Plate Heat Exchanger's Role in Sustainable Packaging Manufacturing

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE in Packaging Evolution

The evolution of plate heat exchangers (PHEs) in packaging manufacturing represents a significant shift towards more sustainable and efficient production processes. Initially developed for the food and beverage industry, PHEs have found their way into various aspects of packaging production, revolutionizing thermal management and energy efficiency.

In the early stages of packaging manufacturing, traditional shell-and-tube heat exchangers were the norm. However, as the industry faced increasing pressure to reduce energy consumption and improve product quality, PHEs emerged as a superior alternative. Their compact design, high heat transfer efficiency, and ability to handle a wide range of temperatures and pressures made them ideal for the diverse needs of packaging production.

The adoption of PHEs in packaging manufacturing began in the 1980s, primarily in the production of plastic packaging materials. As the technology matured, its application expanded to other areas such as paper and cardboard packaging, as well as metal container production. This expansion was driven by the growing demand for more sustainable packaging solutions and the need to optimize production processes.

One of the key milestones in the evolution of PHEs in packaging was the development of specialized plate designs tailored to specific packaging materials and processes. For instance, wide-gap plates were introduced to handle viscous fluids commonly used in adhesive production for packaging, while asymmetric plates were developed to improve heat transfer in processes involving phase changes, such as polymer crystallization.

The integration of PHEs into packaging manufacturing lines led to significant improvements in product quality and consistency. By providing precise temperature control during critical stages of production, such as extrusion, lamination, and coating, PHEs enabled manufacturers to achieve tighter tolerances and reduce waste. This not only improved the overall quality of packaging products but also contributed to sustainability efforts by minimizing material waste.

As environmental concerns gained prominence, the role of PHEs in sustainable packaging manufacturing became even more critical. Their ability to recover and reuse waste heat from various production processes aligned perfectly with the industry's push towards circular economy principles. This led to the development of more advanced PHE systems, including multi-stage heat recovery units and integrated cooling-heating networks, which further optimized energy usage in packaging plants.

The most recent developments in PHE technology for packaging manufacturing focus on digitalization and smart manufacturing concepts. The integration of sensors and data analytics capabilities into PHE systems allows for real-time monitoring and optimization of heat transfer processes. This not only enhances energy efficiency but also enables predictive maintenance, reducing downtime and extending the lifespan of equipment.

In the early stages of packaging manufacturing, traditional shell-and-tube heat exchangers were the norm. However, as the industry faced increasing pressure to reduce energy consumption and improve product quality, PHEs emerged as a superior alternative. Their compact design, high heat transfer efficiency, and ability to handle a wide range of temperatures and pressures made them ideal for the diverse needs of packaging production.

The adoption of PHEs in packaging manufacturing began in the 1980s, primarily in the production of plastic packaging materials. As the technology matured, its application expanded to other areas such as paper and cardboard packaging, as well as metal container production. This expansion was driven by the growing demand for more sustainable packaging solutions and the need to optimize production processes.

One of the key milestones in the evolution of PHEs in packaging was the development of specialized plate designs tailored to specific packaging materials and processes. For instance, wide-gap plates were introduced to handle viscous fluids commonly used in adhesive production for packaging, while asymmetric plates were developed to improve heat transfer in processes involving phase changes, such as polymer crystallization.

The integration of PHEs into packaging manufacturing lines led to significant improvements in product quality and consistency. By providing precise temperature control during critical stages of production, such as extrusion, lamination, and coating, PHEs enabled manufacturers to achieve tighter tolerances and reduce waste. This not only improved the overall quality of packaging products but also contributed to sustainability efforts by minimizing material waste.

As environmental concerns gained prominence, the role of PHEs in sustainable packaging manufacturing became even more critical. Their ability to recover and reuse waste heat from various production processes aligned perfectly with the industry's push towards circular economy principles. This led to the development of more advanced PHE systems, including multi-stage heat recovery units and integrated cooling-heating networks, which further optimized energy usage in packaging plants.

The most recent developments in PHE technology for packaging manufacturing focus on digitalization and smart manufacturing concepts. The integration of sensors and data analytics capabilities into PHE systems allows for real-time monitoring and optimization of heat transfer processes. This not only enhances energy efficiency but also enables predictive maintenance, reducing downtime and extending the lifespan of equipment.

Sustainable Packaging Demand

The demand for sustainable packaging has seen a significant surge in recent years, driven by increasing environmental awareness, regulatory pressures, and changing consumer preferences. This trend has profound implications for the packaging manufacturing industry, particularly in the context of plate heat exchangers' role in sustainable production processes.

Consumer awareness of environmental issues has reached unprecedented levels, with a growing number of customers actively seeking eco-friendly packaging options. This shift in consumer behavior has compelled companies across various sectors to reassess their packaging strategies and invest in sustainable alternatives. As a result, the market for sustainable packaging is experiencing robust growth, with projections indicating continued expansion in the coming years.

Regulatory bodies worldwide are implementing stricter environmental regulations, further propelling the demand for sustainable packaging solutions. Governments are introducing policies aimed at reducing plastic waste, promoting recycling, and encouraging the use of biodegradable materials. These regulatory changes are forcing packaging manufacturers to adapt their production processes and explore innovative technologies to meet compliance requirements.

The food and beverage industry, in particular, has emerged as a key driver of sustainable packaging demand. With consumers increasingly concerned about the environmental impact of their food choices, companies in this sector are under pressure to adopt eco-friendly packaging solutions. This has led to a growing interest in materials such as biodegradable plastics, recycled paper, and compostable packaging alternatives.

E-commerce has also played a significant role in shaping the sustainable packaging landscape. The rapid growth of online retail has highlighted the need for packaging solutions that are not only protective but also environmentally responsible. This has sparked innovation in areas such as right-sized packaging, recyclable mailers, and reusable shipping containers.

The healthcare and pharmaceutical industries are likewise contributing to the demand for sustainable packaging. With increasing focus on reducing medical waste and improving the environmental footprint of healthcare products, there is a growing need for sustainable packaging solutions that meet stringent safety and regulatory requirements.

In response to these market demands, packaging manufacturers are investing in research and development to create innovative, sustainable packaging solutions. This includes exploring new materials, optimizing production processes, and implementing advanced technologies to reduce energy consumption and waste generation. Plate heat exchangers play a crucial role in this context, offering opportunities for energy-efficient heating and cooling processes in packaging production.

As the demand for sustainable packaging continues to grow, manufacturers are faced with the challenge of balancing environmental considerations with performance, cost-effectiveness, and scalability. This has led to increased collaboration between packaging companies, material suppliers, and technology providers to develop holistic solutions that address the complex requirements of sustainable packaging production.

Consumer awareness of environmental issues has reached unprecedented levels, with a growing number of customers actively seeking eco-friendly packaging options. This shift in consumer behavior has compelled companies across various sectors to reassess their packaging strategies and invest in sustainable alternatives. As a result, the market for sustainable packaging is experiencing robust growth, with projections indicating continued expansion in the coming years.

Regulatory bodies worldwide are implementing stricter environmental regulations, further propelling the demand for sustainable packaging solutions. Governments are introducing policies aimed at reducing plastic waste, promoting recycling, and encouraging the use of biodegradable materials. These regulatory changes are forcing packaging manufacturers to adapt their production processes and explore innovative technologies to meet compliance requirements.

The food and beverage industry, in particular, has emerged as a key driver of sustainable packaging demand. With consumers increasingly concerned about the environmental impact of their food choices, companies in this sector are under pressure to adopt eco-friendly packaging solutions. This has led to a growing interest in materials such as biodegradable plastics, recycled paper, and compostable packaging alternatives.

E-commerce has also played a significant role in shaping the sustainable packaging landscape. The rapid growth of online retail has highlighted the need for packaging solutions that are not only protective but also environmentally responsible. This has sparked innovation in areas such as right-sized packaging, recyclable mailers, and reusable shipping containers.

The healthcare and pharmaceutical industries are likewise contributing to the demand for sustainable packaging. With increasing focus on reducing medical waste and improving the environmental footprint of healthcare products, there is a growing need for sustainable packaging solutions that meet stringent safety and regulatory requirements.

In response to these market demands, packaging manufacturers are investing in research and development to create innovative, sustainable packaging solutions. This includes exploring new materials, optimizing production processes, and implementing advanced technologies to reduce energy consumption and waste generation. Plate heat exchangers play a crucial role in this context, offering opportunities for energy-efficient heating and cooling processes in packaging production.

As the demand for sustainable packaging continues to grow, manufacturers are faced with the challenge of balancing environmental considerations with performance, cost-effectiveness, and scalability. This has led to increased collaboration between packaging companies, material suppliers, and technology providers to develop holistic solutions that address the complex requirements of sustainable packaging production.

PHE Challenges in Packaging

Plate Heat Exchangers (PHEs) play a crucial role in sustainable packaging manufacturing, but they face several challenges in this industry. One of the primary issues is fouling, which occurs when deposits accumulate on heat transfer surfaces, reducing efficiency and increasing maintenance requirements. In packaging applications, PHEs often handle fluids with high particulate content or viscous materials, exacerbating the fouling problem.

Another significant challenge is the need for precise temperature control in packaging processes. Many packaging materials, such as plastics and adhesives, require specific temperature ranges for optimal performance. PHEs must maintain consistent temperatures across their plates, which can be difficult when dealing with varying flow rates and fluid properties common in packaging manufacturing.

Corrosion is also a major concern, particularly when PHEs are used with aggressive chemicals or cleaning agents in the packaging industry. The thin plates and gaskets in PHEs are susceptible to chemical attack, potentially leading to leaks or contamination of the product stream. This necessitates careful material selection and regular inspections to ensure integrity.

The high-pressure requirements of some packaging processes pose another challenge for PHEs. While they can handle moderate pressures, extreme pressure differentials can cause plate deformation or gasket failure. This limits their application in certain high-pressure packaging operations, requiring alternative heat exchange solutions or reinforced PHE designs.

Energy efficiency is a critical factor in sustainable packaging manufacturing, and PHEs must continually improve their performance to meet increasingly stringent environmental standards. Balancing heat transfer efficiency with pressure drop across the exchanger remains an ongoing challenge, as does optimizing plate designs for specific packaging applications.

Cleaning and maintenance of PHEs in packaging environments present additional hurdles. The need for frequent cleaning to prevent fouling must be balanced against production downtime. Developing effective cleaning-in-place (CIP) systems that can thoroughly clean PHEs without disassembly is an area of ongoing research and development in the industry.

Lastly, the integration of PHEs into complex packaging production lines poses challenges in terms of control systems and process optimization. Ensuring that PHEs respond quickly to changes in production parameters while maintaining stable operation requires sophisticated control algorithms and sensor technologies. As packaging processes become more automated and data-driven, PHEs must evolve to interface seamlessly with these advanced manufacturing systems.

Another significant challenge is the need for precise temperature control in packaging processes. Many packaging materials, such as plastics and adhesives, require specific temperature ranges for optimal performance. PHEs must maintain consistent temperatures across their plates, which can be difficult when dealing with varying flow rates and fluid properties common in packaging manufacturing.

Corrosion is also a major concern, particularly when PHEs are used with aggressive chemicals or cleaning agents in the packaging industry. The thin plates and gaskets in PHEs are susceptible to chemical attack, potentially leading to leaks or contamination of the product stream. This necessitates careful material selection and regular inspections to ensure integrity.

The high-pressure requirements of some packaging processes pose another challenge for PHEs. While they can handle moderate pressures, extreme pressure differentials can cause plate deformation or gasket failure. This limits their application in certain high-pressure packaging operations, requiring alternative heat exchange solutions or reinforced PHE designs.

Energy efficiency is a critical factor in sustainable packaging manufacturing, and PHEs must continually improve their performance to meet increasingly stringent environmental standards. Balancing heat transfer efficiency with pressure drop across the exchanger remains an ongoing challenge, as does optimizing plate designs for specific packaging applications.

Cleaning and maintenance of PHEs in packaging environments present additional hurdles. The need for frequent cleaning to prevent fouling must be balanced against production downtime. Developing effective cleaning-in-place (CIP) systems that can thoroughly clean PHEs without disassembly is an area of ongoing research and development in the industry.

Lastly, the integration of PHEs into complex packaging production lines poses challenges in terms of control systems and process optimization. Ensuring that PHEs respond quickly to changes in production parameters while maintaining stable operation requires sophisticated control algorithms and sensor technologies. As packaging processes become more automated and data-driven, PHEs must evolve to interface seamlessly with these advanced manufacturing systems.

Current PHE Solutions

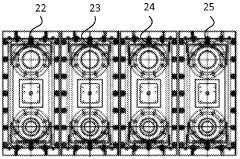

01 Improved plate design for heat exchangers

Advanced plate designs enhance heat transfer efficiency and fluid distribution. These designs may include optimized corrugation patterns, innovative flow channel geometries, or specialized surface treatments to improve thermal performance and reduce fouling.- Improved plate design for heat exchangers: Advanced plate designs are being developed to enhance the efficiency of heat exchangers. These designs focus on optimizing flow distribution, reducing pressure drop, and increasing heat transfer rates. Innovations include specialized corrugation patterns, strategic placement of flow channels, and improved plate geometries to maximize surface area for heat exchange.

- Novel sealing mechanisms for plate heat exchangers: New sealing technologies are being implemented to prevent leakage and improve the overall performance of plate heat exchangers. These innovations include advanced gasket materials, improved sealing techniques, and novel plate edge designs. The focus is on enhancing durability, reducing maintenance requirements, and ensuring reliable operation under various operating conditions.

- Integration of smart technologies in plate heat exchangers: The incorporation of smart technologies is revolutionizing plate heat exchanger design and operation. This includes the integration of sensors for real-time monitoring, advanced control systems for optimized performance, and predictive maintenance capabilities. These innovations aim to improve energy efficiency, reduce downtime, and enhance overall system reliability.

- Modular and customizable plate heat exchanger designs: Manufacturers are developing modular and customizable plate heat exchanger designs to meet diverse industrial needs. These designs allow for easy scaling, quick assembly, and flexibility in application. The focus is on creating versatile solutions that can be tailored to specific heat transfer requirements across various industries.

- Enhanced materials for plate heat exchangers: Research is ongoing to develop and implement advanced materials for plate heat exchangers. This includes the use of corrosion-resistant alloys, high-performance polymers, and composite materials. The goal is to improve durability, extend service life, and enable operation in more demanding environments while maintaining or improving heat transfer efficiency.

02 Sealing and gasket innovations

Novel sealing and gasket technologies improve leak prevention and extend the operational life of plate heat exchangers. These innovations may include advanced materials, unique gasket profiles, or integrated sealing systems that enhance reliability under various operating conditions.Expand Specific Solutions03 Modular and customizable designs

Modular plate heat exchanger designs allow for easy customization, maintenance, and scalability. These systems may feature interchangeable components, adjustable plate configurations, or adaptable frame structures to accommodate various heat transfer requirements and installation constraints.Expand Specific Solutions04 Enhanced flow distribution mechanisms

Innovative flow distribution mechanisms improve fluid circulation and heat transfer efficiency within plate heat exchangers. These may include specialized inlet and outlet designs, internal baffles, or flow guides that optimize fluid dynamics and reduce pressure drop across the exchanger.Expand Specific Solutions05 Integration of smart technologies

Incorporation of smart technologies and sensors enables real-time monitoring, predictive maintenance, and performance optimization of plate heat exchangers. These advancements may include integrated temperature and pressure sensors, data analytics capabilities, or remote monitoring systems for improved operational efficiency.Expand Specific Solutions

Key PHE Manufacturers

The plate heat exchanger market in sustainable packaging manufacturing is in a growth phase, driven by increasing demand for energy-efficient and environmentally friendly solutions. The global market size is expanding, with key players like Alfa Laval, Vahterus, and SWEP leading technological advancements. These companies are focusing on developing innovative designs to improve heat transfer efficiency and reduce environmental impact. The technology is maturing rapidly, with established firms such as Haldor Topsøe and SPX FLOW contributing to its evolution. Emerging players like LHE Co. and Donghwa Entec are also making significant strides, particularly in specialized applications for the packaging industry.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchangers specifically designed for sustainable packaging manufacturing. Their technology utilizes a unique corrugated plate design that maximizes heat transfer efficiency while minimizing fouling[1]. The company's AlfaNova fusion-bonded plate heat exchangers, made of 100% stainless steel, offer superior corrosion resistance and can withstand high temperatures and pressures[2]. These exchangers are particularly effective in recovering waste heat from packaging processes, reducing energy consumption by up to 30%[3]. Alfa Laval's plate heat exchangers also incorporate features like distribution areas that ensure even flow distribution, contributing to optimal heat transfer and reduced environmental impact in packaging production[4].

Strengths: High efficiency, corrosion resistance, and ability to withstand extreme conditions. Weaknesses: Higher initial cost compared to traditional heat exchangers, may require more frequent maintenance due to complex design.

Vahterus Oy

Technical Solution: Vahterus has pioneered the Plate & Shell heat exchanger technology, which combines the benefits of plate and shell-and-tube heat exchangers. This innovation is particularly relevant for sustainable packaging manufacturing. Their exchangers feature a fully welded plate pack enclosed in a pressure vessel, allowing for high-pressure applications up to 200 bar[5]. The design enables efficient heat recovery in packaging processes, with the ability to handle multiple fluids simultaneously. Vahterus' technology has shown to reduce the heat transfer area by up to 85% compared to traditional shell-and-tube exchangers, significantly decreasing the equipment footprint in packaging facilities[6]. The company's exchangers also boast a low hold-up volume, which is crucial for reducing waste and improving process efficiency in sustainable packaging production[7].

Strengths: Compact design, high-pressure capability, and multi-fluid handling. Weaknesses: Limited flexibility for expansion or modification after installation, potentially higher manufacturing costs.

PHE Innovations Analysis

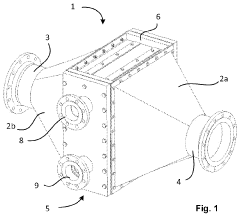

Plate heat exchanger

PatentActiveEP2452149A2

Innovation

- The plate heat exchanger is constructed using plastic plates with connections on the front and end panels, allowing for simple assembly and production by gluing or welding, eliminating the need for seals and enabling the use of disposable units. The plates are designed to be structurally identical and can be produced using a single mold, with flow converters and a collecting space for condensate management, and are made from sterilizable materials for easy sterilization.

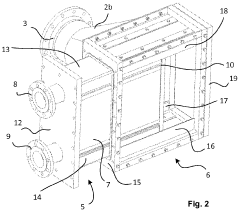

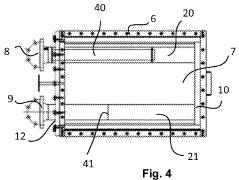

Plate heat exchanger arrangement, use of it in exhaust gas heat recovery and method for recovering heat from exhaust gas

PatentWO2023118653A1

Innovation

- A compact plate heat exchanger arrangement with a removable plate pack module and frame structure, featuring elongated rectangular heat exchange plates, which allows for easy maintenance and scalability, and the ability to arrange multiple modules within a flow channel structure for efficient exhaust gas heat recovery.

Energy Efficiency Impact

Plate heat exchangers play a crucial role in enhancing energy efficiency within sustainable packaging manufacturing processes. These devices facilitate efficient heat transfer between two fluids, significantly reducing energy consumption and operational costs. In the context of packaging production, plate heat exchangers contribute to energy savings in various stages, from material processing to product finishing.

One of the primary applications of plate heat exchangers in packaging manufacturing is in the cooling and heating of process fluids. By recovering waste heat from one stream and transferring it to another, these exchangers minimize the need for external heating or cooling sources. This heat recovery process can lead to substantial energy savings, often ranging from 30% to 50% in typical industrial applications.

In the production of plastic packaging materials, plate heat exchangers are instrumental in maintaining precise temperature control during extrusion and molding processes. By efficiently regulating the temperature of cooling water or oil, these exchangers ensure consistent product quality while reducing energy expenditure. The rapid heat transfer capabilities of plate heat exchangers also contribute to faster production cycles, further enhancing overall energy efficiency.

For paper-based packaging manufacturing, plate heat exchangers are employed in the drying section of paper machines. By recovering heat from exhaust steam and utilizing it to preheat incoming air or water, these systems significantly reduce the steam consumption required for drying. This application can result in energy savings of up to 20% in the drying process, which is typically one of the most energy-intensive stages in paper production.

The compact design of plate heat exchangers offers additional energy efficiency benefits. Their smaller footprint compared to traditional shell-and-tube heat exchangers means reduced pumping power requirements and lower heat losses to the surrounding environment. This compact nature also allows for easier integration into existing production lines, facilitating energy efficiency upgrades without major infrastructure changes.

Furthermore, the modular nature of plate heat exchangers enables easy scalability and maintenance. As production demands change, additional plates can be added or removed to optimize heat transfer efficiency. This flexibility ensures that the heat exchange system operates at peak efficiency regardless of production volume, avoiding energy waste associated with oversized or undersized equipment.

In conclusion, the implementation of plate heat exchangers in sustainable packaging manufacturing processes yields significant energy efficiency improvements. By facilitating effective heat recovery, precise temperature control, and compact system design, these devices contribute to reduced energy consumption, lower operational costs, and a smaller carbon footprint for packaging producers. As the industry continues to prioritize sustainability, the role of plate heat exchangers in energy-efficient manufacturing processes is likely to expand further.

One of the primary applications of plate heat exchangers in packaging manufacturing is in the cooling and heating of process fluids. By recovering waste heat from one stream and transferring it to another, these exchangers minimize the need for external heating or cooling sources. This heat recovery process can lead to substantial energy savings, often ranging from 30% to 50% in typical industrial applications.

In the production of plastic packaging materials, plate heat exchangers are instrumental in maintaining precise temperature control during extrusion and molding processes. By efficiently regulating the temperature of cooling water or oil, these exchangers ensure consistent product quality while reducing energy expenditure. The rapid heat transfer capabilities of plate heat exchangers also contribute to faster production cycles, further enhancing overall energy efficiency.

For paper-based packaging manufacturing, plate heat exchangers are employed in the drying section of paper machines. By recovering heat from exhaust steam and utilizing it to preheat incoming air or water, these systems significantly reduce the steam consumption required for drying. This application can result in energy savings of up to 20% in the drying process, which is typically one of the most energy-intensive stages in paper production.

The compact design of plate heat exchangers offers additional energy efficiency benefits. Their smaller footprint compared to traditional shell-and-tube heat exchangers means reduced pumping power requirements and lower heat losses to the surrounding environment. This compact nature also allows for easier integration into existing production lines, facilitating energy efficiency upgrades without major infrastructure changes.

Furthermore, the modular nature of plate heat exchangers enables easy scalability and maintenance. As production demands change, additional plates can be added or removed to optimize heat transfer efficiency. This flexibility ensures that the heat exchange system operates at peak efficiency regardless of production volume, avoiding energy waste associated with oversized or undersized equipment.

In conclusion, the implementation of plate heat exchangers in sustainable packaging manufacturing processes yields significant energy efficiency improvements. By facilitating effective heat recovery, precise temperature control, and compact system design, these devices contribute to reduced energy consumption, lower operational costs, and a smaller carbon footprint for packaging producers. As the industry continues to prioritize sustainability, the role of plate heat exchangers in energy-efficient manufacturing processes is likely to expand further.

Circular Economy Integration

The integration of plate heat exchangers in sustainable packaging manufacturing aligns closely with circular economy principles, offering significant potential for resource efficiency and waste reduction. By facilitating heat recovery and transfer processes, these devices play a crucial role in optimizing energy use throughout the packaging production cycle. This integration supports the circular economy's core tenets of reducing resource consumption, reusing materials, and recycling waste.

In the context of packaging manufacturing, plate heat exchangers contribute to circular economy goals by enabling the recovery of thermal energy from various processes. This recovered energy can be redirected to other stages of production, significantly reducing overall energy consumption and minimizing waste heat. For instance, heat generated during the cooling of newly formed plastic packaging can be captured and utilized in preheating raw materials or maintaining optimal temperatures in other production areas.

Furthermore, the efficiency of plate heat exchangers in temperature control allows for more precise manufacturing processes, potentially reducing material waste and improving product quality. This precision contributes to the production of more durable and recyclable packaging solutions, aligning with circular economy objectives of extending product lifecycles and facilitating easier recycling.

The compact design and modularity of plate heat exchangers also support circular economy principles by allowing for easier maintenance, repair, and replacement of individual components. This characteristic extends the operational life of the equipment and reduces the need for complete system replacements, thereby minimizing waste and resource consumption associated with manufacturing new equipment.

In addition, the use of plate heat exchangers can facilitate the integration of renewable energy sources into packaging manufacturing processes. By efficiently managing heat transfer, these devices can help balance the intermittent nature of renewable energy inputs, supporting a transition towards more sustainable energy use in industrial settings.

The circular economy integration of plate heat exchangers extends beyond their immediate application in packaging manufacturing. The principles applied in this context can be transferred to other industries, creating a ripple effect of sustainable practices across various sectors. This cross-industry applicability amplifies the impact of circular economy initiatives, fostering a broader shift towards more sustainable industrial practices.

In the context of packaging manufacturing, plate heat exchangers contribute to circular economy goals by enabling the recovery of thermal energy from various processes. This recovered energy can be redirected to other stages of production, significantly reducing overall energy consumption and minimizing waste heat. For instance, heat generated during the cooling of newly formed plastic packaging can be captured and utilized in preheating raw materials or maintaining optimal temperatures in other production areas.

Furthermore, the efficiency of plate heat exchangers in temperature control allows for more precise manufacturing processes, potentially reducing material waste and improving product quality. This precision contributes to the production of more durable and recyclable packaging solutions, aligning with circular economy objectives of extending product lifecycles and facilitating easier recycling.

The compact design and modularity of plate heat exchangers also support circular economy principles by allowing for easier maintenance, repair, and replacement of individual components. This characteristic extends the operational life of the equipment and reduces the need for complete system replacements, thereby minimizing waste and resource consumption associated with manufacturing new equipment.

In addition, the use of plate heat exchangers can facilitate the integration of renewable energy sources into packaging manufacturing processes. By efficiently managing heat transfer, these devices can help balance the intermittent nature of renewable energy inputs, supporting a transition towards more sustainable energy use in industrial settings.

The circular economy integration of plate heat exchangers extends beyond their immediate application in packaging manufacturing. The principles applied in this context can be transferred to other industries, creating a ripple effect of sustainable practices across various sectors. This cross-industry applicability amplifies the impact of circular economy initiatives, fostering a broader shift towards more sustainable industrial practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!