Plate Heat Exchanger Efficiency in Combined Heat and Power Plants

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CHP Plant PHE Background

Combined Heat and Power (CHP) plants have been at the forefront of energy efficiency for decades, utilizing the principle of cogeneration to maximize the use of fuel energy. Within these systems, Plate Heat Exchangers (PHEs) play a crucial role in enhancing overall plant efficiency. The background of PHEs in CHP plants is rooted in the continuous pursuit of improved energy utilization and reduced environmental impact.

PHEs were first introduced in the 1920s and have since evolved significantly, finding widespread application in various industries, including CHP plants. Their compact design, high heat transfer efficiency, and ability to handle multiple fluids simultaneously make them ideal for the complex thermal management requirements of CHP systems.

In the context of CHP plants, PHEs serve multiple functions. They are commonly used in the heat recovery process, extracting thermal energy from exhaust gases or steam to heat water for district heating or industrial processes. Additionally, PHEs are employed in the cooling systems of power generation equipment, ensuring optimal operating temperatures for turbines and generators.

The integration of PHEs in CHP plants has been driven by the need to improve overall plant efficiency and reduce energy losses. As environmental regulations have become more stringent and energy costs have risen, the importance of maximizing heat recovery and minimizing waste has become paramount. PHEs have proven to be effective tools in achieving these goals, offering superior heat transfer capabilities compared to traditional shell-and-tube heat exchangers.

The evolution of PHE technology has been marked by continuous improvements in materials, design, and manufacturing processes. Modern PHEs used in CHP plants feature advanced plate designs that enhance turbulence and heat transfer, while also minimizing fouling and pressure drop. Materials such as titanium and high-grade stainless steel have been introduced to withstand corrosive environments and high temperatures commonly encountered in CHP applications.

The adoption of PHEs in CHP plants has also been influenced by the trend towards modular and flexible plant designs. PHEs' compact nature and scalability allow for easier integration into existing systems and facilitate plant expansions or modifications. This flexibility is particularly valuable in the current energy landscape, where adaptability to changing demand patterns and fuel sources is essential.

As the focus on sustainability and energy efficiency intensifies, the role of PHEs in CHP plants continues to grow. Research and development efforts are ongoing to further enhance PHE performance, exploring areas such as advanced surface treatments, novel plate geometries, and smart monitoring systems to optimize heat transfer and maintenance schedules.

PHEs were first introduced in the 1920s and have since evolved significantly, finding widespread application in various industries, including CHP plants. Their compact design, high heat transfer efficiency, and ability to handle multiple fluids simultaneously make them ideal for the complex thermal management requirements of CHP systems.

In the context of CHP plants, PHEs serve multiple functions. They are commonly used in the heat recovery process, extracting thermal energy from exhaust gases or steam to heat water for district heating or industrial processes. Additionally, PHEs are employed in the cooling systems of power generation equipment, ensuring optimal operating temperatures for turbines and generators.

The integration of PHEs in CHP plants has been driven by the need to improve overall plant efficiency and reduce energy losses. As environmental regulations have become more stringent and energy costs have risen, the importance of maximizing heat recovery and minimizing waste has become paramount. PHEs have proven to be effective tools in achieving these goals, offering superior heat transfer capabilities compared to traditional shell-and-tube heat exchangers.

The evolution of PHE technology has been marked by continuous improvements in materials, design, and manufacturing processes. Modern PHEs used in CHP plants feature advanced plate designs that enhance turbulence and heat transfer, while also minimizing fouling and pressure drop. Materials such as titanium and high-grade stainless steel have been introduced to withstand corrosive environments and high temperatures commonly encountered in CHP applications.

The adoption of PHEs in CHP plants has also been influenced by the trend towards modular and flexible plant designs. PHEs' compact nature and scalability allow for easier integration into existing systems and facilitate plant expansions or modifications. This flexibility is particularly valuable in the current energy landscape, where adaptability to changing demand patterns and fuel sources is essential.

As the focus on sustainability and energy efficiency intensifies, the role of PHEs in CHP plants continues to grow. Research and development efforts are ongoing to further enhance PHE performance, exploring areas such as advanced surface treatments, novel plate geometries, and smart monitoring systems to optimize heat transfer and maintenance schedules.

CHP Market Analysis

The Combined Heat and Power (CHP) market has been experiencing significant growth in recent years, driven by the increasing demand for energy efficiency and sustainable power generation solutions. CHP systems, which simultaneously produce electricity and useful thermal energy from a single fuel source, have gained traction across various industries and applications.

The global CHP market size was valued at approximately $26.6 billion in 2020 and is projected to reach $35.2 billion by 2026, growing at a CAGR of 5.8% during the forecast period. This growth is primarily attributed to the rising focus on energy conservation, stringent environmental regulations, and the need for reliable power supply in critical infrastructure.

Europe currently dominates the CHP market, accounting for the largest share of installations and revenue. Countries like Germany, Denmark, and the Netherlands have been at the forefront of CHP adoption, supported by favorable government policies and incentives. The Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and urbanization in countries such as China and India.

The industrial sector remains the largest end-user of CHP systems, particularly in energy-intensive industries like chemicals, paper, and food processing. However, the commercial and residential sectors are showing increasing interest in CHP solutions, especially for applications in hospitals, hotels, and large residential complexes.

Natural gas-fired CHP systems continue to dominate the market, owing to their relatively low emissions and high efficiency. However, there is a growing trend towards renewable-based CHP systems, utilizing biomass, biogas, and other sustainable fuel sources. This shift is driven by the global push for decarbonization and the increasing availability of renewable feedstocks.

The CHP market is characterized by intense competition among key players such as Siemens Energy, General Electric, Mitsubishi Heavy Industries, and Wartsila. These companies are focusing on technological advancements, particularly in improving the efficiency and flexibility of CHP systems. The integration of digital technologies, such as IoT and AI, for optimizing CHP plant operations is becoming increasingly prevalent.

Government policies and regulations play a crucial role in shaping the CHP market landscape. Many countries have implemented supportive policies, including feed-in tariffs, tax incentives, and grants, to promote CHP adoption. The European Union's Energy Efficiency Directive, for instance, has been instrumental in driving CHP deployment across member states.

The global CHP market size was valued at approximately $26.6 billion in 2020 and is projected to reach $35.2 billion by 2026, growing at a CAGR of 5.8% during the forecast period. This growth is primarily attributed to the rising focus on energy conservation, stringent environmental regulations, and the need for reliable power supply in critical infrastructure.

Europe currently dominates the CHP market, accounting for the largest share of installations and revenue. Countries like Germany, Denmark, and the Netherlands have been at the forefront of CHP adoption, supported by favorable government policies and incentives. The Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and urbanization in countries such as China and India.

The industrial sector remains the largest end-user of CHP systems, particularly in energy-intensive industries like chemicals, paper, and food processing. However, the commercial and residential sectors are showing increasing interest in CHP solutions, especially for applications in hospitals, hotels, and large residential complexes.

Natural gas-fired CHP systems continue to dominate the market, owing to their relatively low emissions and high efficiency. However, there is a growing trend towards renewable-based CHP systems, utilizing biomass, biogas, and other sustainable fuel sources. This shift is driven by the global push for decarbonization and the increasing availability of renewable feedstocks.

The CHP market is characterized by intense competition among key players such as Siemens Energy, General Electric, Mitsubishi Heavy Industries, and Wartsila. These companies are focusing on technological advancements, particularly in improving the efficiency and flexibility of CHP systems. The integration of digital technologies, such as IoT and AI, for optimizing CHP plant operations is becoming increasingly prevalent.

Government policies and regulations play a crucial role in shaping the CHP market landscape. Many countries have implemented supportive policies, including feed-in tariffs, tax incentives, and grants, to promote CHP adoption. The European Union's Energy Efficiency Directive, for instance, has been instrumental in driving CHP deployment across member states.

PHE Tech Challenges

Plate heat exchangers (PHEs) in combined heat and power (CHP) plants face several technical challenges that impact their efficiency and overall performance. One of the primary issues is fouling, which occurs when deposits accumulate on heat transfer surfaces, reducing thermal conductivity and increasing pressure drop. This phenomenon is particularly problematic in CHP applications due to the diverse range of fluids and operating conditions encountered.

Another significant challenge is the optimization of flow distribution within the PHE. Uneven flow can lead to reduced heat transfer efficiency and increased pressure drop. This issue is exacerbated by the complex geometry of PHEs and the varying fluid properties in CHP systems, making it difficult to achieve uniform distribution across all plates.

Thermal stress and fatigue pose additional concerns for PHEs in CHP plants. The frequent temperature fluctuations and high operating pressures can lead to material degradation, plate deformation, and potential leakage. This is particularly critical in applications where high temperature differentials exist between the hot and cold sides of the exchanger.

Corrosion is another persistent challenge, especially in CHP plants where diverse fluid chemistries are present. The combination of high temperatures, potentially aggressive fluids, and varying pH levels can accelerate corrosion processes, leading to reduced heat transfer efficiency and compromised structural integrity of the plates.

The design of gaskets for PHEs in CHP applications presents its own set of challenges. Gaskets must withstand a wide range of temperatures, pressures, and chemical environments while maintaining a reliable seal. Failure of gaskets can result in leaks, reduced efficiency, and potential safety hazards.

Scaling, particularly in water-based systems, is a common issue that affects PHE performance in CHP plants. The deposition of mineral scales on heat transfer surfaces can significantly reduce heat transfer rates and increase pressure drop, necessitating frequent cleaning and maintenance.

The challenge of maintaining optimal performance across varying load conditions is particularly relevant in CHP applications. PHEs must be designed to operate efficiently under both full and partial load scenarios, which can be difficult to achieve without compromising performance at either extreme.

Lastly, the integration of PHEs into existing CHP plant infrastructures presents logistical and engineering challenges. Retrofitting or upgrading PHEs in confined spaces, while ensuring compatibility with existing systems and minimizing downtime, requires careful planning and innovative solutions.

Another significant challenge is the optimization of flow distribution within the PHE. Uneven flow can lead to reduced heat transfer efficiency and increased pressure drop. This issue is exacerbated by the complex geometry of PHEs and the varying fluid properties in CHP systems, making it difficult to achieve uniform distribution across all plates.

Thermal stress and fatigue pose additional concerns for PHEs in CHP plants. The frequent temperature fluctuations and high operating pressures can lead to material degradation, plate deformation, and potential leakage. This is particularly critical in applications where high temperature differentials exist between the hot and cold sides of the exchanger.

Corrosion is another persistent challenge, especially in CHP plants where diverse fluid chemistries are present. The combination of high temperatures, potentially aggressive fluids, and varying pH levels can accelerate corrosion processes, leading to reduced heat transfer efficiency and compromised structural integrity of the plates.

The design of gaskets for PHEs in CHP applications presents its own set of challenges. Gaskets must withstand a wide range of temperatures, pressures, and chemical environments while maintaining a reliable seal. Failure of gaskets can result in leaks, reduced efficiency, and potential safety hazards.

Scaling, particularly in water-based systems, is a common issue that affects PHE performance in CHP plants. The deposition of mineral scales on heat transfer surfaces can significantly reduce heat transfer rates and increase pressure drop, necessitating frequent cleaning and maintenance.

The challenge of maintaining optimal performance across varying load conditions is particularly relevant in CHP applications. PHEs must be designed to operate efficiently under both full and partial load scenarios, which can be difficult to achieve without compromising performance at either extreme.

Lastly, the integration of PHEs into existing CHP plant infrastructures presents logistical and engineering challenges. Retrofitting or upgrading PHEs in confined spaces, while ensuring compatibility with existing systems and minimizing downtime, requires careful planning and innovative solutions.

Current PHE Solutions

01 Improved plate design for enhanced heat transfer

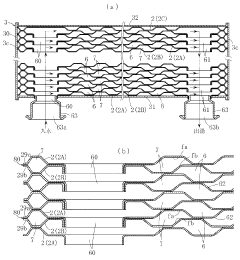

Innovative plate designs, such as corrugated or chevron patterns, can significantly improve heat transfer efficiency in plate heat exchangers. These designs increase turbulence and surface area, leading to better heat exchange between fluids. Advanced manufacturing techniques allow for optimized plate geometries that minimize pressure drop while maximizing heat transfer.- Improved plate design for enhanced heat transfer: Innovative plate designs in heat exchangers can significantly improve efficiency. These designs may include optimized flow patterns, increased surface area, or specialized corrugations that enhance turbulence and heat transfer while minimizing pressure drop.

- Advanced materials for plate construction: Utilizing advanced materials in plate construction can enhance heat transfer efficiency. These materials may have superior thermal conductivity, corrosion resistance, or other properties that improve overall performance and longevity of the heat exchanger.

- Optimized flow distribution and channel design: Improving flow distribution within the heat exchanger and optimizing channel design can lead to increased efficiency. This may involve innovative manifold designs, variable channel geometries, or flow control mechanisms that ensure uniform distribution and maximize heat transfer.

- Integration of turbulence promoters: Incorporating turbulence promoters or enhancers within the plate heat exchanger can improve heat transfer efficiency. These features disrupt fluid flow, creating turbulence that enhances mixing and heat transfer between the fluid and the plate surface.

- Smart control systems for operational optimization: Implementing smart control systems can optimize the operation of plate heat exchangers. These systems may use sensors, algorithms, and adaptive controls to adjust flow rates, temperatures, or other parameters in real-time, maximizing efficiency under varying conditions.

02 Flow distribution optimization

Efficient flow distribution within the plate heat exchanger is crucial for maximizing heat transfer. This can be achieved through carefully designed inlet and outlet ports, as well as internal flow channels. Uniform fluid distribution across the plates ensures that all available surface area is utilized effectively, reducing thermal inefficiencies and improving overall exchanger performance.Expand Specific Solutions03 Material selection for enhanced thermal conductivity

The choice of materials for plate construction plays a significant role in heat exchanger efficiency. High thermal conductivity materials, such as certain alloys or composite materials, can improve heat transfer rates. Additionally, surface treatments or coatings can be applied to plates to enhance their thermal properties or reduce fouling, further improving long-term efficiency.Expand Specific Solutions04 Gasket and sealing technology advancements

Improved gasket designs and sealing technologies contribute to the overall efficiency of plate heat exchangers. High-performance gaskets prevent fluid leakage and maintain proper plate separation, ensuring optimal heat transfer. Advanced sealing methods can also allow for higher operating pressures and temperatures, expanding the range of applications for plate heat exchangers.Expand Specific Solutions05 Smart monitoring and control systems

Integration of smart monitoring and control systems can significantly enhance plate heat exchanger efficiency. These systems can include sensors for real-time performance monitoring, predictive maintenance algorithms, and adaptive control mechanisms. By continuously optimizing operating parameters and detecting potential issues early, these systems ensure that the heat exchanger maintains peak efficiency throughout its operational life.Expand Specific Solutions

CHP Industry Players

The plate heat exchanger efficiency market in combined heat and power plants is in a growth phase, driven by increasing demand for energy-efficient solutions. The market size is expanding due to the rising adoption of cogeneration systems globally. Technologically, the field is advancing rapidly, with companies like Alfa Laval, Danfoss, and Mitsubishi Electric leading innovation. These firms are developing more efficient and compact heat exchangers, integrating smart controls, and improving materials for better heat transfer. Emerging players such as Haldor Topsøe and LG Innotek are also contributing to technological advancements, particularly in areas of specialized applications and novel materials.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced plate heat exchanger technologies tailored for CHP applications. Their plate heat exchangers feature a unique dimple pattern design that enhances turbulence and heat transfer efficiency while reducing pressure drop[1]. For CHP plants, Mitsubishi offers the high-performance MHI series, capable of handling temperatures up to 170°C and pressures up to 25 bar[2]. The company has also introduced a novel plate material composition that improves corrosion resistance in aggressive CHP environments, extending operational life by up to 25%[3]. Mitsubishi's plate heat exchangers incorporate an intelligent flow distribution system that optimizes fluid flow across the plates, resulting in up to 10% improvement in overall heat transfer efficiency compared to conventional designs[4].

Strengths: Innovative plate design for enhanced efficiency, improved corrosion resistance, intelligent flow distribution. Weaknesses: Lower maximum temperature and pressure ratings compared to some competitors, potentially limited size range for larger CHP applications.

Danfoss A/S

Technical Solution: Danfoss has innovated in plate heat exchanger technology for CHP plants with their micro plate heat exchangers (MPHEs). These exchangers feature a unique channel pattern that creates high turbulence, resulting in improved heat transfer coefficients up to 40% higher than traditional plate designs[1]. For CHP applications, Danfoss offers the XG line of plate heat exchangers, which can handle temperatures up to 180°C and pressures up to 25 bar[2]. The company's patented Distribution Control System ensures uniform flow distribution across plates, minimizing temperature differences and enhancing overall efficiency[3]. Danfoss also employs advanced brazing techniques, such as their DuraBraze technology, which increases corrosion resistance and extends the operational life of the exchangers in demanding CHP environments[4].

Strengths: High heat transfer efficiency, compact design, uniform flow distribution. Weaknesses: Limited to smaller capacity applications compared to some competitors, may require more frequent cleaning in certain conditions.

Key PHE Innovations

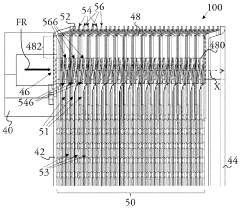

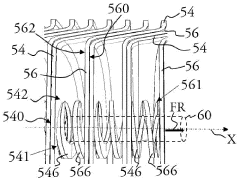

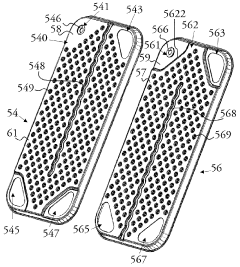

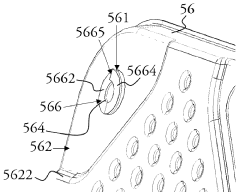

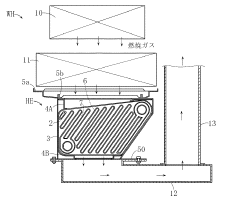

Plate heat exchanger comprising a mixing device

PatentWO2024149630A1

Innovation

- A plate heat exchanger with a mixing device in the refrigerant fluid inlet collector, which disperses the two-phase refrigerant flow by creating singularities and diverting the fluid to improve distribution within the plate bundle, enhancing the heat transfer coefficient and reducing pressure variations.

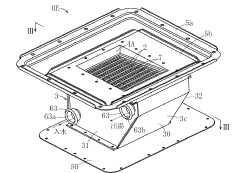

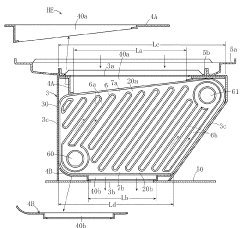

Plate type heat exchanger and hot water device including the same

PatentActiveJP2020070938A

Innovation

- A plate heat exchanger design with a smaller gas outlet opening than inlet opening, upright plates with inclined ends, and optimized liquid channels to maintain flow velocity and enhance heat exchange efficiency, while reducing size and weight, and using minimal brazing to save costs.

Energy Efficiency Policies

Energy efficiency policies play a crucial role in promoting the adoption and optimization of plate heat exchangers in combined heat and power (CHP) plants. These policies are designed to encourage the implementation of energy-efficient technologies and practices, ultimately reducing energy consumption and greenhouse gas emissions.

Many countries have implemented specific policies targeting the industrial sector, including CHP plants. These policies often include financial incentives, such as tax credits or grants, for the installation of high-efficiency equipment like plate heat exchangers. For example, the European Union's Energy Efficiency Directive requires member states to establish energy efficiency obligation schemes, which can directly benefit CHP plants utilizing efficient heat exchange technologies.

Regulatory frameworks also contribute to the promotion of energy-efficient technologies in CHP plants. Building codes and energy performance standards often mandate minimum efficiency levels for heating and cooling systems, indirectly driving the adoption of more efficient plate heat exchangers. Additionally, some jurisdictions have implemented energy audit requirements for large industrial facilities, which can help identify opportunities for improving heat exchanger efficiency in CHP plants.

Carbon pricing mechanisms, such as cap-and-trade systems or carbon taxes, indirectly support the use of efficient plate heat exchangers by creating economic incentives for reducing energy consumption and associated emissions. As CHP plants become subject to these policies, operators are more likely to invest in high-efficiency heat exchange technologies to minimize their carbon footprint and associated costs.

Research and development (R&D) support is another critical aspect of energy efficiency policies relevant to plate heat exchangers in CHP plants. Many governments provide funding for research initiatives aimed at improving heat exchanger technologies, materials, and design methodologies. These R&D programs can lead to breakthroughs in plate heat exchanger efficiency, benefiting the CHP industry as a whole.

Energy management standards, such as ISO 50001, are often promoted or mandated by energy efficiency policies. These standards encourage organizations to implement systematic approaches to energy management, which can include optimizing the performance of plate heat exchangers in CHP plants. By adopting these standards, plant operators can identify and address inefficiencies in their heat exchange systems more effectively.

Lastly, information and awareness campaigns form an essential component of energy efficiency policies. These initiatives aim to educate industrial stakeholders about the benefits of energy-efficient technologies, including high-performance plate heat exchangers. By increasing awareness and providing technical guidance, these campaigns can drive the adoption of more efficient heat exchange solutions in CHP plants.

Many countries have implemented specific policies targeting the industrial sector, including CHP plants. These policies often include financial incentives, such as tax credits or grants, for the installation of high-efficiency equipment like plate heat exchangers. For example, the European Union's Energy Efficiency Directive requires member states to establish energy efficiency obligation schemes, which can directly benefit CHP plants utilizing efficient heat exchange technologies.

Regulatory frameworks also contribute to the promotion of energy-efficient technologies in CHP plants. Building codes and energy performance standards often mandate minimum efficiency levels for heating and cooling systems, indirectly driving the adoption of more efficient plate heat exchangers. Additionally, some jurisdictions have implemented energy audit requirements for large industrial facilities, which can help identify opportunities for improving heat exchanger efficiency in CHP plants.

Carbon pricing mechanisms, such as cap-and-trade systems or carbon taxes, indirectly support the use of efficient plate heat exchangers by creating economic incentives for reducing energy consumption and associated emissions. As CHP plants become subject to these policies, operators are more likely to invest in high-efficiency heat exchange technologies to minimize their carbon footprint and associated costs.

Research and development (R&D) support is another critical aspect of energy efficiency policies relevant to plate heat exchangers in CHP plants. Many governments provide funding for research initiatives aimed at improving heat exchanger technologies, materials, and design methodologies. These R&D programs can lead to breakthroughs in plate heat exchanger efficiency, benefiting the CHP industry as a whole.

Energy management standards, such as ISO 50001, are often promoted or mandated by energy efficiency policies. These standards encourage organizations to implement systematic approaches to energy management, which can include optimizing the performance of plate heat exchangers in CHP plants. By adopting these standards, plant operators can identify and address inefficiencies in their heat exchange systems more effectively.

Lastly, information and awareness campaigns form an essential component of energy efficiency policies. These initiatives aim to educate industrial stakeholders about the benefits of energy-efficient technologies, including high-performance plate heat exchangers. By increasing awareness and providing technical guidance, these campaigns can drive the adoption of more efficient heat exchange solutions in CHP plants.

Environmental Impact

The environmental impact of plate heat exchangers in combined heat and power (CHP) plants is a critical consideration in the pursuit of sustainable energy solutions. These efficient heat transfer devices play a significant role in reducing the overall environmental footprint of CHP systems.

Plate heat exchangers contribute to improved energy efficiency in CHP plants, resulting in reduced fuel consumption and lower greenhouse gas emissions. By effectively transferring heat between fluids, they maximize the utilization of thermal energy that would otherwise be wasted. This increased efficiency translates to a decrease in the amount of fuel required to produce the same amount of electricity and heat, thereby reducing carbon dioxide emissions and other pollutants associated with combustion processes.

The compact design of plate heat exchangers also offers environmental benefits. Their smaller footprint compared to traditional shell-and-tube heat exchangers means less material is required for construction, reducing the embodied energy and carbon footprint of the equipment. Additionally, the reduced size allows for more efficient use of space within CHP plants, potentially decreasing the overall environmental impact of the facility's construction and operation.

Water conservation is another environmental advantage of plate heat exchangers in CHP plants. Their high efficiency in heat transfer often results in lower cooling water requirements compared to other heat exchanger types. This reduction in water usage is particularly beneficial in regions facing water scarcity issues and helps to minimize the environmental impact on local water resources.

The materials used in plate heat exchangers can also contribute to their environmental performance. Many modern designs utilize corrosion-resistant materials that extend the operational lifespan of the equipment, reducing the need for frequent replacements and the associated environmental costs of manufacturing and disposal. Some manufacturers are exploring the use of recyclable or biodegradable materials for certain components, further enhancing the environmental credentials of these systems.

In terms of maintenance and cleaning, plate heat exchangers often require less aggressive chemical treatments compared to other heat exchanger types. This reduction in chemical usage not only lowers the operational costs but also minimizes the potential for harmful substances to be released into the environment during maintenance procedures or through wastewater discharge.

The flexibility of plate heat exchangers in handling various fluid types and operating conditions allows CHP plants to adapt to different fuel sources, including renewable and low-carbon alternatives. This adaptability supports the transition to cleaner energy sources, further reducing the environmental impact of power generation over time.

Plate heat exchangers contribute to improved energy efficiency in CHP plants, resulting in reduced fuel consumption and lower greenhouse gas emissions. By effectively transferring heat between fluids, they maximize the utilization of thermal energy that would otherwise be wasted. This increased efficiency translates to a decrease in the amount of fuel required to produce the same amount of electricity and heat, thereby reducing carbon dioxide emissions and other pollutants associated with combustion processes.

The compact design of plate heat exchangers also offers environmental benefits. Their smaller footprint compared to traditional shell-and-tube heat exchangers means less material is required for construction, reducing the embodied energy and carbon footprint of the equipment. Additionally, the reduced size allows for more efficient use of space within CHP plants, potentially decreasing the overall environmental impact of the facility's construction and operation.

Water conservation is another environmental advantage of plate heat exchangers in CHP plants. Their high efficiency in heat transfer often results in lower cooling water requirements compared to other heat exchanger types. This reduction in water usage is particularly beneficial in regions facing water scarcity issues and helps to minimize the environmental impact on local water resources.

The materials used in plate heat exchangers can also contribute to their environmental performance. Many modern designs utilize corrosion-resistant materials that extend the operational lifespan of the equipment, reducing the need for frequent replacements and the associated environmental costs of manufacturing and disposal. Some manufacturers are exploring the use of recyclable or biodegradable materials for certain components, further enhancing the environmental credentials of these systems.

In terms of maintenance and cleaning, plate heat exchangers often require less aggressive chemical treatments compared to other heat exchanger types. This reduction in chemical usage not only lowers the operational costs but also minimizes the potential for harmful substances to be released into the environment during maintenance procedures or through wastewater discharge.

The flexibility of plate heat exchangers in handling various fluid types and operating conditions allows CHP plants to adapt to different fuel sources, including renewable and low-carbon alternatives. This adaptability supports the transition to cleaner energy sources, further reducing the environmental impact of power generation over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!