Plate Heat Exchanger Impact on Food Safety Standards

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Food Safety Background and Objectives

Plate heat exchangers (PHEs) have become an integral component in modern food processing systems, playing a crucial role in ensuring food safety standards are met. The evolution of PHE technology in the food industry can be traced back to the early 20th century, with significant advancements occurring in the past few decades. As food safety regulations have become increasingly stringent, the demand for more efficient and reliable heat exchange solutions has grown exponentially.

The primary objective of incorporating PHEs in food processing is to achieve rapid and uniform heating or cooling of food products, thereby minimizing the risk of microbial growth and ensuring product quality. This technology has proven particularly effective in pasteurization, sterilization, and temperature control processes across various food sectors, including dairy, beverages, and prepared foods.

The development of PHE technology has been driven by the need to address several key challenges in food safety. These include the prevention of cross-contamination, reduction of processing time to maintain nutritional value, and the ability to handle a wide range of viscosities and particulate-containing products. As a result, PHE designs have evolved to incorporate features such as enhanced plate corrugation patterns, improved gasket materials, and more efficient flow distribution systems.

Recent trends in PHE technology for food safety applications include the development of aseptic systems, which allow for continuous processing of sensitive food products under sterile conditions. Additionally, there has been a focus on creating PHEs with improved cleanability and reduced fouling tendencies, addressing concerns related to biofilm formation and bacterial adhesion.

The global food safety landscape has significantly influenced the trajectory of PHE technology. Regulatory frameworks such as the FDA's Food Safety Modernization Act (FSMA) in the United States and similar regulations in other regions have set new benchmarks for food processing equipment, including heat exchangers. These regulations emphasize preventive controls and validation of food safety measures, driving innovation in PHE design and performance monitoring.

Looking ahead, the objectives for PHE technology in food safety applications are multifaceted. There is a growing emphasis on developing smart PHEs equipped with real-time monitoring capabilities to ensure consistent adherence to food safety standards. Furthermore, research is underway to explore novel materials and surface treatments that can enhance the antimicrobial properties of PHE plates, potentially revolutionizing food safety protocols in processing facilities.

The primary objective of incorporating PHEs in food processing is to achieve rapid and uniform heating or cooling of food products, thereby minimizing the risk of microbial growth and ensuring product quality. This technology has proven particularly effective in pasteurization, sterilization, and temperature control processes across various food sectors, including dairy, beverages, and prepared foods.

The development of PHE technology has been driven by the need to address several key challenges in food safety. These include the prevention of cross-contamination, reduction of processing time to maintain nutritional value, and the ability to handle a wide range of viscosities and particulate-containing products. As a result, PHE designs have evolved to incorporate features such as enhanced plate corrugation patterns, improved gasket materials, and more efficient flow distribution systems.

Recent trends in PHE technology for food safety applications include the development of aseptic systems, which allow for continuous processing of sensitive food products under sterile conditions. Additionally, there has been a focus on creating PHEs with improved cleanability and reduced fouling tendencies, addressing concerns related to biofilm formation and bacterial adhesion.

The global food safety landscape has significantly influenced the trajectory of PHE technology. Regulatory frameworks such as the FDA's Food Safety Modernization Act (FSMA) in the United States and similar regulations in other regions have set new benchmarks for food processing equipment, including heat exchangers. These regulations emphasize preventive controls and validation of food safety measures, driving innovation in PHE design and performance monitoring.

Looking ahead, the objectives for PHE technology in food safety applications are multifaceted. There is a growing emphasis on developing smart PHEs equipped with real-time monitoring capabilities to ensure consistent adherence to food safety standards. Furthermore, research is underway to explore novel materials and surface treatments that can enhance the antimicrobial properties of PHE plates, potentially revolutionizing food safety protocols in processing facilities.

Market Demand Analysis for Safe PHE in Food Industry

The market demand for safe plate heat exchangers (PHEs) in the food industry has been steadily increasing due to growing concerns about food safety and stringent regulatory requirements. Food manufacturers are increasingly recognizing the critical role that PHEs play in ensuring the safety and quality of their products. This demand is driven by several factors, including the need for efficient heat transfer processes, improved hygiene standards, and compliance with food safety regulations.

In recent years, there has been a significant shift towards more stringent food safety standards globally. Regulatory bodies such as the FDA in the United States and the EFSA in Europe have implemented stricter guidelines for food processing equipment, including heat exchangers. This has led to a surge in demand for PHEs that meet these enhanced safety standards, particularly in the dairy, beverage, and prepared foods sectors.

The market for safe PHEs in the food industry is also being propelled by consumer awareness and expectations. With increasing media coverage of foodborne illness outbreaks, consumers are becoming more conscious of food safety issues. This has put pressure on food manufacturers to invest in advanced processing equipment that can ensure product safety and quality.

Furthermore, the trend towards clean label products and minimally processed foods has created a need for gentler heat treatment processes. PHEs that can provide precise temperature control and minimize product degradation are in high demand, as they allow manufacturers to meet consumer preferences while maintaining food safety standards.

The COVID-19 pandemic has further accelerated the demand for safe PHEs in the food industry. The crisis has heightened awareness of hygiene and safety in food production, leading to increased investments in equipment that can ensure product safety and reduce contamination risks.

In terms of market size, the global food-grade heat exchanger market, which includes PHEs, is experiencing robust growth. Industry reports suggest that this market is expected to expand significantly over the next five years, driven by the factors mentioned above.

Geographically, the demand for safe PHEs in the food industry is particularly strong in developed regions such as North America and Europe, where food safety regulations are most stringent. However, emerging markets in Asia-Pacific and Latin America are also showing rapid growth as their food processing sectors modernize and align with international safety standards.

In conclusion, the market demand for safe PHEs in the food industry is robust and growing, driven by regulatory pressures, consumer expectations, technological advancements, and the ongoing need for efficient and hygienic food processing solutions. This trend is expected to continue in the foreseeable future, presenting significant opportunities for manufacturers of food-grade PHEs.

In recent years, there has been a significant shift towards more stringent food safety standards globally. Regulatory bodies such as the FDA in the United States and the EFSA in Europe have implemented stricter guidelines for food processing equipment, including heat exchangers. This has led to a surge in demand for PHEs that meet these enhanced safety standards, particularly in the dairy, beverage, and prepared foods sectors.

The market for safe PHEs in the food industry is also being propelled by consumer awareness and expectations. With increasing media coverage of foodborne illness outbreaks, consumers are becoming more conscious of food safety issues. This has put pressure on food manufacturers to invest in advanced processing equipment that can ensure product safety and quality.

Furthermore, the trend towards clean label products and minimally processed foods has created a need for gentler heat treatment processes. PHEs that can provide precise temperature control and minimize product degradation are in high demand, as they allow manufacturers to meet consumer preferences while maintaining food safety standards.

The COVID-19 pandemic has further accelerated the demand for safe PHEs in the food industry. The crisis has heightened awareness of hygiene and safety in food production, leading to increased investments in equipment that can ensure product safety and reduce contamination risks.

In terms of market size, the global food-grade heat exchanger market, which includes PHEs, is experiencing robust growth. Industry reports suggest that this market is expected to expand significantly over the next five years, driven by the factors mentioned above.

Geographically, the demand for safe PHEs in the food industry is particularly strong in developed regions such as North America and Europe, where food safety regulations are most stringent. However, emerging markets in Asia-Pacific and Latin America are also showing rapid growth as their food processing sectors modernize and align with international safety standards.

In conclusion, the market demand for safe PHEs in the food industry is robust and growing, driven by regulatory pressures, consumer expectations, technological advancements, and the ongoing need for efficient and hygienic food processing solutions. This trend is expected to continue in the foreseeable future, presenting significant opportunities for manufacturers of food-grade PHEs.

Current PHE Technology and Food Safety Challenges

Plate Heat Exchangers (PHEs) have become integral components in food processing industries, offering efficient heat transfer capabilities. However, their impact on food safety standards presents both opportunities and challenges. Current PHE technology has evolved to address many food safety concerns, yet some challenges persist.

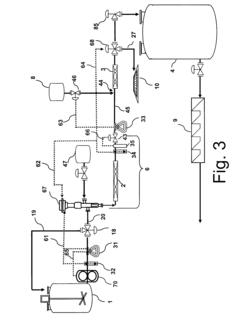

Modern PHEs are designed with food-grade materials, typically stainless steel, to prevent contamination and ensure easy cleaning. The plates are engineered with intricate patterns to enhance turbulence and heat transfer efficiency while minimizing fouling. Advanced gasket materials and designs have been developed to withstand high temperatures and pressures, reducing the risk of leaks and cross-contamination.

One of the primary food safety advantages of PHEs is their ability to achieve rapid heating and cooling, crucial for pasteurization and sterilization processes. This quick temperature change helps maintain food quality while effectively eliminating harmful microorganisms. Additionally, the compact design of PHEs allows for easier inspection and maintenance, contributing to better hygiene practices.

Despite these advancements, several food safety challenges remain. Biofilm formation on plate surfaces is a persistent issue, potentially harboring pathogens and compromising food safety. While PHEs are designed for easy cleaning, the complexity of plate patterns can sometimes create hard-to-reach areas where contaminants may accumulate.

Another challenge is ensuring uniform heat distribution across all plates, particularly in large-scale operations. Uneven heating can lead to inadequate pasteurization or sterilization in some areas, posing food safety risks. This issue is compounded by the difficulty in real-time monitoring of temperature distribution within the PHE during operation.

The integrity of gaskets and seals remains a critical concern. While materials have improved, prolonged exposure to high temperatures, pressure, and aggressive cleaning chemicals can degrade these components over time, potentially leading to leaks or cross-contamination between product and utility streams.

Cleaning-in-Place (CIP) systems have significantly enhanced the sanitation of PHEs, but optimizing CIP protocols for different food products and PHE configurations remains challenging. Ensuring complete removal of all food residues and cleaning chemicals is crucial to maintain food safety standards.

As food safety regulations become increasingly stringent, PHE manufacturers and food processors face the ongoing challenge of adapting technology to meet these evolving standards. This includes developing more robust materials, improving plate designs for better cleanability, and integrating advanced monitoring systems to ensure consistent performance and early detection of potential food safety issues.

Modern PHEs are designed with food-grade materials, typically stainless steel, to prevent contamination and ensure easy cleaning. The plates are engineered with intricate patterns to enhance turbulence and heat transfer efficiency while minimizing fouling. Advanced gasket materials and designs have been developed to withstand high temperatures and pressures, reducing the risk of leaks and cross-contamination.

One of the primary food safety advantages of PHEs is their ability to achieve rapid heating and cooling, crucial for pasteurization and sterilization processes. This quick temperature change helps maintain food quality while effectively eliminating harmful microorganisms. Additionally, the compact design of PHEs allows for easier inspection and maintenance, contributing to better hygiene practices.

Despite these advancements, several food safety challenges remain. Biofilm formation on plate surfaces is a persistent issue, potentially harboring pathogens and compromising food safety. While PHEs are designed for easy cleaning, the complexity of plate patterns can sometimes create hard-to-reach areas where contaminants may accumulate.

Another challenge is ensuring uniform heat distribution across all plates, particularly in large-scale operations. Uneven heating can lead to inadequate pasteurization or sterilization in some areas, posing food safety risks. This issue is compounded by the difficulty in real-time monitoring of temperature distribution within the PHE during operation.

The integrity of gaskets and seals remains a critical concern. While materials have improved, prolonged exposure to high temperatures, pressure, and aggressive cleaning chemicals can degrade these components over time, potentially leading to leaks or cross-contamination between product and utility streams.

Cleaning-in-Place (CIP) systems have significantly enhanced the sanitation of PHEs, but optimizing CIP protocols for different food products and PHE configurations remains challenging. Ensuring complete removal of all food residues and cleaning chemicals is crucial to maintain food safety standards.

As food safety regulations become increasingly stringent, PHE manufacturers and food processors face the ongoing challenge of adapting technology to meet these evolving standards. This includes developing more robust materials, improving plate designs for better cleanability, and integrating advanced monitoring systems to ensure consistent performance and early detection of potential food safety issues.

Existing PHE Solutions for Food Safety Compliance

01 Design and construction of plate heat exchangers for food safety

Plate heat exchangers used in food processing must be designed and constructed to meet specific food safety standards. This includes using food-grade materials, ensuring easy cleanability, and preventing contamination. The design should allow for effective heat transfer while maintaining hygienic conditions throughout the exchanger.- Hygienic design of plate heat exchangers: Plate heat exchangers for food processing applications are designed with hygienic considerations to prevent contamination and ensure food safety. This includes the use of food-grade materials, smooth surfaces, and easy-to-clean designs that minimize the risk of bacterial growth and product residue accumulation.

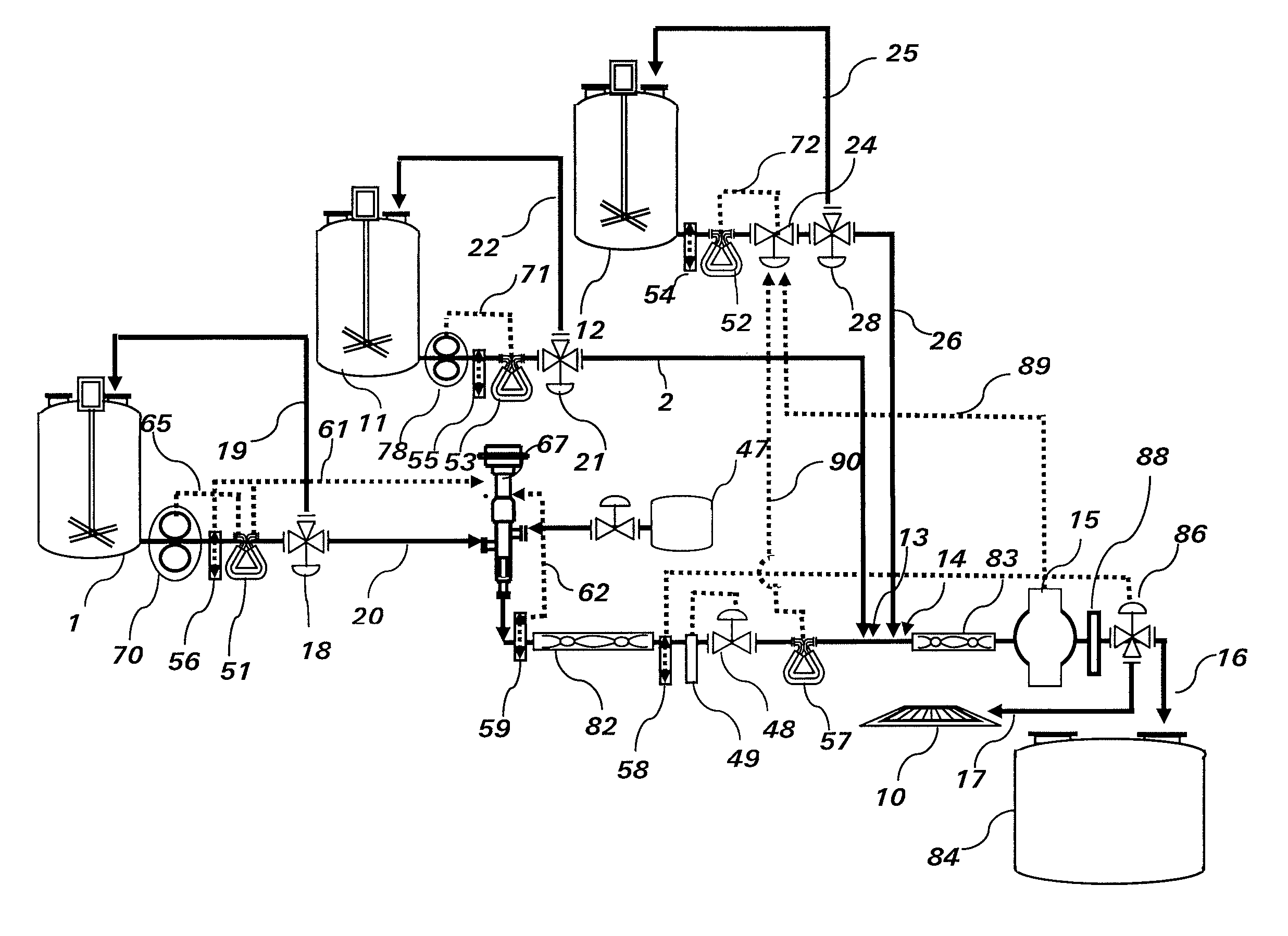

- Cleaning and sanitation protocols: Specific cleaning and sanitation protocols are developed for plate heat exchangers used in food processing. These protocols often involve Clean-in-Place (CIP) systems, which allow for thorough cleaning without disassembly, ensuring that all surfaces in contact with food products are properly sanitized to meet food safety standards.

- Material selection for food contact surfaces: The selection of materials for plate heat exchangers in food applications is critical to meet food safety standards. Stainless steel and other corrosion-resistant, non-toxic materials are commonly used to prevent contamination and ensure durability under frequent cleaning and sanitization processes.

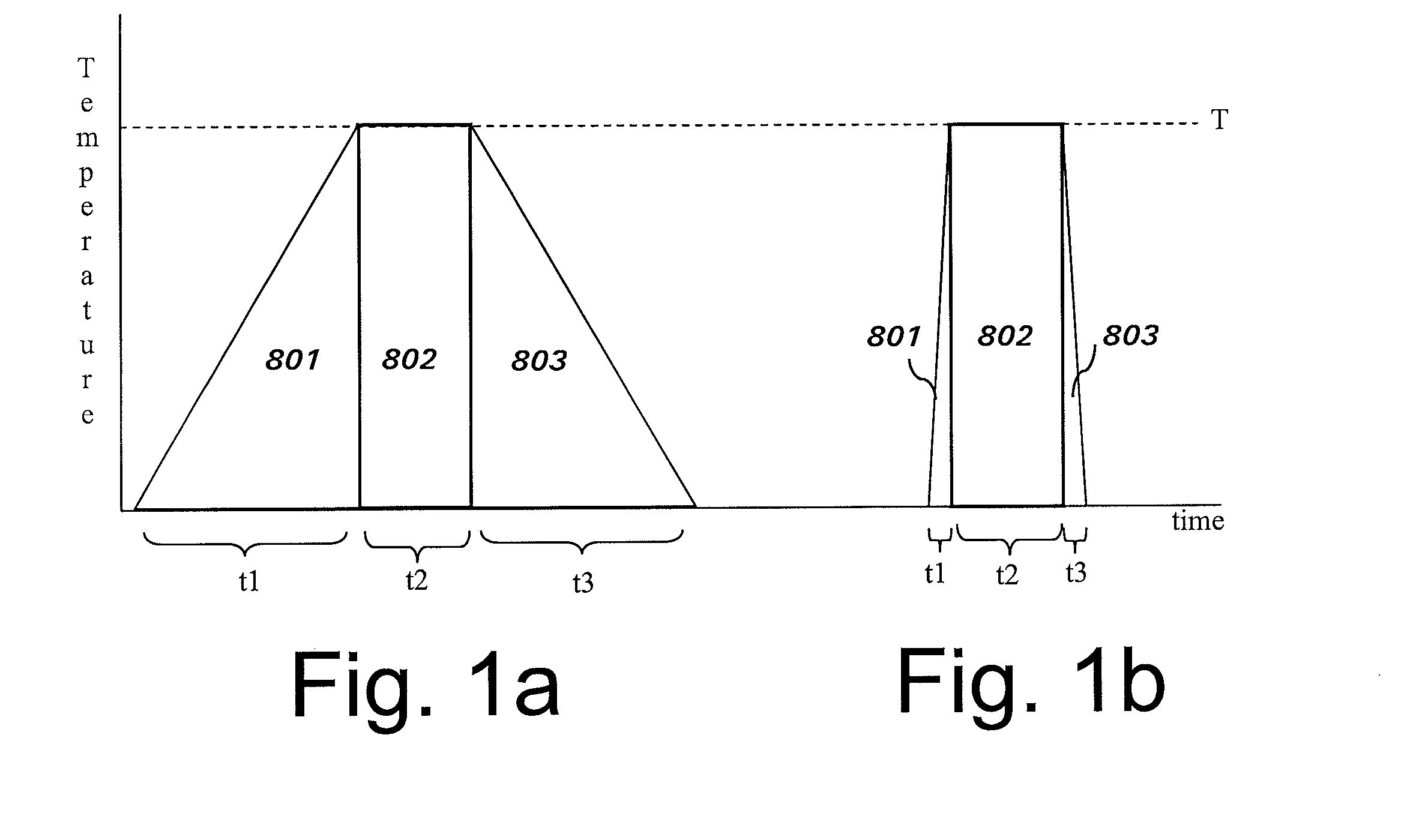

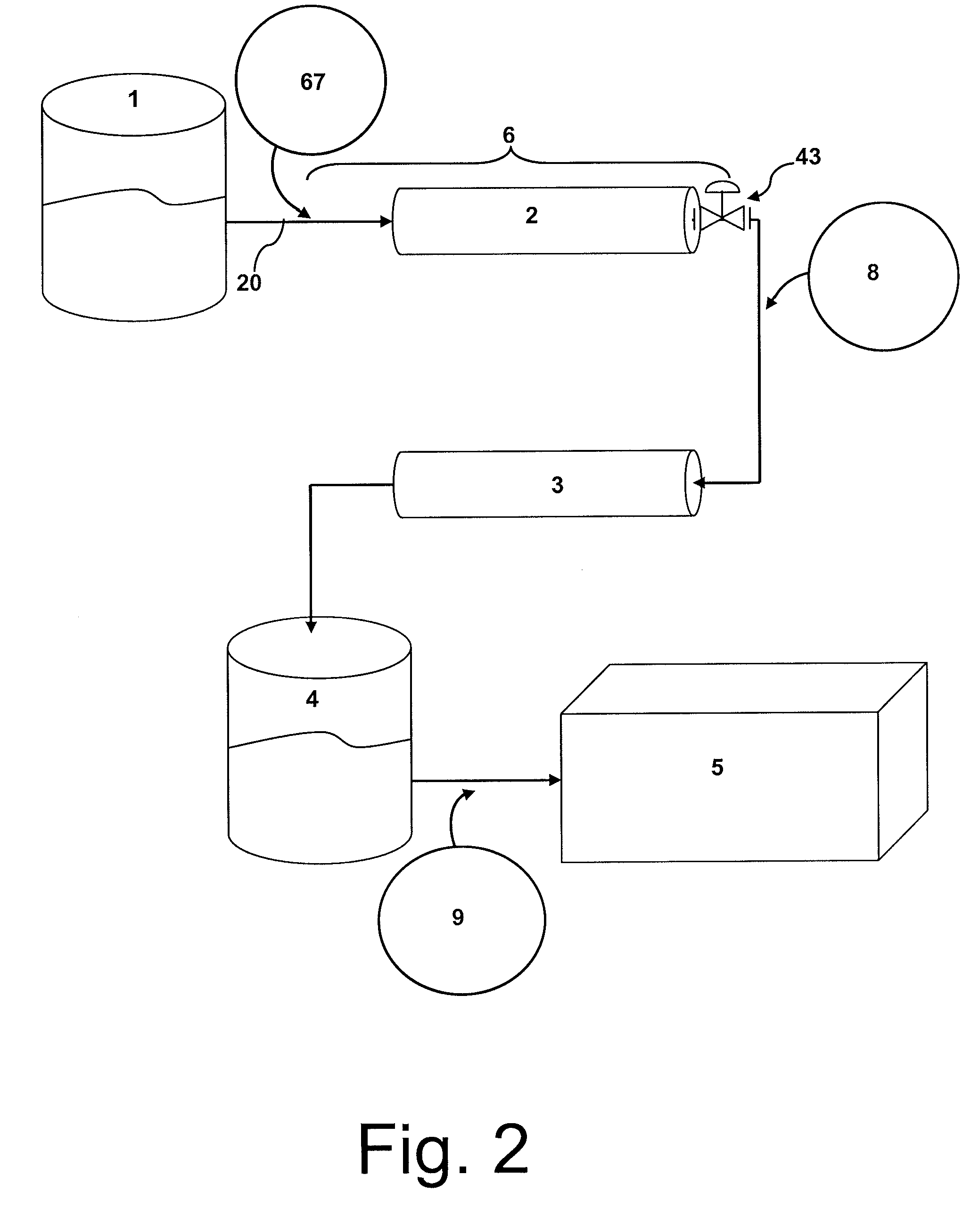

- Temperature control and monitoring: Precise temperature control and monitoring systems are integrated into plate heat exchangers for food processing to ensure that proper temperatures are maintained throughout the process. This is crucial for preventing microbial growth and ensuring food safety, particularly in pasteurization and sterilization applications.

- Compliance with food safety regulations: Plate heat exchangers used in food processing must comply with various food safety regulations and standards, such as FDA guidelines, HACCP principles, and ISO standards. This includes requirements for design, materials, performance, and documentation to ensure the safety and quality of food products.

02 Cleaning and sanitation protocols for plate heat exchangers

Proper cleaning and sanitation procedures are crucial for maintaining food safety in plate heat exchangers. This involves developing and implementing effective cleaning-in-place (CIP) systems, using appropriate cleaning agents, and ensuring thorough sanitization between production runs. Regular inspection and maintenance are also essential to prevent microbial growth and contamination.Expand Specific Solutions03 Temperature control and monitoring in food processing

Maintaining precise temperature control during food processing is critical for ensuring food safety. Plate heat exchangers must be equipped with accurate temperature monitoring systems and control mechanisms to prevent under-processing or over-processing of food products. This helps in eliminating harmful microorganisms and preserving food quality.Expand Specific Solutions04 Material selection for food-grade plate heat exchangers

The selection of appropriate materials for plate heat exchangers in food processing is crucial. Materials must be food-grade, corrosion-resistant, and able to withstand repeated cleaning and sanitization processes. Commonly used materials include stainless steel and certain food-safe polymers that meet regulatory requirements for food contact surfaces.Expand Specific Solutions05 Compliance with international food safety standards

Plate heat exchangers used in food processing must comply with various international food safety standards and regulations. This includes adherence to guidelines set by organizations such as the FDA, USDA, and European Food Safety Authority. Manufacturers must ensure their equipment meets these standards and obtain necessary certifications to operate in different markets.Expand Specific Solutions

Key Players in PHE Manufacturing for Food Industry

The plate heat exchanger market in food safety is experiencing robust growth, driven by increasing food safety regulations and demand for efficient heat transfer solutions. The industry is in a mature stage, with a global market size expected to reach several billion dollars by 2025. Technological advancements are focusing on improving energy efficiency and reducing fouling. Key players like Alfa Laval, Danfoss, and LHE Co. are leading innovation, with emerging companies such as GD Midea and Guangdong Vanward New Electric also making significant contributions. The market is characterized by intense competition and a strong focus on R&D to meet evolving food safety standards and energy efficiency requirements.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchanger technologies specifically designed to enhance food safety standards. Their innovative AlfaFusion technology creates a fusion-bonded, all-stainless steel plate heat exchanger that eliminates the need for gaskets, minimizing contamination risks[1]. The company's hygienic design principles include features like optimized plate patterns for improved cleanability, reducing bacterial growth potential. Alfa Laval's PureBallast system, utilizing UV technology, ensures effective microbial decontamination in food processing applications[2]. Their plate heat exchangers also incorporate CIP (Cleaning-in-Place) compatibility, allowing for thorough sanitization without disassembly, which is crucial for maintaining food safety standards[3].

Strengths: Superior hygienic design, innovative bonding technology, and efficient cleaning systems. Weaknesses: Potentially higher initial costs and specialized maintenance requirements.

Electrolux Professionnel SAS

Technical Solution: Electrolux Professional has developed a range of plate heat exchangers tailored for the food industry, focusing on enhancing food safety standards. Their heat exchangers feature a hygienic design with smooth surfaces and minimal crevices to prevent bacterial growth. The company utilizes advanced gasket materials that are FDA-compliant and resistant to cleaning chemicals[4]. Electrolux's plate heat exchangers incorporate a unique plate corrugation pattern that optimizes heat transfer while minimizing fouling, a critical factor in maintaining food safety. Their systems are designed for easy disassembly and inspection, facilitating regular maintenance and ensuring compliance with HACCP principles[5]. Additionally, Electrolux offers plate heat exchangers with double-wall protection for critical applications where cross-contamination must be absolutely prevented[6].

Strengths: Hygienic design, compliance with food industry standards, and versatile application range. Weaknesses: May have limitations in extreme temperature or pressure conditions.

Core Innovations in PHE Food Safety Technology

Sterilization of Flowable Food Products

PatentInactiveUS20080160149A1

Innovation

- Direct steam injection at high temperatures (up to 250°F) for short durations, followed by rapid cooling, using in-line static mixers and feed-forward control systems to ensure consistent and efficient microbial kill while minimizing thermal abuse and maintaining organoleptic properties.

Heat exchanger

PatentActiveEP2232185A2

Innovation

- A heat exchanger design featuring cassettes with corrugated patterns on plates, where the distance between side walls of adjacent cassettes is kept constant, minimizing flow restrictions and preventing material accumulation, while maintaining mechanical rigidity and improving heat transfer through undulating patterns perpendicular to the flow direction.

Regulatory Framework for PHE in Food Processing

The regulatory framework for Plate Heat Exchangers (PHEs) in food processing is a critical aspect of ensuring food safety standards are met. Governments and international organizations have established comprehensive guidelines and regulations to govern the use of PHEs in the food industry.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating PHEs through the Food Safety Modernization Act (FSMA). This act emphasizes preventive controls and requires food processors to implement hazard analysis and risk-based preventive controls. PHEs, as critical components in food processing, must comply with these regulations to ensure the safety of food products.

The European Union has implemented stringent regulations through the European Hygienic Engineering and Design Group (EHEDG) guidelines. These guidelines provide detailed specifications for the design, construction, and operation of PHEs in food processing applications. They focus on hygienic design principles to minimize contamination risks and ensure easy cleanability of equipment.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global food standards that include guidelines for PHEs in food processing. These standards emphasize the importance of proper design, installation, and maintenance of heat exchangers to prevent microbial contamination and ensure food safety.

The 3-A Sanitary Standards, widely recognized in the dairy industry, also provide specific guidelines for PHEs used in dairy processing. These standards cover materials of construction, surface finish requirements, and design criteria to ensure hygienic operation and ease of cleaning.

Regulatory bodies often require food processors to implement Hazard Analysis and Critical Control Points (HACCP) systems. PHEs are typically identified as critical control points within these systems, necessitating strict monitoring and documentation of their operation and maintenance.

Many countries have adopted Good Manufacturing Practices (GMPs) that include specific requirements for PHEs in food processing. These practices cover aspects such as materials selection, design considerations, and cleaning procedures to ensure the safe and hygienic operation of PHEs.

Compliance with these regulatory frameworks often requires food processors to maintain detailed records of PHE operation, cleaning, and maintenance. Regular inspections and audits are conducted to ensure adherence to these regulations, with non-compliance potentially resulting in severe penalties or operational shutdowns.

As food safety standards continue to evolve, regulatory frameworks for PHEs in food processing are likely to become more stringent. This ongoing development underscores the importance of staying informed about regulatory changes and implementing proactive measures to ensure compliance and maintain food safety standards.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating PHEs through the Food Safety Modernization Act (FSMA). This act emphasizes preventive controls and requires food processors to implement hazard analysis and risk-based preventive controls. PHEs, as critical components in food processing, must comply with these regulations to ensure the safety of food products.

The European Union has implemented stringent regulations through the European Hygienic Engineering and Design Group (EHEDG) guidelines. These guidelines provide detailed specifications for the design, construction, and operation of PHEs in food processing applications. They focus on hygienic design principles to minimize contamination risks and ensure easy cleanability of equipment.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global food standards that include guidelines for PHEs in food processing. These standards emphasize the importance of proper design, installation, and maintenance of heat exchangers to prevent microbial contamination and ensure food safety.

The 3-A Sanitary Standards, widely recognized in the dairy industry, also provide specific guidelines for PHEs used in dairy processing. These standards cover materials of construction, surface finish requirements, and design criteria to ensure hygienic operation and ease of cleaning.

Regulatory bodies often require food processors to implement Hazard Analysis and Critical Control Points (HACCP) systems. PHEs are typically identified as critical control points within these systems, necessitating strict monitoring and documentation of their operation and maintenance.

Many countries have adopted Good Manufacturing Practices (GMPs) that include specific requirements for PHEs in food processing. These practices cover aspects such as materials selection, design considerations, and cleaning procedures to ensure the safe and hygienic operation of PHEs.

Compliance with these regulatory frameworks often requires food processors to maintain detailed records of PHE operation, cleaning, and maintenance. Regular inspections and audits are conducted to ensure adherence to these regulations, with non-compliance potentially resulting in severe penalties or operational shutdowns.

As food safety standards continue to evolve, regulatory frameworks for PHEs in food processing are likely to become more stringent. This ongoing development underscores the importance of staying informed about regulatory changes and implementing proactive measures to ensure compliance and maintain food safety standards.

Environmental Impact of PHE in Food Industry

The environmental impact of Plate Heat Exchangers (PHEs) in the food industry is a critical consideration as the sector strives for sustainability and efficiency. PHEs have become integral to food processing operations, offering significant advantages in terms of energy efficiency and product safety. However, their widespread use also raises important environmental concerns that warrant careful examination.

One of the primary environmental benefits of PHEs in the food industry is their contribution to energy conservation. These devices are highly efficient in heat transfer, allowing for the recovery and reuse of thermal energy that would otherwise be wasted. This efficiency translates to reduced energy consumption in heating and cooling processes, thereby lowering the overall carbon footprint of food production facilities. Studies have shown that PHEs can achieve energy savings of up to 30% compared to traditional heat exchange methods, significantly reducing greenhouse gas emissions associated with energy production.

Water conservation is another area where PHEs demonstrate positive environmental impact. Their design allows for effective heat transfer with minimal water usage, particularly in closed-loop systems. This is especially crucial in regions facing water scarcity, where the food industry's water consumption is a growing concern. By optimizing water use in processing operations, PHEs contribute to the preservation of this vital resource and reduce the strain on local water supplies.

However, the environmental impact of PHEs extends beyond operational efficiency. The manufacturing process of these heat exchangers involves the use of materials such as stainless steel, titanium, or other alloys. The extraction and processing of these materials have their own environmental implications, including energy consumption, emissions, and potential habitat disruption. Additionally, the production of specialized gaskets and seals used in PHEs may involve synthetic materials with varying degrees of environmental impact.

Maintenance and cleaning of PHEs also present environmental considerations. While these processes are essential for ensuring food safety and maintaining efficiency, they often require the use of chemical cleaning agents. The disposal of these chemicals and the wastewater generated during cleaning cycles must be carefully managed to prevent environmental contamination. Some food processors have adopted more environmentally friendly cleaning methods, such as enzyme-based solutions, to mitigate this impact.

At the end of their lifecycle, the disposal or recycling of PHEs poses another environmental challenge. While many of the materials used in PHEs are recyclable, the process of separating and recycling components can be energy-intensive. Proper disposal protocols are crucial to prevent the release of potentially harmful materials into the environment.

Despite these challenges, the overall environmental impact of PHEs in the food industry is generally positive when compared to alternative heat exchange technologies. Their superior efficiency in energy and water use often outweighs the environmental costs associated with their production and maintenance. As the food industry continues to prioritize sustainability, ongoing research and development in PHE technology are focused on further improving their environmental performance, exploring more sustainable materials, and enhancing their recyclability.

One of the primary environmental benefits of PHEs in the food industry is their contribution to energy conservation. These devices are highly efficient in heat transfer, allowing for the recovery and reuse of thermal energy that would otherwise be wasted. This efficiency translates to reduced energy consumption in heating and cooling processes, thereby lowering the overall carbon footprint of food production facilities. Studies have shown that PHEs can achieve energy savings of up to 30% compared to traditional heat exchange methods, significantly reducing greenhouse gas emissions associated with energy production.

Water conservation is another area where PHEs demonstrate positive environmental impact. Their design allows for effective heat transfer with minimal water usage, particularly in closed-loop systems. This is especially crucial in regions facing water scarcity, where the food industry's water consumption is a growing concern. By optimizing water use in processing operations, PHEs contribute to the preservation of this vital resource and reduce the strain on local water supplies.

However, the environmental impact of PHEs extends beyond operational efficiency. The manufacturing process of these heat exchangers involves the use of materials such as stainless steel, titanium, or other alloys. The extraction and processing of these materials have their own environmental implications, including energy consumption, emissions, and potential habitat disruption. Additionally, the production of specialized gaskets and seals used in PHEs may involve synthetic materials with varying degrees of environmental impact.

Maintenance and cleaning of PHEs also present environmental considerations. While these processes are essential for ensuring food safety and maintaining efficiency, they often require the use of chemical cleaning agents. The disposal of these chemicals and the wastewater generated during cleaning cycles must be carefully managed to prevent environmental contamination. Some food processors have adopted more environmentally friendly cleaning methods, such as enzyme-based solutions, to mitigate this impact.

At the end of their lifecycle, the disposal or recycling of PHEs poses another environmental challenge. While many of the materials used in PHEs are recyclable, the process of separating and recycling components can be energy-intensive. Proper disposal protocols are crucial to prevent the release of potentially harmful materials into the environment.

Despite these challenges, the overall environmental impact of PHEs in the food industry is generally positive when compared to alternative heat exchange technologies. Their superior efficiency in energy and water use often outweighs the environmental costs associated with their production and maintenance. As the food industry continues to prioritize sustainability, ongoing research and development in PHE technology are focused on further improving their environmental performance, exploring more sustainable materials, and enhancing their recyclability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!