Precision Enhancement in Gas Welding Through Digital Controls

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution and Precision Goals

Gas welding has undergone significant evolution since its inception in the late 19th century. Initially developed as a method for joining metals using heat generated by the combustion of gases, it has progressed from rudimentary techniques to sophisticated processes. The early 20th century saw rapid advancements in gas welding technology, with improvements in gas mixtures, torch designs, and safety measures.

As industrial demands grew, so did the need for precision in welding processes. The mid-20th century marked a turning point with the introduction of automated welding systems, which laid the groundwork for more precise control over welding parameters. However, gas welding faced challenges in maintaining consistent quality and precision, especially when compared to emerging technologies like arc welding.

The advent of digital technologies in the late 20th and early 21st centuries opened new avenues for enhancing precision in gas welding. Digital controls have enabled real-time monitoring and adjustment of gas flow rates, flame temperature, and torch positioning. These advancements have significantly improved the accuracy and repeatability of gas welding processes, addressing long-standing issues of inconsistency and operator dependency.

Current technological goals in gas welding focus on further improving precision through the integration of advanced digital control systems. Key objectives include achieving micron-level accuracy in weld placement, maintaining consistent weld quality across varying environmental conditions, and minimizing heat-affected zones. There is also a push towards developing intelligent welding systems that can adapt to different materials and geometries in real-time.

Another critical goal is the reduction of human error through automation and augmented reality guidance systems. These technologies aim to provide welders with real-time feedback and instructions, ensuring optimal torch positioning and movement. Additionally, there is a growing emphasis on enhancing energy efficiency and reducing emissions, aligning gas welding practices with modern sustainability standards.

The future of gas welding precision lies in the convergence of digital controls with artificial intelligence and machine learning. These technologies promise to revolutionize welding processes by enabling predictive maintenance, adaptive welding parameters, and self-optimizing systems. As the industry moves towards Industry 4.0 standards, the integration of gas welding with broader manufacturing ecosystems is becoming increasingly important, driving the need for interoperable and data-driven welding solutions.

As industrial demands grew, so did the need for precision in welding processes. The mid-20th century marked a turning point with the introduction of automated welding systems, which laid the groundwork for more precise control over welding parameters. However, gas welding faced challenges in maintaining consistent quality and precision, especially when compared to emerging technologies like arc welding.

The advent of digital technologies in the late 20th and early 21st centuries opened new avenues for enhancing precision in gas welding. Digital controls have enabled real-time monitoring and adjustment of gas flow rates, flame temperature, and torch positioning. These advancements have significantly improved the accuracy and repeatability of gas welding processes, addressing long-standing issues of inconsistency and operator dependency.

Current technological goals in gas welding focus on further improving precision through the integration of advanced digital control systems. Key objectives include achieving micron-level accuracy in weld placement, maintaining consistent weld quality across varying environmental conditions, and minimizing heat-affected zones. There is also a push towards developing intelligent welding systems that can adapt to different materials and geometries in real-time.

Another critical goal is the reduction of human error through automation and augmented reality guidance systems. These technologies aim to provide welders with real-time feedback and instructions, ensuring optimal torch positioning and movement. Additionally, there is a growing emphasis on enhancing energy efficiency and reducing emissions, aligning gas welding practices with modern sustainability standards.

The future of gas welding precision lies in the convergence of digital controls with artificial intelligence and machine learning. These technologies promise to revolutionize welding processes by enabling predictive maintenance, adaptive welding parameters, and self-optimizing systems. As the industry moves towards Industry 4.0 standards, the integration of gas welding with broader manufacturing ecosystems is becoming increasingly important, driving the need for interoperable and data-driven welding solutions.

Market Demand for High-Precision Gas Welding

The market demand for high-precision gas welding has been steadily increasing across various industries, driven by the need for improved quality, efficiency, and cost-effectiveness in manufacturing processes. Industries such as aerospace, automotive, and advanced manufacturing are particularly keen on adopting precision gas welding technologies to meet stringent quality standards and enhance product performance.

In the aerospace sector, the demand for high-precision gas welding is fueled by the need for lightweight yet strong structures in aircraft and spacecraft manufacturing. The ability to create precise, high-strength welds in thin materials is crucial for reducing overall weight while maintaining structural integrity. This demand is further amplified by the growing commercial space industry and the increasing production of satellites and launch vehicles.

The automotive industry is another significant driver of market demand for precision gas welding. As vehicle designs become more complex and incorporate advanced materials, the need for precise welding techniques has grown. Electric vehicle production, in particular, requires high-precision welding for battery enclosures and lightweight body structures, contributing to the overall demand for advanced welding technologies.

Advanced manufacturing sectors, including electronics and medical device production, are also contributing to the market demand. These industries require extremely precise welds for miniature components and sensitive materials, where even minor deviations can lead to product failure or compromised performance.

The push towards Industry 4.0 and smart manufacturing has further accelerated the demand for digitally controlled gas welding systems. Manufacturers are seeking solutions that can integrate seamlessly with their digital ecosystems, providing real-time data, process control, and quality assurance. This trend is driving the development of gas welding systems with advanced sensors, data analytics capabilities, and machine learning algorithms to optimize welding parameters and ensure consistent quality.

Moreover, the global focus on sustainability and energy efficiency is influencing market demand. Precision gas welding technologies that minimize material waste, reduce energy consumption, and improve overall process efficiency are highly sought after. This aligns with corporate sustainability goals and regulatory requirements for reducing environmental impact in manufacturing processes.

The market is also seeing increased demand from emerging economies, where rapid industrialization and infrastructure development projects require advanced welding technologies. As these countries invest in modernizing their manufacturing capabilities, the adoption of high-precision gas welding systems is expected to grow significantly.

In conclusion, the market demand for high-precision gas welding through digital controls is robust and multifaceted, driven by diverse industry needs, technological advancements, and global economic trends. This demand is expected to continue growing as industries increasingly recognize the value of precision welding in enhancing product quality, operational efficiency, and competitive advantage in the global marketplace.

In the aerospace sector, the demand for high-precision gas welding is fueled by the need for lightweight yet strong structures in aircraft and spacecraft manufacturing. The ability to create precise, high-strength welds in thin materials is crucial for reducing overall weight while maintaining structural integrity. This demand is further amplified by the growing commercial space industry and the increasing production of satellites and launch vehicles.

The automotive industry is another significant driver of market demand for precision gas welding. As vehicle designs become more complex and incorporate advanced materials, the need for precise welding techniques has grown. Electric vehicle production, in particular, requires high-precision welding for battery enclosures and lightweight body structures, contributing to the overall demand for advanced welding technologies.

Advanced manufacturing sectors, including electronics and medical device production, are also contributing to the market demand. These industries require extremely precise welds for miniature components and sensitive materials, where even minor deviations can lead to product failure or compromised performance.

The push towards Industry 4.0 and smart manufacturing has further accelerated the demand for digitally controlled gas welding systems. Manufacturers are seeking solutions that can integrate seamlessly with their digital ecosystems, providing real-time data, process control, and quality assurance. This trend is driving the development of gas welding systems with advanced sensors, data analytics capabilities, and machine learning algorithms to optimize welding parameters and ensure consistent quality.

Moreover, the global focus on sustainability and energy efficiency is influencing market demand. Precision gas welding technologies that minimize material waste, reduce energy consumption, and improve overall process efficiency are highly sought after. This aligns with corporate sustainability goals and regulatory requirements for reducing environmental impact in manufacturing processes.

The market is also seeing increased demand from emerging economies, where rapid industrialization and infrastructure development projects require advanced welding technologies. As these countries invest in modernizing their manufacturing capabilities, the adoption of high-precision gas welding systems is expected to grow significantly.

In conclusion, the market demand for high-precision gas welding through digital controls is robust and multifaceted, driven by diverse industry needs, technological advancements, and global economic trends. This demand is expected to continue growing as industries increasingly recognize the value of precision welding in enhancing product quality, operational efficiency, and competitive advantage in the global marketplace.

Current Challenges in Gas Welding Precision

Gas welding, despite its long-standing presence in the industry, continues to face significant challenges in achieving high precision. The primary issue lies in the manual nature of the process, which inherently introduces variability and inconsistency. Welders' skill levels, fatigue, and environmental factors can all contribute to fluctuations in weld quality and precision.

One of the most pressing challenges is maintaining consistent temperature control throughout the welding process. The flame temperature in gas welding can vary due to fluctuations in gas pressure, mixing ratios, and ambient conditions. These variations can lead to inconsistent heat input, affecting the weld pool dynamics and ultimately the weld quality. Achieving uniform heat distribution across the weld joint is crucial for ensuring proper fusion and minimizing defects.

Another significant challenge is the difficulty in controlling the welding speed and torch angle with high precision. Manual welding relies heavily on the welder's ability to maintain a steady hand and consistent movement. Even slight deviations in speed or angle can result in uneven penetration, poor bead formation, or incomplete fusion. This challenge becomes particularly acute when dealing with complex geometries or long weld runs.

The control of filler material addition presents yet another hurdle in precision gas welding. The rate and timing of filler rod introduction significantly impact the weld profile and strength. Manual feeding of the filler material is subject to human error and inconsistency, potentially leading to over- or under-filling of the joint.

Gas flow regulation is also a critical factor affecting precision. Maintaining the optimal gas mixture and flow rate throughout the welding process is essential for creating a stable shielding atmosphere. Fluctuations in gas flow can lead to porosity, oxidation, or other weld defects that compromise the integrity of the joint.

Furthermore, the lack of real-time feedback mechanisms in traditional gas welding setups makes it challenging to detect and correct deviations from optimal welding parameters during the process. This absence of immediate corrective measures can result in the completion of suboptimal welds before issues are identified.

Lastly, the repeatability of high-precision welds across different operators and over extended periods remains a significant challenge. The reliance on individual skill and judgment introduces variability that can be difficult to standardize, especially in industries requiring consistent, high-quality welds for critical applications.

Addressing these challenges through the integration of digital controls and automation technologies presents a promising avenue for enhancing precision in gas welding. By leveraging advanced sensors, real-time monitoring systems, and computer-controlled parameter adjustments, the industry can potentially overcome many of the limitations inherent to manual gas welding processes.

One of the most pressing challenges is maintaining consistent temperature control throughout the welding process. The flame temperature in gas welding can vary due to fluctuations in gas pressure, mixing ratios, and ambient conditions. These variations can lead to inconsistent heat input, affecting the weld pool dynamics and ultimately the weld quality. Achieving uniform heat distribution across the weld joint is crucial for ensuring proper fusion and minimizing defects.

Another significant challenge is the difficulty in controlling the welding speed and torch angle with high precision. Manual welding relies heavily on the welder's ability to maintain a steady hand and consistent movement. Even slight deviations in speed or angle can result in uneven penetration, poor bead formation, or incomplete fusion. This challenge becomes particularly acute when dealing with complex geometries or long weld runs.

The control of filler material addition presents yet another hurdle in precision gas welding. The rate and timing of filler rod introduction significantly impact the weld profile and strength. Manual feeding of the filler material is subject to human error and inconsistency, potentially leading to over- or under-filling of the joint.

Gas flow regulation is also a critical factor affecting precision. Maintaining the optimal gas mixture and flow rate throughout the welding process is essential for creating a stable shielding atmosphere. Fluctuations in gas flow can lead to porosity, oxidation, or other weld defects that compromise the integrity of the joint.

Furthermore, the lack of real-time feedback mechanisms in traditional gas welding setups makes it challenging to detect and correct deviations from optimal welding parameters during the process. This absence of immediate corrective measures can result in the completion of suboptimal welds before issues are identified.

Lastly, the repeatability of high-precision welds across different operators and over extended periods remains a significant challenge. The reliance on individual skill and judgment introduces variability that can be difficult to standardize, especially in industries requiring consistent, high-quality welds for critical applications.

Addressing these challenges through the integration of digital controls and automation technologies presents a promising avenue for enhancing precision in gas welding. By leveraging advanced sensors, real-time monitoring systems, and computer-controlled parameter adjustments, the industry can potentially overcome many of the limitations inherent to manual gas welding processes.

Existing Digital Control Solutions for Gas Welding

01 Precision control systems for gas welding

Advanced control systems are implemented to enhance the precision of gas welding processes. These systems may include computerized controls, sensors, and feedback mechanisms to regulate gas flow, temperature, and torch positioning. Such precision control allows for more accurate and consistent welds, particularly in applications requiring high precision.- Precision control systems for gas welding: Advanced control systems are implemented to enhance the precision of gas welding processes. These systems may include computerized monitoring of gas flow rates, temperature, and pressure to maintain optimal welding conditions. Real-time adjustments and feedback mechanisms ensure consistent weld quality and minimize errors.

- Specialized nozzle designs for improved gas welding accuracy: Innovative nozzle designs are developed to improve the accuracy of gas welding. These nozzles may feature adjustable gas flow patterns, precise orifice configurations, or multi-channel designs to optimize gas distribution and flame characteristics. Such advancements contribute to more precise and controlled welding operations.

- Integration of sensors and monitoring devices: Gas welding equipment is equipped with various sensors and monitoring devices to enhance precision. These may include temperature sensors, gas flow meters, and position tracking systems. The integration of these devices allows for real-time monitoring and adjustment of welding parameters, resulting in improved accuracy and consistency.

- Automated positioning and movement systems: Automated systems are developed to control the positioning and movement of welding torches or workpieces during gas welding operations. These systems may utilize robotic arms, CNC-controlled platforms, or other precision motion control mechanisms to ensure accurate and repeatable welding paths, enhancing overall precision.

- Advanced gas mixture control and regulation: Precision gas welding is achieved through advanced gas mixture control and regulation techniques. This may involve the use of high-precision gas flow controllers, digital gas mixing systems, or intelligent gas management algorithms. These advancements allow for precise control of gas composition and flow rates, resulting in improved weld quality and consistency.

02 Specialized gas welding torches for precision work

Innovative torch designs are developed specifically for precision gas welding. These torches may feature fine-tip nozzles, adjustable flame settings, and ergonomic designs to allow welders greater control and accuracy. Some designs may incorporate cooling systems or heat shields to maintain stability during delicate operations.Expand Specific Solutions03 Gas mixture optimization for precision welding

Research focuses on optimizing gas mixtures to achieve higher precision in welding. This may involve developing new gas blends or fine-tuning existing mixtures to provide better heat control, reduce spatter, and improve weld quality. Advanced gas delivery systems may be employed to maintain precise ratios and flow rates during the welding process.Expand Specific Solutions04 Automated and robotic systems for precision gas welding

Integration of automation and robotics into gas welding processes to enhance precision. These systems may include robotic arms with advanced motion control, vision systems for weld seam tracking, and AI-driven process optimization. Automated systems can maintain consistent welding parameters and reduce human error in precision applications.Expand Specific Solutions05 Micro-gas welding techniques for high-precision applications

Development of micro-gas welding techniques for extremely small or delicate components. This may involve miniaturized torch designs, ultra-fine gas flow control, and specialized fixturing to achieve welds on a microscopic scale. These techniques are particularly relevant in industries such as electronics, medical device manufacturing, and precision instrument fabrication.Expand Specific Solutions

Key Players in Digital Welding Technology

The precision enhancement in gas welding through digital controls is currently in a growth phase, with the market expanding due to increasing demand for high-precision welding in various industries. The global market size for advanced welding technologies is projected to grow significantly in the coming years. Technologically, the field is rapidly evolving, with companies like Fronius International GmbH, Shanghai Hugong Electric Group Co., Ltd., and Shenzhen Riland Industry Group Co., Ltd. leading innovation in digital control systems for welding. These firms are developing sophisticated solutions that integrate sensors, real-time monitoring, and AI-driven adjustments to enhance welding precision and efficiency. However, the technology is still maturing, with ongoing research and development focused on improving accuracy, reliability, and user-friendliness of digital control systems in gas welding applications.

Fronius International GmbH

Technical Solution: Fronius has developed advanced digital control systems for gas welding, incorporating their TPS/i (Intelligent Revolution) platform. This system utilizes high-speed microprocessors and sophisticated algorithms to precisely control gas flow, pressure, and mixture in real-time. The technology includes adaptive gas regulation that adjusts to environmental conditions and welding parameters[1]. Their digital gas control can achieve accuracy levels of ±1% in gas flow rates, significantly improving weld quality and consistency[2]. Fronius has also integrated IoT capabilities, allowing for remote monitoring and adjustment of welding parameters, enhancing precision in industrial settings[3].

Strengths: High precision gas control, adaptive systems, IoT integration. Weaknesses: Potentially higher initial cost, may require specialized training for operators.

Shanghai Hugong Electric Group Co., Ltd.

Technical Solution: Shanghai Hugong has introduced a digital gas control system for their welding equipment that utilizes advanced sensors and microcontrollers. Their technology incorporates pulse width modulation (PWM) for precise gas flow control, achieving flow rate accuracies of ±2%[4]. The system includes a digital interface for easy parameter setting and real-time monitoring of gas consumption. Hugong's solution also features automatic gas saving functions, which can reduce gas usage by up to 30% compared to traditional systems[5]. They have implemented machine learning algorithms to optimize gas flow based on welding conditions and historical data.

Strengths: Cost-effective solution, gas-saving features, user-friendly interface. Weaknesses: May not match the precision of top-tier competitors, limited IoT integration.

Innovative Digital Precision Control Techniques

Multi-electrode submerged arc welding method, welded joint, and method for manufacturing same

PatentWO2016199419A1

Innovation

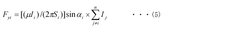

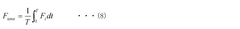

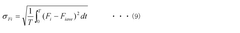

- A digitally controlled welding method that arbitrarily controls the phase, waveform, and frequency of the alternating current, ensuring specific relationships between maximum, average, and standard deviation of electromagnetic forces acting on each electrode, thereby stabilizing the arc and improving weld quality.

Flash butt welding machine modernisation system and method

PatentWO2025144286A1

Innovation

- Integration of digital display, process memory, adjustable preheating system, and gas protection systems into the welding process, utilizing a PLC for automated control and data recording, enabling precise adjustments and monitoring, and expanding material compatibility through inert gas environments.

Safety Standards for Digitally Controlled Welding

The implementation of digital controls in gas welding processes has significantly enhanced precision and efficiency, but it also introduces new safety considerations. To ensure the safe operation of digitally controlled welding systems, comprehensive safety standards must be developed and rigorously enforced.

These standards should address the unique risks associated with automated and digitally controlled welding processes. One key area of focus is the prevention of equipment malfunctions that could lead to accidents. This includes implementing fail-safe mechanisms and redundant safety systems to mitigate the risks of software glitches or hardware failures.

Another critical aspect of safety standards for digitally controlled welding is the protection against unauthorized access and cyber threats. As these systems become increasingly connected and networked, they become potential targets for cyberattacks. Robust cybersecurity measures, including encryption protocols and secure authentication methods, must be integrated into the digital control systems.

Operator training and certification programs should be updated to include specific modules on the safe operation of digitally controlled welding equipment. These programs should cover not only the technical aspects of operating the equipment but also the potential hazards and emergency procedures unique to digital systems.

Environmental safety is another crucial consideration. Standards should address the proper ventilation and fume extraction requirements for digitally controlled welding processes, which may differ from traditional manual welding setups due to potentially higher duty cycles or altered welding parameters.

Electromagnetic compatibility (EMC) standards must be established to ensure that digital control systems do not interfere with other electronic equipment in the workplace, and vice versa. This is particularly important in industrial settings where multiple electronic systems operate in close proximity.

Regular maintenance and inspection protocols tailored to digitally controlled welding systems should be mandated. These should include checks on both hardware components and software integrity to ensure continued safe operation over time.

Emergency shutdown procedures specific to digitally controlled welding systems need to be standardized and clearly communicated. These procedures should be designed to quickly and safely halt operations in the event of a malfunction or safety breach.

Finally, safety standards should address the integration of advanced monitoring and data logging capabilities. These features can provide valuable insights into system performance and help identify potential safety issues before they escalate into accidents.

These standards should address the unique risks associated with automated and digitally controlled welding processes. One key area of focus is the prevention of equipment malfunctions that could lead to accidents. This includes implementing fail-safe mechanisms and redundant safety systems to mitigate the risks of software glitches or hardware failures.

Another critical aspect of safety standards for digitally controlled welding is the protection against unauthorized access and cyber threats. As these systems become increasingly connected and networked, they become potential targets for cyberattacks. Robust cybersecurity measures, including encryption protocols and secure authentication methods, must be integrated into the digital control systems.

Operator training and certification programs should be updated to include specific modules on the safe operation of digitally controlled welding equipment. These programs should cover not only the technical aspects of operating the equipment but also the potential hazards and emergency procedures unique to digital systems.

Environmental safety is another crucial consideration. Standards should address the proper ventilation and fume extraction requirements for digitally controlled welding processes, which may differ from traditional manual welding setups due to potentially higher duty cycles or altered welding parameters.

Electromagnetic compatibility (EMC) standards must be established to ensure that digital control systems do not interfere with other electronic equipment in the workplace, and vice versa. This is particularly important in industrial settings where multiple electronic systems operate in close proximity.

Regular maintenance and inspection protocols tailored to digitally controlled welding systems should be mandated. These should include checks on both hardware components and software integrity to ensure continued safe operation over time.

Emergency shutdown procedures specific to digitally controlled welding systems need to be standardized and clearly communicated. These procedures should be designed to quickly and safely halt operations in the event of a malfunction or safety breach.

Finally, safety standards should address the integration of advanced monitoring and data logging capabilities. These features can provide valuable insights into system performance and help identify potential safety issues before they escalate into accidents.

Environmental Impact of Precision Gas Welding

The implementation of precision gas welding through digital controls has significant implications for environmental sustainability in the manufacturing sector. This advanced welding technique offers substantial improvements in energy efficiency compared to traditional gas welding methods. By precisely controlling gas flow and mixture ratios, digital systems minimize excess fuel consumption and reduce greenhouse gas emissions. Studies have shown that digitally controlled gas welding can achieve up to 30% reduction in gas usage, directly translating to a lower carbon footprint for welding operations.

Furthermore, the enhanced precision of digital controls leads to improved weld quality and reduced material waste. This efficiency gain not only conserves raw materials but also decreases the energy required for rework and scrap processing. The reduction in material waste contributes to a more sustainable manufacturing process, aligning with circular economy principles and minimizing the environmental impact associated with resource extraction and processing.

Digital control systems in gas welding also enable more accurate temperature management during the welding process. This precise control helps optimize the heat input, reducing the overall energy consumption of the welding operation. Additionally, it minimizes the formation of harmful fumes and particulate matter, which are common byproducts of less controlled welding processes. The reduction in air pollutants not only improves workplace air quality but also lessens the environmental burden on surrounding ecosystems.

The integration of digital controls in gas welding equipment facilitates the collection and analysis of process data. This data-driven approach allows for continuous optimization of welding parameters, leading to further improvements in energy efficiency and environmental performance over time. By identifying patterns and inefficiencies, manufacturers can implement targeted improvements that reduce resource consumption and emissions across their welding operations.

Moreover, the precision offered by digital controls extends the lifespan of welded components by producing higher quality, more durable welds. This longevity reduces the frequency of replacements and repairs, thereby decreasing the overall environmental impact associated with product lifecycles. The improved durability of welded structures contributes to sustainability efforts by reducing the demand for new materials and the energy required for manufacturing replacement parts.

In conclusion, the adoption of precision gas welding through digital controls represents a significant step towards more environmentally friendly manufacturing practices. By optimizing resource use, reducing emissions, and improving product quality, this technology aligns with global efforts to mitigate industrial environmental impacts and promote sustainable production methods.

Furthermore, the enhanced precision of digital controls leads to improved weld quality and reduced material waste. This efficiency gain not only conserves raw materials but also decreases the energy required for rework and scrap processing. The reduction in material waste contributes to a more sustainable manufacturing process, aligning with circular economy principles and minimizing the environmental impact associated with resource extraction and processing.

Digital control systems in gas welding also enable more accurate temperature management during the welding process. This precise control helps optimize the heat input, reducing the overall energy consumption of the welding operation. Additionally, it minimizes the formation of harmful fumes and particulate matter, which are common byproducts of less controlled welding processes. The reduction in air pollutants not only improves workplace air quality but also lessens the environmental burden on surrounding ecosystems.

The integration of digital controls in gas welding equipment facilitates the collection and analysis of process data. This data-driven approach allows for continuous optimization of welding parameters, leading to further improvements in energy efficiency and environmental performance over time. By identifying patterns and inefficiencies, manufacturers can implement targeted improvements that reduce resource consumption and emissions across their welding operations.

Moreover, the precision offered by digital controls extends the lifespan of welded components by producing higher quality, more durable welds. This longevity reduces the frequency of replacements and repairs, thereby decreasing the overall environmental impact associated with product lifecycles. The improved durability of welded structures contributes to sustainability efforts by reducing the demand for new materials and the energy required for manufacturing replacement parts.

In conclusion, the adoption of precision gas welding through digital controls represents a significant step towards more environmentally friendly manufacturing practices. By optimizing resource use, reducing emissions, and improving product quality, this technology aligns with global efforts to mitigate industrial environmental impacts and promote sustainable production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!