Adaptations of Power Steering Fluid for Snowplows and Winter Equipment

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Fluid Evolution

Power steering fluid has undergone significant evolution since its introduction in the mid-20th century. Initially developed to reduce steering effort in vehicles, the fluid has adapted to meet the changing demands of automotive technology and environmental conditions. The evolution of power steering fluid can be traced through several key stages, each marked by advancements in fluid composition and performance characteristics.

In the early days of power steering systems, mineral oil-based fluids were commonly used. These fluids provided basic lubrication and pressure transfer capabilities but were limited in their temperature range and durability. As vehicles became more sophisticated and operating conditions more demanding, the need for improved fluid formulations became apparent.

The 1970s and 1980s saw the introduction of synthetic-based power steering fluids. These fluids offered enhanced thermal stability, improved wear protection, and better low-temperature performance compared to their mineral oil counterparts. Synthetic fluids also demonstrated superior resistance to oxidation and degradation, leading to extended service life and reduced maintenance requirements.

As environmental concerns gained prominence in the automotive industry, the focus shifted towards developing more eco-friendly power steering fluids. This led to the creation of biodegradable formulations that minimized environmental impact in case of leaks or spills. These fluids were designed to break down naturally without causing long-term harm to ecosystems.

The advent of electric power steering systems in the late 1990s and early 2000s prompted further advancements in fluid technology. While these systems reduced the overall fluid volume required, they placed new demands on fluid performance, particularly in terms of electrical conductivity and compatibility with electronic components.

In recent years, the evolution of power steering fluid has been driven by the need for specialized formulations to address extreme operating conditions. This is particularly relevant for vehicles operating in harsh winter environments, such as snowplows and other winter equipment. These applications require fluids that maintain optimal viscosity and performance at extremely low temperatures while providing enhanced protection against corrosion and wear.

The latest generation of power steering fluids incorporates advanced additive packages designed to improve cold-weather performance, reduce foaming, and enhance seal compatibility. These fluids often feature multi-grade formulations that maintain consistent viscosity across a wide temperature range, ensuring reliable steering performance in both freezing and warm conditions.

As research continues, the focus is on developing power steering fluids that can adapt to the specific needs of winter equipment, offering improved low-temperature flow properties, enhanced anti-wear protection for components subjected to heavy loads, and increased resistance to moisture contamination. These advancements aim to enhance the reliability and efficiency of snowplows and other winter maintenance vehicles operating in challenging arctic conditions.

In the early days of power steering systems, mineral oil-based fluids were commonly used. These fluids provided basic lubrication and pressure transfer capabilities but were limited in their temperature range and durability. As vehicles became more sophisticated and operating conditions more demanding, the need for improved fluid formulations became apparent.

The 1970s and 1980s saw the introduction of synthetic-based power steering fluids. These fluids offered enhanced thermal stability, improved wear protection, and better low-temperature performance compared to their mineral oil counterparts. Synthetic fluids also demonstrated superior resistance to oxidation and degradation, leading to extended service life and reduced maintenance requirements.

As environmental concerns gained prominence in the automotive industry, the focus shifted towards developing more eco-friendly power steering fluids. This led to the creation of biodegradable formulations that minimized environmental impact in case of leaks or spills. These fluids were designed to break down naturally without causing long-term harm to ecosystems.

The advent of electric power steering systems in the late 1990s and early 2000s prompted further advancements in fluid technology. While these systems reduced the overall fluid volume required, they placed new demands on fluid performance, particularly in terms of electrical conductivity and compatibility with electronic components.

In recent years, the evolution of power steering fluid has been driven by the need for specialized formulations to address extreme operating conditions. This is particularly relevant for vehicles operating in harsh winter environments, such as snowplows and other winter equipment. These applications require fluids that maintain optimal viscosity and performance at extremely low temperatures while providing enhanced protection against corrosion and wear.

The latest generation of power steering fluids incorporates advanced additive packages designed to improve cold-weather performance, reduce foaming, and enhance seal compatibility. These fluids often feature multi-grade formulations that maintain consistent viscosity across a wide temperature range, ensuring reliable steering performance in both freezing and warm conditions.

As research continues, the focus is on developing power steering fluids that can adapt to the specific needs of winter equipment, offering improved low-temperature flow properties, enhanced anti-wear protection for components subjected to heavy loads, and increased resistance to moisture contamination. These advancements aim to enhance the reliability and efficiency of snowplows and other winter maintenance vehicles operating in challenging arctic conditions.

Winter Equipment Market Analysis

The winter equipment market, particularly for snowplows and related machinery, has shown significant growth in recent years due to increasing urbanization and the need for efficient snow removal in cold regions. This market segment is driven by the demand for reliable and high-performance equipment capable of operating in harsh winter conditions. The power steering fluid used in these vehicles plays a crucial role in their functionality and durability.

Market analysis indicates that North America dominates the global snowplow market, followed by Europe and Asia-Pacific regions. The United States and Canada, in particular, have a substantial market share due to their extensive road networks and frequent snowfall. In Europe, countries like Norway, Sweden, and Finland contribute significantly to the market demand. The Asia-Pacific region, especially Japan and South Korea, is emerging as a growing market for winter equipment.

The market for snowplows and winter equipment is characterized by a mix of established players and new entrants. Key market drivers include increasing government investments in road infrastructure maintenance, growing concerns about road safety during winter, and the rise in extreme weather events attributed to climate change. These factors have led to a steady increase in the adoption of advanced winter maintenance equipment.

Power steering fluid adaptations for winter equipment have become a focal point for manufacturers and end-users alike. The harsh operating conditions of snowplows and other winter machinery necessitate specialized fluids that can maintain optimal performance at extremely low temperatures. This has created a niche market for cold-weather-specific power steering fluids, with several lubricant companies developing formulations tailored for winter use.

The market trend shows a shift towards synthetic and semi-synthetic power steering fluids that offer better low-temperature fluidity and resistance to oxidation. These advanced fluids help in reducing wear and tear on steering components, thereby extending the lifespan of expensive winter equipment. The demand for such specialized fluids is expected to grow as municipalities and private contractors seek to optimize their winter maintenance operations and reduce downtime.

Analysis of market data reveals that the power steering fluid segment for winter equipment is projected to grow at a compound annual growth rate (CAGR) higher than the overall lubricant market. This growth is attributed to the increasing awareness among end-users about the benefits of using specialized fluids in extreme conditions. The market is also seeing a trend towards environmentally friendly and biodegradable power steering fluids, aligning with the global push for sustainable practices in all industries.

Market analysis indicates that North America dominates the global snowplow market, followed by Europe and Asia-Pacific regions. The United States and Canada, in particular, have a substantial market share due to their extensive road networks and frequent snowfall. In Europe, countries like Norway, Sweden, and Finland contribute significantly to the market demand. The Asia-Pacific region, especially Japan and South Korea, is emerging as a growing market for winter equipment.

The market for snowplows and winter equipment is characterized by a mix of established players and new entrants. Key market drivers include increasing government investments in road infrastructure maintenance, growing concerns about road safety during winter, and the rise in extreme weather events attributed to climate change. These factors have led to a steady increase in the adoption of advanced winter maintenance equipment.

Power steering fluid adaptations for winter equipment have become a focal point for manufacturers and end-users alike. The harsh operating conditions of snowplows and other winter machinery necessitate specialized fluids that can maintain optimal performance at extremely low temperatures. This has created a niche market for cold-weather-specific power steering fluids, with several lubricant companies developing formulations tailored for winter use.

The market trend shows a shift towards synthetic and semi-synthetic power steering fluids that offer better low-temperature fluidity and resistance to oxidation. These advanced fluids help in reducing wear and tear on steering components, thereby extending the lifespan of expensive winter equipment. The demand for such specialized fluids is expected to grow as municipalities and private contractors seek to optimize their winter maintenance operations and reduce downtime.

Analysis of market data reveals that the power steering fluid segment for winter equipment is projected to grow at a compound annual growth rate (CAGR) higher than the overall lubricant market. This growth is attributed to the increasing awareness among end-users about the benefits of using specialized fluids in extreme conditions. The market is also seeing a trend towards environmentally friendly and biodegradable power steering fluids, aligning with the global push for sustainable practices in all industries.

Cold Weather Challenges

Power steering fluid plays a crucial role in the operation of snowplows and winter equipment, but its performance is significantly challenged by cold weather conditions. As temperatures drop, the viscosity of standard power steering fluid increases, leading to reduced flow and potentially compromising the steering system's responsiveness and efficiency.

One of the primary challenges in cold weather is the fluid's tendency to thicken, which can cause increased resistance in the power steering system. This thickening effect can result in sluggish steering response, increased wear on pump components, and in extreme cases, system failure. The problem is particularly acute during vehicle start-up when the fluid is at its coldest and most viscous state.

Extreme cold can also lead to the formation of ice crystals within the power steering fluid, potentially causing blockages in narrow passages of the steering system. This phenomenon not only impairs steering performance but can also lead to damage of seals, hoses, and other components due to the expansion of frozen fluid.

Another significant challenge is the potential for moisture contamination in the power steering system. In cold climates, temperature fluctuations can cause condensation within the system, introducing water into the fluid. When this moisture freezes, it can create ice particles that may damage internal components and further impede fluid flow.

The cold weather also affects the seals and gaskets in the power steering system. These components may become brittle and less flexible in low temperatures, increasing the risk of leaks and system failures. This can lead to a loss of fluid and potentially catastrophic steering system malfunction during critical snow removal operations.

Furthermore, the extreme temperature differentials experienced by snowplows and winter equipment – from sub-zero outdoor temperatures to warmer engine compartments – can cause thermal stress on the power steering fluid. This cycling between temperature extremes can accelerate fluid breakdown and reduce its overall lifespan and effectiveness.

To address these cold weather challenges, research into adaptations of power steering fluid for snowplows and winter equipment is essential. This research focuses on developing fluids with improved low-temperature viscosity characteristics, enhanced resistance to moisture contamination, and better overall stability in extreme cold conditions. The goal is to create a fluid that maintains optimal performance across a wide temperature range, ensuring reliable and responsive steering even in the harshest winter environments.

One of the primary challenges in cold weather is the fluid's tendency to thicken, which can cause increased resistance in the power steering system. This thickening effect can result in sluggish steering response, increased wear on pump components, and in extreme cases, system failure. The problem is particularly acute during vehicle start-up when the fluid is at its coldest and most viscous state.

Extreme cold can also lead to the formation of ice crystals within the power steering fluid, potentially causing blockages in narrow passages of the steering system. This phenomenon not only impairs steering performance but can also lead to damage of seals, hoses, and other components due to the expansion of frozen fluid.

Another significant challenge is the potential for moisture contamination in the power steering system. In cold climates, temperature fluctuations can cause condensation within the system, introducing water into the fluid. When this moisture freezes, it can create ice particles that may damage internal components and further impede fluid flow.

The cold weather also affects the seals and gaskets in the power steering system. These components may become brittle and less flexible in low temperatures, increasing the risk of leaks and system failures. This can lead to a loss of fluid and potentially catastrophic steering system malfunction during critical snow removal operations.

Furthermore, the extreme temperature differentials experienced by snowplows and winter equipment – from sub-zero outdoor temperatures to warmer engine compartments – can cause thermal stress on the power steering fluid. This cycling between temperature extremes can accelerate fluid breakdown and reduce its overall lifespan and effectiveness.

To address these cold weather challenges, research into adaptations of power steering fluid for snowplows and winter equipment is essential. This research focuses on developing fluids with improved low-temperature viscosity characteristics, enhanced resistance to moisture contamination, and better overall stability in extreme cold conditions. The goal is to create a fluid that maintains optimal performance across a wide temperature range, ensuring reliable and responsive steering even in the harshest winter environments.

Current Cold-Resistant Solutions

01 Power steering fluid composition

Power steering fluids are specially formulated to provide optimal performance in power steering systems. These fluids typically contain a base oil, additives for improved lubrication, anti-wear properties, and corrosion protection. The composition may also include viscosity modifiers to ensure proper flow characteristics across a range of temperatures.- Composition of power steering fluid: Power steering fluid typically consists of a base oil and various additives. The base oil can be mineral oil or synthetic oil, while additives may include viscosity modifiers, anti-wear agents, anti-oxidants, and corrosion inhibitors. These components work together to ensure proper lubrication, heat dissipation, and protection of the power steering system.

- Power steering fluid reservoirs and systems: Power steering systems incorporate reservoirs to store and supply fluid to the steering mechanism. These reservoirs are designed to maintain proper fluid levels, prevent contamination, and facilitate easy refilling. Advanced systems may include features for fluid circulation, cooling, and filtration to enhance performance and longevity of the power steering system.

- Power steering pumps and fluid circulation: Power steering pumps are crucial components that circulate fluid through the system, providing the necessary hydraulic pressure for steering assistance. These pumps are designed to maintain consistent fluid flow and pressure under various operating conditions, ensuring smooth and responsive steering performance.

- Maintenance and monitoring of power steering fluid: Regular maintenance of power steering fluid is essential for optimal system performance. This includes periodic checks of fluid levels, quality, and replacement intervals. Some advanced systems incorporate sensors or indicators to monitor fluid condition and alert drivers when maintenance is required, helping to prevent system failures and extend the lifespan of power steering components.

- Environmental considerations in power steering fluid formulation: Modern power steering fluid formulations are being developed with increased focus on environmental sustainability. This includes the use of biodegradable base oils, reduced toxicity additives, and improved energy efficiency. These eco-friendly formulations aim to minimize environmental impact while maintaining or improving the performance characteristics of traditional power steering fluids.

02 Power steering fluid reservoirs and systems

Power steering systems incorporate reservoirs to store and supply fluid to the steering mechanism. These reservoirs are designed to maintain proper fluid levels, prevent contamination, and allow for easy fluid checks and refills. The design of the reservoir and associated components can impact the overall performance and efficiency of the power steering system.Expand Specific Solutions03 Power steering pumps and fluid circulation

Power steering pumps are crucial components that circulate fluid through the system, providing the necessary hydraulic pressure for power assistance. The design and efficiency of these pumps can significantly affect the performance of the power steering system. Innovations in pump technology focus on improving fluid flow, reducing energy consumption, and enhancing overall system reliability.Expand Specific Solutions04 Power steering fluid maintenance and replacement

Regular maintenance of power steering fluid is essential for optimal system performance and longevity. This includes periodic checks of fluid levels, quality, and replacement intervals. Advanced systems may incorporate features for easier fluid monitoring and replacement, such as integrated sensors or quick-connect fittings.Expand Specific Solutions05 Environmental considerations in power steering fluid design

As environmental concerns grow, there is an increasing focus on developing more eco-friendly power steering fluids. This includes the use of biodegradable base oils, reducing harmful additives, and improving overall fluid efficiency to minimize waste and environmental impact. Additionally, some systems are being designed to use alternative fluids or even electric power steering to reduce reliance on traditional hydraulic fluids.Expand Specific Solutions

Key Industry Players

The research on adaptations of power steering fluid for snowplows and winter equipment is in a developing stage, with a growing market driven by the need for specialized solutions in harsh winter conditions. The technology is moderately mature, with established players like JTEKT Corp., Eaton Corp., and Mercedes-Benz Group AG leading innovation. However, there's room for advancement, particularly in fluid formulations for extreme cold. The market size is expanding as more regions invest in winter maintenance equipment, creating opportunities for companies like Afton Chemical Corp. and ThyssenKrupp Presta AG to develop tailored solutions. The competitive landscape is diverse, with automotive giants and specialized chemical manufacturers vying for market share in this niche but crucial sector.

Eaton Corp.

Technical Solution: Eaton Corporation has developed an advanced power steering fluid specifically adapted for use in snowplows and winter equipment. Their formulation focuses on maintaining optimal viscosity and performance across a wide temperature range, with particular emphasis on extreme cold conditions. Eaton's fluid utilizes a blend of synthetic base oils that provide exceptional low-temperature fluidity, ensuring reliable power steering operation down to -50°C [9]. The fluid incorporates advanced shear-stable viscosity modifiers that resist breakdown under high stress, maintaining consistent performance throughout extended use in demanding winter conditions. Eaton's solution also features a unique anti-wear package that forms a protective layer on metal surfaces, reducing friction and wear in critical components of the power steering system. Additionally, the fluid includes advanced seal conditioners and corrosion inhibitors to protect against the harsh effects of road salt, moisture, and temperature fluctuations commonly encountered in winter maintenance operations [10].

Strengths: Exceptional low-temperature performance, excellent wear protection, and corrosion resistance. Weaknesses: Potentially higher cost compared to standard fluids, may require specialized handling or storage.

Afton Chemical Corp.

Technical Solution: Afton Chemical has developed a specialized power steering fluid formulation for snowplows and winter equipment, focusing on low-temperature performance and anti-wear properties. Their solution incorporates advanced polymer technology to maintain optimal viscosity in extreme cold conditions, ensuring smooth operation of power steering systems down to -40°C [1]. The fluid also contains proprietary anti-wear additives that protect metal surfaces from increased wear due to frequent start-stop operations typical in snowplow use. Additionally, Afton's formulation includes anti-corrosion agents to combat the effects of road salt and moisture, extending the lifespan of power steering components [3].

Strengths: Excellent low-temperature performance, enhanced wear protection, and corrosion resistance. Weaknesses: Potentially higher cost compared to standard fluids, may require more frequent changes in harsh conditions.

Innovative Fluid Formulations

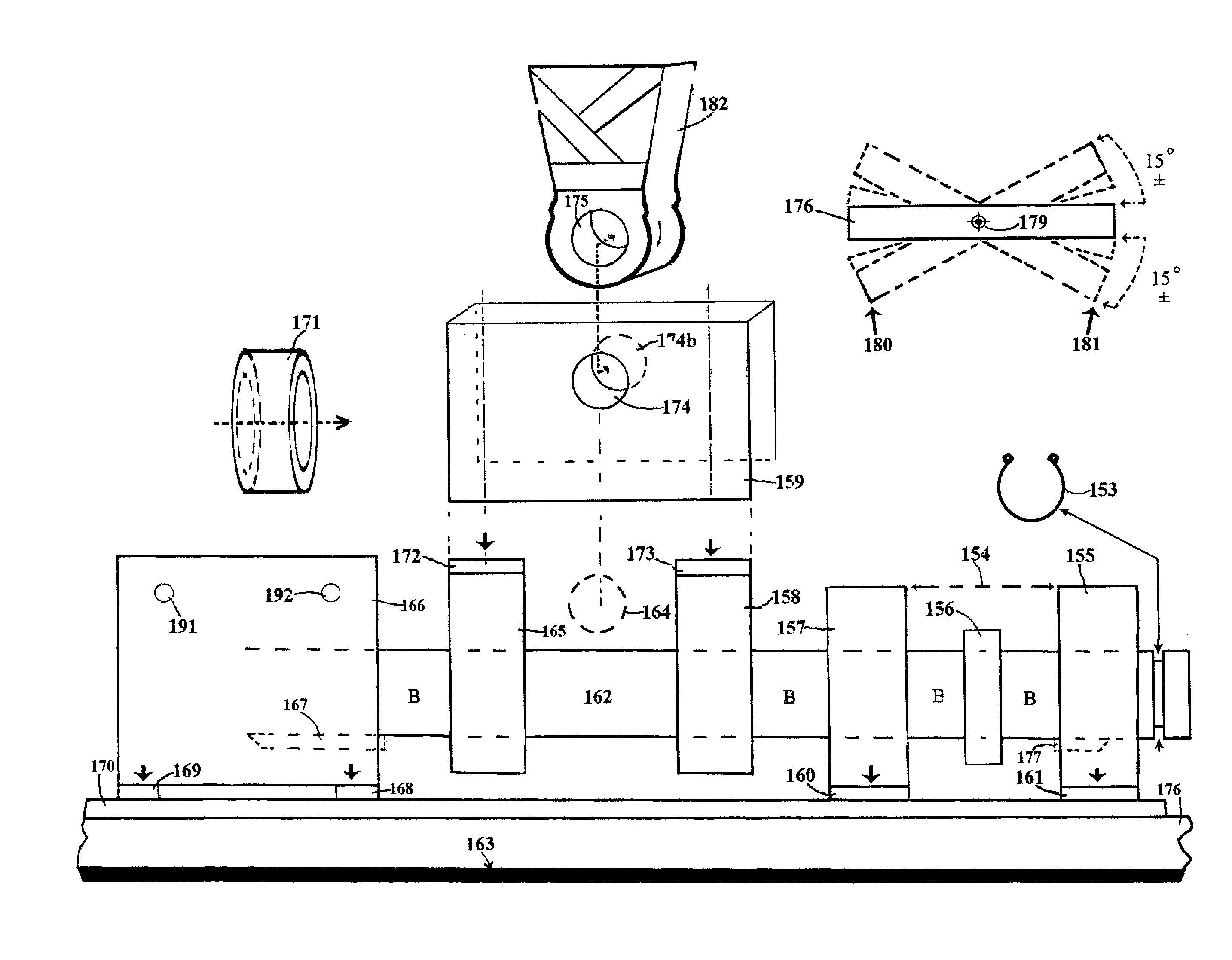

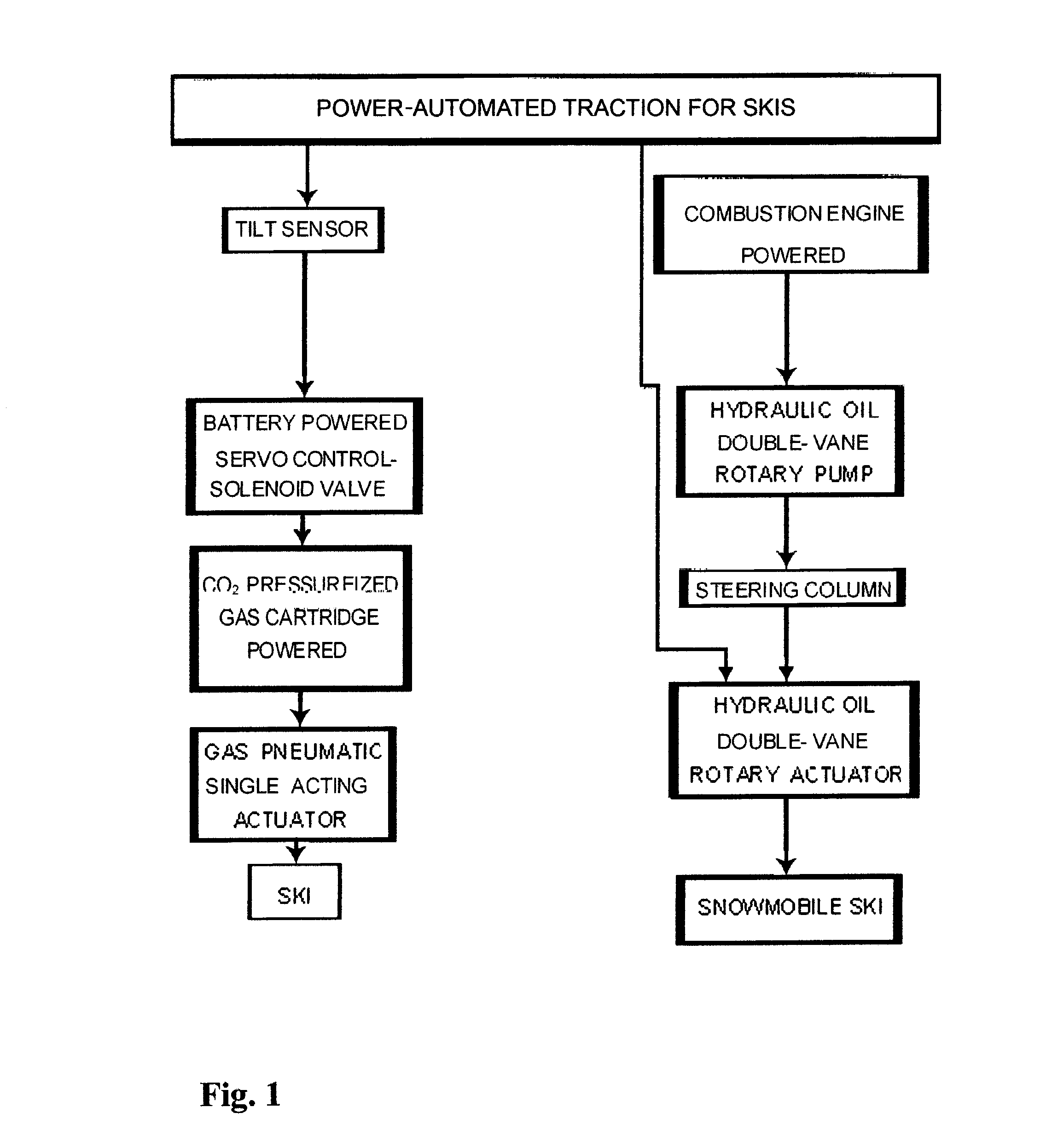

Power-automated traction for skis

PatentInactiveUS20160158633A1

Innovation

- A lightweight pneumatic system using pressurized CO2 gas for backcountry skis and oil hydraulic or electric motor-powered systems for snowmobile skis, with tilt sensors and servo-solenoid valves to automate gripping mechanisms, and pivotable ski designs to enhance traction and stability during turns.

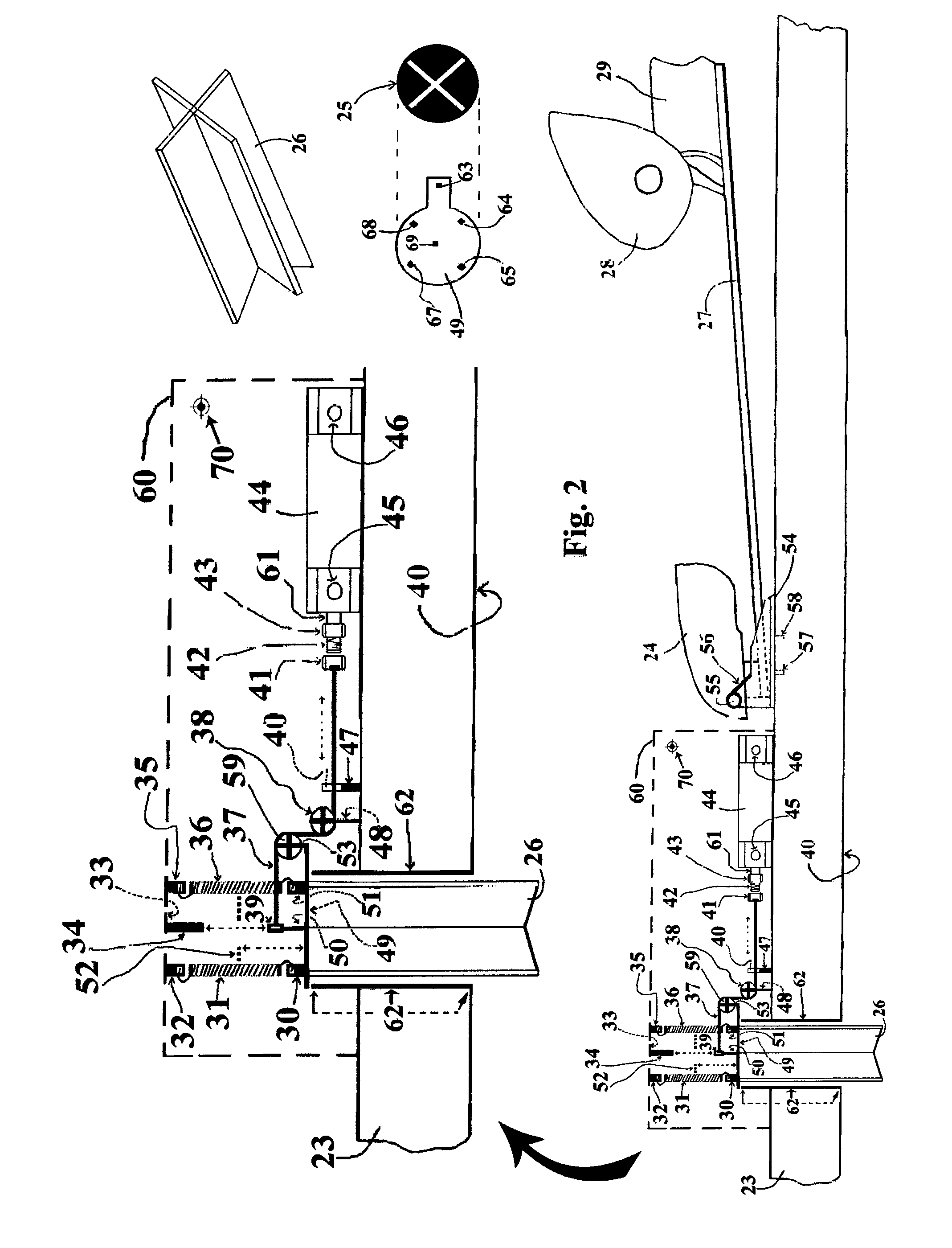

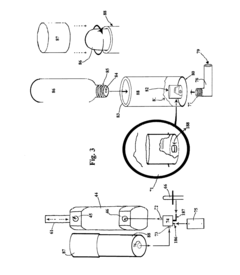

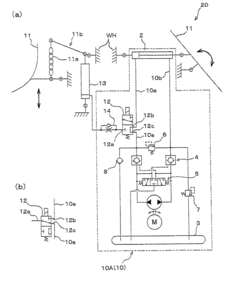

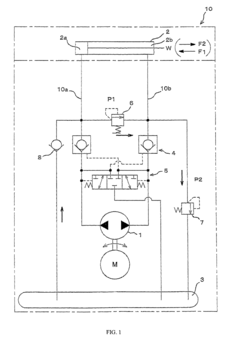

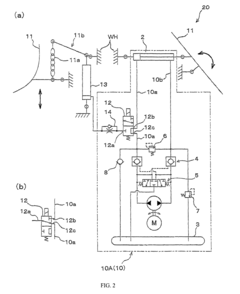

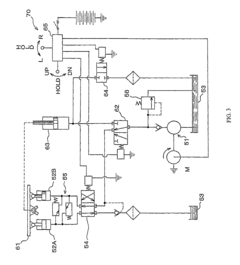

Fluid pressure drive unit and snow removal unit

PatentInactiveUS8186082B2

Innovation

- A fluid pressure drive unit incorporating a single-rod double acting cylinder with a first excessive load relief valve, a second excessive load relief valve, and a negative pressure preventing check valve, which manage fluid flow and pressure to prevent negative pressures and maintain stability even after external forces are applied.

Environmental Impact Assessment

The environmental impact of power steering fluid adaptations for snowplows and winter equipment is a critical consideration in the development and implementation of these technologies. The use of specialized fluids in harsh winter conditions can have both positive and negative effects on the surrounding ecosystem.

One of the primary environmental concerns is the potential for fluid leakage or spillage during operation or maintenance of snowplows and winter equipment. Traditional power steering fluids often contain petroleum-based compounds that can be harmful to soil and water systems if released into the environment. Adaptations that focus on improving fluid retention and reducing the likelihood of leaks can significantly mitigate this risk.

The development of biodegradable power steering fluids for winter applications represents a significant step towards reducing environmental impact. These fluids are designed to break down naturally over time, minimizing long-term contamination risks. However, the effectiveness and durability of biodegradable options in extreme cold conditions must be carefully evaluated to ensure they meet the performance requirements of snowplows and winter equipment.

Another important aspect is the impact on air quality. Some adapted power steering fluids may have different volatility characteristics compared to standard formulations. This could potentially lead to increased emissions of volatile organic compounds (VOCs) during operation, particularly in cold temperatures. Research into low-VOC formulations that maintain performance in winter conditions is crucial for minimizing air pollution.

The production and disposal of specialized power steering fluids also have environmental implications. Manufacturing processes may require additional energy or resources, potentially increasing the carbon footprint associated with these products. End-of-life considerations, such as proper disposal methods and recycling options for used fluids, must be integrated into the overall environmental assessment.

Adaptations that extend the lifespan of power steering fluids in winter conditions can have positive environmental effects by reducing the frequency of fluid changes and associated waste. This not only decreases the volume of used fluid requiring disposal but also conserves resources used in the production of new fluid.

The potential impact on wildlife and vegetation near roadways where snowplows operate should also be considered. Improved fluid formulations that are less toxic to plants and animals can help protect local ecosystems from accidental exposure during snow removal operations.

In conclusion, the environmental impact assessment of power steering fluid adaptations for winter equipment must balance performance requirements with ecological considerations. Ongoing research should focus on developing solutions that minimize environmental risks while meeting the demanding operational needs of snowplows and other winter maintenance vehicles.

One of the primary environmental concerns is the potential for fluid leakage or spillage during operation or maintenance of snowplows and winter equipment. Traditional power steering fluids often contain petroleum-based compounds that can be harmful to soil and water systems if released into the environment. Adaptations that focus on improving fluid retention and reducing the likelihood of leaks can significantly mitigate this risk.

The development of biodegradable power steering fluids for winter applications represents a significant step towards reducing environmental impact. These fluids are designed to break down naturally over time, minimizing long-term contamination risks. However, the effectiveness and durability of biodegradable options in extreme cold conditions must be carefully evaluated to ensure they meet the performance requirements of snowplows and winter equipment.

Another important aspect is the impact on air quality. Some adapted power steering fluids may have different volatility characteristics compared to standard formulations. This could potentially lead to increased emissions of volatile organic compounds (VOCs) during operation, particularly in cold temperatures. Research into low-VOC formulations that maintain performance in winter conditions is crucial for minimizing air pollution.

The production and disposal of specialized power steering fluids also have environmental implications. Manufacturing processes may require additional energy or resources, potentially increasing the carbon footprint associated with these products. End-of-life considerations, such as proper disposal methods and recycling options for used fluids, must be integrated into the overall environmental assessment.

Adaptations that extend the lifespan of power steering fluids in winter conditions can have positive environmental effects by reducing the frequency of fluid changes and associated waste. This not only decreases the volume of used fluid requiring disposal but also conserves resources used in the production of new fluid.

The potential impact on wildlife and vegetation near roadways where snowplows operate should also be considered. Improved fluid formulations that are less toxic to plants and animals can help protect local ecosystems from accidental exposure during snow removal operations.

In conclusion, the environmental impact assessment of power steering fluid adaptations for winter equipment must balance performance requirements with ecological considerations. Ongoing research should focus on developing solutions that minimize environmental risks while meeting the demanding operational needs of snowplows and other winter maintenance vehicles.

Safety Standards Compliance

Safety standards compliance is a critical aspect of adapting power steering fluid for snowplows and winter equipment. These vehicles operate in harsh conditions and must meet stringent safety requirements to ensure reliable performance and protect operators and the public.

The primary safety standards governing power steering fluid for snowplows and winter equipment are set by organizations such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO). These standards define the minimum performance requirements, chemical properties, and testing procedures for power steering fluids used in heavy-duty vehicles operating in extreme cold conditions.

One key safety standard is SAE J1703, which specifies the requirements for brake fluids used in motor vehicles. While this standard primarily focuses on brake fluids, it also applies to power steering fluids due to their similar operating conditions and safety-critical nature. The standard outlines requirements for fluid viscosity, boiling point, and corrosion resistance, all of which are crucial for maintaining steering system performance in cold weather.

ISO 7308 is another relevant standard that defines the specifications for mineral oil-based hydraulic fluids, including those used in power steering systems. This standard addresses the fluid's physical and chemical properties, such as viscosity index, pour point, and oxidation stability, which are essential for ensuring proper function in extreme temperatures.

Compliance with these safety standards requires extensive testing of power steering fluids under simulated winter conditions. This includes low-temperature viscosity tests to ensure the fluid remains fluid and responsive at sub-zero temperatures, as well as corrosion tests to verify the fluid's ability to protect metal components from rust and degradation in the presence of road salt and other de-icing chemicals.

Manufacturers must also consider the compatibility of power steering fluids with various seal materials used in snowplow and winter equipment steering systems. ASTM D471 provides standardized test methods for evaluating the effects of liquids on rubber and elastomeric seals, which is crucial for preventing leaks and maintaining system integrity in cold environments.

Additionally, environmental safety standards play a role in the development of power steering fluids for winter equipment. Regulations such as the U.S. Environmental Protection Agency's (EPA) guidelines on biodegradability and toxicity must be considered to minimize the environmental impact of potential fluid leaks or spills during winter operations.

To ensure ongoing compliance, manufacturers and operators of snowplows and winter equipment must regularly review and update their power steering fluid specifications in line with evolving safety standards. This may involve reformulating fluids to meet new requirements or conducting additional testing to validate performance under increasingly stringent criteria.

The primary safety standards governing power steering fluid for snowplows and winter equipment are set by organizations such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO). These standards define the minimum performance requirements, chemical properties, and testing procedures for power steering fluids used in heavy-duty vehicles operating in extreme cold conditions.

One key safety standard is SAE J1703, which specifies the requirements for brake fluids used in motor vehicles. While this standard primarily focuses on brake fluids, it also applies to power steering fluids due to their similar operating conditions and safety-critical nature. The standard outlines requirements for fluid viscosity, boiling point, and corrosion resistance, all of which are crucial for maintaining steering system performance in cold weather.

ISO 7308 is another relevant standard that defines the specifications for mineral oil-based hydraulic fluids, including those used in power steering systems. This standard addresses the fluid's physical and chemical properties, such as viscosity index, pour point, and oxidation stability, which are essential for ensuring proper function in extreme temperatures.

Compliance with these safety standards requires extensive testing of power steering fluids under simulated winter conditions. This includes low-temperature viscosity tests to ensure the fluid remains fluid and responsive at sub-zero temperatures, as well as corrosion tests to verify the fluid's ability to protect metal components from rust and degradation in the presence of road salt and other de-icing chemicals.

Manufacturers must also consider the compatibility of power steering fluids with various seal materials used in snowplow and winter equipment steering systems. ASTM D471 provides standardized test methods for evaluating the effects of liquids on rubber and elastomeric seals, which is crucial for preventing leaks and maintaining system integrity in cold environments.

Additionally, environmental safety standards play a role in the development of power steering fluids for winter equipment. Regulations such as the U.S. Environmental Protection Agency's (EPA) guidelines on biodegradability and toxicity must be considered to minimize the environmental impact of potential fluid leaks or spills during winter operations.

To ensure ongoing compliance, manufacturers and operators of snowplows and winter equipment must regularly review and update their power steering fluid specifications in line with evolving safety standards. This may involve reformulating fluids to meet new requirements or conducting additional testing to validate performance under increasingly stringent criteria.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!