Plate Heat Exchanger Design for Minimal Environmental Impact

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Design Background and Objectives

Plate heat exchangers (PHEs) have been a cornerstone of industrial heat transfer applications for decades, offering efficient and compact solutions for various processes. The evolution of PHE technology has been driven by the need for improved performance, reduced energy consumption, and minimized environmental impact. As global concerns about sustainability and environmental protection continue to grow, the focus on designing PHEs with minimal environmental impact has become increasingly critical.

The primary objective of this technological exploration is to investigate and develop innovative plate heat exchanger designs that significantly reduce environmental impact while maintaining or enhancing thermal efficiency. This goal aligns with the broader industry trend towards sustainable engineering solutions and the global push for reducing carbon footprints across all sectors.

The development of PHEs has seen several key milestones since their introduction in the 1920s. Initial designs focused on simple corrugated plates, which evolved into more complex geometries to enhance heat transfer and reduce fouling. Recent advancements have introduced novel materials, surface treatments, and flow patterns to optimize performance further. However, these improvements have often come at the cost of increased material usage or energy-intensive manufacturing processes.

Current technological trends in PHE design include the exploration of biomimetic surface structures, advanced computational fluid dynamics (CFD) modeling for optimized flow distribution, and the integration of nanotechnology for enhanced heat transfer properties. These trends offer promising avenues for achieving the desired balance between performance and environmental sustainability.

The environmental impact of PHEs extends beyond their operational efficiency. It encompasses the entire lifecycle, including raw material extraction, manufacturing processes, transportation, operational lifespan, and end-of-life disposal or recycling. Therefore, a holistic approach to minimizing environmental impact must consider all these aspects.

Key challenges in achieving this objective include developing materials that are both highly efficient in heat transfer and environmentally friendly, designing plate geometries that maximize performance while minimizing material usage, and creating manufacturing processes that reduce energy consumption and waste. Additionally, there is a need to improve the recyclability and reusability of PHE components to support a circular economy model.

By addressing these challenges and leveraging emerging technologies, the aim is to create a new generation of plate heat exchangers that set new standards in environmental performance. This endeavor not only supports sustainability goals but also has the potential to drive innovation in related fields and create new market opportunities for environmentally conscious heat transfer solutions.

The primary objective of this technological exploration is to investigate and develop innovative plate heat exchanger designs that significantly reduce environmental impact while maintaining or enhancing thermal efficiency. This goal aligns with the broader industry trend towards sustainable engineering solutions and the global push for reducing carbon footprints across all sectors.

The development of PHEs has seen several key milestones since their introduction in the 1920s. Initial designs focused on simple corrugated plates, which evolved into more complex geometries to enhance heat transfer and reduce fouling. Recent advancements have introduced novel materials, surface treatments, and flow patterns to optimize performance further. However, these improvements have often come at the cost of increased material usage or energy-intensive manufacturing processes.

Current technological trends in PHE design include the exploration of biomimetic surface structures, advanced computational fluid dynamics (CFD) modeling for optimized flow distribution, and the integration of nanotechnology for enhanced heat transfer properties. These trends offer promising avenues for achieving the desired balance between performance and environmental sustainability.

The environmental impact of PHEs extends beyond their operational efficiency. It encompasses the entire lifecycle, including raw material extraction, manufacturing processes, transportation, operational lifespan, and end-of-life disposal or recycling. Therefore, a holistic approach to minimizing environmental impact must consider all these aspects.

Key challenges in achieving this objective include developing materials that are both highly efficient in heat transfer and environmentally friendly, designing plate geometries that maximize performance while minimizing material usage, and creating manufacturing processes that reduce energy consumption and waste. Additionally, there is a need to improve the recyclability and reusability of PHE components to support a circular economy model.

By addressing these challenges and leveraging emerging technologies, the aim is to create a new generation of plate heat exchangers that set new standards in environmental performance. This endeavor not only supports sustainability goals but also has the potential to drive innovation in related fields and create new market opportunities for environmentally conscious heat transfer solutions.

Market Demand Analysis for Eco-Friendly PHEs

The market demand for eco-friendly Plate Heat Exchangers (PHEs) has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations across various industries. This trend is particularly evident in sectors such as chemical processing, food and beverage, HVAC, and power generation, where energy efficiency and sustainability have become paramount.

In the chemical processing industry, there is a significant push towards greener technologies to reduce carbon footprints and minimize environmental impact. Eco-friendly PHEs are gaining traction due to their ability to enhance heat transfer efficiency while using less material and energy. This sector is expected to be a major driver of market growth for environmentally conscious heat exchanger designs.

The food and beverage industry is another key market for eco-friendly PHEs. With increasing consumer awareness about sustainable production practices, companies are investing in energy-efficient and hygienic heat transfer solutions. PHEs designed for minimal environmental impact offer advantages in terms of reduced water consumption, lower energy usage, and improved product quality, aligning well with the industry's sustainability goals.

In the HVAC sector, the demand for eco-friendly PHEs is being fueled by the global focus on energy-efficient buildings and sustainable urban development. These heat exchangers play a crucial role in optimizing heating and cooling systems, contributing to reduced energy consumption and lower operational costs. As green building certifications become more prevalent, the adoption of environmentally friendly PHEs is expected to accelerate.

The power generation industry, particularly in renewable energy sectors such as geothermal and solar thermal, is also driving demand for eco-friendly PHEs. These heat exchangers are essential components in improving the efficiency of power plants and reducing their environmental footprint. As countries worldwide transition towards cleaner energy sources, the market for sustainable heat transfer solutions is projected to expand significantly.

Geographically, developed regions such as North America and Europe are currently leading the market for eco-friendly PHEs, owing to strict environmental regulations and a strong emphasis on sustainability. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand as they increasingly adopt green technologies and implement stricter environmental policies.

The market size for eco-friendly PHEs is projected to grow substantially over the next decade. Factors such as increasing industrial automation, the need for energy-efficient processes, and the rising costs of traditional energy sources are expected to drive this growth. Additionally, government initiatives promoting clean technologies and offering incentives for sustainable industrial practices are likely to further boost market demand for environmentally conscious heat exchanger designs.

In the chemical processing industry, there is a significant push towards greener technologies to reduce carbon footprints and minimize environmental impact. Eco-friendly PHEs are gaining traction due to their ability to enhance heat transfer efficiency while using less material and energy. This sector is expected to be a major driver of market growth for environmentally conscious heat exchanger designs.

The food and beverage industry is another key market for eco-friendly PHEs. With increasing consumer awareness about sustainable production practices, companies are investing in energy-efficient and hygienic heat transfer solutions. PHEs designed for minimal environmental impact offer advantages in terms of reduced water consumption, lower energy usage, and improved product quality, aligning well with the industry's sustainability goals.

In the HVAC sector, the demand for eco-friendly PHEs is being fueled by the global focus on energy-efficient buildings and sustainable urban development. These heat exchangers play a crucial role in optimizing heating and cooling systems, contributing to reduced energy consumption and lower operational costs. As green building certifications become more prevalent, the adoption of environmentally friendly PHEs is expected to accelerate.

The power generation industry, particularly in renewable energy sectors such as geothermal and solar thermal, is also driving demand for eco-friendly PHEs. These heat exchangers are essential components in improving the efficiency of power plants and reducing their environmental footprint. As countries worldwide transition towards cleaner energy sources, the market for sustainable heat transfer solutions is projected to expand significantly.

Geographically, developed regions such as North America and Europe are currently leading the market for eco-friendly PHEs, owing to strict environmental regulations and a strong emphasis on sustainability. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand as they increasingly adopt green technologies and implement stricter environmental policies.

The market size for eco-friendly PHEs is projected to grow substantially over the next decade. Factors such as increasing industrial automation, the need for energy-efficient processes, and the rising costs of traditional energy sources are expected to drive this growth. Additionally, government initiatives promoting clean technologies and offering incentives for sustainable industrial practices are likely to further boost market demand for environmentally conscious heat exchanger designs.

Current PHE Technology and Environmental Challenges

Plate heat exchangers (PHEs) have become a cornerstone in various industries due to their efficiency and compact design. However, as environmental concerns grow, the focus has shifted towards minimizing their ecological impact. Current PHE technology faces several challenges in achieving this goal.

One of the primary environmental challenges is the materials used in PHE construction. Traditional PHEs often utilize materials that are not easily recyclable or have a high carbon footprint during production. Stainless steel, while durable, requires significant energy in its manufacturing process. Additionally, the gaskets used in PHEs are typically made from synthetic rubber compounds, which are not biodegradable and can pose disposal issues at the end of their lifecycle.

Energy efficiency remains a critical concern in PHE design. While PHEs are generally more efficient than other heat exchanger types, there is still room for improvement. Current designs may not always optimize heat transfer, leading to unnecessary energy consumption. This inefficiency not only increases operational costs but also contributes to higher carbon emissions in energy-intensive industries.

Water consumption and treatment present another significant environmental challenge. PHEs in certain applications, particularly in cooling systems, can consume large volumes of water. The treatment of this water often involves chemicals that, if not properly managed, can have detrimental effects on local ecosystems. Moreover, the discharge of heated water can disrupt aquatic environments, affecting biodiversity.

Fouling and scaling are persistent issues in PHE operation, leading to decreased efficiency and increased maintenance needs. The chemicals used for cleaning and descaling can be harmful to the environment if not properly handled and disposed of. This challenge necessitates the development of more environmentally friendly cleaning methods or materials that resist fouling.

The manufacturing process of PHEs itself poses environmental challenges. Current production methods may involve energy-intensive processes and the use of harmful chemicals or coatings. Reducing the environmental impact of PHE production requires innovations in manufacturing techniques and materials selection.

Lastly, the end-of-life management of PHEs presents a significant environmental challenge. Many PHEs are not designed with easy disassembly or recycling in mind, leading to difficulties in material recovery and proper disposal. This issue is compounded by the presence of mixed materials in PHE construction, making separation and recycling more complex.

Addressing these environmental challenges requires a holistic approach to PHE design and operation. Innovations in materials science, manufacturing processes, and operational strategies are needed to create more sustainable PHE solutions that minimize environmental impact throughout their lifecycle.

One of the primary environmental challenges is the materials used in PHE construction. Traditional PHEs often utilize materials that are not easily recyclable or have a high carbon footprint during production. Stainless steel, while durable, requires significant energy in its manufacturing process. Additionally, the gaskets used in PHEs are typically made from synthetic rubber compounds, which are not biodegradable and can pose disposal issues at the end of their lifecycle.

Energy efficiency remains a critical concern in PHE design. While PHEs are generally more efficient than other heat exchanger types, there is still room for improvement. Current designs may not always optimize heat transfer, leading to unnecessary energy consumption. This inefficiency not only increases operational costs but also contributes to higher carbon emissions in energy-intensive industries.

Water consumption and treatment present another significant environmental challenge. PHEs in certain applications, particularly in cooling systems, can consume large volumes of water. The treatment of this water often involves chemicals that, if not properly managed, can have detrimental effects on local ecosystems. Moreover, the discharge of heated water can disrupt aquatic environments, affecting biodiversity.

Fouling and scaling are persistent issues in PHE operation, leading to decreased efficiency and increased maintenance needs. The chemicals used for cleaning and descaling can be harmful to the environment if not properly handled and disposed of. This challenge necessitates the development of more environmentally friendly cleaning methods or materials that resist fouling.

The manufacturing process of PHEs itself poses environmental challenges. Current production methods may involve energy-intensive processes and the use of harmful chemicals or coatings. Reducing the environmental impact of PHE production requires innovations in manufacturing techniques and materials selection.

Lastly, the end-of-life management of PHEs presents a significant environmental challenge. Many PHEs are not designed with easy disassembly or recycling in mind, leading to difficulties in material recovery and proper disposal. This issue is compounded by the presence of mixed materials in PHE construction, making separation and recycling more complex.

Addressing these environmental challenges requires a holistic approach to PHE design and operation. Innovations in materials science, manufacturing processes, and operational strategies are needed to create more sustainable PHE solutions that minimize environmental impact throughout their lifecycle.

Existing Eco-Friendly PHE Solutions

01 Energy efficiency improvements

Plate heat exchangers are designed to improve energy efficiency in various applications. They optimize heat transfer between fluids, reducing energy consumption and minimizing heat loss. This leads to lower operational costs and decreased environmental impact through reduced energy usage and greenhouse gas emissions.- Energy efficiency improvements: Plate heat exchangers are designed to improve energy efficiency in various applications. They optimize heat transfer between fluids, reducing energy consumption and minimizing heat loss. This leads to lower operational costs and decreased environmental impact through reduced energy usage and greenhouse gas emissions.

- Compact design and material reduction: The compact design of plate heat exchangers allows for a smaller footprint and reduced material usage compared to traditional heat exchangers. This results in less raw material consumption during manufacturing and lower transportation costs, contributing to a reduced environmental impact throughout the product lifecycle.

- Enhanced heat recovery and waste reduction: Plate heat exchangers are effective in recovering waste heat from industrial processes, improving overall system efficiency. By utilizing waste heat, these exchangers help reduce the need for additional energy sources and minimize thermal pollution, leading to a positive environmental impact through resource conservation and waste reduction.

- Improved fluid handling and reduced contamination risk: The design of plate heat exchangers allows for better fluid handling and separation, reducing the risk of cross-contamination between fluids. This feature is particularly important in applications where environmental safety is crucial, such as in the food and pharmaceutical industries, helping to prevent potential environmental hazards caused by leaks or mixing of incompatible fluids.

- Adaptability and maintenance efficiency: Plate heat exchangers offer high adaptability and ease of maintenance. Their modular design allows for easy cleaning, inspection, and replacement of individual plates, extending the overall lifespan of the equipment. This reduces the frequency of complete system replacements, leading to less waste generation and lower environmental impact associated with manufacturing and disposal of heat exchange equipment.

02 Compact design and material reduction

The compact design of plate heat exchangers allows for a smaller footprint and reduced material usage compared to traditional heat exchangers. This results in less raw material consumption during manufacturing, lower transportation costs, and reduced waste at the end of the product lifecycle, contributing to overall environmental sustainability.Expand Specific Solutions03 Enhanced heat recovery and waste reduction

Plate heat exchangers are effective in recovering waste heat from industrial processes and HVAC systems. By capturing and reusing this heat, they help reduce overall energy consumption and minimize thermal pollution. This improved heat recovery capability contributes to waste reduction and promotes a more circular economy approach in various industries.Expand Specific Solutions04 Refrigerant reduction and alternative coolants

In refrigeration and air conditioning applications, plate heat exchangers can help reduce the amount of refrigerant required in systems. Some designs also facilitate the use of alternative, more environmentally friendly coolants with lower global warming potential. This contributes to reducing the environmental impact associated with refrigerant leaks and disposal.Expand Specific Solutions05 Improved maintenance and longevity

Plate heat exchangers are designed for easy maintenance and cleaning, which helps maintain their efficiency over time. Their modular nature allows for the replacement of individual plates rather than entire units, reducing waste and extending the overall lifespan of the equipment. This improved longevity and maintainability contribute to reduced environmental impact through decreased resource consumption and waste generation.Expand Specific Solutions

Key Players in Sustainable PHE Manufacturing

The plate heat exchanger design for minimal environmental impact is in a mature stage of development, with a growing market driven by increasing environmental concerns. The global market size for energy-efficient heat exchangers is projected to expand significantly in the coming years. Technologically, the field is well-established but continues to evolve, with companies like Alfa Laval, SWEP International, and Vahterus Oy leading innovation. These firms, along with others such as Klingenburg GmbH and LHE Co., Ltd., are focusing on enhancing efficiency and reducing environmental footprint through advanced designs and materials. The competitive landscape is characterized by a mix of large, established players and specialized manufacturers, all striving to meet the growing demand for sustainable heat exchange solutions.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed innovative plate heat exchanger designs focusing on minimal environmental impact. Their AlfaNova fusion-bonded plate heat exchangers use 100% stainless steel construction, eliminating the need for gaskets and brazing materials[1]. This design reduces material waste and improves recyclability. Additionally, Alfa Laval's WideGap technology allows for processing of fluids with fibers or particles, reducing the need for pre-filtration and associated energy consumption[2]. The company has also introduced the AlfaQ series, which utilizes optimized plate geometry to enhance heat transfer efficiency while minimizing fouling, resulting in reduced cleaning frequency and extended operational lifespan[3].

Strengths: Advanced materials and construction techniques for improved durability and recyclability; innovative plate designs for enhanced efficiency and reduced maintenance. Weaknesses: Higher initial cost compared to traditional designs; may require specialized knowledge for maintenance and repairs.

Vahterus Oy

Technical Solution: Vahterus has pioneered the Plate & Shell heat exchanger design, which combines the thermal efficiency of plate heat exchangers with the pressure and temperature resistance of shell and tube heat exchangers[1]. This hybrid design allows for a more compact footprint, reducing material usage by up to 85% compared to traditional shell and tube exchangers[2]. Vahterus' fully welded construction eliminates gaskets, minimizing the risk of leaks and associated environmental hazards. The company has also developed a multi-pass configuration that optimizes flow distribution, enhancing heat transfer efficiency and reducing pumping power requirements[3]. Furthermore, Vahterus incorporates advanced computational fluid dynamics (CFD) modeling in their design process to optimize plate patterns for specific applications, minimizing pressure drop and maximizing heat transfer performance[4].

Strengths: Compact design reduces material usage and space requirements; high pressure and temperature capabilities; improved energy efficiency. Weaknesses: Limited flexibility for maintenance compared to gasketed plate heat exchangers; potentially higher manufacturing costs.

Core Innovations in Green PHE Technology

Plate heat exchanger

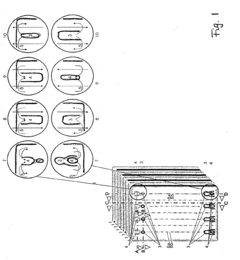

PatentInactiveEP1691158A1

Innovation

- A plate heat exchanger design featuring a stack of plates with alternating cocurrent and countercurrent flow paths, smooth unprofiled surfaces, and strategically placed distribution and collection channels to facilitate laminar flow, optimizing plate spacing for low pressure loss and high heat transfer efficiency.

Plate heat exchanger

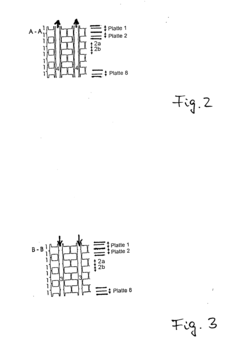

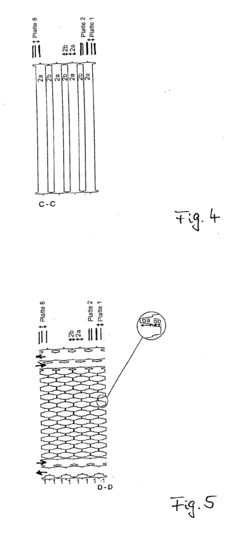

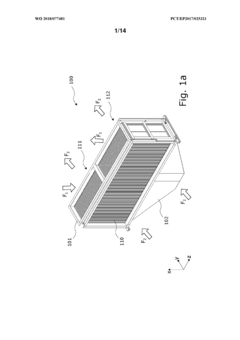

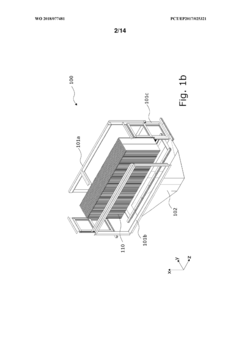

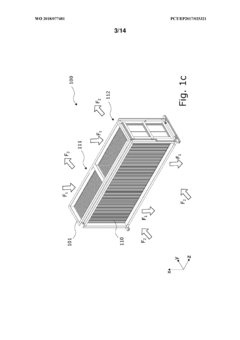

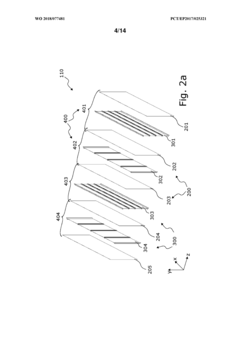

PatentWO2018077481A1

Innovation

- A plate heat exchanger design featuring a plate pack with alternating flat heat transfer plates and profiled intermediate plates, where the intermediate plates serve as spacers and supports, reducing the need for additional spacers and simplifying the manufacturing process by using standard, inexpensive materials.

Environmental Regulations for Heat Exchangers

Environmental regulations for heat exchangers have become increasingly stringent in recent years, reflecting growing concerns about energy efficiency and environmental impact. These regulations primarily focus on reducing greenhouse gas emissions, minimizing waste, and promoting sustainable manufacturing practices. In the United States, the Department of Energy (DOE) has established minimum efficiency standards for various types of heat exchangers, including plate heat exchangers, under the Energy Policy and Conservation Act.

The European Union has implemented the Ecodesign Directive, which sets eco-design requirements for energy-related products, including heat exchangers. This directive aims to improve the environmental performance of products throughout their lifecycle. Additionally, the EU's F-Gas Regulation imposes restrictions on the use of fluorinated greenhouse gases in certain heat exchange applications, promoting the adoption of more environmentally friendly refrigerants.

In China, the National Development and Reform Commission (NDRC) has issued guidelines for energy efficiency in industrial equipment, including heat exchangers. These guidelines set targets for energy consumption reduction and encourage the adoption of advanced technologies to minimize environmental impact.

The Montreal Protocol and its subsequent amendments have had a significant impact on heat exchanger design, particularly in refrigeration and air conditioning applications. This international treaty has phased out the use of ozone-depleting substances, leading to the development of alternative refrigerants and new heat exchanger designs optimized for these substances.

Many countries have also implemented regulations regarding the materials used in heat exchanger construction. For instance, the Restriction of Hazardous Substances (RoHS) directive in the EU limits the use of certain hazardous materials in electrical and electronic equipment, including some types of heat exchangers.

Water conservation regulations have implications for heat exchanger design as well. In water-scarce regions, regulations often mandate the use of closed-loop cooling systems or air-cooled heat exchangers to reduce water consumption. This has led to innovations in dry cooling technologies and hybrid cooling systems for industrial applications.

As environmental concerns continue to grow, future regulations are likely to focus on promoting circular economy principles in heat exchanger design and manufacturing. This may include requirements for increased recyclability, extended product lifespans, and the use of sustainable materials. Additionally, regulations may evolve to address emerging environmental challenges, such as microplastic pollution from heat exchanger degradation in marine environments.

The European Union has implemented the Ecodesign Directive, which sets eco-design requirements for energy-related products, including heat exchangers. This directive aims to improve the environmental performance of products throughout their lifecycle. Additionally, the EU's F-Gas Regulation imposes restrictions on the use of fluorinated greenhouse gases in certain heat exchange applications, promoting the adoption of more environmentally friendly refrigerants.

In China, the National Development and Reform Commission (NDRC) has issued guidelines for energy efficiency in industrial equipment, including heat exchangers. These guidelines set targets for energy consumption reduction and encourage the adoption of advanced technologies to minimize environmental impact.

The Montreal Protocol and its subsequent amendments have had a significant impact on heat exchanger design, particularly in refrigeration and air conditioning applications. This international treaty has phased out the use of ozone-depleting substances, leading to the development of alternative refrigerants and new heat exchanger designs optimized for these substances.

Many countries have also implemented regulations regarding the materials used in heat exchanger construction. For instance, the Restriction of Hazardous Substances (RoHS) directive in the EU limits the use of certain hazardous materials in electrical and electronic equipment, including some types of heat exchangers.

Water conservation regulations have implications for heat exchanger design as well. In water-scarce regions, regulations often mandate the use of closed-loop cooling systems or air-cooled heat exchangers to reduce water consumption. This has led to innovations in dry cooling technologies and hybrid cooling systems for industrial applications.

As environmental concerns continue to grow, future regulations are likely to focus on promoting circular economy principles in heat exchanger design and manufacturing. This may include requirements for increased recyclability, extended product lifespans, and the use of sustainable materials. Additionally, regulations may evolve to address emerging environmental challenges, such as microplastic pollution from heat exchanger degradation in marine environments.

Life Cycle Assessment of PHEs

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of Plate Heat Exchangers (PHEs) throughout their entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to manufacturing, use, and end-of-life disposal. For PHEs, the assessment typically begins with the sourcing of materials, primarily metals such as stainless steel, titanium, or copper, depending on the specific application requirements.

The manufacturing phase of PHEs involves energy-intensive processes, including metal forming, welding, and assembly. LCA studies have shown that this stage often contributes significantly to the overall environmental footprint. Efforts to minimize impact during production focus on optimizing energy efficiency, reducing waste, and implementing cleaner manufacturing technologies.

During the use phase, PHEs generally have a positive environmental impact due to their high efficiency in heat transfer, which leads to energy savings in various industrial processes. However, the extent of this benefit depends on factors such as operational conditions, maintenance practices, and the energy mix used to power the systems in which PHEs are integrated.

Maintenance and cleaning of PHEs also factor into the lifecycle assessment. The frequency and methods of cleaning can affect both the operational efficiency and the environmental impact. Chemical cleaning agents, if used, must be considered for their potential environmental effects.

The end-of-life stage of PHEs presents both challenges and opportunities. Many of the materials used in PHEs, particularly metals, are highly recyclable. Proper recycling can significantly reduce the overall environmental impact by offsetting the need for virgin material extraction and processing. However, the disassembly and separation of components can be energy-intensive and may involve hazardous materials, depending on the specific PHE design and application.

Recent LCA studies on PHEs have highlighted the importance of design choices in minimizing environmental impact. For instance, selecting materials with lower embodied energy, designing for easier disassembly and recycling, and optimizing plate geometry for improved heat transfer efficiency can all contribute to a reduced lifecycle impact.

Furthermore, the application of LCA to PHEs has led to innovations in design and material selection. Some manufacturers are exploring the use of bio-based or recycled materials for gaskets and exploring advanced manufacturing techniques that reduce material waste and energy consumption during production.

In conclusion, LCA provides valuable insights into the environmental performance of PHEs, guiding designers and engineers towards more sustainable solutions. By considering the entire lifecycle, from cradle to grave, LCA helps identify hotspots of environmental impact and informs strategies for improvement, ultimately contributing to the development of PHEs with minimal environmental footprint.

The manufacturing phase of PHEs involves energy-intensive processes, including metal forming, welding, and assembly. LCA studies have shown that this stage often contributes significantly to the overall environmental footprint. Efforts to minimize impact during production focus on optimizing energy efficiency, reducing waste, and implementing cleaner manufacturing technologies.

During the use phase, PHEs generally have a positive environmental impact due to their high efficiency in heat transfer, which leads to energy savings in various industrial processes. However, the extent of this benefit depends on factors such as operational conditions, maintenance practices, and the energy mix used to power the systems in which PHEs are integrated.

Maintenance and cleaning of PHEs also factor into the lifecycle assessment. The frequency and methods of cleaning can affect both the operational efficiency and the environmental impact. Chemical cleaning agents, if used, must be considered for their potential environmental effects.

The end-of-life stage of PHEs presents both challenges and opportunities. Many of the materials used in PHEs, particularly metals, are highly recyclable. Proper recycling can significantly reduce the overall environmental impact by offsetting the need for virgin material extraction and processing. However, the disassembly and separation of components can be energy-intensive and may involve hazardous materials, depending on the specific PHE design and application.

Recent LCA studies on PHEs have highlighted the importance of design choices in minimizing environmental impact. For instance, selecting materials with lower embodied energy, designing for easier disassembly and recycling, and optimizing plate geometry for improved heat transfer efficiency can all contribute to a reduced lifecycle impact.

Furthermore, the application of LCA to PHEs has led to innovations in design and material selection. Some manufacturers are exploring the use of bio-based or recycled materials for gaskets and exploring advanced manufacturing techniques that reduce material waste and energy consumption during production.

In conclusion, LCA provides valuable insights into the environmental performance of PHEs, guiding designers and engineers towards more sustainable solutions. By considering the entire lifecycle, from cradle to grave, LCA helps identify hotspots of environmental impact and informs strategies for improvement, ultimately contributing to the development of PHEs with minimal environmental footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!