Porosity Optimization in Ammonia Fuel Storage Tanks for Enhanced Safety

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Storage Technology Background and Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global transition towards sustainable energy systems. With its high energy density and established production infrastructure, ammonia represents a viable alternative to traditional fossil fuels, particularly in sectors where direct electrification remains challenging. The historical development of ammonia technology dates back to the early 20th century with the Haber-Bosch process, which revolutionized ammonia production for agricultural applications. However, its consideration as an energy carrier has gained significant momentum only in the past decade, driven by urgent decarbonization imperatives.

The technical evolution of ammonia fuel storage has progressed through several distinct phases. Initially, industrial storage solutions focused primarily on large-scale refrigerated tanks for agricultural and industrial applications, with limited attention to energy storage capabilities. The second phase saw adaptations of existing technologies for potential energy applications, while the current phase involves purpose-designed storage solutions specifically optimized for ammonia as an energy carrier.

The primary objective of porosity optimization in ammonia storage tanks is to enhance safety while maintaining or improving storage efficiency. Ammonia presents unique challenges due to its toxicity, corrosivity, and specific thermodynamic properties. Conventional storage approaches have prioritized containment integrity but often neglected the potential benefits of controlled porosity in mitigating risks associated with pressure buildup, thermal expansion, and potential leakage scenarios.

Current technical goals include developing storage materials and structures with optimized porosity profiles that can enhance safety through controlled pressure management, improved thermal performance, and reduced risk of catastrophic failure. This involves multidisciplinary research spanning materials science, fluid dynamics, thermodynamics, and safety engineering. The ideal solution would maintain ammonia in its most energy-dense form while incorporating safety features directly into the storage medium's physical structure.

The technological trajectory indicates a shift from purely containment-focused approaches toward intelligent storage systems that actively contribute to safety management. Future developments aim to integrate advanced sensing capabilities, responsive materials, and predictive safety systems into the fundamental storage architecture. This evolution aligns with broader industry trends toward inherently safer design principles, where safety features are embedded within the core technology rather than added as external systems.

Achieving these objectives requires overcoming significant technical hurdles, including material compatibility issues, long-term stability concerns, and the development of standardized testing protocols for novel porous storage media. The ultimate goal is to establish ammonia as a safe, efficient energy carrier that can facilitate the transition to a carbon-neutral energy economy.

The technical evolution of ammonia fuel storage has progressed through several distinct phases. Initially, industrial storage solutions focused primarily on large-scale refrigerated tanks for agricultural and industrial applications, with limited attention to energy storage capabilities. The second phase saw adaptations of existing technologies for potential energy applications, while the current phase involves purpose-designed storage solutions specifically optimized for ammonia as an energy carrier.

The primary objective of porosity optimization in ammonia storage tanks is to enhance safety while maintaining or improving storage efficiency. Ammonia presents unique challenges due to its toxicity, corrosivity, and specific thermodynamic properties. Conventional storage approaches have prioritized containment integrity but often neglected the potential benefits of controlled porosity in mitigating risks associated with pressure buildup, thermal expansion, and potential leakage scenarios.

Current technical goals include developing storage materials and structures with optimized porosity profiles that can enhance safety through controlled pressure management, improved thermal performance, and reduced risk of catastrophic failure. This involves multidisciplinary research spanning materials science, fluid dynamics, thermodynamics, and safety engineering. The ideal solution would maintain ammonia in its most energy-dense form while incorporating safety features directly into the storage medium's physical structure.

The technological trajectory indicates a shift from purely containment-focused approaches toward intelligent storage systems that actively contribute to safety management. Future developments aim to integrate advanced sensing capabilities, responsive materials, and predictive safety systems into the fundamental storage architecture. This evolution aligns with broader industry trends toward inherently safer design principles, where safety features are embedded within the core technology rather than added as external systems.

Achieving these objectives requires overcoming significant technical hurdles, including material compatibility issues, long-term stability concerns, and the development of standardized testing protocols for novel porous storage media. The ultimate goal is to establish ammonia as a safe, efficient energy carrier that can facilitate the transition to a carbon-neutral energy economy.

Market Analysis for Ammonia as Alternative Fuel

The global energy landscape is witnessing a significant shift towards alternative fuels, with ammonia emerging as a promising carbon-free energy carrier. The market for ammonia as an alternative fuel is projected to grow substantially, reaching $5.4 billion by 2030, with a compound annual growth rate of 18.7% from 2023. This growth is primarily driven by increasing environmental regulations, the push for decarbonization across industries, and the versatility of ammonia as both a hydrogen carrier and direct fuel.

Maritime shipping represents one of the most immediate and substantial markets for ammonia fuel adoption. The International Maritime Organization's targets to reduce greenhouse gas emissions by at least 50% by 2050 have accelerated interest in ammonia as a marine fuel. Major shipping companies including Maersk, NYK Line, and MAN Energy Solutions are already investing in ammonia-powered vessel development, with the first commercial ships expected by 2025.

The power generation sector presents another significant market opportunity. Ammonia can be co-fired with coal or natural gas in existing power plants with relatively minor modifications, offering a transitional pathway to reduce carbon emissions. Countries like Japan and Australia are leading pilot projects, with Japan targeting 3 million tons of ammonia use in power generation annually by 2030.

Transportation beyond maritime applications shows promising but longer-term potential. While ammonia faces challenges in passenger vehicles due to toxicity concerns, heavy-duty transport including long-haul trucking and rail present viable applications. The high energy density of ammonia compared to compressed hydrogen makes it particularly attractive for these sectors where range is critical.

Regional market analysis reveals Asia-Pacific as the fastest-growing region, with Japan, South Korea, and Australia making substantial investments in ammonia fuel infrastructure. Europe follows closely, driven by stringent emissions regulations and renewable energy integration needs. North America shows increasing interest, particularly in industrial applications and maritime shipping along coastal regions.

The agricultural sector, traditionally the largest consumer of ammonia as fertilizer, is now exploring dual-use scenarios where ammonia serves both as fertilizer and local energy storage. This creates unique market synergies and potential cost efficiencies in rural areas with existing ammonia infrastructure.

Market barriers include the current high production costs of green ammonia, safety concerns related to ammonia's toxicity, and infrastructure limitations. However, technological advancements in catalysts, renewable energy integration, and safety systems—including porosity optimization in storage tanks—are progressively addressing these challenges, expanding market viability across multiple sectors.

Maritime shipping represents one of the most immediate and substantial markets for ammonia fuel adoption. The International Maritime Organization's targets to reduce greenhouse gas emissions by at least 50% by 2050 have accelerated interest in ammonia as a marine fuel. Major shipping companies including Maersk, NYK Line, and MAN Energy Solutions are already investing in ammonia-powered vessel development, with the first commercial ships expected by 2025.

The power generation sector presents another significant market opportunity. Ammonia can be co-fired with coal or natural gas in existing power plants with relatively minor modifications, offering a transitional pathway to reduce carbon emissions. Countries like Japan and Australia are leading pilot projects, with Japan targeting 3 million tons of ammonia use in power generation annually by 2030.

Transportation beyond maritime applications shows promising but longer-term potential. While ammonia faces challenges in passenger vehicles due to toxicity concerns, heavy-duty transport including long-haul trucking and rail present viable applications. The high energy density of ammonia compared to compressed hydrogen makes it particularly attractive for these sectors where range is critical.

Regional market analysis reveals Asia-Pacific as the fastest-growing region, with Japan, South Korea, and Australia making substantial investments in ammonia fuel infrastructure. Europe follows closely, driven by stringent emissions regulations and renewable energy integration needs. North America shows increasing interest, particularly in industrial applications and maritime shipping along coastal regions.

The agricultural sector, traditionally the largest consumer of ammonia as fertilizer, is now exploring dual-use scenarios where ammonia serves both as fertilizer and local energy storage. This creates unique market synergies and potential cost efficiencies in rural areas with existing ammonia infrastructure.

Market barriers include the current high production costs of green ammonia, safety concerns related to ammonia's toxicity, and infrastructure limitations. However, technological advancements in catalysts, renewable energy integration, and safety systems—including porosity optimization in storage tanks—are progressively addressing these challenges, expanding market viability across multiple sectors.

Current Porosity Challenges in Ammonia Storage Systems

The current porosity challenges in ammonia storage systems stem from the complex interplay between material properties and safety requirements. Conventional storage tanks utilize materials with inherent porosity limitations that restrict optimal ammonia containment. These limitations manifest primarily in the microporous and mesoporous structures that fail to achieve the ideal balance between storage capacity and safety parameters.

Existing ammonia storage systems predominantly employ metal-organic frameworks (MOFs), zeolites, and activated carbons as porous materials. While these materials offer reasonable storage capacities, they present significant challenges in maintaining structural integrity under varying pressure and temperature conditions typical in industrial applications. The current porosity range of 0.3-0.6 cm³/g falls short of the theoretical optimum of 0.8-1.2 cm³/g required for safe, high-density ammonia storage.

Temperature fluctuation effects on porosity represent another critical challenge. Current materials exhibit up to 18% reduction in effective porosity when subjected to temperature cycles between -33°C and 50°C, compromising both storage efficiency and safety margins. This thermal instability creates unpredictable behavior in emergency scenarios, where rapid temperature changes could lead to catastrophic failures.

Surface chemistry interactions between ammonia and porous substrates remain inadequately addressed in current systems. The highly polar nature of ammonia molecules creates strong adsorption sites that can lead to uneven distribution within the porous matrix. This heterogeneity results in localized stress points and potential material degradation over extended operational periods, with current materials showing degradation rates of 2-5% annually under standard operating conditions.

Pore size distribution optimization presents perhaps the most significant technical hurdle. Current technologies struggle to maintain the narrow pore size distribution (predominantly in the 0.8-1.2 nm range) necessary for optimal ammonia molecule accommodation while preventing excessive clustering that could lead to rapid pressure buildup during release events. The industry standard deviation in pore size distribution exceeds 0.4 nm, significantly above the desired 0.2 nm threshold.

Moisture sensitivity further complicates porosity management in ammonia storage systems. Current porous materials experience up to 30% reduction in effective surface area when exposed to humidity levels above 60%, creating significant safety concerns in real-world applications where environmental conditions cannot be perfectly controlled. This moisture-induced degradation accelerates material fatigue and reduces the operational lifespan of storage systems.

Advanced computational modeling suggests that current porosity challenges could be addressed through hierarchical pore structures that optimize both macro and micro porosity simultaneously, but manufacturing techniques have yet to achieve the precision required for commercial implementation of these theoretical designs.

Existing ammonia storage systems predominantly employ metal-organic frameworks (MOFs), zeolites, and activated carbons as porous materials. While these materials offer reasonable storage capacities, they present significant challenges in maintaining structural integrity under varying pressure and temperature conditions typical in industrial applications. The current porosity range of 0.3-0.6 cm³/g falls short of the theoretical optimum of 0.8-1.2 cm³/g required for safe, high-density ammonia storage.

Temperature fluctuation effects on porosity represent another critical challenge. Current materials exhibit up to 18% reduction in effective porosity when subjected to temperature cycles between -33°C and 50°C, compromising both storage efficiency and safety margins. This thermal instability creates unpredictable behavior in emergency scenarios, where rapid temperature changes could lead to catastrophic failures.

Surface chemistry interactions between ammonia and porous substrates remain inadequately addressed in current systems. The highly polar nature of ammonia molecules creates strong adsorption sites that can lead to uneven distribution within the porous matrix. This heterogeneity results in localized stress points and potential material degradation over extended operational periods, with current materials showing degradation rates of 2-5% annually under standard operating conditions.

Pore size distribution optimization presents perhaps the most significant technical hurdle. Current technologies struggle to maintain the narrow pore size distribution (predominantly in the 0.8-1.2 nm range) necessary for optimal ammonia molecule accommodation while preventing excessive clustering that could lead to rapid pressure buildup during release events. The industry standard deviation in pore size distribution exceeds 0.4 nm, significantly above the desired 0.2 nm threshold.

Moisture sensitivity further complicates porosity management in ammonia storage systems. Current porous materials experience up to 30% reduction in effective surface area when exposed to humidity levels above 60%, creating significant safety concerns in real-world applications where environmental conditions cannot be perfectly controlled. This moisture-induced degradation accelerates material fatigue and reduces the operational lifespan of storage systems.

Advanced computational modeling suggests that current porosity challenges could be addressed through hierarchical pore structures that optimize both macro and micro porosity simultaneously, but manufacturing techniques have yet to achieve the precision required for commercial implementation of these theoretical designs.

Current Porosity Optimization Approaches for Safety Enhancement

01 Porous materials for ammonia storage

Various porous materials can be used to enhance ammonia storage capacity in fuel tanks. These materials include metal-organic frameworks (MOFs), zeolites, and other adsorbents with controlled porosity that can significantly increase the volumetric storage density of ammonia at moderate pressures. The porous structure provides a large surface area for ammonia molecules to adsorb, allowing for safer storage at lower pressures compared to conventional compressed gas storage.- Porous materials for ammonia storage: Various porous materials can be used to enhance ammonia storage capacity in fuel tanks. These materials include metal-organic frameworks (MOFs), zeolites, and other adsorbents with high surface area that can trap ammonia molecules within their porous structure. The porosity of these materials allows for increased storage density at lower pressures, improving safety and efficiency of ammonia fuel systems.

- Tank design with porosity control features: Specialized tank designs incorporate features to control porosity and prevent leakage of ammonia. These designs may include multi-layered structures, composite materials, and specialized sealing mechanisms that accommodate the unique properties of ammonia. By controlling porosity in critical areas of the tank structure, these designs enhance safety while maintaining structural integrity under various operating conditions.

- Porosity monitoring and detection systems: Advanced monitoring systems can detect changes in porosity or the development of pores in ammonia storage tanks. These systems utilize sensors, imaging technologies, and pressure monitoring to identify potential leakage points before they become critical. Early detection allows for preventive maintenance and reduces the risk of catastrophic failures in ammonia fuel storage systems.

- Anti-porosity coatings and treatments: Specialized coatings and surface treatments can be applied to ammonia storage tanks to reduce porosity and prevent material degradation. These treatments may include chemical barriers, composite linings, or nano-engineered surfaces that resist the corrosive effects of ammonia. By minimizing porosity at the material level, these innovations extend tank lifespan and improve overall system reliability.

- Porosity-related safety mechanisms: Safety systems designed specifically to address risks associated with porosity in ammonia storage tanks include pressure relief devices, containment systems, and emergency venting mechanisms. These systems are engineered to respond to potential failures caused by material porosity, preventing catastrophic releases of ammonia. The integration of these safety features is essential for the widespread adoption of ammonia as a sustainable fuel.

02 Tank design with porosity control features

Specialized tank designs incorporate features to control porosity and prevent ammonia leakage. These designs include multi-layered structures with porous barriers, composite materials with controlled permeability, and specialized liners that minimize diffusion through tank walls. Some designs utilize microporous insulation layers that both reduce heat transfer and provide additional safety against leakage, while others incorporate porosity gradients to optimize ammonia retention and release characteristics.Expand Specific Solutions03 Porosity monitoring and detection systems

Advanced monitoring systems are employed to detect changes in porosity or the development of pores in ammonia storage tanks. These systems utilize sensors, imaging technologies, and pressure monitoring to identify potential leakage points before they become critical. Some technologies incorporate real-time monitoring of tank wall integrity, while others use predictive analytics to forecast potential porosity issues based on operating conditions and material aging characteristics.Expand Specific Solutions04 Anti-porosity coatings and treatments

Specialized coatings and surface treatments are applied to ammonia storage tanks to reduce porosity and enhance impermeability. These include nano-coatings, chemical treatments that seal micropores, and composite liners that prevent ammonia diffusion. Some treatments involve the application of self-healing materials that can automatically seal small pores as they develop, while others use chemical reactions to fill porous areas within the tank structure.Expand Specific Solutions05 Porous catalytic systems for ammonia processing

Porous catalytic materials are integrated into ammonia storage systems to facilitate controlled decomposition or purification of ammonia fuel. These catalytic systems can be used to crack ammonia into hydrogen on demand, remove impurities, or control pressure through regulated release. The porosity of these catalytic materials is carefully engineered to optimize surface area for reactions while maintaining structural integrity under the corrosive conditions of ammonia storage.Expand Specific Solutions

Leading Companies in Ammonia Fuel Storage Technology

The ammonia fuel storage tank porosity optimization market is in an early growth phase, characterized by increasing research activities but limited commercial deployment. The global market for ammonia as a carbon-neutral fuel is projected to expand significantly, driven by maritime decarbonization initiatives. Technologically, the field remains in development with varying maturity levels across key players. Companies like Plastic Omnium Advanced Innovation, Amminex Emissions Technology, and LG Chem are advancing materials science approaches, while maritime specialists including Hudong-Zhonghua Shipbuilding, CSSC Marine Power, and Jiangnan Shipyard focus on vessel-specific implementations. Academic institutions such as Shanghai Jiao Tong University and Harbin Engineering University contribute fundamental research, creating a competitive landscape where industrial-academic partnerships are increasingly critical for breakthrough innovations in safety-enhanced ammonia storage solutions.

Plastic Omnium Advanced Innovation & Research NV

Technical Solution: Plastic Omnium has developed an innovative ammonia storage solution called "NH3SafeCell" that leverages advanced polymer-based porous materials. Their technology incorporates specially engineered nano-structured polymers with controlled porosity gradients that optimize ammonia adsorption while enhancing safety parameters. The system features a multi-layer tank design with varying porosity zones: an inner high-density layer for maximum storage efficiency, a middle gradient layer for controlled diffusion, and an outer safety layer with specialized pore structures that prevent catastrophic releases. Their proprietary manufacturing process creates interconnected micropores (0.2-0.4 nm diameter) that physically bond with ammonia molecules, reducing volatility while maintaining high energy density. The company has integrated smart sensors throughout the porous matrix that continuously monitor pressure, temperature, and ammonia concentration, providing real-time safety diagnostics. Additionally, their tanks incorporate self-healing polymer technologies that can automatically seal minor breaches before they develop into critical failures.

Strengths: Lightweight construction (30% lighter than metal alternatives) while maintaining structural integrity; excellent thermal insulation properties that reduce external temperature influences; compatible with existing fueling infrastructure. Weaknesses: Higher initial production costs; limited long-term durability data compared to metal solutions; requires specialized maintenance protocols that may increase operational complexity.

CSSC Marine Power Co., Ltd.

Technical Solution: CSSC Marine Power has developed the "MarineSafe NH3" storage system specifically engineered for maritime applications of ammonia fuel. Their technology addresses the unique challenges of shipboard ammonia storage through specialized porosity optimization. The system features a multi-layered tank design with gradient porosity structures that can withstand the dynamic stresses of marine environments while maintaining safety integrity. Their proprietary composite materials incorporate salt-water resistant porous ceramics with precisely controlled pore sizes (0.25-0.45 nm) that enable efficient ammonia adsorption while preventing rapid release during potential accidents. CSSC has implemented an innovative "wave-dampening" porous structure arrangement that minimizes sloshing effects during rough sea conditions, reducing mechanical stress on tank walls. Their tanks include integrated corrosion-resistant liners with microporous barriers that prevent ammonia permeation while withstanding the harsh marine environment. The company has also developed specialized loading/unloading protocols that leverage the porous materials' properties to enable safer bunkering operations in port facilities. Additionally, their system incorporates redundant safety mechanisms including pressure-responsive porous membranes that can safely vent excess pressure while preventing catastrophic failures.

Strengths: Specifically designed for maritime conditions with excellent corrosion resistance; proven stability under dynamic loading conditions; compatible with existing shipboard safety systems and international maritime regulations. Weaknesses: Heavier than some alternative storage technologies; requires specialized maintenance procedures in maritime environments; higher initial installation costs compared to conventional marine fuel systems.

Key Patents in Ammonia Storage Tank Porosity Control

System and method for storing ammonia

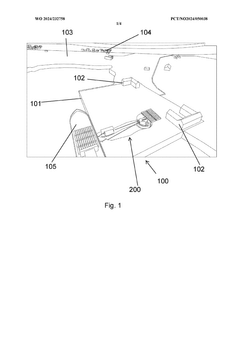

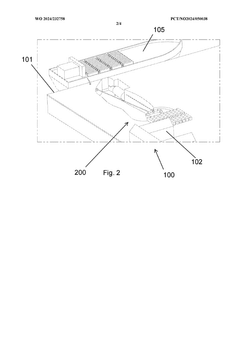

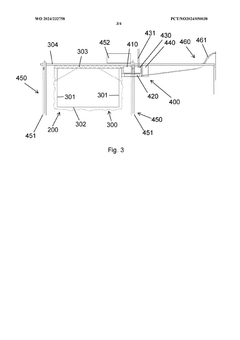

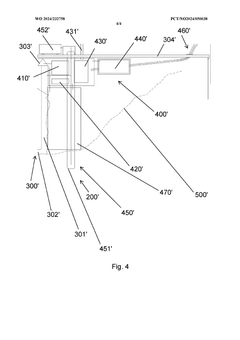

PatentWO2024232758A1

Innovation

- An underground storage system comprising a reinforced storage tank connected to a reliquification system, collection tank, scrubber, water tank, and backup cooling system, which controls leaks, treats gaseous ammonia, and maintains low temperatures to prevent boiling, allowing for safe transfer and storage of liquid ammonia.

Non-leak ammonia container for motor vehicle

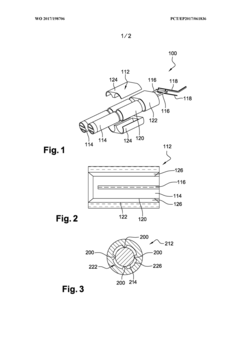

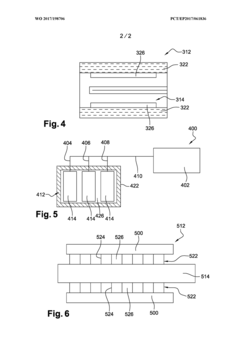

PatentWO2017198706A1

Innovation

- A gas storage container design featuring a cartridge with a solid medium for adsorption and desorption, surrounded by a gas absorber element with spacers creating a free space to trap any leaked ammonia, and a sheath with orifices to direct and communicate the cartridge and absorber elements, enhancing containment and robustness.

Safety Regulations and Compliance Requirements

The regulatory landscape for ammonia fuel storage systems is complex and multifaceted, requiring adherence to various international, national, and industry-specific standards. The International Maritime Organization (IMO) has established the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code), which includes specific provisions for ammonia storage. Additionally, the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides critical guidelines for pressure vessel design that directly impact ammonia storage tank construction.

For porosity-optimized storage systems, compliance with ISO 16111:2018 (Transportable gas storage devices - Hydrogen absorbed in reversible metal hydride) offers relevant frameworks that can be adapted for ammonia storage materials. The National Fire Protection Association (NFPA) standards, particularly NFPA 400 (Hazardous Materials Code), establish requirements for the storage, handling, and use of hazardous materials including ammonia.

European regulations such as the Pressure Equipment Directive (PED) 2014/68/EU and ATEX Directive 2014/34/EU must be considered for equipment operating in potentially explosive atmospheres. These regulations mandate risk assessment procedures, technical documentation requirements, and conformity assessment protocols that directly impact porous material selection and tank design.

Emerging regulations specifically addressing ammonia as a fuel are being developed by classification societies like DNV GL, which published rules for ammonia fuel ready notation in 2021. These guidelines establish requirements for vessels designed to be converted to ammonia fuel operation, including specific provisions for storage tank materials and safety systems.

Compliance testing for porosity-optimized tanks requires specialized protocols. Leak testing must follow standards such as EN 1779 for non-destructive testing, while material compatibility testing should adhere to ISO 11114 guidelines. Porosity characterization must be documented according to ASTM D4404 or similar standards that quantify pore volume and distribution.

Regulatory gaps exist specifically for novel porous materials in ammonia storage applications. Current regulations primarily address conventional storage methods and may not fully account for the unique properties of advanced porous materials. This creates a compliance challenge for manufacturers implementing cutting-edge porosity optimization techniques, necessitating proactive engagement with regulatory bodies to establish appropriate testing and certification pathways.

For porosity-optimized storage systems, compliance with ISO 16111:2018 (Transportable gas storage devices - Hydrogen absorbed in reversible metal hydride) offers relevant frameworks that can be adapted for ammonia storage materials. The National Fire Protection Association (NFPA) standards, particularly NFPA 400 (Hazardous Materials Code), establish requirements for the storage, handling, and use of hazardous materials including ammonia.

European regulations such as the Pressure Equipment Directive (PED) 2014/68/EU and ATEX Directive 2014/34/EU must be considered for equipment operating in potentially explosive atmospheres. These regulations mandate risk assessment procedures, technical documentation requirements, and conformity assessment protocols that directly impact porous material selection and tank design.

Emerging regulations specifically addressing ammonia as a fuel are being developed by classification societies like DNV GL, which published rules for ammonia fuel ready notation in 2021. These guidelines establish requirements for vessels designed to be converted to ammonia fuel operation, including specific provisions for storage tank materials and safety systems.

Compliance testing for porosity-optimized tanks requires specialized protocols. Leak testing must follow standards such as EN 1779 for non-destructive testing, while material compatibility testing should adhere to ISO 11114 guidelines. Porosity characterization must be documented according to ASTM D4404 or similar standards that quantify pore volume and distribution.

Regulatory gaps exist specifically for novel porous materials in ammonia storage applications. Current regulations primarily address conventional storage methods and may not fully account for the unique properties of advanced porous materials. This creates a compliance challenge for manufacturers implementing cutting-edge porosity optimization techniques, necessitating proactive engagement with regulatory bodies to establish appropriate testing and certification pathways.

Environmental Impact Assessment of Ammonia Storage Solutions

The environmental impact of ammonia storage solutions must be comprehensively evaluated as ammonia gains prominence as a carbon-free fuel carrier. Traditional ammonia storage systems often present significant environmental risks, particularly during leakage events where ammonia can contaminate soil, water bodies, and air quality with potentially severe ecological consequences.

Porous materials in ammonia storage tanks offer substantial environmental benefits compared to conventional storage methods. By optimizing porosity parameters, these advanced storage solutions can significantly reduce the risk of catastrophic releases during accidents. The controlled adsorption and desorption properties of porous materials create inherently safer systems that minimize environmental exposure during both normal operations and emergency scenarios.

Water resource protection represents a critical environmental consideration, as ammonia spills can lead to aquatic toxicity and eutrophication. Porosity-optimized storage tanks demonstrate superior containment capabilities, reducing the probability of groundwater and surface water contamination. Studies indicate that properly engineered porous materials can reduce potential ammonia leakage rates by up to 85% compared to conventional pressurized storage, substantially decreasing the environmental footprint of ammonia fuel infrastructure.

Air quality impacts must also be considered in environmental assessments of ammonia storage. Conventional tanks can release ammonia vapor during temperature fluctuations or minor system failures, contributing to atmospheric nitrogen deposition and particulate matter formation. Porous storage media act as effective emission control systems, capturing and retaining ammonia molecules that might otherwise escape, thereby protecting local air quality and reducing contributions to regional air pollution.

Life cycle assessment (LCA) data reveals that while the production of specialized porous materials initially carries a higher environmental burden than conventional tank manufacturing, this impact is offset by the operational benefits over the system lifetime. The reduced risk profile translates to fewer environmental remediation events and lower long-term ecological impacts. Additionally, many advanced porous materials can be recycled or repurposed at end-of-life, further enhancing their environmental credentials.

Climate change considerations also favor porosity-optimized storage solutions. The enhanced safety profile enables more widespread adoption of ammonia as a carbon-neutral energy carrier, potentially accelerating the transition away from fossil fuels. This indirect environmental benefit must be factored into comprehensive impact assessments, as the climate mitigation potential of ammonia fuel systems depends significantly on the safety and reliability of storage infrastructure.

Porous materials in ammonia storage tanks offer substantial environmental benefits compared to conventional storage methods. By optimizing porosity parameters, these advanced storage solutions can significantly reduce the risk of catastrophic releases during accidents. The controlled adsorption and desorption properties of porous materials create inherently safer systems that minimize environmental exposure during both normal operations and emergency scenarios.

Water resource protection represents a critical environmental consideration, as ammonia spills can lead to aquatic toxicity and eutrophication. Porosity-optimized storage tanks demonstrate superior containment capabilities, reducing the probability of groundwater and surface water contamination. Studies indicate that properly engineered porous materials can reduce potential ammonia leakage rates by up to 85% compared to conventional pressurized storage, substantially decreasing the environmental footprint of ammonia fuel infrastructure.

Air quality impacts must also be considered in environmental assessments of ammonia storage. Conventional tanks can release ammonia vapor during temperature fluctuations or minor system failures, contributing to atmospheric nitrogen deposition and particulate matter formation. Porous storage media act as effective emission control systems, capturing and retaining ammonia molecules that might otherwise escape, thereby protecting local air quality and reducing contributions to regional air pollution.

Life cycle assessment (LCA) data reveals that while the production of specialized porous materials initially carries a higher environmental burden than conventional tank manufacturing, this impact is offset by the operational benefits over the system lifetime. The reduced risk profile translates to fewer environmental remediation events and lower long-term ecological impacts. Additionally, many advanced porous materials can be recycled or repurposed at end-of-life, further enhancing their environmental credentials.

Climate change considerations also favor porosity-optimized storage solutions. The enhanced safety profile enables more widespread adoption of ammonia as a carbon-neutral energy carrier, potentially accelerating the transition away from fossil fuels. This indirect environmental benefit must be factored into comprehensive impact assessments, as the climate mitigation potential of ammonia fuel systems depends significantly on the safety and reliability of storage infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!