NMC Battery Vs LiFePO4: Which Provides Better Longevity in ESS?

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Technology Evolution and Objectives

Energy storage systems (ESS) have emerged as a critical component in the global transition towards renewable energy, with battery technology at its core. The evolution of battery technology for ESS applications has been marked by significant advancements over the past decades, transitioning from lead-acid batteries to more sophisticated lithium-ion chemistries. Among these, Nickel Manganese Cobalt (NMC) and Lithium Iron Phosphate (LiFePO4) have emerged as dominant contenders, each offering distinct advantages and limitations for long-term energy storage applications.

The historical development of battery technology began with lead-acid batteries in the 19th century, progressing through nickel-cadmium and nickel-metal hydride systems before reaching the lithium-ion era in the 1990s. The early 2000s saw the commercial introduction of LiFePO4 batteries, valued for their thermal stability and safety characteristics. NMC batteries followed, gaining prominence for their higher energy density and improved performance metrics.

For ESS applications specifically, the technology evolution has been driven by increasing demands for longer cycle life, enhanced safety, improved energy density, and reduced costs. These requirements have shaped the development trajectory of both NMC and LiFePO4 technologies, with manufacturers continuously refining cell chemistry, electrode materials, and battery management systems to optimize performance for stationary storage applications.

The primary technical objective in comparing NMC and LiFePO4 batteries for ESS applications centers on determining which chemistry provides superior longevity under typical operational conditions. Longevity in this context encompasses cycle life (number of charge-discharge cycles before significant capacity degradation), calendar life (total operational lifespan regardless of usage), and capacity retention characteristics over time.

Secondary objectives include evaluating the technologies based on safety profiles, particularly thermal runaway resistance; efficiency metrics including round-trip efficiency; performance under various environmental conditions; and total cost of ownership calculations that factor in initial capital expenditure, maintenance requirements, and end-of-life considerations.

The technological trajectory suggests continued refinement of both chemistries, with research focusing on increasing energy density while maintaining or improving cycle life. For NMC batteries, this includes developing variants with reduced cobalt content (such as NMC 811) and improved electrode structures. For LiFePO4, advancements are targeting enhanced conductivity and higher voltage cathodes while preserving the inherent safety advantages.

Understanding the comparative longevity of these technologies requires examining their fundamental degradation mechanisms, operational parameters that influence aging, and real-world performance data from deployed systems. This analysis forms the foundation for strategic decision-making regarding battery selection for specific ESS applications and use cases.

The historical development of battery technology began with lead-acid batteries in the 19th century, progressing through nickel-cadmium and nickel-metal hydride systems before reaching the lithium-ion era in the 1990s. The early 2000s saw the commercial introduction of LiFePO4 batteries, valued for their thermal stability and safety characteristics. NMC batteries followed, gaining prominence for their higher energy density and improved performance metrics.

For ESS applications specifically, the technology evolution has been driven by increasing demands for longer cycle life, enhanced safety, improved energy density, and reduced costs. These requirements have shaped the development trajectory of both NMC and LiFePO4 technologies, with manufacturers continuously refining cell chemistry, electrode materials, and battery management systems to optimize performance for stationary storage applications.

The primary technical objective in comparing NMC and LiFePO4 batteries for ESS applications centers on determining which chemistry provides superior longevity under typical operational conditions. Longevity in this context encompasses cycle life (number of charge-discharge cycles before significant capacity degradation), calendar life (total operational lifespan regardless of usage), and capacity retention characteristics over time.

Secondary objectives include evaluating the technologies based on safety profiles, particularly thermal runaway resistance; efficiency metrics including round-trip efficiency; performance under various environmental conditions; and total cost of ownership calculations that factor in initial capital expenditure, maintenance requirements, and end-of-life considerations.

The technological trajectory suggests continued refinement of both chemistries, with research focusing on increasing energy density while maintaining or improving cycle life. For NMC batteries, this includes developing variants with reduced cobalt content (such as NMC 811) and improved electrode structures. For LiFePO4, advancements are targeting enhanced conductivity and higher voltage cathodes while preserving the inherent safety advantages.

Understanding the comparative longevity of these technologies requires examining their fundamental degradation mechanisms, operational parameters that influence aging, and real-world performance data from deployed systems. This analysis forms the foundation for strategic decision-making regarding battery selection for specific ESS applications and use cases.

Market Analysis for ESS Battery Solutions

The global Energy Storage System (ESS) market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. As of 2023, the ESS market was valued at approximately $12.5 billion and is projected to reach $31.2 billion by 2030, representing a CAGR of 12.3%. This remarkable expansion creates a substantial opportunity for battery manufacturers, with lithium-ion technologies dominating the current landscape.

Within the lithium-ion segment, NMC (Nickel Manganese Cobalt) and LiFePO4 (Lithium Iron Phosphate) chemistries are emerging as the primary contenders for ESS applications. Market analysis indicates that LiFePO4 batteries are gaining significant traction in the stationary storage sector, capturing nearly 60% of new installations in 2022, up from 43% in 2020. This shift is largely attributed to their superior safety profile and longer cycle life, despite having lower energy density compared to NMC variants.

Regional market dynamics reveal interesting patterns in technology adoption. Asia-Pacific, particularly China, leads in LiFePO4 production and deployment, controlling approximately 75% of global manufacturing capacity. Meanwhile, European markets have traditionally favored NMC chemistry due to its higher energy density, though recent safety concerns have accelerated a transition toward LiFePO4 solutions, especially for residential and commercial applications.

Price sensitivity analysis shows that while LiFePO4 batteries typically command a 10-15% premium over NMC alternatives in initial capital expenditure, their total cost of ownership over a 10-year operational period is approximately 20% lower due to extended service life and reduced maintenance requirements. This economic advantage is particularly compelling for utility-scale projects where operational expenditure optimization is prioritized over initial deployment costs.

Customer segment analysis reveals distinct preferences across different ESS applications. Utility-scale developers increasingly favor LiFePO4 technology, with adoption rates growing by 32% annually since 2020. Residential systems show a more balanced distribution, though LiFePO4 gained 8 percentage points of market share in 2022 alone, reflecting growing consumer awareness of safety and longevity benefits.

Market forecasts suggest that by 2025, LiFePO4 chemistry will account for approximately 65-70% of all new ESS installations globally, with NMC variants retaining strength in specific applications where energy density remains the primary consideration. This trend is reinforced by recent supply chain constraints affecting cobalt and nickel, key components in NMC batteries, which have experienced price volatility of up to 40% in recent years.

Within the lithium-ion segment, NMC (Nickel Manganese Cobalt) and LiFePO4 (Lithium Iron Phosphate) chemistries are emerging as the primary contenders for ESS applications. Market analysis indicates that LiFePO4 batteries are gaining significant traction in the stationary storage sector, capturing nearly 60% of new installations in 2022, up from 43% in 2020. This shift is largely attributed to their superior safety profile and longer cycle life, despite having lower energy density compared to NMC variants.

Regional market dynamics reveal interesting patterns in technology adoption. Asia-Pacific, particularly China, leads in LiFePO4 production and deployment, controlling approximately 75% of global manufacturing capacity. Meanwhile, European markets have traditionally favored NMC chemistry due to its higher energy density, though recent safety concerns have accelerated a transition toward LiFePO4 solutions, especially for residential and commercial applications.

Price sensitivity analysis shows that while LiFePO4 batteries typically command a 10-15% premium over NMC alternatives in initial capital expenditure, their total cost of ownership over a 10-year operational period is approximately 20% lower due to extended service life and reduced maintenance requirements. This economic advantage is particularly compelling for utility-scale projects where operational expenditure optimization is prioritized over initial deployment costs.

Customer segment analysis reveals distinct preferences across different ESS applications. Utility-scale developers increasingly favor LiFePO4 technology, with adoption rates growing by 32% annually since 2020. Residential systems show a more balanced distribution, though LiFePO4 gained 8 percentage points of market share in 2022 alone, reflecting growing consumer awareness of safety and longevity benefits.

Market forecasts suggest that by 2025, LiFePO4 chemistry will account for approximately 65-70% of all new ESS installations globally, with NMC variants retaining strength in specific applications where energy density remains the primary consideration. This trend is reinforced by recent supply chain constraints affecting cobalt and nickel, key components in NMC batteries, which have experienced price volatility of up to 40% in recent years.

Current Limitations and Technical Challenges

Despite their widespread adoption in energy storage systems (ESS), both NMC (Nickel Manganese Cobalt) and LiFePO4 (Lithium Iron Phosphate) batteries face significant technical limitations that affect their longevity performance. NMC batteries struggle with thermal stability issues, particularly at high states of charge, making them susceptible to thermal runaway events when subjected to mechanical stress or electrical abuse. This inherent safety concern necessitates sophisticated battery management systems, adding complexity and cost to ESS implementations.

Capacity degradation represents another critical challenge for NMC batteries in long-duration storage applications. These batteries typically experience 2-3% capacity loss per year under optimal conditions, with accelerated degradation occurring at high temperatures or when maintained at extreme states of charge. The cobalt content in NMC batteries also presents supply chain vulnerabilities, as cobalt mining is concentrated in politically unstable regions, creating potential material shortages and price volatility.

LiFePO4 batteries, while offering superior thermal stability, face their own set of limitations. Their lower energy density (90-120 Wh/kg compared to NMC's 150-220 Wh/kg) necessitates larger installations for equivalent energy capacity, increasing spatial requirements and installation costs for grid-scale applications. This limitation becomes particularly problematic in space-constrained urban environments or applications where energy density is paramount.

Low-temperature performance represents a significant challenge for LiFePO4 technology. These batteries experience substantial capacity reduction and increased internal resistance at temperatures below 0°C, limiting their effectiveness in cold climate installations without additional thermal management systems. This characteristic necessitates supplementary heating systems in cold regions, increasing system complexity and parasitic energy losses.

Both chemistries face cycling limitations that impact their longevity in high-throughput ESS applications. While LiFePO4 generally offers superior cycle life (3,000-7,000 cycles compared to NMC's 1,000-3,000 cycles at 80% depth of discharge), both technologies experience accelerated degradation under high C-rate operations or frequent deep discharges, common in grid-balancing applications.

Manufacturing consistency presents another industry-wide challenge. Cell-to-cell variations in both chemistries can lead to imbalances within battery packs, reducing overall system efficiency and accelerating degradation of the weakest cells. This variation necessitates sophisticated battery management systems to monitor and balance individual cells, adding complexity to large-scale ESS deployments.

Recycling infrastructure remains underdeveloped for both chemistries, though LiFePO4 presents fewer environmental concerns due to its reduced heavy metal content. The lack of economically viable recycling processes represents a sustainability challenge for the industry, particularly as early ESS installations approach end-of-life in the coming decade.

Capacity degradation represents another critical challenge for NMC batteries in long-duration storage applications. These batteries typically experience 2-3% capacity loss per year under optimal conditions, with accelerated degradation occurring at high temperatures or when maintained at extreme states of charge. The cobalt content in NMC batteries also presents supply chain vulnerabilities, as cobalt mining is concentrated in politically unstable regions, creating potential material shortages and price volatility.

LiFePO4 batteries, while offering superior thermal stability, face their own set of limitations. Their lower energy density (90-120 Wh/kg compared to NMC's 150-220 Wh/kg) necessitates larger installations for equivalent energy capacity, increasing spatial requirements and installation costs for grid-scale applications. This limitation becomes particularly problematic in space-constrained urban environments or applications where energy density is paramount.

Low-temperature performance represents a significant challenge for LiFePO4 technology. These batteries experience substantial capacity reduction and increased internal resistance at temperatures below 0°C, limiting their effectiveness in cold climate installations without additional thermal management systems. This characteristic necessitates supplementary heating systems in cold regions, increasing system complexity and parasitic energy losses.

Both chemistries face cycling limitations that impact their longevity in high-throughput ESS applications. While LiFePO4 generally offers superior cycle life (3,000-7,000 cycles compared to NMC's 1,000-3,000 cycles at 80% depth of discharge), both technologies experience accelerated degradation under high C-rate operations or frequent deep discharges, common in grid-balancing applications.

Manufacturing consistency presents another industry-wide challenge. Cell-to-cell variations in both chemistries can lead to imbalances within battery packs, reducing overall system efficiency and accelerating degradation of the weakest cells. This variation necessitates sophisticated battery management systems to monitor and balance individual cells, adding complexity to large-scale ESS deployments.

Recycling infrastructure remains underdeveloped for both chemistries, though LiFePO4 presents fewer environmental concerns due to its reduced heavy metal content. The lack of economically viable recycling processes represents a sustainability challenge for the industry, particularly as early ESS installations approach end-of-life in the coming decade.

Comparative Analysis of NMC and LiFePO4 Technologies

01 Comparative longevity characteristics of NMC and LiFePO4 batteries

NMC (Nickel Manganese Cobalt) and LiFePO4 (Lithium Iron Phosphate) batteries exhibit different longevity characteristics. LiFePO4 batteries generally demonstrate superior cycle life and calendar life compared to NMC batteries, with some LiFePO4 formulations capable of achieving over 2000 charge-discharge cycles while maintaining 80% capacity. NMC batteries typically offer higher energy density but may experience faster capacity degradation over time, especially at elevated temperatures or when charged to high voltage levels.- Comparative longevity of NMC and LiFePO4 batteries: Studies comparing the longevity of NMC (Lithium Nickel Manganese Cobalt Oxide) and LiFePO4 (Lithium Iron Phosphate) batteries show that LiFePO4 batteries generally have longer cycle life and better thermal stability. LiFePO4 batteries can typically withstand more charge-discharge cycles before significant capacity degradation occurs, making them more durable for long-term applications. NMC batteries, while having higher energy density, tend to experience faster capacity fade over time, especially at higher temperatures or when charged to higher voltage limits.

- Electrode material modifications for enhanced battery life: Modifications to electrode materials can significantly improve the longevity of both NMC and LiFePO4 batteries. For NMC batteries, doping with elements like aluminum or magnesium can stabilize the crystal structure and reduce capacity fade. In LiFePO4 batteries, carbon coating of particles improves electrical conductivity and cycle stability. Nano-sizing of active materials in both battery types enhances lithium-ion diffusion rates and structural stability during cycling, leading to extended battery life and improved performance under various operating conditions.

- Electrolyte formulations affecting battery durability: Specialized electrolyte formulations play a crucial role in determining the longevity of both NMC and LiFePO4 batteries. Additives such as vinylene carbonate and lithium bis(oxalato)borate can form stable solid electrolyte interphase (SEI) layers that protect electrode surfaces from continuous degradation. For LiFePO4 batteries, electrolytes with lower reactivity help maintain performance over thousands of cycles. In NMC batteries, electrolyte formulations that minimize transition metal dissolution from the cathode significantly extend cycle life and calendar life under various operating conditions.

- Battery management systems for optimizing lifespan: Advanced battery management systems (BMS) can significantly extend the operational life of both NMC and LiFePO4 batteries through optimized charging protocols and thermal management. For NMC batteries, limiting the upper charging voltage and implementing slower charging rates at high state-of-charge levels reduces cathode degradation. LiFePO4 batteries benefit from BMS algorithms that maintain balanced cell voltages across battery packs. Thermal management systems that keep batteries within optimal temperature ranges prevent accelerated aging in both chemistries, with particular importance for NMC batteries which are more sensitive to high-temperature operation.

- Application-specific longevity considerations: The relative longevity advantages of NMC and LiFePO4 batteries vary significantly depending on the specific application requirements. For high-cycle applications like grid storage and certain electric vehicles, LiFePO4 batteries often demonstrate superior longevity with cycle lives exceeding 2000-3000 cycles. NMC batteries typically show better performance in applications prioritizing energy density over cycle life. Operating conditions such as depth of discharge, charge rates, and ambient temperature significantly impact the relative longevity advantage between these chemistries. In medical devices requiring long service life, LiFePO4 is often preferred despite its lower energy density due to its exceptional cycle stability.

02 Electrolyte formulations for enhancing battery longevity

Specialized electrolyte formulations can significantly improve the longevity of both NMC and LiFePO4 batteries. Additives such as fluorinated compounds, lithium salts, and film-forming agents help create stable solid electrolyte interphase (SEI) layers that protect electrode materials from degradation. For LiFePO4 batteries, electrolytes with lower reactivity at the cathode interface help maintain structural integrity over numerous cycles, while for NMC batteries, electrolyte formulations that minimize transition metal dissolution are particularly beneficial for extending cycle life.Expand Specific Solutions03 Temperature management systems for extending battery life

Effective temperature management systems are crucial for maximizing the longevity of both NMC and LiFePO4 batteries. LiFePO4 batteries generally demonstrate better thermal stability and longevity across a wider temperature range, while NMC batteries are more sensitive to temperature extremes. Advanced cooling systems, thermal insulation, and intelligent temperature control algorithms help maintain optimal operating temperatures, preventing accelerated degradation mechanisms such as SEI growth, lithium plating, and structural changes in the cathode materials that would otherwise shorten battery life.Expand Specific Solutions04 Electrode coating and doping techniques for improved longevity

Specialized electrode coating and doping techniques can significantly enhance the longevity of both NMC and LiFePO4 batteries. Surface coatings such as metal oxides, phosphates, and carbon-based materials protect cathode particles from direct contact with electrolytes, reducing parasitic reactions. For NMC batteries, gradient concentration cathodes with higher nickel content in the core and more stable compositions at the surface improve structural stability during cycling. In LiFePO4 batteries, doping with elements like manganese, zinc or niobium enhances electronic conductivity and structural stability, leading to improved cycle life.Expand Specific Solutions05 Battery management systems for optimizing cycle life

Advanced battery management systems (BMS) play a critical role in extending the longevity of both NMC and LiFePO4 batteries through sophisticated monitoring and control algorithms. These systems implement optimized charging protocols that prevent lithium plating and minimize mechanical stress on electrode materials. For NMC batteries, the BMS typically limits the upper charging voltage to prevent structural degradation of the cathode, while for LiFePO4 batteries, the management systems focus on balancing cells and preventing deep discharge conditions. Adaptive algorithms that adjust charging parameters based on battery age and usage patterns further extend cycle life by responding to changing battery characteristics over time.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The energy storage system (ESS) market is experiencing rapid growth, currently transitioning from early adoption to mainstream implementation, with projections indicating a market size exceeding $30 billion by 2025. In the NMC versus LiFePO4 battery technology competition, major players are positioning themselves strategically based on specific application advantages. Companies like BMW, Toyota, and Saft are advancing NMC technology for its higher energy density, while firms such as A123 Systems, GODI India, and State Grid Corp. of China are investing in LiFePO4 for its superior thermal stability and longer cycle life. The technology landscape shows LiFePO4 gaining momentum in stationary ESS applications where safety and longevity are paramount, while NMC maintains advantages in applications requiring higher energy density. Research institutions including Xi'an Jiaotong University and IIT Bombay are actively developing next-generation improvements for both chemistries.

Toyota Motor Corp.

Technical Solution: Toyota has leveraged its extensive experience in battery technology to develop comprehensive comparative analyses of NMC and LiFePO4 chemistries for stationary energy storage applications. Their research demonstrates that while their NMC formulations achieve higher energy density (approximately 200 Wh/kg versus 120 Wh/kg for LiFePO4), their accelerated aging tests show LiFePO4 cells consistently outperforming in longevity metrics. Toyota's testing protocols simulate real-world usage patterns including daily cycling, seasonal variations, and occasional deep discharges. Under these conditions, their NMC cells typically maintain 80% capacity for approximately 2,500 cycles, while equivalent LiFePO4 cells exceed 6,000 cycles before reaching the same degradation threshold. Toyota's proprietary battery management system incorporates predictive aging algorithms that demonstrate LiFePO4's superior calendar life, projecting 15-20 year operational lifespans compared to 8-12 years for NMC in stationary applications. Their thermal runaway testing further confirms LiFePO4's inherent safety advantages, with significantly higher thermal stability and reduced risk of catastrophic failure compared to NMC variants.

Strengths: Extensive manufacturing expertise ensures findings translate to production-quality cells; comprehensive testing infrastructure allows for detailed performance characterization; global supply chain understanding informs practical implementation considerations. Weaknesses: Primary focus on automotive applications may influence testing methodologies; proprietary research limits full transparency; commercial offerings may prioritize established technologies over newer innovations.

A123 Systems LLC

Technical Solution: A123 Systems specializes in LiFePO4 battery technology and has developed advanced nanophosphate lithium iron phosphate cells specifically optimized for energy storage systems (ESS). Their proprietary manufacturing process creates highly uniform nanoscale materials that enhance electrode surface area and improve ion transport. Their ESS solutions feature integrated battery management systems that maintain cell balance and prevent thermal runaway. A123's LiFePO4 cells demonstrate cycle life exceeding 7,000 full cycles at 100% depth of discharge while maintaining over 80% of original capacity, significantly outperforming typical NMC batteries which generally achieve 1,000-3,000 cycles under similar conditions. Their Grid Storage Solution utilizes these cells in modular rack-mounted configurations with advanced cooling systems to maintain optimal operating temperatures and further extend longevity.

Strengths: Superior cycle life (3-5x longer than comparable NMC), excellent thermal stability reducing fire risk, consistent performance across wide temperature ranges, and minimal capacity degradation over time. Weaknesses: Lower energy density compared to NMC (approximately 30-40% less), higher initial cost per kWh, and reduced performance in extremely cold conditions.

Key Patents and Research in Battery Longevity

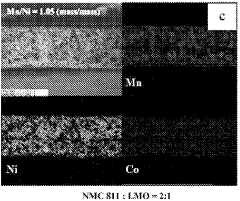

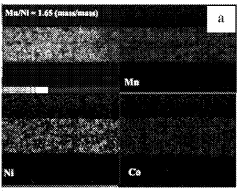

Active material for cathode of lithium-ion battery, cathode comprising said active material, and method for preparing said cathode

PatentWO2023170449A1

Innovation

- A cathode active material is developed by combining lithium manganese oxide (LMO) with lithium nickel manganese cobalt oxide (NMC) in specific mole ratios, enhancing stability and cycle life, and incorporating a binder and conductive material for improved electron and ion transfer, with the mixture's mass ratio optimized for high energy density and long cycle life.

Thermal Management Strategies for Extended Battery Life

Thermal management is a critical factor in determining the longevity of both NMC (Nickel Manganese Cobalt) and LiFePO4 (Lithium Iron Phosphate) batteries in Energy Storage Systems (ESS). The thermal characteristics of these battery chemistries differ significantly, necessitating tailored thermal management approaches to maximize their service life.

NMC batteries typically operate optimally between 15°C and 35°C but are more sensitive to temperature fluctuations compared to LiFePO4. When NMC cells exceed 45°C, accelerated degradation occurs through SEI layer growth and lithium plating, significantly reducing capacity. For NMC-based ESS installations, active cooling systems utilizing liquid coolants that circulate through plates between battery modules have proven most effective, particularly in high-power applications where heat generation is substantial.

LiFePO4 batteries demonstrate superior thermal stability, maintaining performance across a wider temperature range (-20°C to 60°C) and exhibiting minimal thermal runaway risk. This inherent stability allows for simpler thermal management solutions. Air cooling systems with strategic airflow channels often suffice for LiFePO4 installations, reducing system complexity and maintenance requirements while maintaining adequate temperature control.

Advanced thermal management strategies applicable to both chemistries include phase change materials (PCMs) that absorb excess heat during high-load operations and release it during cooler periods, effectively dampening temperature fluctuations. These materials can be integrated into battery module designs to provide passive thermal regulation without energy consumption.

Predictive thermal management systems represent the cutting edge for ESS applications, utilizing machine learning algorithms to anticipate temperature changes based on usage patterns, ambient conditions, and battery state of charge. These systems can preemptively adjust cooling or heating parameters before critical temperature thresholds are reached, extending battery life by preventing thermal stress events.

For large-scale ESS deployments, geographic considerations significantly impact thermal management strategy selection. In hot climates, NMC installations require more robust cooling infrastructure, increasing both capital and operational expenses. Conversely, LiFePO4 systems can often operate with reduced cooling requirements in these environments, offering potential cost advantages despite their typically higher initial cost per kWh.

The thermal management approach ultimately influences the total cost of ownership calculation when comparing these battery technologies for ESS applications. While NMC may offer higher energy density, the additional thermal management infrastructure required can offset this advantage in lifecycle cost analyses, particularly in applications where thermal conditions are challenging.

NMC batteries typically operate optimally between 15°C and 35°C but are more sensitive to temperature fluctuations compared to LiFePO4. When NMC cells exceed 45°C, accelerated degradation occurs through SEI layer growth and lithium plating, significantly reducing capacity. For NMC-based ESS installations, active cooling systems utilizing liquid coolants that circulate through plates between battery modules have proven most effective, particularly in high-power applications where heat generation is substantial.

LiFePO4 batteries demonstrate superior thermal stability, maintaining performance across a wider temperature range (-20°C to 60°C) and exhibiting minimal thermal runaway risk. This inherent stability allows for simpler thermal management solutions. Air cooling systems with strategic airflow channels often suffice for LiFePO4 installations, reducing system complexity and maintenance requirements while maintaining adequate temperature control.

Advanced thermal management strategies applicable to both chemistries include phase change materials (PCMs) that absorb excess heat during high-load operations and release it during cooler periods, effectively dampening temperature fluctuations. These materials can be integrated into battery module designs to provide passive thermal regulation without energy consumption.

Predictive thermal management systems represent the cutting edge for ESS applications, utilizing machine learning algorithms to anticipate temperature changes based on usage patterns, ambient conditions, and battery state of charge. These systems can preemptively adjust cooling or heating parameters before critical temperature thresholds are reached, extending battery life by preventing thermal stress events.

For large-scale ESS deployments, geographic considerations significantly impact thermal management strategy selection. In hot climates, NMC installations require more robust cooling infrastructure, increasing both capital and operational expenses. Conversely, LiFePO4 systems can often operate with reduced cooling requirements in these environments, offering potential cost advantages despite their typically higher initial cost per kWh.

The thermal management approach ultimately influences the total cost of ownership calculation when comparing these battery technologies for ESS applications. While NMC may offer higher energy density, the additional thermal management infrastructure required can offset this advantage in lifecycle cost analyses, particularly in applications where thermal conditions are challenging.

Environmental Impact and Recycling Considerations

The environmental impact of battery technologies is becoming increasingly important as energy storage systems (ESS) deployments grow worldwide. NMC (Nickel Manganese Cobalt) batteries contain significant amounts of cobalt, a material associated with controversial mining practices in regions like the Democratic Republic of Congo, where child labor and human rights concerns persist. Additionally, nickel mining has been linked to substantial environmental degradation, including deforestation and water pollution. The carbon footprint of NMC production is generally higher due to the energy-intensive processes required to refine these metals.

LiFePO4 (Lithium Iron Phosphate) batteries, by comparison, utilize more abundant and less controversial raw materials. Iron and phosphate are widely available and have less environmental impact during extraction. The absence of cobalt and nickel significantly reduces the ethical concerns associated with battery production. Manufacturing processes for LiFePO4 typically require lower temperatures, resulting in reduced energy consumption and a smaller carbon footprint during production.

When considering end-of-life management, both chemistries present different recycling profiles. NMC batteries have a more established recycling infrastructure, primarily driven by the economic value of recovering cobalt and nickel. Current recycling processes can recover up to 95% of these valuable metals, creating a circular economy incentive. However, the recycling processes themselves can be energy-intensive and potentially hazardous if not properly managed.

LiFePO4 batteries, while containing fewer valuable materials to incentivize recycling, are generally considered less toxic and safer to handle during the recycling process. The challenge lies in developing economically viable recycling methods for these batteries, as the recovered materials have lower market value compared to cobalt and nickel from NMC batteries.

From a lifecycle assessment perspective, LiFePO4 batteries typically demonstrate lower environmental impact scores across categories including global warming potential, resource depletion, and human toxicity. Their longer cycle life further enhances their environmental credentials, as fewer replacements are needed over the operational lifetime of an ESS installation, reducing the cumulative environmental impact.

Regulatory frameworks worldwide are increasingly focusing on battery sustainability, with the EU Battery Directive and similar regulations in other regions mandating recycling rates and restricting hazardous materials. These evolving regulations may favor LiFePO4 technology in the long term due to its reduced environmental footprint and lower toxicity profile.

LiFePO4 (Lithium Iron Phosphate) batteries, by comparison, utilize more abundant and less controversial raw materials. Iron and phosphate are widely available and have less environmental impact during extraction. The absence of cobalt and nickel significantly reduces the ethical concerns associated with battery production. Manufacturing processes for LiFePO4 typically require lower temperatures, resulting in reduced energy consumption and a smaller carbon footprint during production.

When considering end-of-life management, both chemistries present different recycling profiles. NMC batteries have a more established recycling infrastructure, primarily driven by the economic value of recovering cobalt and nickel. Current recycling processes can recover up to 95% of these valuable metals, creating a circular economy incentive. However, the recycling processes themselves can be energy-intensive and potentially hazardous if not properly managed.

LiFePO4 batteries, while containing fewer valuable materials to incentivize recycling, are generally considered less toxic and safer to handle during the recycling process. The challenge lies in developing economically viable recycling methods for these batteries, as the recovered materials have lower market value compared to cobalt and nickel from NMC batteries.

From a lifecycle assessment perspective, LiFePO4 batteries typically demonstrate lower environmental impact scores across categories including global warming potential, resource depletion, and human toxicity. Their longer cycle life further enhances their environmental credentials, as fewer replacements are needed over the operational lifetime of an ESS installation, reducing the cumulative environmental impact.

Regulatory frameworks worldwide are increasingly focusing on battery sustainability, with the EU Battery Directive and similar regulations in other regions mandating recycling rates and restricting hazardous materials. These evolving regulations may favor LiFePO4 technology in the long term due to its reduced environmental footprint and lower toxicity profile.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!