Plate Heat Exchanger Design for Fast Dynamics in Petrochemicals

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Design Background and Objectives

Plate heat exchangers (PHEs) have been a cornerstone in the petrochemical industry for decades, offering efficient heat transfer solutions in various processes. The evolution of PHE technology has been driven by the increasing demand for more responsive and dynamic systems in petrochemical operations. This technological progression aims to address the challenges posed by rapidly changing process conditions and the need for precise temperature control in complex chemical reactions.

The primary objective of designing PHEs for fast dynamics in petrochemicals is to enhance the overall efficiency and responsiveness of heat transfer processes. This involves developing innovative plate designs, optimizing flow patterns, and incorporating advanced materials to achieve rapid heat exchange rates while maintaining process stability. By improving the dynamic performance of PHEs, petrochemical plants can achieve better control over reaction temperatures, reduce energy consumption, and increase product quality.

Historical developments in PHE technology have laid the foundation for current research efforts. Early designs focused primarily on maximizing heat transfer area and minimizing pressure drop. However, as the petrochemical industry evolved, the need for more agile and responsive heat exchange systems became apparent. This shift in focus has led to a new era of PHE design, where fast dynamics are prioritized alongside traditional performance metrics.

The trajectory of PHE technology is closely aligned with broader trends in process intensification and smart manufacturing within the petrochemical sector. As industries move towards more flexible and adaptive production methods, the demand for heat exchangers capable of rapid response to changing process conditions has intensified. This trend is further amplified by the increasing integration of renewable energy sources and the need for more sustainable petrochemical processes.

Current research in PHE design for fast dynamics encompasses several key areas. These include the development of novel plate geometries that promote turbulent flow and enhance heat transfer coefficients, the exploration of advanced materials with superior thermal conductivity and corrosion resistance, and the integration of smart sensors and control systems for real-time performance optimization. Additionally, computational fluid dynamics (CFD) and machine learning techniques are being leveraged to model and predict PHE behavior under dynamic operating conditions.

The goals of this technological pursuit extend beyond mere performance improvements. By achieving faster dynamics in PHEs, petrochemical operations can become more flexible, allowing for quicker product changeovers and more efficient use of resources. This adaptability is crucial in today's volatile market conditions, where the ability to rapidly adjust production processes can provide a significant competitive advantage.

The primary objective of designing PHEs for fast dynamics in petrochemicals is to enhance the overall efficiency and responsiveness of heat transfer processes. This involves developing innovative plate designs, optimizing flow patterns, and incorporating advanced materials to achieve rapid heat exchange rates while maintaining process stability. By improving the dynamic performance of PHEs, petrochemical plants can achieve better control over reaction temperatures, reduce energy consumption, and increase product quality.

Historical developments in PHE technology have laid the foundation for current research efforts. Early designs focused primarily on maximizing heat transfer area and minimizing pressure drop. However, as the petrochemical industry evolved, the need for more agile and responsive heat exchange systems became apparent. This shift in focus has led to a new era of PHE design, where fast dynamics are prioritized alongside traditional performance metrics.

The trajectory of PHE technology is closely aligned with broader trends in process intensification and smart manufacturing within the petrochemical sector. As industries move towards more flexible and adaptive production methods, the demand for heat exchangers capable of rapid response to changing process conditions has intensified. This trend is further amplified by the increasing integration of renewable energy sources and the need for more sustainable petrochemical processes.

Current research in PHE design for fast dynamics encompasses several key areas. These include the development of novel plate geometries that promote turbulent flow and enhance heat transfer coefficients, the exploration of advanced materials with superior thermal conductivity and corrosion resistance, and the integration of smart sensors and control systems for real-time performance optimization. Additionally, computational fluid dynamics (CFD) and machine learning techniques are being leveraged to model and predict PHE behavior under dynamic operating conditions.

The goals of this technological pursuit extend beyond mere performance improvements. By achieving faster dynamics in PHEs, petrochemical operations can become more flexible, allowing for quicker product changeovers and more efficient use of resources. This adaptability is crucial in today's volatile market conditions, where the ability to rapidly adjust production processes can provide a significant competitive advantage.

Petrochemical Market Demand Analysis

The petrochemical industry's demand for efficient heat exchange solutions has been steadily growing, driven by the need for improved process efficiency, energy conservation, and environmental sustainability. Plate heat exchangers (PHEs) with fast dynamics are increasingly sought after in this sector due to their ability to rapidly respond to changes in process conditions, enhancing overall system performance and control.

Market analysis indicates a significant uptick in the adoption of advanced PHE designs across various petrochemical applications. This trend is particularly pronounced in processes requiring quick temperature adjustments, such as in the production of polymers, specialty chemicals, and refined petroleum products. The global market for PHEs in the petrochemical sector is expected to grow substantially over the next five years, with a notable shift towards designs optimized for fast dynamics.

The demand for PHEs with rapid response capabilities is largely fueled by the industry's push towards process intensification and smart manufacturing. Petrochemical companies are increasingly focusing on maximizing yield and product quality while minimizing energy consumption and environmental impact. Fast-dynamic PHEs play a crucial role in achieving these objectives by enabling precise temperature control and quick process adjustments.

In terms of regional demand, Asia-Pacific leads the market due to the rapid expansion of petrochemical facilities in countries like China and India. North America and Europe follow closely, with a strong emphasis on upgrading existing infrastructure to meet stricter environmental regulations and efficiency standards. The Middle East, traditionally a stronghold of petrochemical production, is also showing increased interest in advanced PHE technologies to maintain its competitive edge.

The market demand is further segmented based on specific petrochemical processes. For instance, the polymer production sector shows a high demand for PHEs capable of handling rapid temperature fluctuations during polymerization reactions. Similarly, in the refining sector, there's a growing need for PHEs that can quickly adapt to varying feed compositions and process conditions.

Emerging trends in the petrochemical industry, such as the shift towards renewable feedstocks and the integration of digital technologies, are also influencing the demand for advanced PHE designs. These trends necessitate heat exchange solutions that can accommodate a wider range of operating conditions and integrate seamlessly with digital control systems for real-time optimization.

As environmental regulations become more stringent, there's an increasing demand for PHEs that not only offer fast dynamics but also contribute to overall energy efficiency and emissions reduction. This has led to a market preference for designs that minimize fouling, reduce pressure drop, and maximize heat recovery, all while maintaining the ability to respond quickly to process changes.

Market analysis indicates a significant uptick in the adoption of advanced PHE designs across various petrochemical applications. This trend is particularly pronounced in processes requiring quick temperature adjustments, such as in the production of polymers, specialty chemicals, and refined petroleum products. The global market for PHEs in the petrochemical sector is expected to grow substantially over the next five years, with a notable shift towards designs optimized for fast dynamics.

The demand for PHEs with rapid response capabilities is largely fueled by the industry's push towards process intensification and smart manufacturing. Petrochemical companies are increasingly focusing on maximizing yield and product quality while minimizing energy consumption and environmental impact. Fast-dynamic PHEs play a crucial role in achieving these objectives by enabling precise temperature control and quick process adjustments.

In terms of regional demand, Asia-Pacific leads the market due to the rapid expansion of petrochemical facilities in countries like China and India. North America and Europe follow closely, with a strong emphasis on upgrading existing infrastructure to meet stricter environmental regulations and efficiency standards. The Middle East, traditionally a stronghold of petrochemical production, is also showing increased interest in advanced PHE technologies to maintain its competitive edge.

The market demand is further segmented based on specific petrochemical processes. For instance, the polymer production sector shows a high demand for PHEs capable of handling rapid temperature fluctuations during polymerization reactions. Similarly, in the refining sector, there's a growing need for PHEs that can quickly adapt to varying feed compositions and process conditions.

Emerging trends in the petrochemical industry, such as the shift towards renewable feedstocks and the integration of digital technologies, are also influencing the demand for advanced PHE designs. These trends necessitate heat exchange solutions that can accommodate a wider range of operating conditions and integrate seamlessly with digital control systems for real-time optimization.

As environmental regulations become more stringent, there's an increasing demand for PHEs that not only offer fast dynamics but also contribute to overall energy efficiency and emissions reduction. This has led to a market preference for designs that minimize fouling, reduce pressure drop, and maximize heat recovery, all while maintaining the ability to respond quickly to process changes.

PHE Technology Status and Challenges

Plate heat exchangers (PHEs) have become increasingly prevalent in the petrochemical industry due to their compact design, high efficiency, and versatility. However, the current state of PHE technology for fast dynamics in petrochemical applications faces several challenges and limitations.

One of the primary challenges is the need for improved heat transfer performance under rapidly changing process conditions. Traditional PHE designs often struggle to maintain optimal heat transfer rates when subjected to sudden fluctuations in flow rates, temperatures, or fluid compositions. This limitation can lead to reduced efficiency and potential process instabilities in petrochemical operations that require quick response times.

Another significant challenge is the development of advanced materials capable of withstanding the harsh chemical environments and high temperatures commonly encountered in petrochemical processes. While existing PHE materials offer good corrosion resistance, there is a growing demand for materials that can maintain their structural integrity and heat transfer properties under more extreme conditions, particularly in applications involving aggressive chemicals or high-temperature reactions.

The optimization of plate geometry and channel design represents another area of ongoing research and development. Current PHE designs often face limitations in terms of pressure drop and flow distribution, especially when dealing with high-viscosity fluids or two-phase flows. Enhancing the plate geometry to improve fluid dynamics while maintaining structural integrity remains a key focus for researchers and manufacturers.

Furthermore, the integration of smart monitoring and control systems into PHEs presents both opportunities and challenges. While advanced sensors and control algorithms can potentially improve the dynamic response of PHEs, their implementation in the complex and often hazardous environments of petrochemical plants poses significant technical and safety challenges.

The scaling up of PHE technology for larger petrochemical applications is another area of concern. As the demand for higher capacity heat exchangers grows, designers must address issues related to flow distribution, thermal expansion, and mechanical stress in larger PHE units. This scaling challenge is particularly evident in applications requiring fast dynamic response, where maintaining uniform heat transfer across larger plate areas becomes increasingly difficult.

Lastly, the development of predictive modeling and simulation tools for PHE design and operation under dynamic conditions remains an ongoing challenge. While computational fluid dynamics (CFD) and other simulation techniques have advanced significantly, accurately predicting the behavior of PHEs under rapidly changing conditions still requires further refinement and validation.

In conclusion, while PHE technology has made significant strides in recent years, addressing these challenges will be crucial for enhancing their performance and applicability in fast-dynamic petrochemical processes. Overcoming these hurdles will require continued innovation in materials science, design optimization, and control systems integration.

One of the primary challenges is the need for improved heat transfer performance under rapidly changing process conditions. Traditional PHE designs often struggle to maintain optimal heat transfer rates when subjected to sudden fluctuations in flow rates, temperatures, or fluid compositions. This limitation can lead to reduced efficiency and potential process instabilities in petrochemical operations that require quick response times.

Another significant challenge is the development of advanced materials capable of withstanding the harsh chemical environments and high temperatures commonly encountered in petrochemical processes. While existing PHE materials offer good corrosion resistance, there is a growing demand for materials that can maintain their structural integrity and heat transfer properties under more extreme conditions, particularly in applications involving aggressive chemicals or high-temperature reactions.

The optimization of plate geometry and channel design represents another area of ongoing research and development. Current PHE designs often face limitations in terms of pressure drop and flow distribution, especially when dealing with high-viscosity fluids or two-phase flows. Enhancing the plate geometry to improve fluid dynamics while maintaining structural integrity remains a key focus for researchers and manufacturers.

Furthermore, the integration of smart monitoring and control systems into PHEs presents both opportunities and challenges. While advanced sensors and control algorithms can potentially improve the dynamic response of PHEs, their implementation in the complex and often hazardous environments of petrochemical plants poses significant technical and safety challenges.

The scaling up of PHE technology for larger petrochemical applications is another area of concern. As the demand for higher capacity heat exchangers grows, designers must address issues related to flow distribution, thermal expansion, and mechanical stress in larger PHE units. This scaling challenge is particularly evident in applications requiring fast dynamic response, where maintaining uniform heat transfer across larger plate areas becomes increasingly difficult.

Lastly, the development of predictive modeling and simulation tools for PHE design and operation under dynamic conditions remains an ongoing challenge. While computational fluid dynamics (CFD) and other simulation techniques have advanced significantly, accurately predicting the behavior of PHEs under rapidly changing conditions still requires further refinement and validation.

In conclusion, while PHE technology has made significant strides in recent years, addressing these challenges will be crucial for enhancing their performance and applicability in fast-dynamic petrochemical processes. Overcoming these hurdles will require continued innovation in materials science, design optimization, and control systems integration.

Current Fast-Dynamic PHE Solutions

01 Heat transfer efficiency optimization

Plate heat exchangers are designed to optimize heat transfer efficiency through various methods such as improving plate geometry, enhancing fluid distribution, and minimizing pressure drop. These optimizations can lead to better overall performance and energy efficiency in heat exchange processes.- Heat transfer efficiency optimization: Plate heat exchangers are designed to optimize heat transfer efficiency through various methods. These include improving plate geometry, enhancing fluid distribution, and utilizing advanced materials. Such optimizations aim to increase the overall performance and energy efficiency of the heat exchanger system.

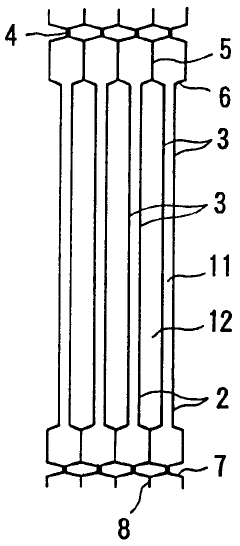

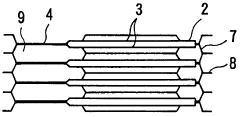

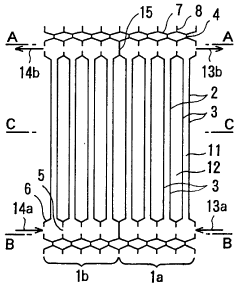

- Flow distribution and control: Effective flow distribution and control mechanisms are crucial for plate heat exchanger dynamics. This involves designing inlet and outlet manifolds, implementing flow baffles, and utilizing advanced flow control systems to ensure uniform fluid distribution across the plates, thereby enhancing heat transfer and reducing pressure drop.

- Thermal expansion and stress management: Managing thermal expansion and stress is essential in plate heat exchanger design. This includes incorporating flexible plate arrangements, using appropriate gasket materials, and implementing thermal compensation mechanisms to accommodate temperature-induced dimensional changes and prevent leakage or structural damage.

- Fouling mitigation and cleaning techniques: Addressing fouling issues is critical for maintaining plate heat exchanger performance. This involves developing anti-fouling plate surfaces, implementing online cleaning systems, and designing easily disassembled structures for maintenance. These techniques help to maintain heat transfer efficiency and extend the operational life of the exchanger.

- Dynamic modeling and simulation: Advanced dynamic modeling and simulation techniques are employed to analyze and predict plate heat exchanger behavior under various operating conditions. These methods involve computational fluid dynamics (CFD), heat transfer modeling, and system-level simulations to optimize design parameters and improve overall performance.

02 Flow distribution and turbulence management

The dynamics of plate heat exchangers involve careful management of flow distribution and turbulence. This includes designing flow channels, corrugation patterns, and inlet/outlet configurations to ensure uniform fluid distribution and enhanced heat transfer while minimizing fouling and pressure drop.Expand Specific Solutions03 Thermal expansion and stress handling

Plate heat exchangers must account for thermal expansion and stress during operation. This involves designing flexible plate arrangements, gasket systems, and frame structures that can accommodate temperature-induced dimensional changes while maintaining sealing integrity and preventing leakage.Expand Specific Solutions04 Fouling mitigation and cleaning strategies

The dynamics of plate heat exchangers include considerations for fouling mitigation and effective cleaning strategies. This involves designing plates with self-cleaning features, implementing appropriate flow velocities, and developing maintenance protocols to ensure long-term performance and efficiency.Expand Specific Solutions05 Multi-phase and variable load operation

Plate heat exchangers are designed to handle multi-phase flows and variable load conditions. This includes optimizing plate arrangements, flow distributions, and control strategies to maintain efficient heat transfer across a range of operating conditions and fluid compositions.Expand Specific Solutions

Key Players in PHE Industry

The plate heat exchanger design for fast dynamics in petrochemicals is in a mature stage of development, with a competitive landscape dominated by established players. The market size is substantial, driven by the petrochemical industry's continuous demand for efficient heat transfer solutions. Companies like Alfa Laval, Haldor Topsøe, and Lanpec Technologies are at the forefront, leveraging their extensive experience and technological capabilities. The technology's maturity is evident in the involvement of diverse players, including academic institutions like Harbin Engineering University and industry giants such as Toyota Industries and BYD. This competitive environment fosters ongoing innovation, focusing on enhancing exchanger performance, reducing response times, and improving overall system efficiency in petrochemical processes.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchanger designs for fast dynamics in petrochemical applications. Their technology incorporates innovative plate patterns and distribution systems that enhance heat transfer efficiency and reduce response times. The company's AlfaNova fusion-bonded plate heat exchangers utilize a unique manufacturing process that allows for high-temperature and high-pressure operations, crucial for petrochemical processes[1]. Alfa Laval's designs also feature optimized flow distribution and reduced fouling, which contribute to improved heat transfer rates and faster system responses[2]. Their latest models incorporate digital twin technology for real-time monitoring and predictive maintenance, further enhancing operational efficiency[3].

Strengths: Industry-leading expertise in heat exchanger technology, innovative plate designs for enhanced efficiency, and advanced manufacturing processes. Weaknesses: Higher initial costs compared to traditional shell-and-tube exchangers, potential limitations in extreme chemical environments.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has developed specialized plate heat exchanger designs tailored for petrochemical processes requiring fast dynamics. Their approach focuses on optimizing catalyst performance in conjunction with heat exchanger design. The company's plate heat exchangers incorporate proprietary catalytic coatings that enhance reaction rates while simultaneously managing heat transfer[4]. This integrated approach allows for more compact designs and faster process responses. Haldor Topsøe's exchangers also feature modular construction, enabling easy scaling and maintenance. Their latest innovations include advanced flow distribution systems that minimize temperature gradients and improve overall system dynamics[5].

Strengths: Integrated catalyst and heat exchanger design expertise, tailored solutions for specific petrochemical processes. Weaknesses: Potentially higher complexity in maintenance due to specialized catalytic coatings, may be less versatile for non-catalytic applications.

Core PHE Innovations for Petrochemicals

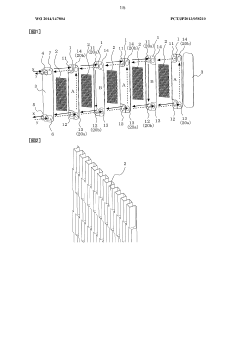

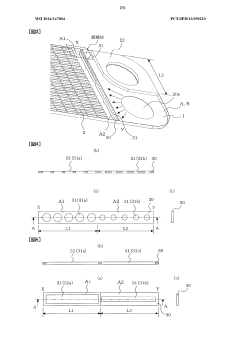

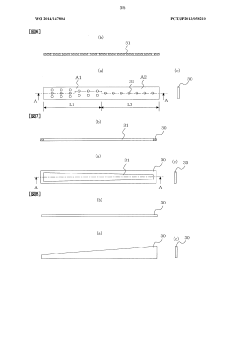

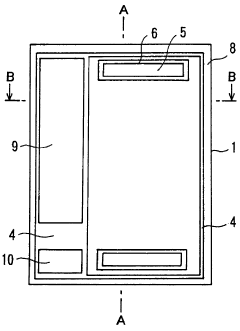

Plate-type heat exchanger and refrigeration cycle device with same

PatentWO2014147804A1

Innovation

- A plate heat exchanger design with alternately formed first and second flow paths, incorporating a plate-like rectifying plate with adjustable opening areas to reduce flow path resistance, and the use of offset fins to promote uniform flow velocity and enhance heat transfer.

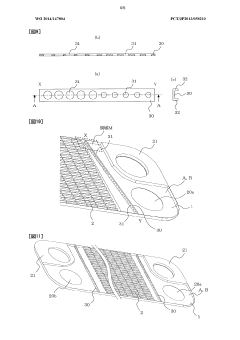

Plate type heat exchanger

PatentWO2000057121A1

Innovation

- A plate heat exchanger design that uses paired plates with unevenness and openings at both ends, where the plates are overlapped to form a sealed passageway for a second fluid, allowing for efficient heat exchange between two fluids with different temperatures using a reduced number of parts and a simplified manufacturing process.

Material Selection for PHE Efficiency

Material selection plays a crucial role in optimizing the efficiency of Plate Heat Exchangers (PHEs) in petrochemical applications. The choice of materials directly impacts heat transfer rates, corrosion resistance, and overall performance under demanding operating conditions. Stainless steel remains a popular choice due to its excellent corrosion resistance and mechanical properties. Grades such as 316L and 304 are commonly used, offering good resistance to a wide range of chemicals and temperatures. However, for more aggressive environments, higher-grade alloys like Hastelloy or titanium may be necessary to ensure longevity and maintain efficiency.

Copper and its alloys, known for their superior thermal conductivity, are also considered for certain applications. These materials can significantly enhance heat transfer rates, potentially reducing the overall size of the PHE. However, their use is limited in petrochemical processes due to potential corrosion issues with certain chemicals. Nickel alloys, such as Inconel, offer an excellent balance of corrosion resistance and thermal properties, making them suitable for high-temperature and high-pressure applications common in petrochemical industries.

Recent advancements in material science have introduced new possibilities for PHE design. Composite materials, such as carbon fiber reinforced polymers (CFRP), are being explored for their potential to combine lightweight properties with excellent thermal performance. These materials could revolutionize PHE design by allowing for more compact and efficient units. Additionally, surface treatments and coatings are being developed to enhance the performance of traditional materials. For instance, hydrophobic coatings can reduce fouling and improve heat transfer efficiency over time.

The selection of gasket materials is equally important in PHE design. Materials like EPDM, Viton, and PTFE are commonly used, each offering specific advantages in terms of temperature resistance, chemical compatibility, and sealing properties. The choice of gasket material must be carefully considered to ensure compatibility with the process fluids and operating conditions, as failure in this area can lead to leaks and reduced efficiency.

In the context of fast dynamics in petrochemical processes, the thermal responsiveness of materials becomes a critical factor. Materials with lower thermal mass and higher thermal conductivity can facilitate quicker temperature changes, allowing for more responsive process control. This aspect is particularly important in batch processes or systems with frequent operational changes. Balancing these thermal properties with the necessary mechanical strength and corrosion resistance presents a significant challenge in material selection for PHEs in dynamic petrochemical applications.

Copper and its alloys, known for their superior thermal conductivity, are also considered for certain applications. These materials can significantly enhance heat transfer rates, potentially reducing the overall size of the PHE. However, their use is limited in petrochemical processes due to potential corrosion issues with certain chemicals. Nickel alloys, such as Inconel, offer an excellent balance of corrosion resistance and thermal properties, making them suitable for high-temperature and high-pressure applications common in petrochemical industries.

Recent advancements in material science have introduced new possibilities for PHE design. Composite materials, such as carbon fiber reinforced polymers (CFRP), are being explored for their potential to combine lightweight properties with excellent thermal performance. These materials could revolutionize PHE design by allowing for more compact and efficient units. Additionally, surface treatments and coatings are being developed to enhance the performance of traditional materials. For instance, hydrophobic coatings can reduce fouling and improve heat transfer efficiency over time.

The selection of gasket materials is equally important in PHE design. Materials like EPDM, Viton, and PTFE are commonly used, each offering specific advantages in terms of temperature resistance, chemical compatibility, and sealing properties. The choice of gasket material must be carefully considered to ensure compatibility with the process fluids and operating conditions, as failure in this area can lead to leaks and reduced efficiency.

In the context of fast dynamics in petrochemical processes, the thermal responsiveness of materials becomes a critical factor. Materials with lower thermal mass and higher thermal conductivity can facilitate quicker temperature changes, allowing for more responsive process control. This aspect is particularly important in batch processes or systems with frequent operational changes. Balancing these thermal properties with the necessary mechanical strength and corrosion resistance presents a significant challenge in material selection for PHEs in dynamic petrochemical applications.

Safety Considerations in PHE Design

Safety considerations are paramount in the design and operation of plate heat exchangers (PHEs) for fast dynamics in petrochemical applications. The high-pressure and often corrosive nature of petrochemical processes necessitates rigorous safety measures to prevent leaks, contamination, and potential catastrophic failures.

Material selection is a critical aspect of PHE safety design. Corrosion-resistant alloys such as stainless steel, titanium, or nickel-based alloys are commonly employed to withstand the aggressive chemical environment. The choice of gasket materials is equally important, as they must maintain integrity under varying temperature and pressure conditions while resisting chemical attack.

Pressure and temperature ratings of PHEs must be carefully calculated to ensure they can withstand the maximum operating conditions with an adequate safety margin. This includes consideration of thermal expansion, pressure fluctuations, and potential pressure spikes during transient operations. Incorporation of pressure relief devices and rupture disks is essential to prevent over-pressurization.

Leak detection systems are crucial for early identification of potential failures. These may include infrared cameras, acoustic sensors, or pressure differential monitoring. Regular inspection and maintenance protocols should be established to detect signs of corrosion, erosion, or fatigue before they lead to failure.

Flow distribution within the PHE is another safety concern. Proper design of flow channels and distribution areas is necessary to prevent dead zones or areas of excessive velocity, which can lead to erosion or localized overheating. Computational fluid dynamics (CFD) analysis can be employed to optimize flow patterns and minimize these risks.

Thermal stress management is particularly important in fast dynamic applications. Rapid temperature changes can induce thermal shock and fatigue in PHE components. Design considerations should include allowances for thermal expansion and the use of flexible connections where appropriate.

Contamination prevention is critical in petrochemical processes where product purity is essential. Double-wall plate designs or intermediate fluid circuits may be employed to provide an additional barrier against cross-contamination between process streams.

Emergency shutdown procedures and systems must be integrated into the PHE design. This includes quick-closing valves, automated control systems, and fail-safe mechanisms to rapidly isolate the exchanger in case of detected anomalies.

Finally, operator safety must be considered in the PHE design. This includes provision of adequate access for inspection and maintenance, proper insulation to prevent burns from hot surfaces, and clear labeling of all connections and potential hazards.

Material selection is a critical aspect of PHE safety design. Corrosion-resistant alloys such as stainless steel, titanium, or nickel-based alloys are commonly employed to withstand the aggressive chemical environment. The choice of gasket materials is equally important, as they must maintain integrity under varying temperature and pressure conditions while resisting chemical attack.

Pressure and temperature ratings of PHEs must be carefully calculated to ensure they can withstand the maximum operating conditions with an adequate safety margin. This includes consideration of thermal expansion, pressure fluctuations, and potential pressure spikes during transient operations. Incorporation of pressure relief devices and rupture disks is essential to prevent over-pressurization.

Leak detection systems are crucial for early identification of potential failures. These may include infrared cameras, acoustic sensors, or pressure differential monitoring. Regular inspection and maintenance protocols should be established to detect signs of corrosion, erosion, or fatigue before they lead to failure.

Flow distribution within the PHE is another safety concern. Proper design of flow channels and distribution areas is necessary to prevent dead zones or areas of excessive velocity, which can lead to erosion or localized overheating. Computational fluid dynamics (CFD) analysis can be employed to optimize flow patterns and minimize these risks.

Thermal stress management is particularly important in fast dynamic applications. Rapid temperature changes can induce thermal shock and fatigue in PHE components. Design considerations should include allowances for thermal expansion and the use of flexible connections where appropriate.

Contamination prevention is critical in petrochemical processes where product purity is essential. Double-wall plate designs or intermediate fluid circuits may be employed to provide an additional barrier against cross-contamination between process streams.

Emergency shutdown procedures and systems must be integrated into the PHE design. This includes quick-closing valves, automated control systems, and fail-safe mechanisms to rapidly isolate the exchanger in case of detected anomalies.

Finally, operator safety must be considered in the PHE design. This includes provision of adequate access for inspection and maintenance, proper insulation to prevent burns from hot surfaces, and clear labeling of all connections and potential hazards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!