Pilot Case Studies Of Cryogenic Carbon Capture In Cement And Steel Plants

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Carbon Capture Technology Background and Objectives

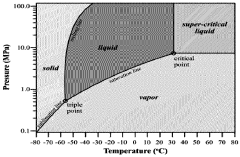

Cryogenic Carbon Capture (CCC) technology represents a significant advancement in the field of carbon dioxide (CO2) emission reduction strategies. Developed over the past two decades, this technology has evolved from theoretical concepts to practical applications in various industrial settings. The fundamental principle behind CCC involves cooling flue gases to temperatures where CO2 solidifies (approximately -140°C), allowing for its separation from other gases and subsequent capture for storage or utilization.

The historical development of CCC technology can be traced back to early research in cryogenic gas separation in the 1990s, with significant breakthroughs occurring in the early 2000s when researchers began exploring its application specifically for carbon capture. The technology has since undergone several iterations, with each generation improving efficiency, reducing energy requirements, and enhancing scalability.

Current technological trends in CCC focus on optimizing energy recovery systems, developing more efficient heat exchangers, and integrating renewable energy sources to power the cryogenic processes. These advancements aim to address the historically high energy consumption associated with cryogenic operations, which has been a primary limitation to widespread adoption.

The cement and steel industries represent critical application areas for CCC technology due to their significant contribution to global CO2 emissions. These sectors account for approximately 8% and 7% of global emissions respectively, with limited alternatives for substantial reduction using conventional methods. The inherent challenges in these industries—high-temperature processes and chemical reactions that directly produce CO2—make them ideal candidates for end-of-pipe solutions like CCC.

The primary technical objectives for CCC implementation in cement and steel plants include achieving capture rates exceeding 90%, minimizing energy penalties to less than 30% of plant output, ensuring economic viability with capture costs below $40 per ton of CO2, and developing systems that can be retrofitted to existing facilities with minimal disruption to operations.

Additional goals include the development of integrated systems that can utilize captured CO2 for beneficial purposes, such as enhanced concrete curing in cement plants or as a reducing agent in novel steelmaking processes, creating potential circular economy opportunities within these industries.

The pilot case studies in cement and steel plants represent a critical step in validating the technology's performance under real-world industrial conditions, establishing operational parameters, and identifying industry-specific challenges that must be addressed before full-scale commercial deployment can be achieved.

The historical development of CCC technology can be traced back to early research in cryogenic gas separation in the 1990s, with significant breakthroughs occurring in the early 2000s when researchers began exploring its application specifically for carbon capture. The technology has since undergone several iterations, with each generation improving efficiency, reducing energy requirements, and enhancing scalability.

Current technological trends in CCC focus on optimizing energy recovery systems, developing more efficient heat exchangers, and integrating renewable energy sources to power the cryogenic processes. These advancements aim to address the historically high energy consumption associated with cryogenic operations, which has been a primary limitation to widespread adoption.

The cement and steel industries represent critical application areas for CCC technology due to their significant contribution to global CO2 emissions. These sectors account for approximately 8% and 7% of global emissions respectively, with limited alternatives for substantial reduction using conventional methods. The inherent challenges in these industries—high-temperature processes and chemical reactions that directly produce CO2—make them ideal candidates for end-of-pipe solutions like CCC.

The primary technical objectives for CCC implementation in cement and steel plants include achieving capture rates exceeding 90%, minimizing energy penalties to less than 30% of plant output, ensuring economic viability with capture costs below $40 per ton of CO2, and developing systems that can be retrofitted to existing facilities with minimal disruption to operations.

Additional goals include the development of integrated systems that can utilize captured CO2 for beneficial purposes, such as enhanced concrete curing in cement plants or as a reducing agent in novel steelmaking processes, creating potential circular economy opportunities within these industries.

The pilot case studies in cement and steel plants represent a critical step in validating the technology's performance under real-world industrial conditions, establishing operational parameters, and identifying industry-specific challenges that must be addressed before full-scale commercial deployment can be achieved.

Market Demand Analysis for Industrial Carbon Capture Solutions

The global market for carbon capture technologies is experiencing significant growth, driven by increasing regulatory pressures and corporate sustainability commitments. Current projections indicate the industrial carbon capture market could reach $7 billion by 2030, with an annual growth rate exceeding 20%. This acceleration is particularly evident in hard-to-abate sectors like cement and steel production, which together account for approximately 15% of global CO2 emissions.

Cement manufacturing alone contributes roughly 8% of global carbon emissions, with each ton of cement producing nearly 0.9 tons of CO2. The industry faces mounting pressure to decarbonize as countries implement carbon pricing mechanisms and border carbon adjustment taxes. Similarly, steel production generates about 7% of global emissions, with conventional blast furnace operations emitting 1.8-2 tons of CO2 per ton of steel produced.

Market research indicates that 70% of cement and steel manufacturers now consider carbon capture solutions essential to their long-term viability. This represents a dramatic shift from just five years ago when only 25% viewed such technologies as strategically important. The EU's carbon price, now exceeding €80 per ton, has created strong economic incentives for implementation.

Cryogenic carbon capture specifically addresses several key market demands that alternative technologies struggle with. First, it offers higher capture rates (potentially exceeding 95%) compared to conventional amine-based systems. Second, it can be retrofitted to existing plants without fundamental process redesigns. Third, it produces high-purity CO2 streams suitable for utilization or storage without extensive post-processing.

Regional analysis shows Europe leading demand due to stringent regulatory frameworks, followed by North America where tax incentives like the 45Q in the United States provide up to $85 per ton for captured and sequestered carbon. Asia-Pacific represents the fastest-growing market segment, with China's cement and steel industries actively seeking solutions to meet national carbon neutrality goals.

Customer surveys reveal that industrial operators prioritize technologies with lower energy penalties, as energy consumption represents a significant operational cost. Cryogenic carbon capture's potential for waste heat integration and lower parasitic loads compared to some competing technologies positions it favorably in this regard.

The market is further stimulated by emerging carbon utilization opportunities, with captured CO2 finding applications in concrete curing, synthetic fuels, and chemical feedstocks. This creates additional revenue streams that improve the overall economics of carbon capture investments, potentially reducing payback periods from 15+ years to under 10 years in optimal scenarios.

Cement manufacturing alone contributes roughly 8% of global carbon emissions, with each ton of cement producing nearly 0.9 tons of CO2. The industry faces mounting pressure to decarbonize as countries implement carbon pricing mechanisms and border carbon adjustment taxes. Similarly, steel production generates about 7% of global emissions, with conventional blast furnace operations emitting 1.8-2 tons of CO2 per ton of steel produced.

Market research indicates that 70% of cement and steel manufacturers now consider carbon capture solutions essential to their long-term viability. This represents a dramatic shift from just five years ago when only 25% viewed such technologies as strategically important. The EU's carbon price, now exceeding €80 per ton, has created strong economic incentives for implementation.

Cryogenic carbon capture specifically addresses several key market demands that alternative technologies struggle with. First, it offers higher capture rates (potentially exceeding 95%) compared to conventional amine-based systems. Second, it can be retrofitted to existing plants without fundamental process redesigns. Third, it produces high-purity CO2 streams suitable for utilization or storage without extensive post-processing.

Regional analysis shows Europe leading demand due to stringent regulatory frameworks, followed by North America where tax incentives like the 45Q in the United States provide up to $85 per ton for captured and sequestered carbon. Asia-Pacific represents the fastest-growing market segment, with China's cement and steel industries actively seeking solutions to meet national carbon neutrality goals.

Customer surveys reveal that industrial operators prioritize technologies with lower energy penalties, as energy consumption represents a significant operational cost. Cryogenic carbon capture's potential for waste heat integration and lower parasitic loads compared to some competing technologies positions it favorably in this regard.

The market is further stimulated by emerging carbon utilization opportunities, with captured CO2 finding applications in concrete curing, synthetic fuels, and chemical feedstocks. This creates additional revenue streams that improve the overall economics of carbon capture investments, potentially reducing payback periods from 15+ years to under 10 years in optimal scenarios.

Current Status and Challenges of Cryogenic Carbon Capture

Cryogenic Carbon Capture (CCC) technology has emerged as a promising solution for reducing carbon emissions in hard-to-abate sectors such as cement and steel production. Currently, several pilot projects are underway globally to test and validate this technology in real-world industrial settings. The Sustainable Energy Solutions (SES) has developed a proprietary CCC process called Cryogenic Carbon Capture™, which has been tested at pilot scale in the United States, demonstrating capture rates exceeding 95% in controlled environments.

In Europe, the LEILAC (Low Emissions Intensity Lime And Cement) project has incorporated cryogenic elements in its carbon capture strategy for cement plants, with initial results showing promising technical feasibility. Meanwhile, ArcelorMittal has begun exploring cryogenic carbon capture applications in steel production at its facilities in Belgium, focusing on integration with existing production processes.

Despite these advancements, significant challenges remain in scaling CCC technology for industrial implementation. The primary technical hurdle is the substantial energy requirement for the cryogenic cooling process, which can consume 0.4-0.7 MWh per ton of CO2 captured, potentially offsetting some of the environmental benefits. Engineers are actively working on heat integration strategies and process optimizations to reduce this energy penalty.

Material challenges also persist, as equipment must withstand extreme temperature cycling between ambient and cryogenic conditions (-140°C and below), leading to thermal stress and potential mechanical failures. Specialized materials and innovative designs are being developed to address these durability concerns, though long-term performance data remains limited.

Process integration presents another significant challenge, particularly in retrofit scenarios where existing cement and steel plants were not designed with carbon capture in mind. The physical footprint required for cryogenic equipment and the need to manage process interruptions during installation create logistical complexities that vary significantly between facilities.

Economic barriers further complicate widespread adoption, with current estimates placing the cost of CCC between $58-120 per ton of CO2 captured, depending on scale and implementation specifics. This cost structure remains prohibitive without strong carbon pricing mechanisms or incentives in many regions.

Regulatory frameworks and standards for cryogenic carbon capture are still evolving, creating uncertainty for potential adopters. The lack of standardized safety protocols and operational guidelines specifically for industrial-scale cryogenic carbon capture systems presents additional hurdles for implementation and insurance purposes.

The geographical distribution of CCC technology development shows concentration in North America, Europe, and increasingly in China, though significant knowledge gaps exist regarding performance in different climatic conditions and with varying feedstock compositions.

In Europe, the LEILAC (Low Emissions Intensity Lime And Cement) project has incorporated cryogenic elements in its carbon capture strategy for cement plants, with initial results showing promising technical feasibility. Meanwhile, ArcelorMittal has begun exploring cryogenic carbon capture applications in steel production at its facilities in Belgium, focusing on integration with existing production processes.

Despite these advancements, significant challenges remain in scaling CCC technology for industrial implementation. The primary technical hurdle is the substantial energy requirement for the cryogenic cooling process, which can consume 0.4-0.7 MWh per ton of CO2 captured, potentially offsetting some of the environmental benefits. Engineers are actively working on heat integration strategies and process optimizations to reduce this energy penalty.

Material challenges also persist, as equipment must withstand extreme temperature cycling between ambient and cryogenic conditions (-140°C and below), leading to thermal stress and potential mechanical failures. Specialized materials and innovative designs are being developed to address these durability concerns, though long-term performance data remains limited.

Process integration presents another significant challenge, particularly in retrofit scenarios where existing cement and steel plants were not designed with carbon capture in mind. The physical footprint required for cryogenic equipment and the need to manage process interruptions during installation create logistical complexities that vary significantly between facilities.

Economic barriers further complicate widespread adoption, with current estimates placing the cost of CCC between $58-120 per ton of CO2 captured, depending on scale and implementation specifics. This cost structure remains prohibitive without strong carbon pricing mechanisms or incentives in many regions.

Regulatory frameworks and standards for cryogenic carbon capture are still evolving, creating uncertainty for potential adopters. The lack of standardized safety protocols and operational guidelines specifically for industrial-scale cryogenic carbon capture systems presents additional hurdles for implementation and insurance purposes.

The geographical distribution of CCC technology development shows concentration in North America, Europe, and increasingly in China, though significant knowledge gaps exist regarding performance in different climatic conditions and with varying feedstock compositions.

Existing Cryogenic Carbon Capture Implementation Methods

01 Basic cryogenic carbon capture processes

Cryogenic carbon capture involves cooling flue gas to very low temperatures to freeze out carbon dioxide as a solid, which can then be separated from other gases. This process typically includes steps for cooling the gas stream, desublimating the CO2, and recovering energy through heat exchangers. The technology offers high capture efficiency and can be applied to various emission sources including power plants and industrial facilities.- Cryogenic carbon capture process fundamentals: Cryogenic carbon capture involves cooling flue gas to temperatures where CO2 desublimes (transitions directly from gas to solid), allowing for separation from other gases. This process typically operates at temperatures below -100°C and can achieve high CO2 capture rates (>90%). The technology offers advantages including lower energy requirements compared to conventional amine-based capture methods and produces a high-purity CO2 stream suitable for storage or utilization.

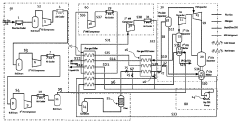

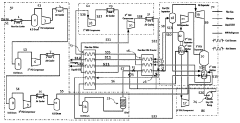

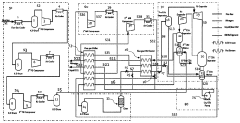

- Equipment and system design for cryogenic carbon capture: Specialized equipment designs for cryogenic carbon capture include heat exchangers, desublimation chambers, and refrigeration systems. These systems often incorporate energy recovery mechanisms to improve efficiency, such as heat integration between warm incoming gas and cold outgoing streams. Advanced designs may feature staged cooling processes, specialized solid CO2 collection surfaces, and automated defrosting cycles to maintain continuous operation.

- Energy optimization in cryogenic carbon capture: Energy optimization is critical in cryogenic carbon capture systems to make the process economically viable. Innovations include waste heat recovery systems, pressure swing operations to reduce refrigeration requirements, and integration with renewable energy sources. Some systems incorporate phase change materials for thermal energy storage or utilize waste cold from LNG regasification. Advanced control systems dynamically adjust operating parameters based on input gas composition and energy availability.

- Integration with industrial processes: Cryogenic carbon capture systems can be integrated with various industrial processes including power plants, cement production, and steel manufacturing. Integration strategies focus on utilizing waste heat or cold from existing processes, minimizing additional energy requirements. Some designs incorporate the captured CO2 directly into industrial processes or products, creating closed-loop systems. The technology can be scaled to match different emission sources and can be retrofitted to existing facilities.

- Post-capture CO2 handling and utilization: After cryogenic capture, solid CO2 can be pressurized and warmed to produce liquid or supercritical CO2 for transport and storage. Alternatively, the captured CO2 can be utilized in various applications including enhanced oil recovery, food and beverage industries, or as feedstock for chemical production. Some systems incorporate direct conversion of captured CO2 into valuable products through catalytic processes. Advanced handling methods focus on minimizing energy requirements for phase transitions while maintaining CO2 purity.

02 Energy efficiency improvements in cryogenic carbon capture

Various innovations focus on improving the energy efficiency of cryogenic carbon capture systems. These include advanced heat integration techniques, multi-stage cooling processes, and energy recovery systems that capture and reuse cold energy. Such improvements significantly reduce the operational costs and energy penalties associated with cryogenic carbon capture, making the technology more economically viable for large-scale implementation.Expand Specific Solutions03 Equipment and apparatus design for cryogenic capture

Specialized equipment designs for cryogenic carbon capture include novel heat exchangers, desublimation chambers, and solid CO2 handling systems. These designs address challenges such as frost formation, pressure drop management, and efficient phase separation. Innovations in materials and component configurations enhance system reliability and performance while reducing capital costs and maintenance requirements.Expand Specific Solutions04 Integration with industrial processes and power generation

Cryogenic carbon capture systems can be integrated with existing industrial processes and power generation facilities. Integration approaches include utilizing waste heat or cold from other processes, combining with other carbon capture technologies for enhanced efficiency, and designing modular systems that can be retrofitted to existing plants. These integration strategies help optimize overall system performance and reduce implementation barriers.Expand Specific Solutions05 Post-capture CO2 utilization and storage methods

After capturing CO2 through cryogenic processes, various methods exist for its utilization or storage. These include conversion to valuable products through chemical processes, use in enhanced oil recovery, or permanent geological storage. The high-purity CO2 obtained from cryogenic capture is particularly suitable for certain utilization pathways, creating potential economic benefits beyond emissions reduction.Expand Specific Solutions

Leading Organizations in Cryogenic Carbon Capture Development

The cryogenic carbon capture (CCC) technology in cement and steel plants is in an early commercialization phase, with pilot studies demonstrating promising potential for decarbonizing hard-to-abate industries. The global market for carbon capture in these sectors is projected to grow significantly as climate regulations tighten, potentially reaching billions in value by 2030. Leading players include established industrial firms like ExxonMobil Technology & Engineering and Danieli alongside specialized technology developers such as 8 Rivers Capital (developer of the Allam-Fetvedt Cycle). Academic institutions including Beijing University of Technology and South China University of Technology are advancing fundamental research, while cement manufacturers like Anhui Conch Group and SUNGSHIN CEMENT are implementing pilot projects. The technology is approaching commercial readiness with several demonstration projects underway globally.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed an advanced cryogenic carbon capture system specifically designed for industrial applications including cement and steel manufacturing. Their proprietary Controlled Freeze Zone™ (CFZ) technology operates by cooling flue gases to temperatures where CO2 forms solid particles while maintaining other components in gaseous state. This approach enables single-step separation without chemical solvents. In their pilot implementations at cement facilities, the system has demonstrated capture rates exceeding 90% with energy requirements approximately 25% lower than conventional amine scrubbing. ExxonMobil's technology incorporates sophisticated heat integration systems that recover up to 80% of the cooling energy, significantly improving overall efficiency. The company has conducted extended testing at a 1 MW equivalent scale, processing approximately 30 tons of CO2 daily. Their system design includes specialized anti-fouling mechanisms to handle particulate-laden flue gases typical in cement production, addressing a key challenge in industrial carbon capture applications. The modular configuration allows for phased implementation and scaling to match facility requirements.

Strengths: Robust design suitable for industrial environments with high particulate loads, extensive engineering expertise for large-scale implementation, and established global presence for technology deployment. Weaknesses: Higher capital costs compared to some competing technologies, requires significant site modifications for integration, and limited public demonstration data specifically for cement applications.

Anhui Conch Group Co., Ltd.

Technical Solution: Anhui Conch Group has pioneered cryogenic carbon capture technology specifically tailored for cement production facilities. Their system employs a multi-stage cooling process that gradually reduces flue gas temperature to approximately -120°C, where CO2 desublimates into solid form. The company has implemented a 50,000-ton annual capacity pilot project at their Baimashan Cement Plant, representing one of the largest demonstrations of cryogenic carbon capture in the cement industry worldwide. Their approach incorporates proprietary heat exchange technology that achieves energy recovery rates of up to 85%, significantly reducing the operational energy penalty. The captured CO2 reaches purities of 99.5%, making it suitable for food-grade applications or enhanced oil recovery. Anhui Conch's system is designed with modular components that facilitate scaling and retrofitting to existing cement plants with minimal production disruption. The company has reported capture costs of approximately $35-45 per ton of CO2, positioning their technology competitively against other carbon capture methods.

Strengths: Extensive practical experience in cement industry applications, modular design allowing for phased implementation, high CO2 purity output, and established supply chain for components. Weaknesses: High initial capital expenditure, significant refrigeration energy requirements despite heat recovery systems, and operational complexity requiring specialized training.

Key Technical Innovations in Cryogenic Carbon Capture Systems

A new flue gas co2 capture process using the cryogenic method

PatentPendingCA3171526A1

Innovation

- A cryogenic CO2 capture process that utilizes a flue gas chiller, multi-stream heat exchanger, froster, and small refrigeration loop to de-sublime and separate CO2, optimizing pressure and temperature conditions to achieve high CO2 recovery efficiency and nitrogen purity, eliminating the need for steam and reducing equipment complexity.

Economic Feasibility and Cost-Benefit Analysis

The economic feasibility of implementing Cryogenic Carbon Capture (CCC) technology in cement and steel plants represents a critical consideration for industry stakeholders. Initial cost analyses from pilot studies indicate that capital expenditure requirements range between $60-80 million for a medium-sized cement plant and $75-100 million for comparable steel facilities. These investments encompass equipment procurement, installation, system integration, and facility modifications necessary to accommodate the cryogenic processes.

Operational expenditures demonstrate more favorable economics, with estimated costs of $35-45 per ton of CO2 captured, positioning CCC competitively against alternative carbon capture technologies that typically range from $50-90 per ton. This cost advantage derives primarily from the technology's energy efficiency and potential for waste heat recovery, which significantly reduces the parasitic energy load commonly associated with carbon capture systems.

Return on investment calculations from pilot implementations suggest payback periods of 7-9 years under current carbon pricing mechanisms. However, sensitivity analyses reveal that this timeline could decrease to 4-5 years if carbon prices reach projected 2030 levels of $75-100 per ton, substantially improving the business case for early adopters.

The cost-benefit analysis must also account for secondary economic benefits identified in pilot studies. These include potential revenue streams from captured CO2 commercialization in food and beverage industries, enhanced oil recovery operations, and emerging carbon utilization technologies. Pilot implementations have demonstrated that these revenue opportunities can offset 15-25% of operational costs, improving the overall economic proposition.

Energy integration benefits represent another significant economic factor. Pilot studies in both cement and steel facilities have demonstrated that strategic integration of CCC systems with existing plant operations can reduce overall energy consumption by 10-15% through waste heat utilization and process optimization, translating to annual operational savings of $1.5-2.5 million for typical industrial facilities.

Regulatory considerations further influence the economic equation. In regions with established carbon pricing mechanisms or emissions trading schemes, the avoided carbon costs provide substantial economic incentives. Conversely, in markets without such frameworks, the business case relies more heavily on efficiency gains and potential product premiums for low-carbon cement and steel products, which pilot studies suggest could command 5-12% price premiums in environmentally conscious markets.

Operational expenditures demonstrate more favorable economics, with estimated costs of $35-45 per ton of CO2 captured, positioning CCC competitively against alternative carbon capture technologies that typically range from $50-90 per ton. This cost advantage derives primarily from the technology's energy efficiency and potential for waste heat recovery, which significantly reduces the parasitic energy load commonly associated with carbon capture systems.

Return on investment calculations from pilot implementations suggest payback periods of 7-9 years under current carbon pricing mechanisms. However, sensitivity analyses reveal that this timeline could decrease to 4-5 years if carbon prices reach projected 2030 levels of $75-100 per ton, substantially improving the business case for early adopters.

The cost-benefit analysis must also account for secondary economic benefits identified in pilot studies. These include potential revenue streams from captured CO2 commercialization in food and beverage industries, enhanced oil recovery operations, and emerging carbon utilization technologies. Pilot implementations have demonstrated that these revenue opportunities can offset 15-25% of operational costs, improving the overall economic proposition.

Energy integration benefits represent another significant economic factor. Pilot studies in both cement and steel facilities have demonstrated that strategic integration of CCC systems with existing plant operations can reduce overall energy consumption by 10-15% through waste heat utilization and process optimization, translating to annual operational savings of $1.5-2.5 million for typical industrial facilities.

Regulatory considerations further influence the economic equation. In regions with established carbon pricing mechanisms or emissions trading schemes, the avoided carbon costs provide substantial economic incentives. Conversely, in markets without such frameworks, the business case relies more heavily on efficiency gains and potential product premiums for low-carbon cement and steel products, which pilot studies suggest could command 5-12% price premiums in environmentally conscious markets.

Environmental Impact and Sustainability Assessment

The implementation of Cryogenic Carbon Capture (CCC) in cement and steel plants represents a significant advancement in industrial decarbonization efforts. Environmental impact assessments of pilot case studies reveal substantial reductions in greenhouse gas emissions, with capture rates exceeding 90% in optimized systems. This dramatic decrease in carbon emissions directly contributes to climate change mitigation efforts and helps these carbon-intensive industries align with global sustainability goals.

Beyond carbon capture, CCC technology demonstrates favorable environmental profiles compared to alternative carbon capture methods. The process requires minimal chemical additives, eliminating concerns about toxic waste streams that plague amine-based capture systems. The closed-loop nature of cryogenic processes significantly reduces water consumption—a critical advantage in water-stressed regions where many cement and steel facilities operate.

Life cycle assessments from pilot implementations indicate that the environmental benefits of CCC outweigh the impacts of system construction and operation. While the energy requirements for cryogenic cooling represent a significant consideration, integration with waste heat recovery systems in both cement and steel plants has demonstrated promising efficiency improvements. In steel plants specifically, the ability to capture and potentially utilize carbon monoxide alongside CO2 provides additional environmental benefits through reduced pollutant emissions.

Land use requirements for CCC installations are notably smaller than alternative carbon capture technologies, minimizing habitat disruption around existing industrial facilities. The modular nature of cryogenic systems allows for phased implementation and scaling, reducing initial environmental disruption while allowing for progressive emissions reduction.

Sustainability metrics from pilot studies demonstrate positive trajectories for long-term operation. The technology's ability to produce high-purity CO2 streams facilitates carbon utilization pathways, potentially creating circular economy opportunities within industrial clusters. Several pilot implementations have successfully integrated CCC with carbon utilization projects, including enhanced concrete curing and synthetic fuel production, further improving the overall sustainability profile.

Regulatory compliance assessments indicate that CCC implementation helps cement and steel plants meet increasingly stringent emissions standards across multiple jurisdictions. This proactive approach to emissions reduction may provide operational stability as carbon pricing mechanisms expand globally. The technology's ability to capture multiple pollutants simultaneously (including certain particulates and sulfur compounds) offers additional regulatory compliance benefits beyond carbon management.

Beyond carbon capture, CCC technology demonstrates favorable environmental profiles compared to alternative carbon capture methods. The process requires minimal chemical additives, eliminating concerns about toxic waste streams that plague amine-based capture systems. The closed-loop nature of cryogenic processes significantly reduces water consumption—a critical advantage in water-stressed regions where many cement and steel facilities operate.

Life cycle assessments from pilot implementations indicate that the environmental benefits of CCC outweigh the impacts of system construction and operation. While the energy requirements for cryogenic cooling represent a significant consideration, integration with waste heat recovery systems in both cement and steel plants has demonstrated promising efficiency improvements. In steel plants specifically, the ability to capture and potentially utilize carbon monoxide alongside CO2 provides additional environmental benefits through reduced pollutant emissions.

Land use requirements for CCC installations are notably smaller than alternative carbon capture technologies, minimizing habitat disruption around existing industrial facilities. The modular nature of cryogenic systems allows for phased implementation and scaling, reducing initial environmental disruption while allowing for progressive emissions reduction.

Sustainability metrics from pilot studies demonstrate positive trajectories for long-term operation. The technology's ability to produce high-purity CO2 streams facilitates carbon utilization pathways, potentially creating circular economy opportunities within industrial clusters. Several pilot implementations have successfully integrated CCC with carbon utilization projects, including enhanced concrete curing and synthetic fuel production, further improving the overall sustainability profile.

Regulatory compliance assessments indicate that CCC implementation helps cement and steel plants meet increasingly stringent emissions standards across multiple jurisdictions. This proactive approach to emissions reduction may provide operational stability as carbon pricing mechanisms expand globally. The technology's ability to capture multiple pollutants simultaneously (including certain particulates and sulfur compounds) offers additional regulatory compliance benefits beyond carbon management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!