Precision Tuning of NMR Equipment: Ensuring Measurement Fidelity

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMR Technology Evolution and Precision Goals

Nuclear Magnetic Resonance (NMR) spectroscopy has evolved significantly since its discovery in the 1940s, transforming from a physics curiosity into an indispensable analytical tool across multiple scientific disciplines. The fundamental principle of NMR—the absorption and re-emission of electromagnetic radiation by nuclei in a magnetic field—has remained constant, but the precision, sensitivity, and applications have expanded exponentially.

The evolution of NMR technology can be traced through several distinct phases. Early NMR systems in the 1950s and 1960s operated at low magnetic field strengths (typically below 100 MHz for proton resonance) with limited resolution. The 1970s marked a revolutionary shift with the introduction of superconducting magnets, enabling significantly higher field strengths and consequently improved spectral resolution.

By the 1980s and 1990s, the integration of Fourier Transform techniques and multidimensional experiments dramatically enhanced the information content obtainable from NMR measurements. This period also saw the development of specialized pulse sequences that allowed for selective excitation and manipulation of nuclear spins, opening new avenues for structural analysis of complex biomolecules.

The 21st century has witnessed further refinements in NMR technology, with ultra-high field magnets (exceeding 1 GHz for proton resonance) becoming available, albeit at significant cost. Parallel advances in cryogenic probe technology have substantially improved signal-to-noise ratios, reducing acquisition times and sample requirements by orders of magnitude.

Current precision goals in NMR equipment tuning focus on several critical parameters. Magnetic field homogeneity remains paramount, with modern systems striving for sub-ppb (parts per billion) variations across the sample volume. This level of uniformity is essential for achieving narrow linewidths and accurate chemical shift measurements, particularly in complex biomolecular studies and materials science applications.

Frequency stability represents another crucial precision target, with state-of-the-art systems aiming for drift rates below 1 Hz per hour. Such stability is vital for long-duration experiments, particularly in protein NMR where data acquisition may continue for days or weeks.

Temperature control precision has emerged as an increasingly important parameter, with variations as small as 0.1°C potentially affecting measurement fidelity in sensitive applications. Modern NMR systems incorporate sophisticated temperature regulation systems to maintain sample conditions within these tight tolerances.

The ultimate goal of precision tuning in NMR equipment is to ensure measurement fidelity—the faithful representation of molecular structure and dynamics through spectral data. This fidelity is essential not only for fundamental research but increasingly for quality control applications in pharmaceuticals, food science, and materials manufacturing, where NMR serves as a gold-standard analytical method.

The evolution of NMR technology can be traced through several distinct phases. Early NMR systems in the 1950s and 1960s operated at low magnetic field strengths (typically below 100 MHz for proton resonance) with limited resolution. The 1970s marked a revolutionary shift with the introduction of superconducting magnets, enabling significantly higher field strengths and consequently improved spectral resolution.

By the 1980s and 1990s, the integration of Fourier Transform techniques and multidimensional experiments dramatically enhanced the information content obtainable from NMR measurements. This period also saw the development of specialized pulse sequences that allowed for selective excitation and manipulation of nuclear spins, opening new avenues for structural analysis of complex biomolecules.

The 21st century has witnessed further refinements in NMR technology, with ultra-high field magnets (exceeding 1 GHz for proton resonance) becoming available, albeit at significant cost. Parallel advances in cryogenic probe technology have substantially improved signal-to-noise ratios, reducing acquisition times and sample requirements by orders of magnitude.

Current precision goals in NMR equipment tuning focus on several critical parameters. Magnetic field homogeneity remains paramount, with modern systems striving for sub-ppb (parts per billion) variations across the sample volume. This level of uniformity is essential for achieving narrow linewidths and accurate chemical shift measurements, particularly in complex biomolecular studies and materials science applications.

Frequency stability represents another crucial precision target, with state-of-the-art systems aiming for drift rates below 1 Hz per hour. Such stability is vital for long-duration experiments, particularly in protein NMR where data acquisition may continue for days or weeks.

Temperature control precision has emerged as an increasingly important parameter, with variations as small as 0.1°C potentially affecting measurement fidelity in sensitive applications. Modern NMR systems incorporate sophisticated temperature regulation systems to maintain sample conditions within these tight tolerances.

The ultimate goal of precision tuning in NMR equipment is to ensure measurement fidelity—the faithful representation of molecular structure and dynamics through spectral data. This fidelity is essential not only for fundamental research but increasingly for quality control applications in pharmaceuticals, food science, and materials manufacturing, where NMR serves as a gold-standard analytical method.

Market Demand for High-Fidelity NMR Measurements

The global Nuclear Magnetic Resonance (NMR) spectroscopy market has been experiencing robust growth, valued at approximately $930 million in 2022 and projected to reach $1.4 billion by 2028, representing a compound annual growth rate of 6.8%. This growth is primarily driven by increasing demand for high-fidelity NMR measurements across various industries, particularly pharmaceuticals, biotechnology, and academic research.

In the pharmaceutical sector, which accounts for nearly 40% of the NMR market, there is a growing need for precise molecular structure determination during drug discovery and development processes. High-fidelity NMR measurements enable researchers to accurately identify and characterize drug candidates, reducing development time and costs. The industry's shift toward biologics and complex molecular entities has further intensified the demand for advanced NMR technologies capable of delivering reliable structural information.

The biotechnology sector represents another significant market segment, with increasing applications in protein structure analysis, metabolomics, and drug metabolism studies. Research institutions and biotech companies are investing heavily in NMR equipment that can provide consistent, reproducible results with minimal signal-to-noise ratios. This trend is particularly evident in proteomics research, where precise NMR measurements are essential for understanding protein-protein interactions and conformational changes.

Academic and research institutions constitute approximately 30% of the market demand, driven by fundamental research in chemistry, biochemistry, and materials science. These institutions typically require NMR equipment with high measurement fidelity to ensure publication-quality data and reproducible research outcomes. Government funding for research infrastructure in developed economies has been a key factor supporting this segment's growth.

The food and beverage industry has emerged as a rapidly growing application area, with a 9.2% growth rate in NMR adoption. Companies are increasingly utilizing NMR spectroscopy for food authentication, quality control, and detection of adulterants. This application demands highly precise measurements to detect subtle differences in chemical compositions that might indicate contamination or fraudulent products.

Geographically, North America dominates the market with a 38% share, followed by Europe at 32% and Asia-Pacific at 24%. The Asia-Pacific region, particularly China and India, is witnessing the fastest growth due to increasing investments in pharmaceutical research and academic institutions.

End-users consistently emphasize three key requirements: measurement accuracy, reproducibility, and ease of calibration. According to a recent industry survey, 78% of users identified measurement fidelity as the most critical factor influencing purchasing decisions, highlighting the significant market opportunity for innovations in precision tuning of NMR equipment.

In the pharmaceutical sector, which accounts for nearly 40% of the NMR market, there is a growing need for precise molecular structure determination during drug discovery and development processes. High-fidelity NMR measurements enable researchers to accurately identify and characterize drug candidates, reducing development time and costs. The industry's shift toward biologics and complex molecular entities has further intensified the demand for advanced NMR technologies capable of delivering reliable structural information.

The biotechnology sector represents another significant market segment, with increasing applications in protein structure analysis, metabolomics, and drug metabolism studies. Research institutions and biotech companies are investing heavily in NMR equipment that can provide consistent, reproducible results with minimal signal-to-noise ratios. This trend is particularly evident in proteomics research, where precise NMR measurements are essential for understanding protein-protein interactions and conformational changes.

Academic and research institutions constitute approximately 30% of the market demand, driven by fundamental research in chemistry, biochemistry, and materials science. These institutions typically require NMR equipment with high measurement fidelity to ensure publication-quality data and reproducible research outcomes. Government funding for research infrastructure in developed economies has been a key factor supporting this segment's growth.

The food and beverage industry has emerged as a rapidly growing application area, with a 9.2% growth rate in NMR adoption. Companies are increasingly utilizing NMR spectroscopy for food authentication, quality control, and detection of adulterants. This application demands highly precise measurements to detect subtle differences in chemical compositions that might indicate contamination or fraudulent products.

Geographically, North America dominates the market with a 38% share, followed by Europe at 32% and Asia-Pacific at 24%. The Asia-Pacific region, particularly China and India, is witnessing the fastest growth due to increasing investments in pharmaceutical research and academic institutions.

End-users consistently emphasize three key requirements: measurement accuracy, reproducibility, and ease of calibration. According to a recent industry survey, 78% of users identified measurement fidelity as the most critical factor influencing purchasing decisions, highlighting the significant market opportunity for innovations in precision tuning of NMR equipment.

Current Challenges in NMR Equipment Calibration

Nuclear Magnetic Resonance (NMR) spectroscopy represents one of the most powerful analytical techniques in modern science, yet its effectiveness hinges entirely on precise calibration. Current NMR equipment calibration faces several significant challenges that impact measurement fidelity across research, medical diagnostics, and industrial applications.

The foremost challenge lies in magnetic field homogeneity maintenance. Even minor fluctuations in the magnetic field can dramatically alter spectral resolution and signal-to-noise ratios. Environmental factors such as temperature variations, building vibrations, and nearby electromagnetic interference sources continue to plague NMR facilities despite advances in shielding technology. These disturbances often necessitate frequent recalibration, consuming valuable research time and resources.

Probe tuning and matching represent another critical calibration hurdle. The complex impedance matching required between the NMR probe and the spectrometer electronics demands extreme precision, particularly at higher field strengths. Current manual tuning methods remain susceptible to operator variability, while automated systems frequently lack the sensitivity required for specialized applications such as protein structure analysis or metabolomics studies.

Pulse sequence optimization presents escalating complexity as multi-dimensional NMR techniques become standard. Calibrating optimal pulse widths, delays, and phase cycling parameters requires sophisticated understanding of spin physics and instrument response characteristics. The interdependence of these parameters creates a multidimensional optimization problem that current software solutions address inadequately, especially for novel pulse sequence designs.

Reference standardization remains inconsistent across the field. While tetramethylsilane (TMS) serves as a universal reference for proton and carbon NMR, equivalent standards for other nuclei lack universal adoption. This hampers cross-laboratory reproducibility and complicates multi-nuclear experiments, particularly problematic for pharmaceutical and materials science applications where absolute chemical shift values are crucial.

Quantitative NMR (qNMR) calibration faces particular challenges in achieving the accuracy levels required for regulatory compliance. Current methods struggle to account for relaxation effects, nuclear Overhauser enhancement variations, and integration region selection subjectivity. These limitations restrict qNMR's broader adoption despite its potential as a primary analytical method.

Cryogenic system stability represents a significant operational challenge. Modern high-field NMR systems require superconducting magnets maintained at liquid helium temperatures. Fluctuations in cryogen levels or cooling efficiency directly impact field stability and consequently, spectral quality. The global helium shortage has exacerbated this challenge, pushing facilities toward recondensing systems that introduce their own calibration complexities.

The foremost challenge lies in magnetic field homogeneity maintenance. Even minor fluctuations in the magnetic field can dramatically alter spectral resolution and signal-to-noise ratios. Environmental factors such as temperature variations, building vibrations, and nearby electromagnetic interference sources continue to plague NMR facilities despite advances in shielding technology. These disturbances often necessitate frequent recalibration, consuming valuable research time and resources.

Probe tuning and matching represent another critical calibration hurdle. The complex impedance matching required between the NMR probe and the spectrometer electronics demands extreme precision, particularly at higher field strengths. Current manual tuning methods remain susceptible to operator variability, while automated systems frequently lack the sensitivity required for specialized applications such as protein structure analysis or metabolomics studies.

Pulse sequence optimization presents escalating complexity as multi-dimensional NMR techniques become standard. Calibrating optimal pulse widths, delays, and phase cycling parameters requires sophisticated understanding of spin physics and instrument response characteristics. The interdependence of these parameters creates a multidimensional optimization problem that current software solutions address inadequately, especially for novel pulse sequence designs.

Reference standardization remains inconsistent across the field. While tetramethylsilane (TMS) serves as a universal reference for proton and carbon NMR, equivalent standards for other nuclei lack universal adoption. This hampers cross-laboratory reproducibility and complicates multi-nuclear experiments, particularly problematic for pharmaceutical and materials science applications where absolute chemical shift values are crucial.

Quantitative NMR (qNMR) calibration faces particular challenges in achieving the accuracy levels required for regulatory compliance. Current methods struggle to account for relaxation effects, nuclear Overhauser enhancement variations, and integration region selection subjectivity. These limitations restrict qNMR's broader adoption despite its potential as a primary analytical method.

Cryogenic system stability represents a significant operational challenge. Modern high-field NMR systems require superconducting magnets maintained at liquid helium temperatures. Fluctuations in cryogen levels or cooling efficiency directly impact field stability and consequently, spectral quality. The global helium shortage has exacerbated this challenge, pushing facilities toward recondensing systems that introduce their own calibration complexities.

State-of-the-Art NMR Calibration Techniques

01 Calibration and reference standards for NMR measurement accuracy

Calibration techniques and reference standards are essential for ensuring the fidelity of NMR measurements. These methods involve the use of known reference compounds or materials to calibrate the NMR equipment, allowing for accurate and reproducible measurements. Advanced calibration protocols can compensate for instrumental drift, environmental variations, and other factors that might affect measurement accuracy. Regular calibration using standardized procedures helps maintain consistent measurement quality over time.- Calibration and reference standards for NMR measurement accuracy: Calibration techniques and reference standards are essential for ensuring the fidelity of NMR measurements. These methods involve using known reference compounds or materials to calibrate the NMR equipment, allowing for accurate and reproducible measurements. Advanced calibration protocols can compensate for instrumental drift, temperature variations, and other factors that might affect measurement accuracy. Regular calibration using standardized procedures helps maintain measurement fidelity over time.

- Hardware optimization for improved signal quality: Hardware components in NMR equipment significantly impact measurement fidelity. Optimized magnet designs, probe configurations, and signal detection systems can enhance signal-to-noise ratios and spectral resolution. Advanced hardware solutions include superconducting magnets, cryogenically cooled probes, and specialized coil arrangements that minimize interference and maximize sensitivity. These hardware optimizations enable more precise measurements of nuclear magnetic resonance phenomena, particularly for complex samples or low-concentration analytes.

- Signal processing algorithms for enhanced data quality: Advanced signal processing algorithms play a crucial role in improving NMR measurement fidelity. These computational methods can filter noise, correct phase distortions, and enhance spectral resolution. Techniques such as Fourier transformation optimization, baseline correction, and peak deconvolution help extract more accurate information from raw NMR data. Machine learning and artificial intelligence approaches are increasingly being applied to automatically identify and correct measurement artifacts, leading to more reliable and reproducible NMR results.

- Environmental control systems for measurement stability: Environmental factors significantly impact NMR measurement fidelity. Temperature fluctuations, vibrations, electromagnetic interference, and humidity changes can all degrade measurement quality. Advanced NMR systems incorporate sophisticated environmental control mechanisms, including temperature stabilization, vibration isolation platforms, electromagnetic shielding, and humidity regulation. These systems ensure consistent measurement conditions, which is particularly important for long-duration experiments or when comparing measurements taken at different times.

- Automated quality control and validation methods: Automated quality control and validation methods ensure consistent NMR measurement fidelity. These systems continuously monitor equipment performance, automatically detect deviations from expected parameters, and can initiate corrective actions when necessary. Self-diagnostic routines test critical components and provide alerts when maintenance is required. Validation protocols compare measurement results against known standards to verify accuracy. These automated approaches reduce human error, increase throughput, and provide documented evidence of measurement reliability for regulatory compliance.

02 Hardware improvements for enhanced signal quality

Hardware innovations in NMR equipment significantly improve measurement fidelity by enhancing signal quality and reducing noise. These improvements include advanced probe designs, superior magnet configurations, and optimized RF coil arrangements. High-performance hardware components enable better signal-to-noise ratios, increased sensitivity, and improved resolution in NMR spectroscopy. Such hardware enhancements are particularly important for detecting subtle spectral features and analyzing complex molecular structures with high precision.Expand Specific Solutions03 Signal processing algorithms for data quality enhancement

Advanced signal processing algorithms play a crucial role in enhancing NMR measurement fidelity. These computational methods include sophisticated noise reduction techniques, baseline correction algorithms, and spectral deconvolution approaches. By applying these algorithms to raw NMR data, researchers can extract cleaner signals, improve peak resolution, and enhance overall spectral quality. Machine learning and artificial intelligence techniques are increasingly being incorporated to further refine signal processing capabilities and automate the identification of spectral features.Expand Specific Solutions04 Temperature and environmental control systems

Precise control of temperature and environmental conditions is critical for maintaining high fidelity in NMR measurements. Fluctuations in temperature can affect sample properties, chemical shift values, and overall spectral quality. Advanced NMR systems incorporate sophisticated temperature regulation mechanisms, vibration isolation systems, and magnetic field stabilization technologies. These environmental control systems ensure consistent measurement conditions, leading to more reliable and reproducible NMR data across multiple experiments and extended time periods.Expand Specific Solutions05 Automated calibration and self-diagnostic capabilities

Modern NMR equipment features automated calibration routines and self-diagnostic capabilities that continuously monitor and adjust system parameters to maintain measurement fidelity. These intelligent systems can detect deviations from optimal performance, automatically apply corrective measures, and alert operators to potential issues. Self-calibration procedures can be programmed to run at regular intervals or before critical measurements, ensuring consistent instrument performance without extensive manual intervention. These automated features significantly improve measurement reliability and reduce operator-dependent variations.Expand Specific Solutions

Leading Manufacturers and Research Institutions in NMR Technology

The NMR equipment precision tuning market is currently in a growth phase, with increasing demand driven by applications in healthcare, oil exploration, and research sectors. The competitive landscape features established industry leaders like Schlumberger Technologies, Halliburton Energy Services, and Agilent Technologies dominating the commercial sector, while academic institutions such as University of Florida and Kyoto University contribute significant research advancements. From a technological maturity perspective, companies like Koninklijke Philips, United Imaging Healthcare, and Bruker BioSpin MRI have achieved high levels of sophistication in measurement fidelity, while emerging players like Wuhan Zhongke-Niujin Magnetic Resonance Technology are introducing innovations that challenge established methodologies. The market is characterized by continuous refinement of calibration techniques and signal processing algorithms to enhance measurement precision.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed specialized NMR precision tuning technologies optimized for downhole and wellbore environments where measurement conditions are extremely challenging. Their Magnetic Resonance Expert (MR Explorer) tool incorporates adaptive pulse sequence technology that automatically adjusts to varying borehole conditions, maintaining measurement fidelity despite temperature fluctuations from 20°C to over 175°C and pressures exceeding 20,000 psi[8]. The system employs proprietary gradient coil designs that minimize the effects of tool motion and vibration, critical for maintaining signal quality in drilling environments. Schlumberger's real-time calibration system continuously monitors magnetic field homogeneity and makes automatic adjustments to compensate for the presence of magnetic minerals in formation rocks. Their signal processing algorithms incorporate advanced noise cancellation techniques specifically designed to filter out electromagnetic interference from drilling equipment and formation characteristics[9]. The company has also pioneered multi-frequency measurement techniques that enable simultaneous acquisition of T1 and T2 relaxation data, improving the accuracy of fluid typing and porosity measurements.

Strengths: Exceptional performance in extreme environmental conditions; robust design withstands mechanical shock and vibration. Weaknesses: Specialized for petroleum applications with limited flexibility for other research domains; higher power requirements compared to laboratory systems.

Koninklijke Philips NV

Technical Solution: Philips has developed sophisticated NMR precision tuning technology primarily focused on clinical MRI applications. Their SmartExam technology implements automated planning, scanning, and processing, ensuring consistent image quality regardless of operator experience[5]. The system employs real-time monitoring of gradient linearity and eddy current compensation to maintain spatial accuracy within 0.1mm. Philips' MultiTransmit 4D technology uses multiple independent RF transmission channels with dynamic RF shimming to optimize B1 field homogeneity throughout the measurement process, adapting to patient-specific characteristics[6]. Their dStream digital broadband technology converts the RF signal to digital as close to the patient as possible, eliminating analog signal degradation and improving signal-to-noise ratio by up to 40%[7]. Additionally, Philips has implemented advanced motion correction algorithms that can detect and compensate for subject movement during scans, preserving measurement fidelity even with non-cooperative subjects.

Strengths: Exceptional clinical focus with patient-adaptive technologies; superior digital signal processing with early digitization. Weaknesses: Systems primarily optimized for clinical rather than research applications; higher cost structure compared to specialized research equipment.

Key Patents and Innovations in NMR Precision Engineering

Switchable manual/motor-driven NMR tuning systems and methods

PatentInactiveEP2271258A2

Innovation

- A switchable manual-mode/motor-driven mode tuning assembly is introduced, allowing for manual adjustment of capacitance using a rotatable longitudinal tuning shaft coupled to a variable capacitor, with a mode-switching coupler that decouples the tuning motor in manual mode, enabling precise tuning without motor interference.

Tuning of nuclear magnetic resonance logging tools

PatentInactiveUS20050156592A1

Innovation

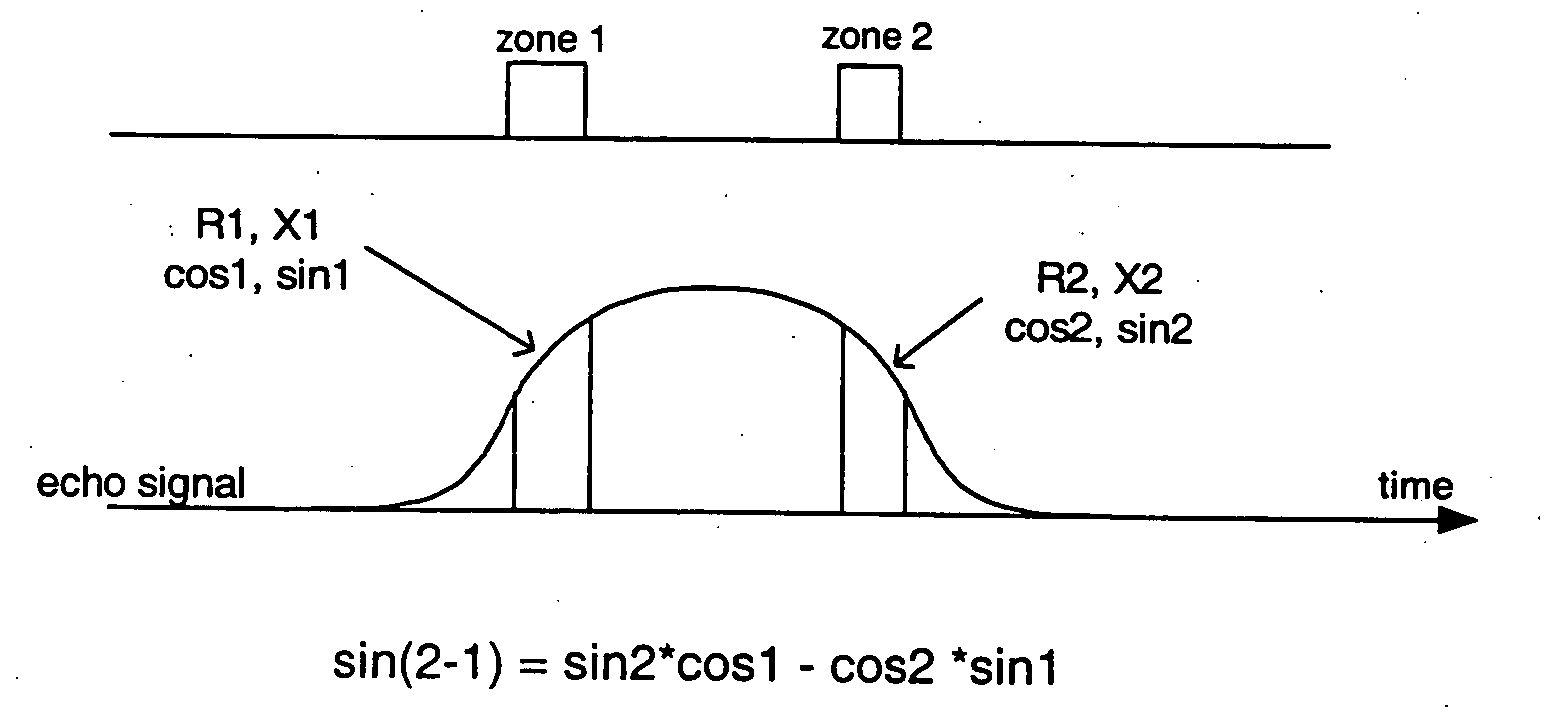

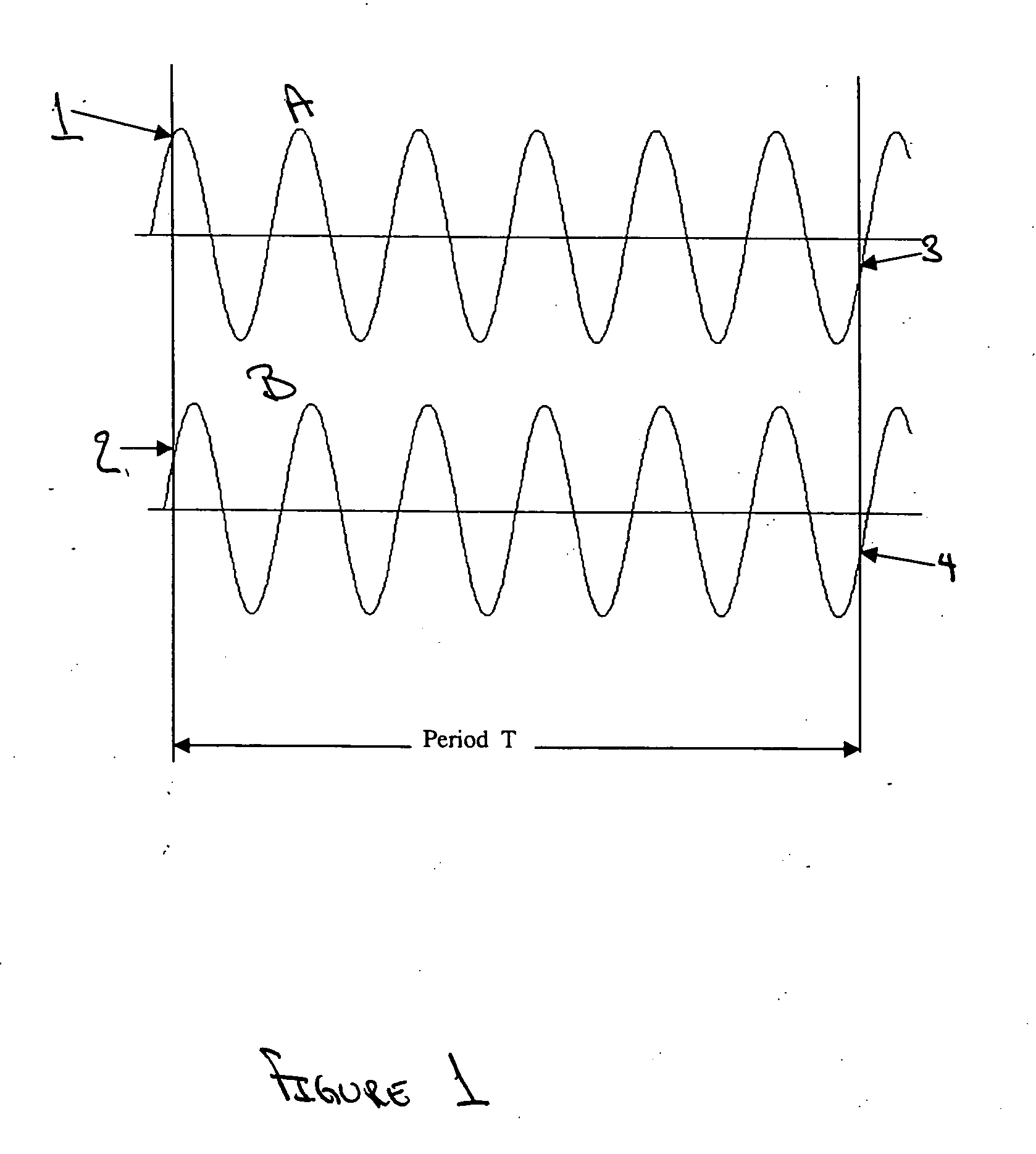

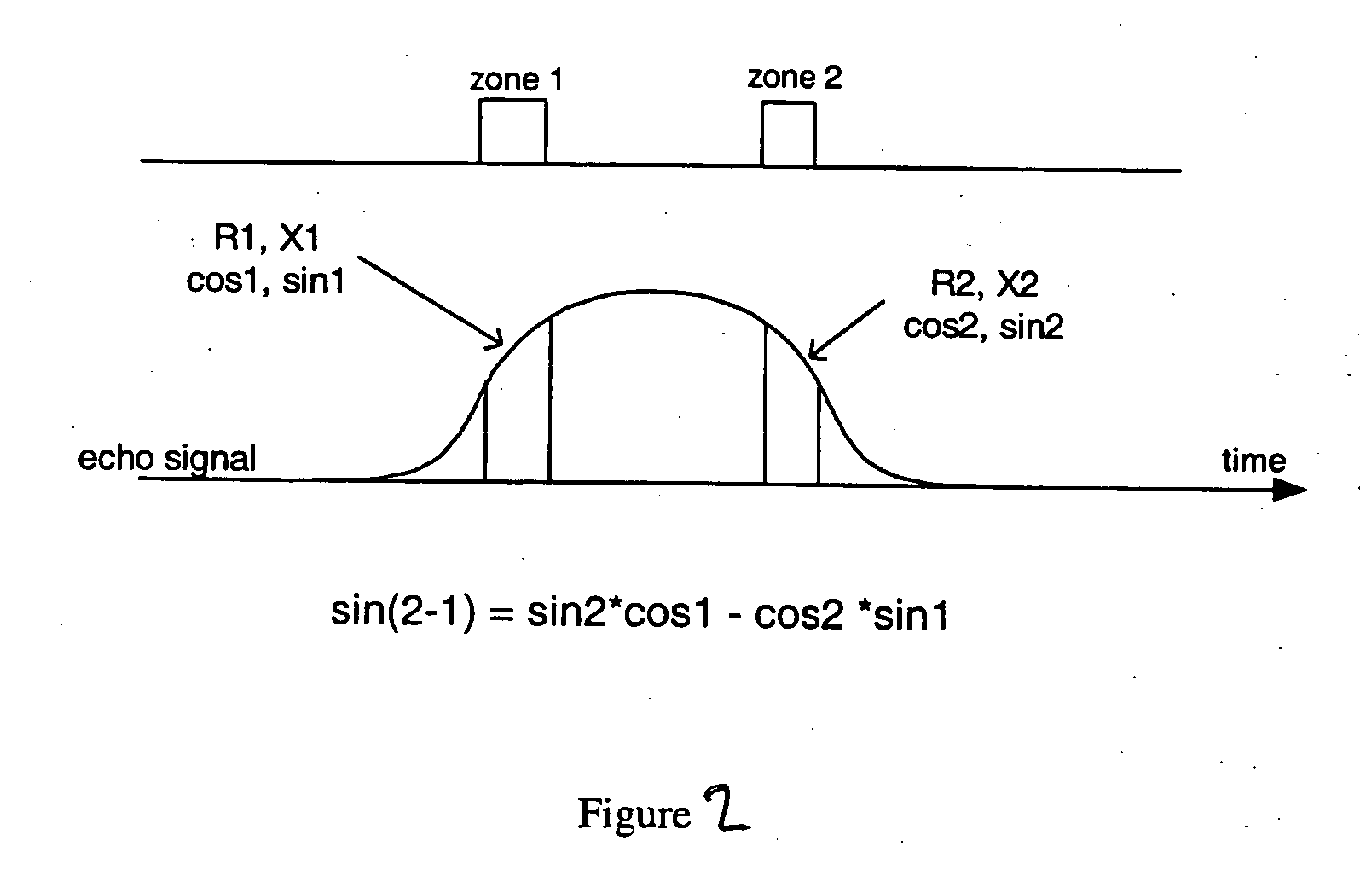

- The method involves continuous analysis of echo signals to detect mistuning of the rf frequency from the Larmor frequency, using phase measurements and feedback loops to adjust antenna tuning and rf frequency in real-time, allowing for continuous maintenance of tool calibration during logging without the need for time-consuming off-line procedures.

Quality Assurance Standards for NMR Equipment

Quality assurance standards for NMR equipment have evolved significantly over the past decades, reflecting the increasing precision demands in various applications from pharmaceutical research to materials science. These standards encompass both hardware specifications and operational protocols designed to ensure consistent, reliable, and accurate measurements across different NMR systems.

The International Organization for Standardization (ISO) has established several relevant standards, including ISO 17025 which specifically addresses the competence of testing and calibration laboratories. For NMR equipment, this translates into rigorous requirements for calibration procedures, maintenance schedules, and performance verification protocols.

ASTM International has developed the ASTM D7171 standard, which provides guidelines for quantitative NMR spectroscopy. This standard outlines procedures for sample preparation, instrument calibration, and data processing that are essential for achieving reproducible results with high measurement fidelity.

The United States Pharmacopeia (USP) and European Pharmacopoeia (EP) have established specific requirements for NMR equipment used in pharmaceutical analysis. These include specifications for resolution, sensitivity, and stability that must be met to ensure compliance with regulatory requirements for drug development and quality control.

Equipment manufacturers have also developed their own quality assurance protocols, often exceeding industry standards. These typically include factory acceptance testing (FAT) and site acceptance testing (SAT) procedures that verify equipment performance against specified parameters before and after installation.

Regular performance verification is a cornerstone of NMR quality assurance. This includes tests for resolution, sensitivity, lineshape, and stability that must be performed at scheduled intervals. Modern NMR systems often incorporate automated testing routines that can detect deviations from established performance baselines.

Traceability to national and international standards is another critical aspect of NMR quality assurance. Reference materials certified by organizations such as the National Institute of Standards and Technology (NIST) are used to validate measurement accuracy and establish traceability chains.

Documentation requirements form an integral part of quality assurance standards. These include maintenance of equipment logs, calibration certificates, and standard operating procedures (SOPs) that ensure consistent operation and facilitate troubleshooting when measurement anomalies occur.

As NMR technology continues to advance, quality assurance standards are evolving to address new challenges, including those related to cryogen-free systems, higher field strengths, and automated sample handling. These emerging standards aim to maintain measurement fidelity while accommodating technological innovations that expand the capabilities and applications of NMR spectroscopy.

The International Organization for Standardization (ISO) has established several relevant standards, including ISO 17025 which specifically addresses the competence of testing and calibration laboratories. For NMR equipment, this translates into rigorous requirements for calibration procedures, maintenance schedules, and performance verification protocols.

ASTM International has developed the ASTM D7171 standard, which provides guidelines for quantitative NMR spectroscopy. This standard outlines procedures for sample preparation, instrument calibration, and data processing that are essential for achieving reproducible results with high measurement fidelity.

The United States Pharmacopeia (USP) and European Pharmacopoeia (EP) have established specific requirements for NMR equipment used in pharmaceutical analysis. These include specifications for resolution, sensitivity, and stability that must be met to ensure compliance with regulatory requirements for drug development and quality control.

Equipment manufacturers have also developed their own quality assurance protocols, often exceeding industry standards. These typically include factory acceptance testing (FAT) and site acceptance testing (SAT) procedures that verify equipment performance against specified parameters before and after installation.

Regular performance verification is a cornerstone of NMR quality assurance. This includes tests for resolution, sensitivity, lineshape, and stability that must be performed at scheduled intervals. Modern NMR systems often incorporate automated testing routines that can detect deviations from established performance baselines.

Traceability to national and international standards is another critical aspect of NMR quality assurance. Reference materials certified by organizations such as the National Institute of Standards and Technology (NIST) are used to validate measurement accuracy and establish traceability chains.

Documentation requirements form an integral part of quality assurance standards. These include maintenance of equipment logs, calibration certificates, and standard operating procedures (SOPs) that ensure consistent operation and facilitate troubleshooting when measurement anomalies occur.

As NMR technology continues to advance, quality assurance standards are evolving to address new challenges, including those related to cryogen-free systems, higher field strengths, and automated sample handling. These emerging standards aim to maintain measurement fidelity while accommodating technological innovations that expand the capabilities and applications of NMR spectroscopy.

Environmental Factors Affecting NMR Measurement Stability

Nuclear Magnetic Resonance (NMR) spectroscopy requires exceptional measurement precision to deliver reliable analytical results. Environmental factors significantly impact the stability and accuracy of NMR measurements, creating challenges that must be systematically addressed to ensure data integrity.

Temperature fluctuations represent one of the most critical environmental variables affecting NMR performance. Even minor temperature variations can alter sample properties, causing chemical shift drift and peak broadening. Modern NMR facilities typically maintain temperature control within ±0.1°C, utilizing advanced HVAC systems with dedicated temperature monitoring. Temperature gradients within the magnet bore itself must also be minimized through specialized shielding and airflow management.

Vibration interference poses another substantial challenge to measurement stability. External vibrations from laboratory equipment, building mechanical systems, or even distant construction can introduce noise artifacts and reduce spectral resolution. High-performance NMR installations incorporate vibration isolation platforms, pneumatic supports, and strategic placement away from mechanical rooms and high-traffic areas. Continuous vibration monitoring using accelerometers helps identify problematic frequency ranges requiring additional isolation.

Electromagnetic interference (EMI) from nearby electronic devices, power lines, or radio transmitters can severely compromise NMR data quality. Faraday cage enclosures surrounding NMR magnets provide essential EMI shielding, while specialized power conditioning equipment eliminates electrical noise from the facility's power supply. RF-tight rooms with copper mesh embedded in walls offer additional protection for particularly sensitive measurements.

Humidity variations affect both electronic components and sample integrity. Excessive humidity accelerates corrosion in sensitive electronic circuits, while insufficient humidity increases static electricity risks. Optimal NMR laboratory conditions maintain relative humidity between 40-60% using dedicated humidity control systems integrated with the facility's environmental management infrastructure.

Barometric pressure fluctuations, though subtle, can impact high-resolution NMR measurements by altering the magnetic susceptibility of samples. Pressure-compensated sample tubes and reference standards help mitigate these effects, particularly for quantitative applications requiring exceptional precision.

Magnetic field homogeneity preservation demands strict control of ferromagnetic materials in the NMR environment. Even small ferromagnetic objects moving near the magnet can distort the carefully shimmed magnetic field. Comprehensive facility design includes non-magnetic construction materials, designated pathways for equipment movement, and staff training regarding ferromagnetic object restrictions.

Addressing these environmental factors requires an integrated approach combining specialized facility design, continuous monitoring systems, and operational protocols. The investment in environmental control infrastructure directly correlates with measurement fidelity, particularly for advanced applications requiring sub-ppm resolution and quantitative accuracy.

Temperature fluctuations represent one of the most critical environmental variables affecting NMR performance. Even minor temperature variations can alter sample properties, causing chemical shift drift and peak broadening. Modern NMR facilities typically maintain temperature control within ±0.1°C, utilizing advanced HVAC systems with dedicated temperature monitoring. Temperature gradients within the magnet bore itself must also be minimized through specialized shielding and airflow management.

Vibration interference poses another substantial challenge to measurement stability. External vibrations from laboratory equipment, building mechanical systems, or even distant construction can introduce noise artifacts and reduce spectral resolution. High-performance NMR installations incorporate vibration isolation platforms, pneumatic supports, and strategic placement away from mechanical rooms and high-traffic areas. Continuous vibration monitoring using accelerometers helps identify problematic frequency ranges requiring additional isolation.

Electromagnetic interference (EMI) from nearby electronic devices, power lines, or radio transmitters can severely compromise NMR data quality. Faraday cage enclosures surrounding NMR magnets provide essential EMI shielding, while specialized power conditioning equipment eliminates electrical noise from the facility's power supply. RF-tight rooms with copper mesh embedded in walls offer additional protection for particularly sensitive measurements.

Humidity variations affect both electronic components and sample integrity. Excessive humidity accelerates corrosion in sensitive electronic circuits, while insufficient humidity increases static electricity risks. Optimal NMR laboratory conditions maintain relative humidity between 40-60% using dedicated humidity control systems integrated with the facility's environmental management infrastructure.

Barometric pressure fluctuations, though subtle, can impact high-resolution NMR measurements by altering the magnetic susceptibility of samples. Pressure-compensated sample tubes and reference standards help mitigate these effects, particularly for quantitative applications requiring exceptional precision.

Magnetic field homogeneity preservation demands strict control of ferromagnetic materials in the NMR environment. Even small ferromagnetic objects moving near the magnet can distort the carefully shimmed magnetic field. Comprehensive facility design includes non-magnetic construction materials, designated pathways for equipment movement, and staff training regarding ferromagnetic object restrictions.

Addressing these environmental factors requires an integrated approach combining specialized facility design, continuous monitoring systems, and operational protocols. The investment in environmental control infrastructure directly correlates with measurement fidelity, particularly for advanced applications requiring sub-ppm resolution and quantitative accuracy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!