Plate Heat Exchanger Applications in Pulp and Paper Industry

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE in Pulp & Paper: Background and Objectives

Plate heat exchangers (PHEs) have become increasingly important in the pulp and paper industry due to their efficiency, compact design, and versatility. The evolution of PHE technology in this sector has been driven by the industry's need for improved energy efficiency, reduced environmental impact, and enhanced process control.

The pulp and paper industry, one of the most energy-intensive manufacturing sectors, has been seeking innovative solutions to optimize its heat transfer processes. PHEs have emerged as a key technology in addressing these challenges, offering significant advantages over traditional shell-and-tube heat exchangers in many applications.

The development of PHEs for pulp and paper applications can be traced back to the mid-20th century, with continuous improvements in design, materials, and manufacturing techniques. Early adopters recognized the potential of PHEs to handle the diverse range of fluids and operating conditions found in pulp and paper mills, from high-temperature black liquor to corrosive bleaching chemicals.

As environmental regulations became more stringent and energy costs increased, the industry's focus shifted towards more sustainable and efficient processes. This trend accelerated the adoption of PHEs, which offer superior heat transfer efficiency and reduced fouling compared to conventional heat exchangers. The ability of PHEs to operate with smaller temperature approaches has led to significant energy savings and improved heat recovery in various mill processes.

The objectives of implementing PHEs in the pulp and paper industry are multifaceted. Primarily, they aim to enhance energy efficiency by maximizing heat recovery and minimizing thermal losses. This not only reduces operational costs but also contributes to the industry's sustainability goals by lowering overall energy consumption and associated carbon emissions.

Another key objective is to improve process control and product quality. PHEs' rapid response to temperature changes and their ability to maintain precise temperature profiles have proven invaluable in critical processes such as bleaching and chemical recovery. This precision contributes to more consistent product quality and reduced waste.

Space optimization is an additional goal, as the compact nature of PHEs allows for more efficient use of plant floor space compared to bulkier shell-and-tube exchangers. This aspect is particularly beneficial in retrofit projects where space constraints are often a significant challenge.

Lastly, the implementation of PHEs aims to enhance the overall reliability and maintainability of heat transfer systems in pulp and paper mills. Their modular design facilitates easier cleaning and maintenance, reducing downtime and extending equipment lifespan.

The pulp and paper industry, one of the most energy-intensive manufacturing sectors, has been seeking innovative solutions to optimize its heat transfer processes. PHEs have emerged as a key technology in addressing these challenges, offering significant advantages over traditional shell-and-tube heat exchangers in many applications.

The development of PHEs for pulp and paper applications can be traced back to the mid-20th century, with continuous improvements in design, materials, and manufacturing techniques. Early adopters recognized the potential of PHEs to handle the diverse range of fluids and operating conditions found in pulp and paper mills, from high-temperature black liquor to corrosive bleaching chemicals.

As environmental regulations became more stringent and energy costs increased, the industry's focus shifted towards more sustainable and efficient processes. This trend accelerated the adoption of PHEs, which offer superior heat transfer efficiency and reduced fouling compared to conventional heat exchangers. The ability of PHEs to operate with smaller temperature approaches has led to significant energy savings and improved heat recovery in various mill processes.

The objectives of implementing PHEs in the pulp and paper industry are multifaceted. Primarily, they aim to enhance energy efficiency by maximizing heat recovery and minimizing thermal losses. This not only reduces operational costs but also contributes to the industry's sustainability goals by lowering overall energy consumption and associated carbon emissions.

Another key objective is to improve process control and product quality. PHEs' rapid response to temperature changes and their ability to maintain precise temperature profiles have proven invaluable in critical processes such as bleaching and chemical recovery. This precision contributes to more consistent product quality and reduced waste.

Space optimization is an additional goal, as the compact nature of PHEs allows for more efficient use of plant floor space compared to bulkier shell-and-tube exchangers. This aspect is particularly beneficial in retrofit projects where space constraints are often a significant challenge.

Lastly, the implementation of PHEs aims to enhance the overall reliability and maintainability of heat transfer systems in pulp and paper mills. Their modular design facilitates easier cleaning and maintenance, reducing downtime and extending equipment lifespan.

Market Analysis: PHE Demand in Pulp & Paper Sector

The pulp and paper industry has shown a growing demand for plate heat exchangers (PHEs) due to their superior efficiency and versatility in various processes. Market analysis indicates a steady increase in PHE adoption across different segments of the industry, driven by the need for energy conservation, process optimization, and environmental compliance.

In the pulp production sector, PHEs are increasingly utilized for black liquor evaporation, pulp washing, and bleaching processes. The market for PHEs in these applications is expected to grow as mills focus on improving energy efficiency and reducing water consumption. The demand is particularly strong in regions with stringent environmental regulations, such as North America and Europe.

The paper manufacturing segment presents significant opportunities for PHE manufacturers. Applications include stock preparation, white water heat recovery, and machine cooling systems. As paper mills strive to reduce their carbon footprint and operating costs, the adoption of PHEs in heat recovery systems has seen a notable uptick. This trend is expected to continue, especially in emerging markets where modernization of existing facilities is underway.

The tissue paper segment has also contributed to the growing demand for PHEs. With the increasing focus on hygiene products, tissue manufacturers are investing in advanced production technologies, including efficient heat transfer solutions. PHEs are favored for their compact design and ability to handle the high-temperature processes involved in tissue production.

Geographically, Asia-Pacific represents the fastest-growing market for PHEs in the pulp and paper industry. The rapid expansion of paper production capacities in countries like China and India is driving the demand. North America and Europe, while mature markets, continue to see steady growth due to the replacement of older heat exchange systems with more efficient PHE solutions.

The market is also influenced by the increasing trend towards sustainable and bio-based products in the pulp and paper industry. As mills explore new processes for producing bio-based materials, the demand for specialized PHEs capable of handling complex fluids and extreme conditions is on the rise.

Factors such as raw material price fluctuations, energy costs, and environmental regulations play a crucial role in shaping the PHE market in this sector. Mills are increasingly looking for heat exchange solutions that offer long-term cost benefits and comply with evolving environmental standards, further boosting the appeal of PHEs.

In the pulp production sector, PHEs are increasingly utilized for black liquor evaporation, pulp washing, and bleaching processes. The market for PHEs in these applications is expected to grow as mills focus on improving energy efficiency and reducing water consumption. The demand is particularly strong in regions with stringent environmental regulations, such as North America and Europe.

The paper manufacturing segment presents significant opportunities for PHE manufacturers. Applications include stock preparation, white water heat recovery, and machine cooling systems. As paper mills strive to reduce their carbon footprint and operating costs, the adoption of PHEs in heat recovery systems has seen a notable uptick. This trend is expected to continue, especially in emerging markets where modernization of existing facilities is underway.

The tissue paper segment has also contributed to the growing demand for PHEs. With the increasing focus on hygiene products, tissue manufacturers are investing in advanced production technologies, including efficient heat transfer solutions. PHEs are favored for their compact design and ability to handle the high-temperature processes involved in tissue production.

Geographically, Asia-Pacific represents the fastest-growing market for PHEs in the pulp and paper industry. The rapid expansion of paper production capacities in countries like China and India is driving the demand. North America and Europe, while mature markets, continue to see steady growth due to the replacement of older heat exchange systems with more efficient PHE solutions.

The market is also influenced by the increasing trend towards sustainable and bio-based products in the pulp and paper industry. As mills explore new processes for producing bio-based materials, the demand for specialized PHEs capable of handling complex fluids and extreme conditions is on the rise.

Factors such as raw material price fluctuations, energy costs, and environmental regulations play a crucial role in shaping the PHE market in this sector. Mills are increasingly looking for heat exchange solutions that offer long-term cost benefits and comply with evolving environmental standards, further boosting the appeal of PHEs.

PHE Technology Status and Challenges

Plate heat exchangers (PHEs) have gained significant traction in the pulp and paper industry due to their efficiency and versatility. However, the current state of PHE technology in this sector faces several challenges and limitations. The harsh operating conditions in pulp and paper processes, including high temperatures, corrosive chemicals, and particulate-laden fluids, pose significant hurdles for PHE applications.

One of the primary challenges is fouling, which occurs when suspended solids and dissolved substances accumulate on heat transfer surfaces. This issue is particularly prevalent in black liquor processing and paper machine heat recovery systems. Fouling reduces heat transfer efficiency and increases maintenance requirements, leading to increased downtime and operational costs. Current PHE designs struggle to maintain optimal performance under these conditions, necessitating frequent cleaning and maintenance cycles.

Corrosion resistance is another critical challenge for PHEs in the pulp and paper industry. The presence of aggressive chemicals, such as those used in pulping and bleaching processes, can rapidly degrade traditional plate materials. While some progress has been made in developing corrosion-resistant alloys and coatings, finding cost-effective solutions that can withstand the full range of chemical exposures remains an ongoing challenge.

The high-temperature requirements of certain pulp and paper processes also present limitations for conventional PHE designs. Many existing PHEs are not suitable for temperatures exceeding 200°C, which restricts their application in areas such as black liquor evaporation and steam systems. Developing PHE technologies capable of operating reliably at higher temperatures without compromising on efficiency or lifespan is a key area of focus for manufacturers and researchers.

Pressure drop across PHEs is another concern, particularly in applications where maintaining specific flow rates is crucial. The complex flow paths within PHEs can lead to significant pressure losses, which may necessitate additional pumping power and increase energy consumption. Balancing the need for efficient heat transfer with minimized pressure drop remains a design challenge for PHE manufacturers.

Scaling, especially in water treatment and recovery systems within paper mills, is an persistent issue that affects PHE performance. The formation of mineral deposits on heat transfer surfaces not only reduces efficiency but can also lead to blockages and equipment damage. Current technologies for scale prevention and removal in PHEs are not always effective in the demanding environments of pulp and paper processes.

Despite these challenges, ongoing research and development efforts are focused on addressing these limitations. Innovations in plate design, materials science, and surface treatments are being pursued to enhance PHE performance in pulp and paper applications. Additionally, the integration of advanced monitoring and control systems is being explored to optimize PHE operation and maintenance strategies in real-time.

The geographical distribution of PHE technology development for pulp and paper applications is primarily concentrated in regions with strong paper industries, such as North America, Northern Europe, and parts of Asia. These areas are driving much of the innovation in PHE technology tailored to the specific needs of the pulp and paper sector.

One of the primary challenges is fouling, which occurs when suspended solids and dissolved substances accumulate on heat transfer surfaces. This issue is particularly prevalent in black liquor processing and paper machine heat recovery systems. Fouling reduces heat transfer efficiency and increases maintenance requirements, leading to increased downtime and operational costs. Current PHE designs struggle to maintain optimal performance under these conditions, necessitating frequent cleaning and maintenance cycles.

Corrosion resistance is another critical challenge for PHEs in the pulp and paper industry. The presence of aggressive chemicals, such as those used in pulping and bleaching processes, can rapidly degrade traditional plate materials. While some progress has been made in developing corrosion-resistant alloys and coatings, finding cost-effective solutions that can withstand the full range of chemical exposures remains an ongoing challenge.

The high-temperature requirements of certain pulp and paper processes also present limitations for conventional PHE designs. Many existing PHEs are not suitable for temperatures exceeding 200°C, which restricts their application in areas such as black liquor evaporation and steam systems. Developing PHE technologies capable of operating reliably at higher temperatures without compromising on efficiency or lifespan is a key area of focus for manufacturers and researchers.

Pressure drop across PHEs is another concern, particularly in applications where maintaining specific flow rates is crucial. The complex flow paths within PHEs can lead to significant pressure losses, which may necessitate additional pumping power and increase energy consumption. Balancing the need for efficient heat transfer with minimized pressure drop remains a design challenge for PHE manufacturers.

Scaling, especially in water treatment and recovery systems within paper mills, is an persistent issue that affects PHE performance. The formation of mineral deposits on heat transfer surfaces not only reduces efficiency but can also lead to blockages and equipment damage. Current technologies for scale prevention and removal in PHEs are not always effective in the demanding environments of pulp and paper processes.

Despite these challenges, ongoing research and development efforts are focused on addressing these limitations. Innovations in plate design, materials science, and surface treatments are being pursued to enhance PHE performance in pulp and paper applications. Additionally, the integration of advanced monitoring and control systems is being explored to optimize PHE operation and maintenance strategies in real-time.

The geographical distribution of PHE technology development for pulp and paper applications is primarily concentrated in regions with strong paper industries, such as North America, Northern Europe, and parts of Asia. These areas are driving much of the innovation in PHE technology tailored to the specific needs of the pulp and paper sector.

Current PHE Solutions for Pulp & Paper Applications

01 Improved plate design for heat exchangers

Advanced plate designs enhance heat transfer efficiency and fluid distribution. These designs may include optimized corrugation patterns, innovative flow channel geometries, or specialized surface treatments to improve thermal performance and reduce fouling.- Plate design and configuration: Innovations in plate design and configuration for heat exchangers, including improvements in plate geometry, corrugation patterns, and stacking arrangements to enhance heat transfer efficiency and reduce pressure drop. These designs aim to optimize fluid flow distribution and increase the overall heat transfer surface area.

- Sealing and gasket systems: Advanced sealing and gasket systems for plate heat exchangers to prevent leakage and improve overall performance. These innovations include new gasket materials, designs, and installation methods to ensure proper sealing between plates, even under high pressure and temperature conditions.

- Flow distribution and turbulence enhancement: Techniques for improving flow distribution and enhancing turbulence within plate heat exchangers. These methods include the use of flow distributors, baffles, and specially designed inlet and outlet ports to ensure uniform fluid distribution and increase heat transfer coefficients.

- Materials and coatings: Development of new materials and coatings for plate heat exchanger components to improve corrosion resistance, fouling mitigation, and overall durability. These advancements include the use of specialized alloys, composite materials, and surface treatments to extend the lifespan of heat exchangers in challenging operating environments.

- Modular and customizable designs: Innovative approaches to modular and customizable plate heat exchanger designs, allowing for easier maintenance, capacity expansion, and adaptation to specific application requirements. These designs feature interchangeable components, scalable configurations, and flexible assembly methods to enhance versatility and reduce downtime during maintenance or modifications.

02 Sealing and gasket innovations

Novel sealing and gasket technologies improve leak prevention and extend the operational life of plate heat exchangers. These may include advanced materials, unique gasket profiles, or integrated sealing systems that enhance reliability under various operating conditions.Expand Specific Solutions03 Modular and customizable designs

Modular plate heat exchanger designs allow for easy customization, maintenance, and scalability. These systems can be adapted to various applications and capacity requirements, offering flexibility in installation and future expansion.Expand Specific Solutions04 Enhanced corrosion resistance

Developments in materials and coatings improve the corrosion resistance of plate heat exchangers, extending their lifespan and allowing use in more aggressive environments. This may include the use of specialized alloys or surface treatments.Expand Specific Solutions05 Integration of smart technologies

Incorporation of sensors, monitoring systems, and smart controls enhance the performance and efficiency of plate heat exchangers. These technologies enable real-time optimization, predictive maintenance, and improved overall system management.Expand Specific Solutions

Key PHE Manufacturers and Industry Players

The plate heat exchanger market in the pulp and paper industry is in a growth phase, driven by increasing demand for energy-efficient solutions. The market size is expanding due to the industry's focus on sustainability and cost reduction. Technologically, plate heat exchangers are mature but continue to evolve, with companies like Alfa Laval, Vahterus, and SPX FLOW leading innovation. These firms, along with others such as Haldor Topsøe and SWEP International, are competing to develop more efficient and specialized solutions for pulp and paper applications, focusing on improved heat transfer, reduced fouling, and enhanced durability in harsh industrial environments.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchangers specifically designed for the pulp and paper industry. Their technology utilizes corrugated plates with a herringbone pattern to enhance turbulence and heat transfer efficiency[1]. The company's AlfaNova fusion-bonded plate heat exchangers offer superior corrosion resistance, crucial for handling aggressive fluids in pulp processing[2]. Alfa Laval's WideGap technology allows for handling of fibrous materials without clogging, making it ideal for black liquor heating and other pulp applications[3]. Their heat exchangers also incorporate features like glue-free gaskets and optimized plate geometry to minimize fouling and extend operational time between cleaning cycles[4].

Strengths: High efficiency, corrosion resistance, and ability to handle fibrous materials. Weaknesses: Higher initial cost compared to traditional shell-and-tube exchangers, potential limitations in extreme temperature applications.

Vahterus Oy

Technical Solution: Vahterus specializes in fully welded plate heat exchangers, offering a unique solution for the pulp and paper industry. Their Plate & Shell heat exchanger design combines the compactness of plate heat exchangers with the pressure and temperature resistance of shell-and-tube units[5]. This technology is particularly effective in black liquor heating and evaporation processes, where it can handle high viscosities and temperatures up to 900°C[6]. Vahterus' exchangers feature a circular plate pack welded into a pressure vessel, eliminating gaskets and reducing the risk of leaks in corrosive environments[7]. The company's heat exchangers also offer improved heat recovery in pulp drying processes, contributing to overall energy efficiency in paper mills[8].

Strengths: High pressure and temperature tolerance, gasket-free design for improved reliability. Weaknesses: Limited flexibility for expansion or modification once installed, potentially higher maintenance complexity for welded units.

Innovative PHE Designs for Pulp & Paper Industry

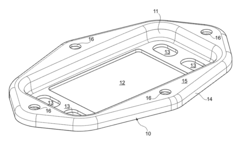

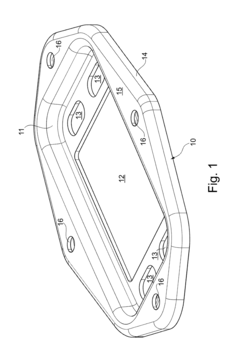

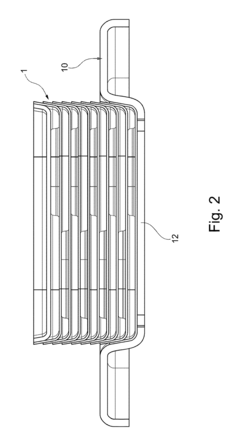

Plate heat exchanger

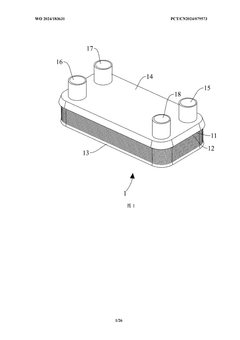

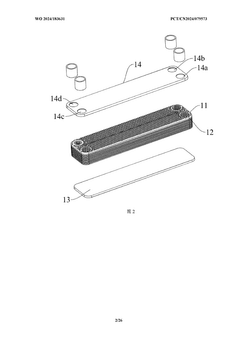

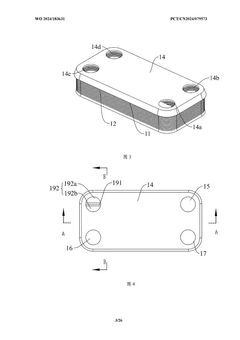

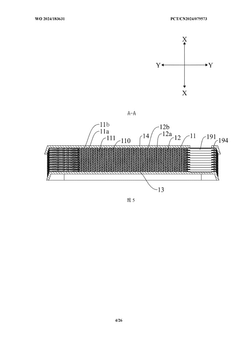

PatentWO2024183631A1

Innovation

- A plate heat exchanger is designed, which uses a plurality of first plates and second plates in an alternating stacked structure, and sets a first channel and a second channel in the distribution part to form a "U"-shaped heat exchange medium flow path. , through the connection between the first hole and the second hole, the flow path is enlarged to ensure uniform flow distribution of the medium.

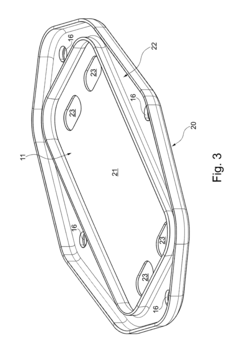

Plate heat exchanger with flanged base or connecting plate

PatentInactiveUS9863715B2

Innovation

- A lightweight, thin-walled base or connecting plate with a flange that is circumferentially bent and forms a receptacle to rest against the plate stack's bottom edge, providing a large-area contact and reducing the load on connections, allowing for a more stable and durable assembly.

Environmental Impact of PHE in Pulp & Paper Industry

The implementation of Plate Heat Exchangers (PHEs) in the pulp and paper industry has significant environmental implications, contributing to improved sustainability and reduced ecological footprint. One of the primary environmental benefits is the substantial reduction in energy consumption. PHEs are highly efficient in heat transfer, allowing for better utilization of thermal energy and reducing the overall energy demand of pulp and paper processes. This decreased energy requirement directly translates to lower greenhouse gas emissions, particularly CO2, thus mitigating the industry's impact on climate change.

Water conservation is another crucial environmental advantage of PHEs in this sector. The compact design and efficient heat transfer capabilities of PHEs enable more effective water recycling and reuse within the production processes. This leads to a significant reduction in freshwater consumption, alleviating pressure on local water resources and minimizing wastewater discharge. The improved water management also results in decreased thermal pollution of water bodies, as less heated water is released into the environment.

PHEs contribute to resource efficiency by enabling better heat recovery from various streams in pulp and paper production. This includes recovering heat from wastewater, steam condensate, and other process fluids that would otherwise be wasted. By reusing this thermal energy, the industry reduces its reliance on primary energy sources, further decreasing its environmental footprint and promoting circular economy principles.

The use of PHEs also leads to a reduction in chemical consumption. The precise temperature control afforded by PHEs allows for optimized chemical reactions in pulping and bleaching processes, potentially reducing the amount of chemicals required. This not only has economic benefits but also decreases the environmental impact associated with chemical production and disposal.

Furthermore, the compact nature of PHEs compared to traditional shell and tube heat exchangers results in a smaller physical footprint. This can lead to more efficient use of factory space, potentially reducing the need for facility expansion and the associated land use impacts. The smaller size also means less material is required for construction, indirectly reducing the environmental impact of manufacturing and transportation of equipment.

Maintenance and cleaning of PHEs in the pulp and paper industry can be performed with environmentally friendly methods. Many PHEs can be cleaned using clean-in-place (CIP) systems, which often use less aggressive chemicals and consume less water compared to traditional cleaning methods. This contributes to reduced chemical waste and water pollution associated with maintenance activities.

In conclusion, the adoption of PHEs in the pulp and paper industry aligns well with environmental sustainability goals. By improving energy efficiency, conserving water, enhancing resource utilization, reducing chemical use, and minimizing spatial requirements, PHEs play a crucial role in mitigating the environmental impact of this traditionally resource-intensive industry. As the sector continues to face pressure to reduce its ecological footprint, the widespread implementation of PHEs represents a significant step towards more sustainable production practices.

Water conservation is another crucial environmental advantage of PHEs in this sector. The compact design and efficient heat transfer capabilities of PHEs enable more effective water recycling and reuse within the production processes. This leads to a significant reduction in freshwater consumption, alleviating pressure on local water resources and minimizing wastewater discharge. The improved water management also results in decreased thermal pollution of water bodies, as less heated water is released into the environment.

PHEs contribute to resource efficiency by enabling better heat recovery from various streams in pulp and paper production. This includes recovering heat from wastewater, steam condensate, and other process fluids that would otherwise be wasted. By reusing this thermal energy, the industry reduces its reliance on primary energy sources, further decreasing its environmental footprint and promoting circular economy principles.

The use of PHEs also leads to a reduction in chemical consumption. The precise temperature control afforded by PHEs allows for optimized chemical reactions in pulping and bleaching processes, potentially reducing the amount of chemicals required. This not only has economic benefits but also decreases the environmental impact associated with chemical production and disposal.

Furthermore, the compact nature of PHEs compared to traditional shell and tube heat exchangers results in a smaller physical footprint. This can lead to more efficient use of factory space, potentially reducing the need for facility expansion and the associated land use impacts. The smaller size also means less material is required for construction, indirectly reducing the environmental impact of manufacturing and transportation of equipment.

Maintenance and cleaning of PHEs in the pulp and paper industry can be performed with environmentally friendly methods. Many PHEs can be cleaned using clean-in-place (CIP) systems, which often use less aggressive chemicals and consume less water compared to traditional cleaning methods. This contributes to reduced chemical waste and water pollution associated with maintenance activities.

In conclusion, the adoption of PHEs in the pulp and paper industry aligns well with environmental sustainability goals. By improving energy efficiency, conserving water, enhancing resource utilization, reducing chemical use, and minimizing spatial requirements, PHEs play a crucial role in mitigating the environmental impact of this traditionally resource-intensive industry. As the sector continues to face pressure to reduce its ecological footprint, the widespread implementation of PHEs represents a significant step towards more sustainable production practices.

Energy Efficiency Improvements with PHE Technology

Plate heat exchangers (PHEs) have emerged as a transformative technology in the pulp and paper industry, offering significant energy efficiency improvements. These compact and versatile heat transfer devices have revolutionized various processes within the industry, leading to substantial energy savings and enhanced operational performance.

One of the primary areas where PHEs have made a significant impact is in the recovery of waste heat from process streams. In pulp mills, the black liquor evaporation process generates considerable amounts of low-grade heat that was traditionally discarded. By implementing PHEs, this waste heat can be effectively captured and utilized to preheat incoming process streams, reducing the overall energy consumption of the mill.

The bleaching process in paper production has also benefited greatly from PHE technology. Traditional bleaching methods often required large amounts of steam for heating. PHEs allow for efficient heat recovery between different bleaching stages, minimizing the need for external heating sources. This not only reduces energy consumption but also improves the consistency of the bleaching process, leading to higher quality paper products.

In the paper drying section, PHEs have proven invaluable for optimizing steam usage. By incorporating PHEs into the dryer section's heat recovery systems, mills can recycle a significant portion of the heat that would otherwise be lost to the environment. This recycled heat can be used to preheat incoming air or water, reducing the steam demand and improving overall energy efficiency.

The compact design of PHEs has also enabled more efficient use of space within pulp and paper mills. Compared to traditional shell-and-tube heat exchangers, PHEs occupy a much smaller footprint while providing equivalent or superior heat transfer capabilities. This space-saving aspect allows for easier integration into existing mill layouts and provides flexibility for future expansions or modifications.

Furthermore, PHEs have demonstrated excellent performance in handling the challenging fluids often encountered in pulp and paper processes. Their ability to effectively transfer heat between liquids with high fiber content or varying viscosities has made them particularly suitable for applications such as black liquor heating and white water cooling.

The implementation of PHE technology has also contributed to reduced maintenance requirements and improved operational reliability. The plate design allows for easy disassembly and cleaning, minimizing downtime for maintenance activities. Additionally, the modular nature of PHEs enables quick capacity adjustments by adding or removing plates, providing mills with the flexibility to adapt to changing production demands.

In conclusion, the adoption of plate heat exchanger technology in the pulp and paper industry has led to substantial energy efficiency improvements across various processes. From waste heat recovery to optimized steam usage and enhanced process integration, PHEs have proven to be a valuable tool in reducing energy consumption and improving overall operational performance in this energy-intensive industry.

One of the primary areas where PHEs have made a significant impact is in the recovery of waste heat from process streams. In pulp mills, the black liquor evaporation process generates considerable amounts of low-grade heat that was traditionally discarded. By implementing PHEs, this waste heat can be effectively captured and utilized to preheat incoming process streams, reducing the overall energy consumption of the mill.

The bleaching process in paper production has also benefited greatly from PHE technology. Traditional bleaching methods often required large amounts of steam for heating. PHEs allow for efficient heat recovery between different bleaching stages, minimizing the need for external heating sources. This not only reduces energy consumption but also improves the consistency of the bleaching process, leading to higher quality paper products.

In the paper drying section, PHEs have proven invaluable for optimizing steam usage. By incorporating PHEs into the dryer section's heat recovery systems, mills can recycle a significant portion of the heat that would otherwise be lost to the environment. This recycled heat can be used to preheat incoming air or water, reducing the steam demand and improving overall energy efficiency.

The compact design of PHEs has also enabled more efficient use of space within pulp and paper mills. Compared to traditional shell-and-tube heat exchangers, PHEs occupy a much smaller footprint while providing equivalent or superior heat transfer capabilities. This space-saving aspect allows for easier integration into existing mill layouts and provides flexibility for future expansions or modifications.

Furthermore, PHEs have demonstrated excellent performance in handling the challenging fluids often encountered in pulp and paper processes. Their ability to effectively transfer heat between liquids with high fiber content or varying viscosities has made them particularly suitable for applications such as black liquor heating and white water cooling.

The implementation of PHE technology has also contributed to reduced maintenance requirements and improved operational reliability. The plate design allows for easy disassembly and cleaning, minimizing downtime for maintenance activities. Additionally, the modular nature of PHEs enables quick capacity adjustments by adding or removing plates, providing mills with the flexibility to adapt to changing production demands.

In conclusion, the adoption of plate heat exchanger technology in the pulp and paper industry has led to substantial energy efficiency improvements across various processes. From waste heat recovery to optimized steam usage and enhanced process integration, PHEs have proven to be a valuable tool in reducing energy consumption and improving overall operational performance in this energy-intensive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!