Pressure Adjustments in Gas Welding to Combat Metal Distortion

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Pressure Control Evolution and Objectives

Gas welding has been a cornerstone of metal fabrication since its inception in the late 19th century. The evolution of pressure control in gas welding has been driven by the persistent challenge of metal distortion, a problem that has plagued welders for decades. Initially, welders relied on experience and intuition to adjust gas pressures, leading to inconsistent results and frequent distortion issues.

The primary objective in the development of pressure control systems for gas welding has been to minimize metal distortion while maintaining weld quality. This goal has necessitated a deep understanding of the relationship between gas pressure, heat input, and material behavior. Over time, researchers and engineers have worked to quantify these relationships, leading to more precise control mechanisms.

Early advancements focused on improving the regulators and valves used to control gas flow. The introduction of two-stage regulators in the mid-20th century marked a significant milestone, allowing for more stable pressure delivery. This was followed by the development of flow meters, which provided welders with visual feedback on gas consumption rates, enabling more accurate adjustments.

The advent of electronic pressure sensors and digital control systems in the late 20th century revolutionized gas welding pressure control. These technologies allowed for real-time monitoring and adjustment of gas pressures, significantly reducing the risk of metal distortion. Programmable logic controllers (PLCs) further enhanced this capability by enabling the implementation of pre-set pressure profiles for different welding scenarios.

Recent technological objectives have centered on integrating artificial intelligence and machine learning algorithms into pressure control systems. These advanced systems aim to predict and preemptively adjust gas pressures based on real-time analysis of welding conditions, material properties, and environmental factors. The goal is to create adaptive systems that can optimize pressure settings on-the-fly, further minimizing the risk of distortion.

Another key objective in the evolution of gas welding pressure control has been the development of user-friendly interfaces. Modern systems often feature touch-screen displays and intuitive controls, making it easier for welders of all skill levels to achieve optimal results. This democratization of advanced pressure control technology has been crucial in improving overall welding quality across the industry.

Looking forward, the objectives for gas welding pressure control continue to focus on achieving ever-finer degrees of precision and automation. Researchers are exploring the potential of nanotechnology in sensor development, aiming to create ultra-sensitive pressure detection systems. Additionally, there is a growing emphasis on integrating pressure control with other welding parameters, such as torch angle and travel speed, to create holistic welding optimization systems that can effectively combat metal distortion.

The primary objective in the development of pressure control systems for gas welding has been to minimize metal distortion while maintaining weld quality. This goal has necessitated a deep understanding of the relationship between gas pressure, heat input, and material behavior. Over time, researchers and engineers have worked to quantify these relationships, leading to more precise control mechanisms.

Early advancements focused on improving the regulators and valves used to control gas flow. The introduction of two-stage regulators in the mid-20th century marked a significant milestone, allowing for more stable pressure delivery. This was followed by the development of flow meters, which provided welders with visual feedback on gas consumption rates, enabling more accurate adjustments.

The advent of electronic pressure sensors and digital control systems in the late 20th century revolutionized gas welding pressure control. These technologies allowed for real-time monitoring and adjustment of gas pressures, significantly reducing the risk of metal distortion. Programmable logic controllers (PLCs) further enhanced this capability by enabling the implementation of pre-set pressure profiles for different welding scenarios.

Recent technological objectives have centered on integrating artificial intelligence and machine learning algorithms into pressure control systems. These advanced systems aim to predict and preemptively adjust gas pressures based on real-time analysis of welding conditions, material properties, and environmental factors. The goal is to create adaptive systems that can optimize pressure settings on-the-fly, further minimizing the risk of distortion.

Another key objective in the evolution of gas welding pressure control has been the development of user-friendly interfaces. Modern systems often feature touch-screen displays and intuitive controls, making it easier for welders of all skill levels to achieve optimal results. This democratization of advanced pressure control technology has been crucial in improving overall welding quality across the industry.

Looking forward, the objectives for gas welding pressure control continue to focus on achieving ever-finer degrees of precision and automation. Researchers are exploring the potential of nanotechnology in sensor development, aiming to create ultra-sensitive pressure detection systems. Additionally, there is a growing emphasis on integrating pressure control with other welding parameters, such as torch angle and travel speed, to create holistic welding optimization systems that can effectively combat metal distortion.

Market Demand for Distortion-Free Welding Solutions

The demand for distortion-free welding solutions has been steadily increasing across various industries, driven by the need for higher quality, precision, and efficiency in manufacturing processes. Gas welding, while a traditional technique, continues to play a significant role in many sectors, particularly in repair and maintenance operations. However, the persistent challenge of metal distortion during welding has created a substantial market opportunity for innovative solutions that can mitigate this issue.

In the automotive industry, where lightweight materials and complex designs are becoming more prevalent, the need for precise welding techniques that minimize distortion is paramount. Manufacturers are actively seeking solutions that can maintain the structural integrity of components while ensuring aesthetic quality. This demand extends to the aerospace sector, where even minor distortions can have critical implications for safety and performance.

The construction and infrastructure industries also represent a significant market for distortion-free welding solutions. Large-scale projects involving structural steel require welding techniques that can maintain the dimensional accuracy of components, ensuring the overall stability and longevity of structures. The ability to reduce or eliminate distortion can lead to substantial cost savings by minimizing the need for post-weld corrections and rework.

In the shipbuilding industry, where large metal plates and complex geometries are common, the demand for distortion control is particularly acute. Shipyards are increasingly looking for welding technologies that can improve productivity while maintaining high quality standards. The ability to adjust pressure in gas welding to combat metal distortion could offer a competitive advantage in this sector.

The energy sector, including oil and gas, power generation, and renewable energy industries, also presents a significant market for advanced welding solutions. The construction and maintenance of pipelines, pressure vessels, and wind turbine components require welding techniques that can ensure structural integrity under extreme conditions. Distortion-free welding is crucial for preventing leaks, failures, and costly downtime.

Market analysis indicates that companies offering solutions to combat metal distortion in welding processes can expect substantial growth opportunities. The global welding equipment and consumables market is projected to expand significantly in the coming years, with a notable portion of this growth attributed to advanced technologies that address quality and efficiency concerns.

Furthermore, the increasing adoption of automation and robotics in welding processes is creating additional demand for precision welding techniques. Manufacturers are seeking integrated solutions that can combine pressure adjustments with automated systems to achieve consistent, high-quality welds with minimal distortion across large production runs.

In the automotive industry, where lightweight materials and complex designs are becoming more prevalent, the need for precise welding techniques that minimize distortion is paramount. Manufacturers are actively seeking solutions that can maintain the structural integrity of components while ensuring aesthetic quality. This demand extends to the aerospace sector, where even minor distortions can have critical implications for safety and performance.

The construction and infrastructure industries also represent a significant market for distortion-free welding solutions. Large-scale projects involving structural steel require welding techniques that can maintain the dimensional accuracy of components, ensuring the overall stability and longevity of structures. The ability to reduce or eliminate distortion can lead to substantial cost savings by minimizing the need for post-weld corrections and rework.

In the shipbuilding industry, where large metal plates and complex geometries are common, the demand for distortion control is particularly acute. Shipyards are increasingly looking for welding technologies that can improve productivity while maintaining high quality standards. The ability to adjust pressure in gas welding to combat metal distortion could offer a competitive advantage in this sector.

The energy sector, including oil and gas, power generation, and renewable energy industries, also presents a significant market for advanced welding solutions. The construction and maintenance of pipelines, pressure vessels, and wind turbine components require welding techniques that can ensure structural integrity under extreme conditions. Distortion-free welding is crucial for preventing leaks, failures, and costly downtime.

Market analysis indicates that companies offering solutions to combat metal distortion in welding processes can expect substantial growth opportunities. The global welding equipment and consumables market is projected to expand significantly in the coming years, with a notable portion of this growth attributed to advanced technologies that address quality and efficiency concerns.

Furthermore, the increasing adoption of automation and robotics in welding processes is creating additional demand for precision welding techniques. Manufacturers are seeking integrated solutions that can combine pressure adjustments with automated systems to achieve consistent, high-quality welds with minimal distortion across large production runs.

Current Challenges in Gas Welding Pressure Management

Gas welding pressure management faces several significant challenges in the context of combating metal distortion. One of the primary issues is the difficulty in maintaining consistent pressure throughout the welding process. Fluctuations in gas pressure can lead to uneven heat distribution, resulting in localized thermal stresses that contribute to warping and distortion of the metal workpiece.

Another challenge lies in the precise control of gas flow rates. Achieving the optimal balance between fuel gas and oxygen is crucial for creating the ideal flame characteristics. However, many existing systems lack the sensitivity required for fine-tuning these parameters, especially when working with different metal types and thicknesses. This limitation often results in suboptimal welding conditions that exacerbate distortion issues.

The dynamic nature of the welding environment poses additional complications. As the metal heats up and cools down during the welding process, its thermal properties change, necessitating real-time adjustments to gas pressure. Current systems often struggle to adapt quickly enough to these changing conditions, leading to inconsistencies in weld quality and increased likelihood of distortion.

Furthermore, the human factor introduces variability in pressure management. Welders' skill levels and experience can significantly impact their ability to manually adjust gas pressures effectively. This reliance on operator expertise can lead to inconsistencies in weld quality and distortion control, particularly in large-scale manufacturing operations where multiple welders are involved.

The integration of pressure management systems with other welding parameters also presents a challenge. Factors such as travel speed, torch angle, and filler material feed rate all interact with gas pressure to influence the final weld quality and distortion levels. Developing comprehensive control systems that can harmonize these various elements remains a complex task.

Additionally, the industry faces challenges in accurately measuring and monitoring gas pressures in real-time during the welding process. Many current systems rely on pre-set pressures or periodic manual checks, which may not capture rapid fluctuations or gradual drift in gas flow. This lack of continuous monitoring can result in undetected pressure issues that contribute to metal distortion.

Lastly, the cost and complexity of implementing advanced pressure management systems pose barriers to widespread adoption, particularly for smaller welding operations. Balancing the need for sophisticated control mechanisms with practical considerations of affordability and ease of use remains an ongoing challenge in the field of gas welding pressure management.

Another challenge lies in the precise control of gas flow rates. Achieving the optimal balance between fuel gas and oxygen is crucial for creating the ideal flame characteristics. However, many existing systems lack the sensitivity required for fine-tuning these parameters, especially when working with different metal types and thicknesses. This limitation often results in suboptimal welding conditions that exacerbate distortion issues.

The dynamic nature of the welding environment poses additional complications. As the metal heats up and cools down during the welding process, its thermal properties change, necessitating real-time adjustments to gas pressure. Current systems often struggle to adapt quickly enough to these changing conditions, leading to inconsistencies in weld quality and increased likelihood of distortion.

Furthermore, the human factor introduces variability in pressure management. Welders' skill levels and experience can significantly impact their ability to manually adjust gas pressures effectively. This reliance on operator expertise can lead to inconsistencies in weld quality and distortion control, particularly in large-scale manufacturing operations where multiple welders are involved.

The integration of pressure management systems with other welding parameters also presents a challenge. Factors such as travel speed, torch angle, and filler material feed rate all interact with gas pressure to influence the final weld quality and distortion levels. Developing comprehensive control systems that can harmonize these various elements remains a complex task.

Additionally, the industry faces challenges in accurately measuring and monitoring gas pressures in real-time during the welding process. Many current systems rely on pre-set pressures or periodic manual checks, which may not capture rapid fluctuations or gradual drift in gas flow. This lack of continuous monitoring can result in undetected pressure issues that contribute to metal distortion.

Lastly, the cost and complexity of implementing advanced pressure management systems pose barriers to widespread adoption, particularly for smaller welding operations. Balancing the need for sophisticated control mechanisms with practical considerations of affordability and ease of use remains an ongoing challenge in the field of gas welding pressure management.

Existing Pressure Adjustment Techniques for Distortion Mitigation

01 Controlling heat input to minimize distortion

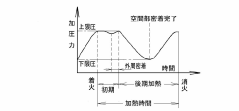

Techniques for controlling heat input during gas welding to minimize metal distortion. This includes methods for regulating gas flow, adjusting flame intensity, and optimizing welding speed to reduce thermal stress and prevent warping of the metal.- Controlling heat input to minimize distortion: Techniques for controlling heat input during gas welding to minimize metal distortion. This includes methods for regulating gas flow, adjusting flame intensity, and optimizing welding speed to reduce thermal stress and prevent warping of the metal.

- Pre-welding preparation and fixturing: Methods for preparing metal components and using fixtures to reduce distortion during gas welding. This involves proper cleaning, alignment, and clamping of workpieces to maintain their shape and position throughout the welding process.

- Post-welding distortion correction: Techniques for correcting distortion after gas welding, including heat treatment, mechanical straightening, and stress relief processes. These methods aim to restore the desired shape and properties of the welded metal components.

- Welding sequence and pattern optimization: Strategies for optimizing welding sequences and patterns to minimize cumulative distortion in gas welding. This includes techniques such as back-stepping, skip welding, and balanced heat distribution to reduce overall thermal stress on the workpiece.

- Advanced gas welding technologies for distortion control: Innovative gas welding technologies and equipment designed to minimize metal distortion. This includes pulsed gas welding systems, computer-controlled heat input, and real-time distortion monitoring and correction during the welding process.

02 Pre-welding preparation and fixturing

Methods for preparing metal components and using fixtures to reduce distortion during gas welding. This involves proper alignment, clamping, and tacking techniques to maintain the desired shape and dimensions of the welded parts.Expand Specific Solutions03 Post-welding distortion correction

Techniques for correcting distortion after gas welding, including heat treatment, mechanical straightening, and stress relief processes. These methods aim to restore the original shape and properties of the welded metal components.Expand Specific Solutions04 Welding sequence and pattern optimization

Strategies for optimizing welding sequences and patterns to minimize cumulative distortion in gas welding. This includes techniques such as back-stepping, skip welding, and balanced heat distribution to reduce overall thermal stress on the metal.Expand Specific Solutions05 Advanced gas welding technologies

Innovative gas welding technologies and equipment designed to reduce metal distortion. This includes pulsed gas welding, computer-controlled gas flow systems, and specialized torch designs that provide better control over heat input and distribution.Expand Specific Solutions

Key Players in Gas Welding Equipment Industry

The competitive landscape for "Pressure Adjustments in Gas Welding to Combat Metal Distortion" is in a mature stage, with established players and well-developed technologies. The market size is substantial, driven by the widespread use of gas welding in various industries. Companies like Air Liquide, Linde GmbH, and Lincoln Global, Inc. are at the forefront of technological advancements in this field. These industry leaders have developed sophisticated pressure control systems and innovative welding techniques to minimize metal distortion. The technology's maturity is evident in the diverse range of solutions offered by companies such as KUKA Systems GmbH and Azbil Corp., which integrate advanced automation and control systems into welding processes.

Linde GmbH

Technical Solution: Linde GmbH has developed advanced gas management solutions to address pressure-related issues in gas welding and combat metal distortion. Their ADDvance® O2 precision system provides real-time monitoring and adjustment of oxygen levels in the welding atmosphere, crucial for maintaining optimal pressure and reducing oxidation-induced distortion[1]. Linde has also introduced the CORGON® gas mixture series, which incorporates pressure-optimized blends to enhance arc stability and reduce heat input, thereby minimizing distortion in various materials[3]. The company's VARIGON® range offers customizable gas compositions that can be fine-tuned to specific welding requirements, allowing for precise pressure control in challenging applications[5]. Additionally, Linde has developed the BASELINE® gas flow management system, which ensures consistent pressure delivery across multiple welding stations, critical for maintaining quality in large-scale production environments[7].

Strengths: Comprehensive range of specialized gas solutions, advanced monitoring systems, adaptability to various welding processes. Weaknesses: May require investment in compatible equipment, potential dependence on Linde's proprietary gas mixtures.

Lincoln Global, Inc.

Technical Solution: Lincoln Global has developed advanced pressure control systems for gas welding to combat metal distortion. Their technology utilizes real-time pressure sensors and adaptive algorithms to dynamically adjust gas flow and pressure during the welding process[1]. This system continuously monitors the welding environment and makes micro-adjustments to maintain optimal pressure levels, reducing thermal stress and minimizing distortion[3]. The company has also integrated this technology with their digital welding power sources, allowing for precise synchronization between arc characteristics and gas pressure[5]. Additionally, Lincoln Global has introduced pulsed gas flow techniques, which alternate between high and low pressure cycles to further control heat input and reduce distortion in sensitive materials[7].

Strengths: Precise control over welding parameters, reduced distortion in complex geometries, improved weld quality. Weaknesses: Higher initial equipment cost, requires operator training for optimal use.

Innovative Pressure Control Systems for Gas Welding

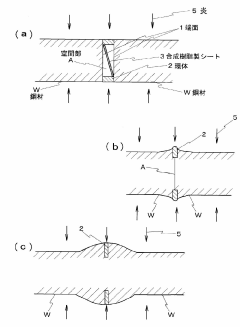

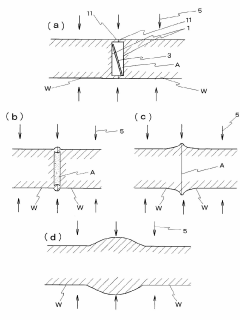

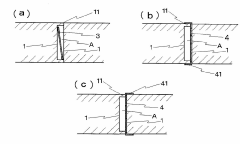

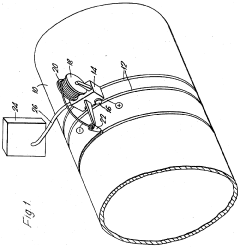

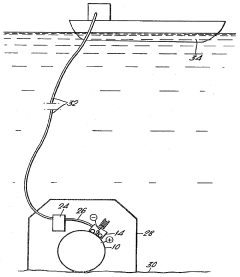

Gas pressure welding method

PatentInactiveJP2010149142A

Innovation

- A method involving an annular body of the same material as the steel, with a synthetic resin sheet in the space, using an acetylene-oxygen flame for initial and late heating, eliminating the need for a feathered flame and reducing oxygen consumption.

Welding at pressures greater than atmospheric pressure

PatentInactiveUS4400611A

Innovation

- Adopting a metal inert gas welding process with the electrode negative to the workpiece, using a higher power supply slope (6-15 V/100 A) and predominantly argon or helium with added oxidizing gases, to improve arc stability and penetration, and employing mechanized processes for increased efficiency.

Safety Standards and Regulations in Gas Welding

Safety standards and regulations play a crucial role in ensuring the well-being of workers and maintaining the integrity of gas welding operations. In the context of pressure adjustments to combat metal distortion, adherence to safety protocols becomes even more critical. The Occupational Safety and Health Administration (OSHA) in the United States has established comprehensive guidelines for gas welding safety, which are widely adopted internationally.

These regulations mandate the use of personal protective equipment (PPE) such as flame-resistant clothing, safety glasses, and welding helmets. When adjusting pressures to mitigate metal distortion, welders must be particularly vigilant about potential gas leaks or sudden pressure changes. OSHA standards require regular inspection and maintenance of pressure regulators, hoses, and valves to prevent equipment failure.

The American Welding Society (AWS) provides additional safety standards specific to gas welding processes. These standards emphasize the importance of proper ventilation to prevent the accumulation of harmful gases and fumes, especially when working with varying gas pressures. The AWS also outlines guidelines for the safe storage and handling of gas cylinders, which is crucial when implementing pressure adjustment techniques.

In Europe, the EN ISO 5172 standard governs the safety requirements for gas welding equipment. This standard specifies the design and construction requirements for blowpipes and regulators used in gas welding, ensuring they can withstand the pressures involved in distortion-combating techniques. Compliance with these standards is essential for manufacturers and users of gas welding equipment.

The International Organization for Standardization (ISO) has developed ISO 11611, which sets global standards for protective clothing used in welding and allied processes. This standard becomes particularly relevant when adjusting gas pressures, as it ensures that welders' clothing can withstand potential increases in heat or sparks generated during the process.

Safety training and certification programs, such as those offered by the National Fire Protection Association (NFPA), emphasize the importance of understanding pressure dynamics in gas welding. These programs teach welders how to safely adjust pressures while maintaining awareness of potential hazards such as flashback and backfire.

Regulatory bodies also mandate the implementation of emergency shutdown procedures and the installation of safety devices such as flashback arrestors. These measures are critical when experimenting with pressure adjustments, as they provide an additional layer of protection against accidents caused by unexpected pressure fluctuations.

As technology advances and new pressure adjustment techniques emerge, safety standards continue to evolve. Regulatory bodies work closely with industry experts to update guidelines, ensuring they remain relevant and effective in addressing the latest safety challenges associated with gas welding pressure adjustments.

These regulations mandate the use of personal protective equipment (PPE) such as flame-resistant clothing, safety glasses, and welding helmets. When adjusting pressures to mitigate metal distortion, welders must be particularly vigilant about potential gas leaks or sudden pressure changes. OSHA standards require regular inspection and maintenance of pressure regulators, hoses, and valves to prevent equipment failure.

The American Welding Society (AWS) provides additional safety standards specific to gas welding processes. These standards emphasize the importance of proper ventilation to prevent the accumulation of harmful gases and fumes, especially when working with varying gas pressures. The AWS also outlines guidelines for the safe storage and handling of gas cylinders, which is crucial when implementing pressure adjustment techniques.

In Europe, the EN ISO 5172 standard governs the safety requirements for gas welding equipment. This standard specifies the design and construction requirements for blowpipes and regulators used in gas welding, ensuring they can withstand the pressures involved in distortion-combating techniques. Compliance with these standards is essential for manufacturers and users of gas welding equipment.

The International Organization for Standardization (ISO) has developed ISO 11611, which sets global standards for protective clothing used in welding and allied processes. This standard becomes particularly relevant when adjusting gas pressures, as it ensures that welders' clothing can withstand potential increases in heat or sparks generated during the process.

Safety training and certification programs, such as those offered by the National Fire Protection Association (NFPA), emphasize the importance of understanding pressure dynamics in gas welding. These programs teach welders how to safely adjust pressures while maintaining awareness of potential hazards such as flashback and backfire.

Regulatory bodies also mandate the implementation of emergency shutdown procedures and the installation of safety devices such as flashback arrestors. These measures are critical when experimenting with pressure adjustments, as they provide an additional layer of protection against accidents caused by unexpected pressure fluctuations.

As technology advances and new pressure adjustment techniques emerge, safety standards continue to evolve. Regulatory bodies work closely with industry experts to update guidelines, ensuring they remain relevant and effective in addressing the latest safety challenges associated with gas welding pressure adjustments.

Economic Impact of Improved Welding Precision

The economic impact of improved welding precision through pressure adjustments in gas welding to combat metal distortion is significant and far-reaching. This technological advancement has the potential to revolutionize various industries that rely heavily on welding processes, particularly in manufacturing, construction, and aerospace sectors.

One of the primary economic benefits is the reduction in material waste. By minimizing metal distortion, companies can significantly decrease the amount of scrap material produced during welding operations. This not only leads to direct cost savings on raw materials but also reduces the environmental impact associated with waste disposal and the production of replacement parts.

Improved welding precision also translates to enhanced product quality and reliability. Products manufactured with more precise welding techniques are less likely to fail or require repairs, leading to increased customer satisfaction and reduced warranty claims. This improvement in product performance can strengthen a company's market position and potentially increase market share, driving revenue growth.

The efficiency gains from improved welding precision are substantial. With reduced distortion, the need for post-welding corrective measures such as straightening or heat treatment is minimized. This streamlines the production process, reducing labor costs and increasing overall productivity. Faster production times can lead to quicker turnaround on orders and improved capacity utilization, allowing companies to take on more projects and increase their revenue potential.

In the construction industry, more precise welding techniques can lead to stronger and more durable structures. This can result in longer-lasting buildings and infrastructure, reducing maintenance costs over time and improving safety standards. The ability to create more complex and precise welded structures may also open up new design possibilities, potentially spurring innovation in architecture and engineering.

For the aerospace and automotive industries, where weight and structural integrity are critical factors, improved welding precision can lead to lighter yet stronger components. This can contribute to improved fuel efficiency in vehicles and aircraft, resulting in significant cost savings for operators and reduced environmental impact.

The adoption of advanced welding techniques may also drive investment in workforce development. As companies seek to implement these new technologies, there will be an increased demand for skilled welders and technicians proficient in operating advanced welding equipment. This could lead to job creation and higher-paying positions in the manufacturing sector, contributing to economic growth.

Furthermore, the development and commercialization of improved welding technologies create opportunities for equipment manufacturers and technology providers. Companies that can offer innovative solutions for pressure-adjusted gas welding may see increased demand for their products, potentially leading to the growth of a specialized industry segment.

One of the primary economic benefits is the reduction in material waste. By minimizing metal distortion, companies can significantly decrease the amount of scrap material produced during welding operations. This not only leads to direct cost savings on raw materials but also reduces the environmental impact associated with waste disposal and the production of replacement parts.

Improved welding precision also translates to enhanced product quality and reliability. Products manufactured with more precise welding techniques are less likely to fail or require repairs, leading to increased customer satisfaction and reduced warranty claims. This improvement in product performance can strengthen a company's market position and potentially increase market share, driving revenue growth.

The efficiency gains from improved welding precision are substantial. With reduced distortion, the need for post-welding corrective measures such as straightening or heat treatment is minimized. This streamlines the production process, reducing labor costs and increasing overall productivity. Faster production times can lead to quicker turnaround on orders and improved capacity utilization, allowing companies to take on more projects and increase their revenue potential.

In the construction industry, more precise welding techniques can lead to stronger and more durable structures. This can result in longer-lasting buildings and infrastructure, reducing maintenance costs over time and improving safety standards. The ability to create more complex and precise welded structures may also open up new design possibilities, potentially spurring innovation in architecture and engineering.

For the aerospace and automotive industries, where weight and structural integrity are critical factors, improved welding precision can lead to lighter yet stronger components. This can contribute to improved fuel efficiency in vehicles and aircraft, resulting in significant cost savings for operators and reduced environmental impact.

The adoption of advanced welding techniques may also drive investment in workforce development. As companies seek to implement these new technologies, there will be an increased demand for skilled welders and technicians proficient in operating advanced welding equipment. This could lead to job creation and higher-paying positions in the manufacturing sector, contributing to economic growth.

Furthermore, the development and commercialization of improved welding technologies create opportunities for equipment manufacturers and technology providers. Companies that can offer innovative solutions for pressure-adjusted gas welding may see increased demand for their products, potentially leading to the growth of a specialized industry segment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!