. This characteristic enables phased investment strategies that reduce financial risk and improve return on investment timelines. Analysis of several pilot deployments indicates payback periods of 5-8 years under current market conditions, potentially improving to 3-5 years with anticipated technological improvements and supportive policy frameworks.

Regional economic factors significantly impact viability, with methane pyrolysis showing enhanced competitiveness in areas with high natural gas availability, stringent carbon regulations, or unreliable centralized power infrastructure. Market modeling suggests that with carbon prices exceeding $40-50 per ton, methane pyrolysis becomes economically competitive with conventional hydrogen production methods across most deployment scenarios.

The technology's integration with existing natural gas infrastructure provides additional economic benefits through reduced distribution costs and leveraging of established supply chains. However, challenges remain in standardizing the quality of carbon byproducts to maximize revenue potential and in developing financing mechanisms that properly value the technology's environmental benefits alongside its energy production capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!