PEEK Polymer Properties and Their Impact on Market Trends

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Evolution and Research Objectives

Polyether ether ketone (PEEK) emerged in the late 1970s as a high-performance thermoplastic polymer, developed by Imperial Chemical Industries (ICI). Since its inception, PEEK has undergone significant evolution in terms of synthesis methods, property enhancement, and application diversification. The initial development focused primarily on creating a polymer with exceptional thermal stability and mechanical strength for aerospace applications.

Throughout the 1980s and 1990s, researchers concentrated on understanding the fundamental structure-property relationships of PEEK, particularly its semi-crystalline nature which contributes to its remarkable thermal resistance and mechanical properties. The crystallization behavior, which directly influences the polymer's performance characteristics, became a central focus of academic and industrial research efforts.

The early 2000s witnessed a paradigm shift in PEEK research, with emphasis moving toward modification techniques to enhance specific properties. These included the incorporation of various fillers such as carbon fibers, glass fibers, and nanomaterials to create composites with tailored characteristics. Concurrently, surface modification techniques were developed to improve PEEK's compatibility with other materials and enhance its performance in specific applications.

Recent technological advancements have enabled more precise control over PEEK's molecular weight distribution and crystallinity, resulting in grades with optimized properties for specific applications. The development of processing technologies, including injection molding, extrusion, and additive manufacturing methods specifically adapted for PEEK, has further expanded its application potential.

The current research landscape is characterized by efforts to address PEEK's limitations while capitalizing on its inherent strengths. These include reducing its relatively high processing temperature, improving its adhesion properties, and enhancing its resistance to specific chemicals and environments. Additionally, there is growing interest in developing more sustainable and cost-effective production methods to broaden PEEK's market accessibility.

Looking forward, the technical objectives for PEEK research include developing novel composite formulations with enhanced properties, establishing more efficient processing methodologies, and expanding its application domains. Particular emphasis is placed on exploring PEEK's potential in emerging fields such as biomedical implants, 3D printing, and sustainable engineering solutions.

The evolution trajectory suggests that future PEEK development will likely focus on tailoring its properties for specific high-value applications, rather than competing with commodity plastics on cost. This strategic direction aligns with global trends toward materials that offer exceptional performance, longevity, and sustainability, positioning PEEK as a critical material in the advanced polymer landscape for decades to come.

Throughout the 1980s and 1990s, researchers concentrated on understanding the fundamental structure-property relationships of PEEK, particularly its semi-crystalline nature which contributes to its remarkable thermal resistance and mechanical properties. The crystallization behavior, which directly influences the polymer's performance characteristics, became a central focus of academic and industrial research efforts.

The early 2000s witnessed a paradigm shift in PEEK research, with emphasis moving toward modification techniques to enhance specific properties. These included the incorporation of various fillers such as carbon fibers, glass fibers, and nanomaterials to create composites with tailored characteristics. Concurrently, surface modification techniques were developed to improve PEEK's compatibility with other materials and enhance its performance in specific applications.

Recent technological advancements have enabled more precise control over PEEK's molecular weight distribution and crystallinity, resulting in grades with optimized properties for specific applications. The development of processing technologies, including injection molding, extrusion, and additive manufacturing methods specifically adapted for PEEK, has further expanded its application potential.

The current research landscape is characterized by efforts to address PEEK's limitations while capitalizing on its inherent strengths. These include reducing its relatively high processing temperature, improving its adhesion properties, and enhancing its resistance to specific chemicals and environments. Additionally, there is growing interest in developing more sustainable and cost-effective production methods to broaden PEEK's market accessibility.

Looking forward, the technical objectives for PEEK research include developing novel composite formulations with enhanced properties, establishing more efficient processing methodologies, and expanding its application domains. Particular emphasis is placed on exploring PEEK's potential in emerging fields such as biomedical implants, 3D printing, and sustainable engineering solutions.

The evolution trajectory suggests that future PEEK development will likely focus on tailoring its properties for specific high-value applications, rather than competing with commodity plastics on cost. This strategic direction aligns with global trends toward materials that offer exceptional performance, longevity, and sustainability, positioning PEEK as a critical material in the advanced polymer landscape for decades to come.

PEEK Market Demand Analysis

The global PEEK (Polyetheretherketone) market has demonstrated robust growth patterns, driven primarily by increasing demand across multiple high-performance industrial applications. Current market valuations place the global PEEK market at approximately 850 million USD, with projections indicating growth to reach 1.2 billion USD by 2026, representing a compound annual growth rate of 7.2% during the forecast period.

The aerospace and automotive sectors constitute the largest demand segments for PEEK materials, collectively accounting for nearly 45% of total consumption. This demand is primarily fueled by the material's exceptional properties including high temperature resistance (operational stability up to 260°C), superior mechanical strength, and excellent chemical resistance, making it an ideal replacement for metal components in weight-sensitive applications.

Healthcare represents the fastest-growing application segment, with demand increasing at 9.3% annually. The biocompatibility of PEEK has positioned it as a preferred material for implantable medical devices, dental applications, and surgical instruments. The material's radiolucency (transparency to X-rays) provides significant advantages in medical imaging contexts, further driving adoption in orthopedic and spinal implant applications.

Regional analysis reveals that North America and Europe currently dominate PEEK consumption, together representing approximately 60% of global demand. However, the Asia-Pacific region, particularly China and India, is experiencing the most rapid growth rate at 8.5% annually, driven by expanding industrial manufacturing bases and increasing adoption of high-performance materials in domestic industries.

Market demand is further segmented by product form, with PEEK resins accounting for 55% of the market, followed by compounds (30%) and finished parts (15%). The growing trend toward custom compounds with specific fillers (carbon fiber, glass fiber, etc.) reflects increasing specialization in end-use applications requiring tailored performance characteristics.

Price sensitivity analysis indicates that despite PEEK's premium positioning (20-30 times the cost of conventional engineering plastics), demand remains relatively inelastic in critical applications where performance requirements cannot be met by alternative materials. However, cost remains the primary barrier to wider adoption in price-sensitive markets and applications.

Future demand projections suggest continued growth in established markets, with emerging applications in 3D printing, electronics, and renewable energy technologies representing significant expansion opportunities. The development of lower-cost production methods and processing technologies could potentially accelerate market penetration in previously cost-prohibitive applications.

The aerospace and automotive sectors constitute the largest demand segments for PEEK materials, collectively accounting for nearly 45% of total consumption. This demand is primarily fueled by the material's exceptional properties including high temperature resistance (operational stability up to 260°C), superior mechanical strength, and excellent chemical resistance, making it an ideal replacement for metal components in weight-sensitive applications.

Healthcare represents the fastest-growing application segment, with demand increasing at 9.3% annually. The biocompatibility of PEEK has positioned it as a preferred material for implantable medical devices, dental applications, and surgical instruments. The material's radiolucency (transparency to X-rays) provides significant advantages in medical imaging contexts, further driving adoption in orthopedic and spinal implant applications.

Regional analysis reveals that North America and Europe currently dominate PEEK consumption, together representing approximately 60% of global demand. However, the Asia-Pacific region, particularly China and India, is experiencing the most rapid growth rate at 8.5% annually, driven by expanding industrial manufacturing bases and increasing adoption of high-performance materials in domestic industries.

Market demand is further segmented by product form, with PEEK resins accounting for 55% of the market, followed by compounds (30%) and finished parts (15%). The growing trend toward custom compounds with specific fillers (carbon fiber, glass fiber, etc.) reflects increasing specialization in end-use applications requiring tailored performance characteristics.

Price sensitivity analysis indicates that despite PEEK's premium positioning (20-30 times the cost of conventional engineering plastics), demand remains relatively inelastic in critical applications where performance requirements cannot be met by alternative materials. However, cost remains the primary barrier to wider adoption in price-sensitive markets and applications.

Future demand projections suggest continued growth in established markets, with emerging applications in 3D printing, electronics, and renewable energy technologies representing significant expansion opportunities. The development of lower-cost production methods and processing technologies could potentially accelerate market penetration in previously cost-prohibitive applications.

PEEK Technical Challenges and Development Status

PEEK (Polyetheretherketone) currently faces several significant technical challenges that impact its broader adoption across industries. The primary challenge remains its high processing temperature, typically requiring 370-400°C, which necessitates specialized equipment and increases manufacturing costs. This temperature requirement creates difficulties in processing and limits the accessibility of PEEK manufacturing to facilities with advanced capabilities.

Material consistency presents another major challenge, as achieving uniform properties throughout complex parts remains problematic. The semi-crystalline nature of PEEK means that cooling rates significantly affect crystallinity levels, which in turn impacts mechanical properties. Manufacturers struggle to maintain consistent crystallization rates across different part geometries, resulting in variable performance characteristics within the same component.

Surface modification of PEEK represents a persistent technical hurdle. The material's inherent chemical resistance, while beneficial for many applications, makes surface treatments for improved adhesion or biocompatibility difficult to achieve. Current techniques often compromise the bulk properties of the material or provide only temporary surface modifications that degrade over time.

Globally, PEEK technology development shows geographic concentration patterns. The United States, Germany, Japan, and the United Kingdom lead in PEEK research and production capabilities, with China rapidly expanding its presence. This distribution reflects historical expertise in high-performance polymers and significant R&D investment in these regions.

Recent advancements have focused on addressing PEEK's limitations through composite formulations. Carbon fiber reinforced PEEK has gained significant traction, improving mechanical properties while maintaining the base polymer's chemical resistance. However, these composites introduce new processing challenges, particularly in achieving uniform fiber distribution and orientation.

The medical grade PEEK sector has seen substantial development, with efforts concentrated on enhancing biocompatibility and osseointegration properties. Surface treatments including plasma modification, hydroxyapatite coating, and nano-texturing have shown promise but remain costly and difficult to scale commercially.

Recycling and sustainability represent emerging challenges in the PEEK ecosystem. The high processing temperatures and chemical stability that make PEEK valuable also complicate recycling efforts. Current recycling methods often result in material property degradation, limiting closed-loop applications. Research into more effective recycling technologies remains in early stages, with chemical recycling showing the most promise for maintaining material integrity.

Material consistency presents another major challenge, as achieving uniform properties throughout complex parts remains problematic. The semi-crystalline nature of PEEK means that cooling rates significantly affect crystallinity levels, which in turn impacts mechanical properties. Manufacturers struggle to maintain consistent crystallization rates across different part geometries, resulting in variable performance characteristics within the same component.

Surface modification of PEEK represents a persistent technical hurdle. The material's inherent chemical resistance, while beneficial for many applications, makes surface treatments for improved adhesion or biocompatibility difficult to achieve. Current techniques often compromise the bulk properties of the material or provide only temporary surface modifications that degrade over time.

Globally, PEEK technology development shows geographic concentration patterns. The United States, Germany, Japan, and the United Kingdom lead in PEEK research and production capabilities, with China rapidly expanding its presence. This distribution reflects historical expertise in high-performance polymers and significant R&D investment in these regions.

Recent advancements have focused on addressing PEEK's limitations through composite formulations. Carbon fiber reinforced PEEK has gained significant traction, improving mechanical properties while maintaining the base polymer's chemical resistance. However, these composites introduce new processing challenges, particularly in achieving uniform fiber distribution and orientation.

The medical grade PEEK sector has seen substantial development, with efforts concentrated on enhancing biocompatibility and osseointegration properties. Surface treatments including plasma modification, hydroxyapatite coating, and nano-texturing have shown promise but remain costly and difficult to scale commercially.

Recycling and sustainability represent emerging challenges in the PEEK ecosystem. The high processing temperatures and chemical stability that make PEEK valuable also complicate recycling efforts. Current recycling methods often result in material property degradation, limiting closed-loop applications. Research into more effective recycling technologies remains in early stages, with chemical recycling showing the most promise for maintaining material integrity.

Current PEEK Processing Methods and Applications

01 Thermal and mechanical properties of PEEK polymers

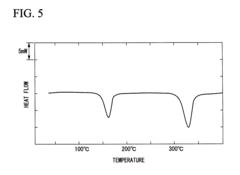

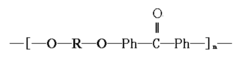

PEEK (Polyether ether ketone) polymers exhibit exceptional thermal stability and mechanical strength. They maintain their structural integrity at high temperatures, with a glass transition temperature of approximately 143°C and melting point around 343°C. PEEK materials demonstrate excellent mechanical properties including high tensile strength, stiffness, and impact resistance. These properties make PEEK suitable for applications requiring durability under extreme conditions.- Mechanical properties of PEEK polymers: PEEK (Polyetheretherketone) polymers exhibit exceptional mechanical properties, including high tensile strength, excellent fatigue resistance, and dimensional stability. These polymers maintain their mechanical integrity under high stress conditions and demonstrate superior wear resistance. The mechanical properties make PEEK suitable for applications requiring durability and strength, particularly in demanding environments where traditional polymers would fail.

- Thermal properties and stability of PEEK: PEEK polymers possess remarkable thermal properties, including high heat resistance with a glass transition temperature of approximately 143°C and melting point around 343°C. They maintain structural integrity and mechanical properties at elevated temperatures, making them suitable for high-temperature applications. PEEK also exhibits excellent thermal stability with minimal degradation during prolonged exposure to high temperatures and demonstrates low thermal expansion, contributing to dimensional stability in varying thermal conditions.

- Chemical resistance of PEEK polymers: PEEK polymers demonstrate exceptional resistance to a wide range of chemicals, including acids, bases, hydrocarbons, and organic solvents. This chemical inertness makes them suitable for applications in aggressive chemical environments where other polymers would degrade. The polymer's resistance to hydrolysis and chemical attack contributes to its long-term durability in industrial applications, medical implants, and chemical processing equipment.

- Electrical and insulation properties of PEEK: PEEK polymers feature excellent electrical insulation properties with high dielectric strength and volume resistivity. They maintain these electrical properties across a wide temperature range and in various environmental conditions. The polymer's low dielectric constant and dissipation factor make it suitable for high-frequency applications. Additionally, PEEK exhibits good arc resistance and tracking resistance, making it valuable for electrical components in demanding applications.

- Modification and enhancement of PEEK properties: PEEK polymers can be modified through various methods to enhance specific properties. Reinforcement with carbon fibers, glass fibers, or other fillers significantly improves mechanical strength and stiffness. Surface treatments can enhance adhesion properties and compatibility with other materials. Chemical modifications can alter properties such as crystallinity, processing characteristics, and biocompatibility. These modifications expand the application range of PEEK polymers across industries including aerospace, automotive, medical, and electronics.

02 Chemical resistance and biocompatibility of PEEK

PEEK polymers possess outstanding chemical resistance to a wide range of solvents, acids, and bases. They show minimal degradation when exposed to harsh chemical environments, making them valuable in industrial applications. Additionally, PEEK materials demonstrate excellent biocompatibility, with low toxicity and minimal inflammatory response, allowing their use in medical implants and devices. Their resistance to hydrolysis and sterilization processes further enhances their suitability for biomedical applications.Expand Specific Solutions03 PEEK composite formulations and enhanced properties

PEEK can be formulated into composites by incorporating various fillers such as carbon fibers, glass fibers, and ceramic particles. These composites exhibit enhanced mechanical properties, including improved stiffness, strength, and wear resistance compared to unfilled PEEK. The addition of carbon fibers can significantly increase the tensile strength and modulus while reducing the coefficient of thermal expansion. These composite formulations allow for customization of properties to meet specific application requirements.Expand Specific Solutions04 Processing techniques for PEEK polymers

PEEK polymers can be processed using various techniques including injection molding, extrusion, compression molding, and additive manufacturing. Due to their high melting temperatures, specialized equipment capable of reaching processing temperatures of 360-400°C is required. The crystallinity of PEEK can be controlled through processing parameters such as cooling rate and annealing conditions, which significantly affects the final properties of the material. Proper processing is essential to achieve optimal mechanical and thermal performance.Expand Specific Solutions05 Surface modification and functionalization of PEEK

The surface properties of PEEK can be modified through various treatments including plasma treatment, chemical etching, and coating applications. These modifications can enhance adhesion, wettability, and bioactivity of PEEK surfaces. Functionalization with specific chemical groups can impart additional properties such as antimicrobial activity or improved cell attachment for biomedical applications. Surface-modified PEEK materials show improved integration with other materials in composite structures and enhanced performance in specific environments.Expand Specific Solutions

Key PEEK Manufacturers and Competitive Landscape

The PEEK polymer market is currently in a growth phase, characterized by increasing adoption across high-performance applications due to its exceptional thermal stability, chemical resistance, and mechanical strength. The global market size is estimated to reach $1 billion by 2025, with a CAGR of approximately 7-8%. Technologically, PEEK has reached commercial maturity but continues to evolve through modifications and composites. Leading players include Victrex Manufacturing, which dominates with approximately 40% market share, followed by Solvay Specialty Polymers with significant R&D investments in medical and aerospace applications. Other key competitors include Ticona LLC, Jilin Joinature Polymer, and Nanjing Comptech Composites, which are expanding their presence through specialized formulations and regional market penetration, particularly in Asia where demand is growing fastest.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has pioneered PEEK polymer technology with their VICTREX™ PEEK portfolio, featuring exceptional mechanical properties and thermal stability up to 260°C. Their proprietary manufacturing process delivers consistent high molecular weight PEEK with superior crystallinity control. Victrex has developed specialized PEEK grades including VICTREX™ PEEK-OPTIMA® for medical implants with proven long-term biocompatibility and APTIV® film for flexible electronics applications. Their recent innovations include VICTREX™ AE™ 250 composites with up to 60% continuous carbon fiber reinforcement, delivering metal-replacing performance with 70% weight reduction. Victrex has also developed VICTREX™ PEEK-HT™ with improved hydrolysis resistance for harsh environments and VICTREX™ FG™ grades specifically formulated for food contact applications with enhanced purity profiles.

Strengths: Victrex offers the broadest PEEK portfolio with specialized grades for diverse industries, backed by extensive technical support and application development expertise. Their vertically integrated manufacturing ensures quality control and supply security. Weaknesses: Higher cost compared to conventional polymers limits adoption in price-sensitive applications, and processing requires specialized equipment and expertise.

Ticona LLC

Technical Solution: Ticona LLC (now part of Celanese Corporation) has developed VESTAKEEP® PEEK polymers with exceptional thermal stability (continuous use temperatures up to 240°C) and outstanding chemical resistance to most industrial chemicals and solvents. Their proprietary manufacturing process ensures high purity PEEK with controlled molecular weight distribution for consistent processing. Ticona's PEEK portfolio includes unfilled grades and compounds with various fillers like glass fiber, carbon fiber, and PTFE for enhanced mechanical properties and wear resistance. Their recent innovations include VESTAKEEP® PEEK for medical implants with demonstrated biocompatibility and VESTAKEEP® 3D printing grades optimized for additive manufacturing processes. Ticona has also developed specialized PEEK compounds for oil and gas applications that withstand extreme pressures and temperatures in downhole environments.

Strengths: Ticona's PEEK formulations offer excellent mechanical properties and chemical resistance with specialized grades for demanding applications like aerospace and medical devices. Their global manufacturing capabilities ensure consistent quality and supply reliability. Weaknesses: Premium pricing compared to conventional engineering polymers limits broader market adoption, and processing requires specialized equipment and expertise.

Critical PEEK Property Enhancement Patents

Polyether ether ketone composite material

PatentInactiveUS20140039127A1

Innovation

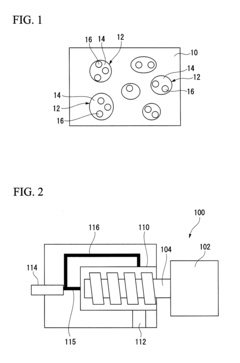

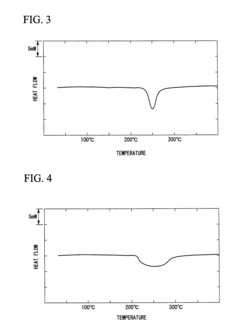

- A PEEK composite material comprising PEEK and polyolefin with a compatible structure, where the polyolefin is dispersed in a matrix of PEEK, achieving a single endothermic peak in DSC, allowing for a lower molding temperature and preventing colorant discoloration, with particle sizes of dispersed parts optimized to 1 μm or smaller for efficient thermal properties.

A process for preparing a polyether ether ketone

PatentActiveEP2292673A1

Innovation

- A method utilizing Na2CO3 as the only condensing agent, with step-by-step addition of reactants and hydroquinone, to control viscosity and enhance molecular weight, involving sequential addition of 4,4'-difluorobenzophenone, hydroquinone, and diphenol biphenyl, followed by polymerization and chain extension to achieve high molecular weight PEEK with narrow molecular weight distribution.

Environmental Impact and Sustainability of PEEK

PEEK (Polyetheretherketone) polymers, despite being synthetic materials, demonstrate several environmentally favorable characteristics compared to traditional plastics and metals. The production of PEEK requires significant energy input due to its high processing temperatures (typically 370-400°C), resulting in a considerable carbon footprint during manufacturing. However, this initial environmental cost is often offset by PEEK's exceptional longevity and performance benefits throughout its lifecycle.

The durability and chemical resistance of PEEK contribute significantly to its sustainability profile. With a service life that can exceed 10-15 years in demanding applications, PEEK components require less frequent replacement than conventional materials. This extended lifespan translates directly to reduced resource consumption and waste generation over time, particularly in industries like aerospace and automotive where component reliability is paramount.

PEEK's recyclability presents both challenges and opportunities. While technically recyclable, the high-performance nature of PEEK applications often means components are used in complex assemblies that complicate end-of-life recovery. Current recycling rates remain relatively low, estimated at less than 10% globally. However, emerging mechanical and chemical recycling technologies are showing promise for recovering and repurposing PEEK waste without significant property degradation.

The lightweight properties of PEEK offer substantial environmental benefits in transportation applications. When replacing metals in aircraft or automotive components, PEEK's lower density (approximately 1.32 g/cm³ compared to aluminum's 2.7 g/cm³) contributes to weight reduction, improved fuel efficiency, and consequently reduced emissions. Studies indicate that for every kilogram of weight saved in an aircraft, approximately 3,000 liters of fuel can be saved over the aircraft's operational lifetime.

Regulatory frameworks increasingly favor materials with lower environmental impact, positioning PEEK advantageously in several markets. The European Union's REACH regulations and similar global initiatives have restricted certain traditional materials while creating opportunities for PEEK as a compliant alternative. Additionally, PEEK's biocompatibility and non-toxicity eliminate concerns about leaching harmful substances into the environment, unlike some competing materials.

Industry leaders are investing in more sustainable PEEK production methods, including energy-efficient processing techniques and bio-based precursors. These innovations aim to reduce the material's environmental footprint while maintaining its exceptional performance characteristics. The development of PEEK composites incorporating recycled carbon fibers represents another promising direction for enhancing the material's sustainability profile while potentially reducing production costs.

The durability and chemical resistance of PEEK contribute significantly to its sustainability profile. With a service life that can exceed 10-15 years in demanding applications, PEEK components require less frequent replacement than conventional materials. This extended lifespan translates directly to reduced resource consumption and waste generation over time, particularly in industries like aerospace and automotive where component reliability is paramount.

PEEK's recyclability presents both challenges and opportunities. While technically recyclable, the high-performance nature of PEEK applications often means components are used in complex assemblies that complicate end-of-life recovery. Current recycling rates remain relatively low, estimated at less than 10% globally. However, emerging mechanical and chemical recycling technologies are showing promise for recovering and repurposing PEEK waste without significant property degradation.

The lightweight properties of PEEK offer substantial environmental benefits in transportation applications. When replacing metals in aircraft or automotive components, PEEK's lower density (approximately 1.32 g/cm³ compared to aluminum's 2.7 g/cm³) contributes to weight reduction, improved fuel efficiency, and consequently reduced emissions. Studies indicate that for every kilogram of weight saved in an aircraft, approximately 3,000 liters of fuel can be saved over the aircraft's operational lifetime.

Regulatory frameworks increasingly favor materials with lower environmental impact, positioning PEEK advantageously in several markets. The European Union's REACH regulations and similar global initiatives have restricted certain traditional materials while creating opportunities for PEEK as a compliant alternative. Additionally, PEEK's biocompatibility and non-toxicity eliminate concerns about leaching harmful substances into the environment, unlike some competing materials.

Industry leaders are investing in more sustainable PEEK production methods, including energy-efficient processing techniques and bio-based precursors. These innovations aim to reduce the material's environmental footprint while maintaining its exceptional performance characteristics. The development of PEEK composites incorporating recycled carbon fibers represents another promising direction for enhancing the material's sustainability profile while potentially reducing production costs.

Regulatory Framework for High-Performance Polymers

The regulatory landscape governing high-performance polymers like PEEK (Polyether Ether Ketone) has evolved significantly in response to growing applications across critical industries. Global regulatory bodies, including the FDA in the United States and the European Chemicals Agency (ECHA), have established comprehensive frameworks that manufacturers must navigate to ensure compliance.

In the medical sector, PEEK materials must adhere to stringent biocompatibility standards outlined in ISO 10993, which evaluates cytotoxicity, sensitization, and long-term implantation effects. The FDA's 510(k) clearance process specifically addresses PEEK-based medical devices, requiring extensive documentation of material properties and processing methods to demonstrate safety and efficacy.

For aerospace and automotive applications, regulations focus on flame retardancy and smoke emission characteristics. The Federal Aviation Administration (FAA) mandates compliance with FAR 25.853 for interior components, while the automotive industry follows standards like FMVSS 302 for flammability resistance. These requirements have directly influenced PEEK formulation development, driving manufacturers to create specialized grades with enhanced flame-retardant properties.

Environmental regulations have become increasingly influential in shaping the PEEK market. The EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requires thorough documentation of chemical substances in polymers, while RoHS (Restriction of Hazardous Substances) limits certain additives in electronic applications. These frameworks have accelerated the development of halogen-free PEEK formulations and environmentally sustainable processing methods.

Food contact applications face particularly complex regulatory hurdles. Both the FDA's 21 CFR 177.2415 and the EU's Regulation No 10/2011 establish specific migration limits and testing protocols for PEEK materials intended for food processing equipment. Manufacturers must demonstrate compliance through extensive extraction studies and compositional analysis.

Emerging regulations around circular economy principles and end-of-life management are reshaping PEEK's market positioning. The EU's Circular Economy Action Plan and similar initiatives worldwide are incentivizing research into recyclability and sustainable production methods for high-performance polymers, despite the inherent challenges in recycling these complex materials.

Regional variations in regulatory frameworks create significant compliance challenges for global PEEK manufacturers. China's GB standards, Japan's MHLW approvals, and other country-specific requirements necessitate tailored testing and documentation strategies, adding complexity to international market access.

In the medical sector, PEEK materials must adhere to stringent biocompatibility standards outlined in ISO 10993, which evaluates cytotoxicity, sensitization, and long-term implantation effects. The FDA's 510(k) clearance process specifically addresses PEEK-based medical devices, requiring extensive documentation of material properties and processing methods to demonstrate safety and efficacy.

For aerospace and automotive applications, regulations focus on flame retardancy and smoke emission characteristics. The Federal Aviation Administration (FAA) mandates compliance with FAR 25.853 for interior components, while the automotive industry follows standards like FMVSS 302 for flammability resistance. These requirements have directly influenced PEEK formulation development, driving manufacturers to create specialized grades with enhanced flame-retardant properties.

Environmental regulations have become increasingly influential in shaping the PEEK market. The EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requires thorough documentation of chemical substances in polymers, while RoHS (Restriction of Hazardous Substances) limits certain additives in electronic applications. These frameworks have accelerated the development of halogen-free PEEK formulations and environmentally sustainable processing methods.

Food contact applications face particularly complex regulatory hurdles. Both the FDA's 21 CFR 177.2415 and the EU's Regulation No 10/2011 establish specific migration limits and testing protocols for PEEK materials intended for food processing equipment. Manufacturers must demonstrate compliance through extensive extraction studies and compositional analysis.

Emerging regulations around circular economy principles and end-of-life management are reshaping PEEK's market positioning. The EU's Circular Economy Action Plan and similar initiatives worldwide are incentivizing research into recyclability and sustainable production methods for high-performance polymers, despite the inherent challenges in recycling these complex materials.

Regional variations in regulatory frameworks create significant compliance challenges for global PEEK manufacturers. China's GB standards, Japan's MHLW approvals, and other country-specific requirements necessitate tailored testing and documentation strategies, adding complexity to international market access.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!