Liquid Nitrogen in High Stress Environment Testing

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Nitrogen Testing Background and Objectives

Liquid nitrogen testing in high stress environments has evolved significantly over the past several decades, transitioning from basic cryogenic applications to sophisticated testing methodologies essential for modern industrial and scientific advancement. The fundamental principle behind this technology leverages liquid nitrogen's extremely low temperature (-196°C) to evaluate material performance under combined thermal and mechanical stress conditions, simulating extreme operational scenarios that many critical components must withstand.

The historical development of liquid nitrogen testing began in aerospace and defense industries during the mid-20th century, where understanding material behavior at cryogenic temperatures became crucial for space exploration and military applications. As industries evolved, this testing methodology expanded into sectors including automotive, electronics, energy, and medical device manufacturing, each adapting the core principles to their specific requirements.

Current technological trends in this field focus on enhancing precision, automation, and data analytics capabilities. Advanced sensor technologies now enable real-time monitoring of multiple parameters simultaneously, while computer-controlled testing systems allow for more complex stress profiles and testing sequences. The integration of artificial intelligence and machine learning algorithms has further revolutionized data interpretation, enabling predictive analysis of material failure modes and performance optimization.

The primary objective of liquid nitrogen testing in high stress environments is to validate material integrity and functionality under extreme conditions that combine cryogenic temperatures with mechanical stresses such as tension, compression, torsion, and vibration. This validation is critical for components used in applications where failure could lead to catastrophic consequences, including aerospace systems, critical infrastructure, and medical devices.

Secondary objectives include accelerated life testing to predict long-term reliability, identification of potential failure modes before field deployment, optimization of material selection and design parameters, and compliance verification with industry standards and regulatory requirements. These objectives collectively support risk mitigation strategies essential for high-reliability applications.

The technological goals for advancement in this field include developing more sophisticated multi-parameter testing methodologies, improving the correlation between laboratory results and real-world performance, enhancing the efficiency and cost-effectiveness of testing procedures, and establishing standardized protocols that ensure consistency across different testing facilities and applications.

As industries continue to push the boundaries of material performance in increasingly demanding environments, liquid nitrogen testing under high stress conditions remains a cornerstone technology for ensuring safety, reliability, and innovation across multiple sectors of the global economy.

The historical development of liquid nitrogen testing began in aerospace and defense industries during the mid-20th century, where understanding material behavior at cryogenic temperatures became crucial for space exploration and military applications. As industries evolved, this testing methodology expanded into sectors including automotive, electronics, energy, and medical device manufacturing, each adapting the core principles to their specific requirements.

Current technological trends in this field focus on enhancing precision, automation, and data analytics capabilities. Advanced sensor technologies now enable real-time monitoring of multiple parameters simultaneously, while computer-controlled testing systems allow for more complex stress profiles and testing sequences. The integration of artificial intelligence and machine learning algorithms has further revolutionized data interpretation, enabling predictive analysis of material failure modes and performance optimization.

The primary objective of liquid nitrogen testing in high stress environments is to validate material integrity and functionality under extreme conditions that combine cryogenic temperatures with mechanical stresses such as tension, compression, torsion, and vibration. This validation is critical for components used in applications where failure could lead to catastrophic consequences, including aerospace systems, critical infrastructure, and medical devices.

Secondary objectives include accelerated life testing to predict long-term reliability, identification of potential failure modes before field deployment, optimization of material selection and design parameters, and compliance verification with industry standards and regulatory requirements. These objectives collectively support risk mitigation strategies essential for high-reliability applications.

The technological goals for advancement in this field include developing more sophisticated multi-parameter testing methodologies, improving the correlation between laboratory results and real-world performance, enhancing the efficiency and cost-effectiveness of testing procedures, and establishing standardized protocols that ensure consistency across different testing facilities and applications.

As industries continue to push the boundaries of material performance in increasingly demanding environments, liquid nitrogen testing under high stress conditions remains a cornerstone technology for ensuring safety, reliability, and innovation across multiple sectors of the global economy.

Market Demand Analysis for Cryogenic Testing Solutions

The global market for cryogenic testing solutions has experienced significant growth in recent years, driven primarily by increasing demands across aerospace, defense, automotive, and semiconductor industries. Current market valuations indicate the cryogenic testing equipment sector reached approximately $2.3 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028. This growth trajectory is particularly pronounced in regions with concentrated high-tech manufacturing capabilities such as North America, Western Europe, and East Asia.

The aerospace and defense sectors represent the largest market segments, collectively accounting for nearly 42% of demand for liquid nitrogen-based testing solutions. These industries require extensive materials and component validation under extreme temperature conditions to ensure operational reliability in diverse environments. Recent procurement trends show increased investment in cryogenic testing infrastructure, with major aerospace contractors expanding their testing capabilities to accommodate next-generation aircraft and spacecraft development programs.

Automotive manufacturers, particularly those focused on electric vehicles, constitute a rapidly expanding market segment. The need to validate battery performance under extreme temperature conditions has driven a 23% increase in demand for specialized cryogenic testing equipment since 2020. This trend aligns with the broader industry shift toward electric mobility and the associated requirements for comprehensive thermal performance validation.

The semiconductor industry presents another significant growth vector, with manufacturers increasingly implementing cryogenic testing protocols to validate chip performance under varying thermal conditions. This segment has shown particular sensitivity to testing precision and reliability, creating demand for advanced cryogenic solutions capable of maintaining stable testing environments with temperature fluctuation tolerances below ±0.5°C.

Customer requirements across these sectors demonstrate consistent patterns, with emphasis on testing system reliability, precise temperature control, automation capabilities, and comprehensive data acquisition features. Survey data indicates that 78% of industrial customers prioritize testing solution longevity and maintenance requirements over initial acquisition costs, suggesting a market preference for premium solutions offering superior operational characteristics.

Regional market analysis reveals emerging opportunities in developing economies, particularly in India and Southeast Asia, where expanding manufacturing capabilities in aerospace and electronics sectors are creating new demand centers. These markets are projected to grow at rates exceeding 9% annually through 2027, outpacing established markets and presenting significant expansion opportunities for cryogenic testing solution providers.

The aerospace and defense sectors represent the largest market segments, collectively accounting for nearly 42% of demand for liquid nitrogen-based testing solutions. These industries require extensive materials and component validation under extreme temperature conditions to ensure operational reliability in diverse environments. Recent procurement trends show increased investment in cryogenic testing infrastructure, with major aerospace contractors expanding their testing capabilities to accommodate next-generation aircraft and spacecraft development programs.

Automotive manufacturers, particularly those focused on electric vehicles, constitute a rapidly expanding market segment. The need to validate battery performance under extreme temperature conditions has driven a 23% increase in demand for specialized cryogenic testing equipment since 2020. This trend aligns with the broader industry shift toward electric mobility and the associated requirements for comprehensive thermal performance validation.

The semiconductor industry presents another significant growth vector, with manufacturers increasingly implementing cryogenic testing protocols to validate chip performance under varying thermal conditions. This segment has shown particular sensitivity to testing precision and reliability, creating demand for advanced cryogenic solutions capable of maintaining stable testing environments with temperature fluctuation tolerances below ±0.5°C.

Customer requirements across these sectors demonstrate consistent patterns, with emphasis on testing system reliability, precise temperature control, automation capabilities, and comprehensive data acquisition features. Survey data indicates that 78% of industrial customers prioritize testing solution longevity and maintenance requirements over initial acquisition costs, suggesting a market preference for premium solutions offering superior operational characteristics.

Regional market analysis reveals emerging opportunities in developing economies, particularly in India and Southeast Asia, where expanding manufacturing capabilities in aerospace and electronics sectors are creating new demand centers. These markets are projected to grow at rates exceeding 9% annually through 2027, outpacing established markets and presenting significant expansion opportunities for cryogenic testing solution providers.

Current Challenges in High Stress Cryogenic Testing

Despite significant advancements in cryogenic testing technologies, the field of high stress environment testing using liquid nitrogen faces several persistent challenges. The extreme temperature conditions (approximately -196°C) combined with high mechanical stress create unique technical difficulties that current methodologies struggle to address comprehensively.

Material compatibility remains a primary concern as most conventional materials experience significant property changes at cryogenic temperatures. Standard sensors, fixtures, and measurement devices often fail or provide unreliable data when exposed to liquid nitrogen while simultaneously experiencing high mechanical loads. The dramatic thermal contraction rates between different materials in testing apparatus create unpredictable stress distributions that can compromise test integrity.

Thermal management presents another major challenge. The rapid cooling rates associated with liquid nitrogen can induce thermal shock in test specimens, potentially creating microcracks or structural anomalies that confound test results. Maintaining uniform temperature distribution throughout test specimens becomes increasingly difficult as component size and complexity increase, leading to thermal gradients that can skew stress distribution patterns and test outcomes.

Instrumentation limitations severely restrict data collection capabilities in these extreme environments. Conventional strain gauges, thermocouples, and pressure sensors often exhibit drift, calibration issues, or complete failure when subjected to the dual challenges of cryogenic temperatures and high mechanical stress. This creates significant gaps in real-time monitoring capabilities and reduces the reliability of collected data.

Safety concerns add another layer of complexity to high stress cryogenic testing. The combination of pressurized systems, extreme cold, and high mechanical forces creates multiple potential failure points. Oxygen displacement risks, material embrittlement, and sudden pressure releases require sophisticated containment and monitoring systems that add considerable complexity to test setups.

Standardization deficiencies further complicate the field, as there is limited consensus on testing protocols specifically designed for high stress cryogenic environments. This lack of standardized methodologies makes cross-comparison between different research efforts challenging and hinders the establishment of reliable benchmarks for material and component performance.

Cost factors also present significant barriers to advancement. The specialized equipment required for simultaneous application of cryogenic temperatures and high mechanical stress demands substantial investment. The high consumption rate of liquid nitrogen during extended testing periods adds considerable operational expenses, limiting the accessibility of comprehensive testing for smaller research institutions and companies.

Material compatibility remains a primary concern as most conventional materials experience significant property changes at cryogenic temperatures. Standard sensors, fixtures, and measurement devices often fail or provide unreliable data when exposed to liquid nitrogen while simultaneously experiencing high mechanical loads. The dramatic thermal contraction rates between different materials in testing apparatus create unpredictable stress distributions that can compromise test integrity.

Thermal management presents another major challenge. The rapid cooling rates associated with liquid nitrogen can induce thermal shock in test specimens, potentially creating microcracks or structural anomalies that confound test results. Maintaining uniform temperature distribution throughout test specimens becomes increasingly difficult as component size and complexity increase, leading to thermal gradients that can skew stress distribution patterns and test outcomes.

Instrumentation limitations severely restrict data collection capabilities in these extreme environments. Conventional strain gauges, thermocouples, and pressure sensors often exhibit drift, calibration issues, or complete failure when subjected to the dual challenges of cryogenic temperatures and high mechanical stress. This creates significant gaps in real-time monitoring capabilities and reduces the reliability of collected data.

Safety concerns add another layer of complexity to high stress cryogenic testing. The combination of pressurized systems, extreme cold, and high mechanical forces creates multiple potential failure points. Oxygen displacement risks, material embrittlement, and sudden pressure releases require sophisticated containment and monitoring systems that add considerable complexity to test setups.

Standardization deficiencies further complicate the field, as there is limited consensus on testing protocols specifically designed for high stress cryogenic environments. This lack of standardized methodologies makes cross-comparison between different research efforts challenging and hinders the establishment of reliable benchmarks for material and component performance.

Cost factors also present significant barriers to advancement. The specialized equipment required for simultaneous application of cryogenic temperatures and high mechanical stress demands substantial investment. The high consumption rate of liquid nitrogen during extended testing periods adds considerable operational expenses, limiting the accessibility of comprehensive testing for smaller research institutions and companies.

Current Liquid Nitrogen Testing Methodologies

01 Liquid nitrogen storage and transportation systems

Various systems and containers designed for the safe storage and transportation of liquid nitrogen. These include specialized vessels with vacuum insulation to minimize heat transfer, pressure relief mechanisms to prevent over-pressurization, and structural designs that maintain cryogenic temperatures. These systems are crucial for industries requiring stable storage of liquid nitrogen for extended periods while ensuring safety and efficiency.- Liquid nitrogen storage and transportation systems: Various systems and containers designed for the safe storage and transportation of liquid nitrogen. These include specialized vessels with vacuum insulation to minimize heat transfer, pressure relief mechanisms to prevent over-pressurization, and structural designs that maintain cryogenic temperatures. These systems are crucial for industries requiring stable storage of liquid nitrogen for extended periods while ensuring safety and efficiency.

- Cryogenic treatment applications using liquid nitrogen: Applications of liquid nitrogen for cryogenic treatment of various materials and products. The extreme cold temperatures of liquid nitrogen are utilized for processes such as metal hardening, food freezing, medical tissue preservation, and superconductivity research. These treatments exploit the rapid cooling properties of liquid nitrogen to achieve specific material properties or preservation effects that cannot be achieved through conventional cooling methods.

- Liquid nitrogen cooling systems for electronic devices: Specialized cooling systems that utilize liquid nitrogen to maintain optimal operating temperatures for high-performance electronic components and devices. These systems are particularly valuable for overclocking processors, cooling superconducting materials, and managing heat in advanced computing applications. The extreme cooling capacity of liquid nitrogen allows for significant performance improvements in electronic systems that generate substantial heat during operation.

- Production and purification methods for liquid nitrogen: Processes and equipment used for the production, purification, and liquefaction of nitrogen from air or other sources. These methods typically involve air separation units, cryogenic distillation, pressure swing adsorption, or membrane separation technologies. The purification processes ensure the removal of contaminants and other gases to produce high-purity liquid nitrogen suitable for industrial, medical, and scientific applications.

- Medical and biological applications of liquid nitrogen: The use of liquid nitrogen in medical and biological fields, including cryosurgery, dermatological treatments, cell and tissue preservation, and reproductive medicine. Liquid nitrogen's extremely low temperature makes it effective for targeted tissue destruction in wart removal and cancer treatment, as well as for the long-term preservation of biological samples, embryos, and stem cells. Specialized delivery systems ensure precise application in medical procedures.

02 Cryogenic treatment applications

Applications of liquid nitrogen for cryogenic treatment of various materials and products. The extreme cold temperatures of liquid nitrogen are utilized for processes such as cryogenic hardening of metals, preservation of biological samples, and rapid freezing in food processing. These treatments can enhance material properties, extend shelf life, or preserve cellular structures depending on the specific application.Expand Specific Solutions03 Liquid nitrogen cooling systems

Cooling systems that utilize liquid nitrogen as a refrigerant for various industrial and scientific applications. These systems leverage the extremely low temperature of liquid nitrogen to achieve rapid cooling effects in processes requiring precise temperature control. Applications include cooling of electronic components, superconducting devices, and industrial machinery where conventional cooling methods are insufficient.Expand Specific Solutions04 Liquid nitrogen production methods

Methods and apparatus for the production of liquid nitrogen from atmospheric air or other nitrogen sources. These include air separation units, cryogenic distillation processes, and pressure swing adsorption systems. The technologies focus on energy efficiency, purity control, and production scale optimization to meet various industrial and commercial requirements for liquid nitrogen supply.Expand Specific Solutions05 Medical and biological applications of liquid nitrogen

Specialized applications of liquid nitrogen in medical treatments and biological preservation. These include cryosurgery for removing abnormal tissues, cryopreservation of biological samples and reproductive cells, and dermatological treatments. The controlled use of extreme cold temperatures allows for precise tissue destruction or long-term preservation while minimizing damage to surrounding healthy tissues or cellular structures.Expand Specific Solutions

Key Industry Players in Cryogenic Testing Equipment

The liquid nitrogen testing in high stress environments market is in a growth phase, characterized by increasing demand for materials performance evaluation under extreme conditions. The market size is expanding due to rising applications in aerospace, automotive, and energy sectors, with an estimated annual growth rate of 5-7%. Technologically, the field is moderately mature but evolving rapidly with innovations in testing methodologies and equipment. Leading academic institutions like South China University of Technology, Zhejiang University, and China University of Petroleum are advancing fundamental research, while companies such as China National Petroleum Corp., Samsung Heavy Industries, and Safran Aircraft Engines are developing practical applications. The competitive landscape shows collaboration between research institutions and industry players, with specialized testing companies like Changzhou Dams Testing Technology emerging to bridge laboratory research and industrial implementation.

China National Petroleum Corp.

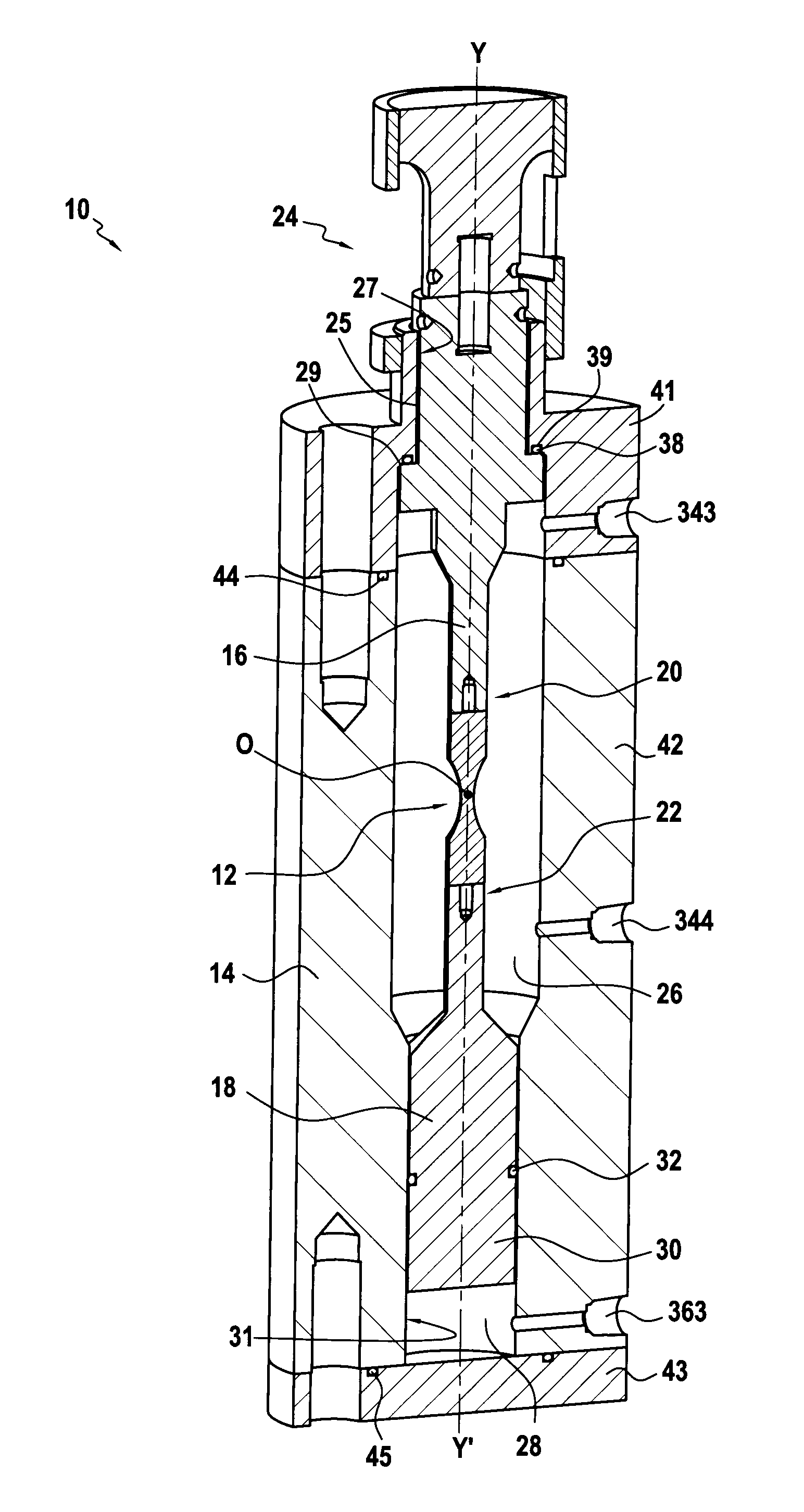

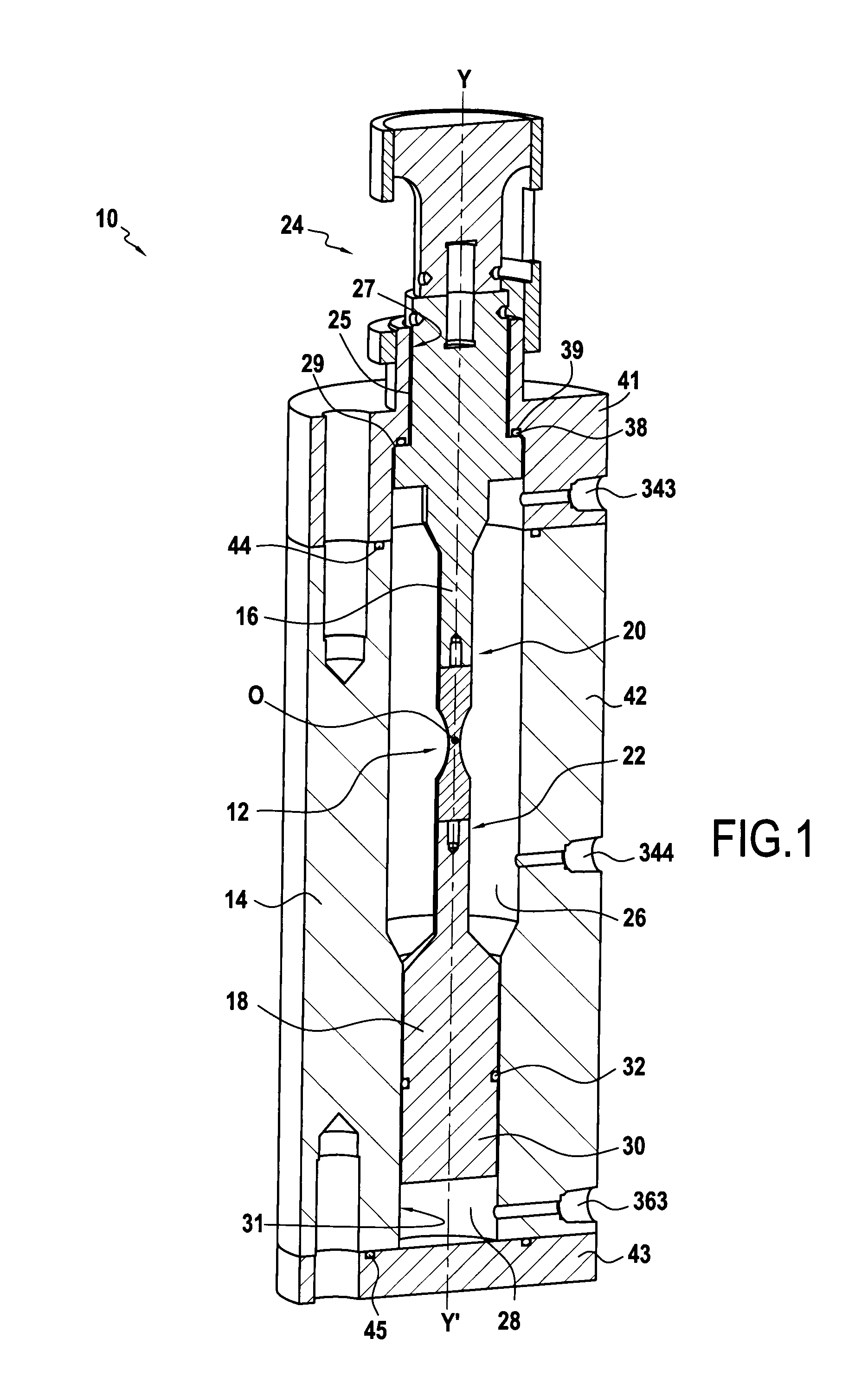

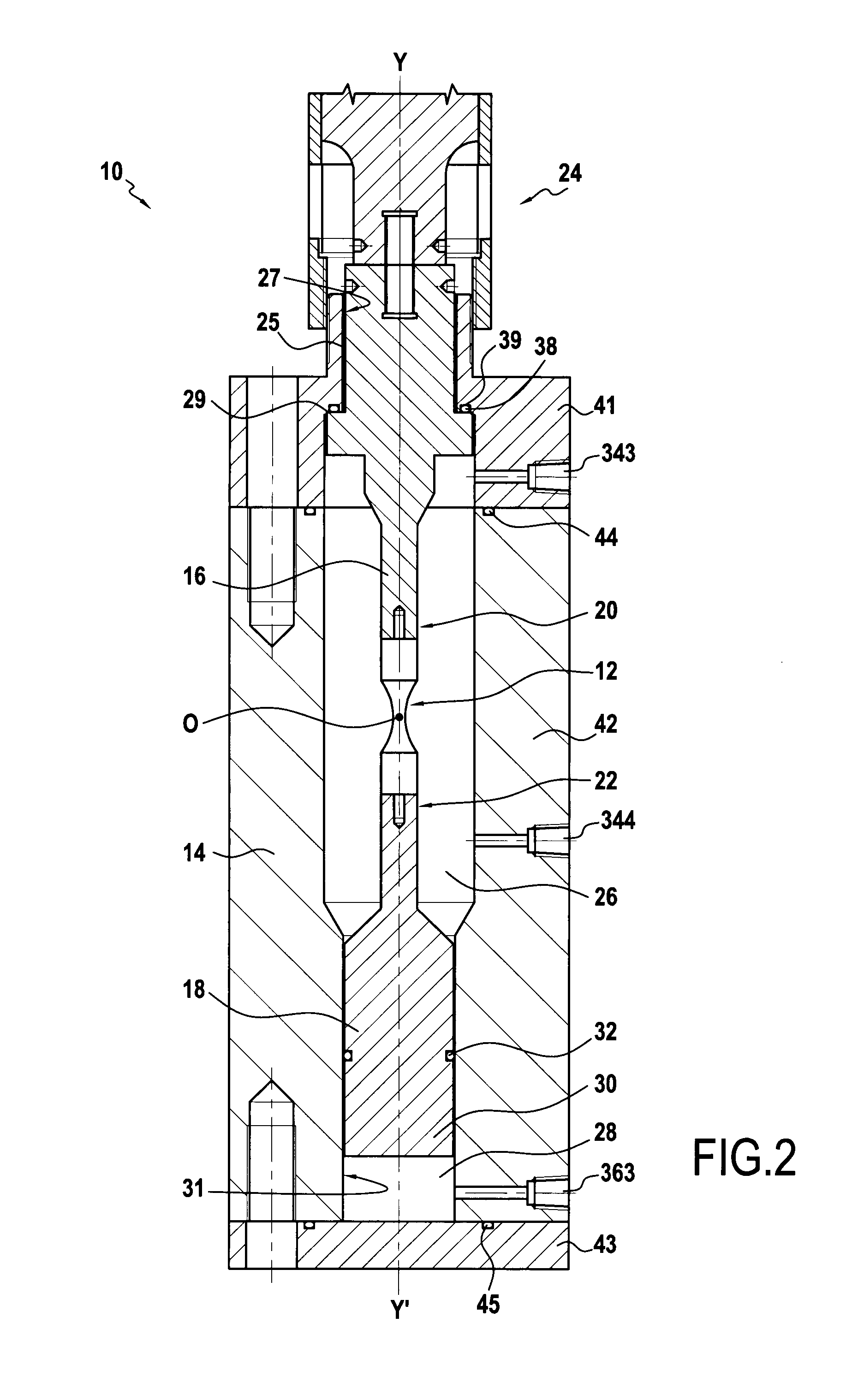

Technical Solution: China National Petroleum Corp. (CNPC) has developed advanced liquid nitrogen testing protocols for high-stress environments in petroleum equipment. Their technology utilizes cryogenic chambers capable of reaching -196°C while simultaneously applying mechanical stress up to 500 MPa to simulate extreme operating conditions for deep-well drilling equipment[1]. CNPC's approach incorporates multi-parameter monitoring systems that track material deformation, crack propagation, and structural integrity changes in real-time during thermal cycling between ambient and cryogenic temperatures[3]. The company has pioneered specialized testing methodologies for evaluating elastomer seals and composite materials used in ultra-deep drilling operations, where equipment must withstand both extreme cold and high pressure environments. Their research has led to the development of proprietary materials with enhanced low-temperature ductility and reduced brittleness, specifically designed for Arctic and deep-sea petroleum extraction operations where equipment may experience rapid temperature fluctuations under high mechanical stress[7].

Strengths: Extensive practical application experience in real-world petroleum extraction environments; comprehensive testing infrastructure capable of simulating combined thermal and mechanical stresses; proprietary materials development informed by testing results. Weaknesses: Testing methodologies primarily focused on petroleum industry applications rather than broader industrial applications; limited published research on fundamental material science aspects compared to academic institutions.

UT-Battelle LLC

Technical Solution: UT-Battelle LLC, which manages Oak Ridge National Laboratory, has developed sophisticated liquid nitrogen testing protocols for materials under extreme stress conditions. Their approach utilizes custom-designed cryogenic testing chambers that can maintain temperatures of -196°C while applying variable mechanical loads up to 200 kN[2]. The technology incorporates advanced in-situ monitoring capabilities including acoustic emission detection, high-speed imaging, and real-time crystallographic analysis using neutron scattering techniques available at their specialized facilities[4]. This allows for unprecedented observation of microstructural changes during deformation under cryogenic conditions. Their research has particularly focused on advanced alloys and composite materials for aerospace, energy, and defense applications, where materials must maintain structural integrity under combined thermal and mechanical extremes. The company has pioneered techniques for evaluating hydrogen embrittlement and stress corrosion cracking mechanisms at cryogenic temperatures, providing critical data for next-generation energy storage and transportation systems[8].

Strengths: Access to world-class neutron scattering and materials characterization facilities; interdisciplinary approach combining materials science, mechanical engineering, and computational modeling; strong connections to both government and industry applications. Weaknesses: Testing methodologies often require specialized equipment not widely available in industry; focus sometimes prioritizes fundamental research over immediate commercial applications.

Core Technical Innovations in Cryogenic Material Testing

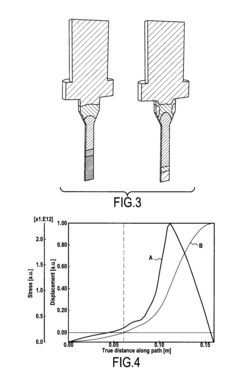

Apparatus and method for carrying out in a controlled atmosphere material fatigue tests in a high cycle regime with a controlled strain ratio

PatentActiveUS20140245833A1

Innovation

- A pressure vessel with two chambers, allowing different gas pressures to apply static stress to a specimen without mechanical feedthroughs, using ultrasonic excitation to induce dynamic stress, thereby enhancing safety and enabling testing in hazardous environments.

Nitrogenous gas sustained releasing agent and nitrogenous gas sustained releaser composed of the same as well as nitrogenous gas sustained releasing method, respiratory equipment, package, and sustained releasing apparatus using the sustained releaser

PatentPendingUS20250170169A1

Innovation

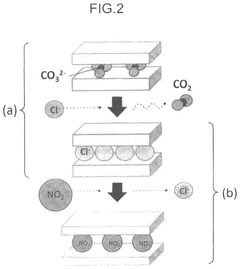

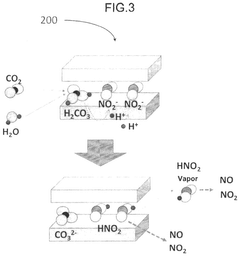

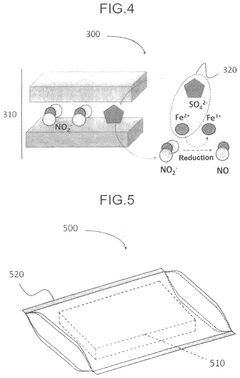

- A nitrogenous gas sustained releasing agent based on a layered double hydroxide (LDH) that includes nitrite or nitrate ions between its layers, allowing for the sustained release of nitrogenous gases, including nitrogen monoxide, at normal temperature and in a controlled manner.

Safety Protocols and Risk Management

Working with liquid nitrogen in high stress environment testing requires comprehensive safety protocols and risk management strategies due to its extreme low temperature (-196°C) and potential hazards. Organizations must establish a multi-layered safety framework beginning with mandatory personnel training programs covering proper handling techniques, emergency procedures, and first aid for cryogenic injuries. All staff must be certified before participating in testing operations.

Personal Protective Equipment (PPE) requirements are non-negotiable and include insulated gloves, face shields, closed-toe shoes, and cryogenic aprons. Laboratory infrastructure must feature adequate ventilation systems to prevent nitrogen accumulation, oxygen level monitors with automated alarms, and clearly marked emergency exits. Storage protocols should mandate double-walled vacuum-insulated containers placed in well-ventilated areas away from heat sources.

Risk assessment methodologies specific to high stress testing environments must be implemented, identifying potential failure points when liquid nitrogen interacts with materials under extreme mechanical stress. This includes analyzing material embrittlement risks, pressure vessel integrity, and potential for catastrophic releases during testing. Formal documentation systems should track all near-misses and incidents, enabling continuous improvement of safety protocols.

Emergency response procedures require special attention, with clearly defined evacuation routes, readily accessible emergency equipment, and regular drills simulating various scenarios including large-scale spills and oxygen depletion events. Medical response protocols must address frostbite, asphyxiation, and other cryogenic injuries with designated first responders trained in specialized treatment techniques.

Regulatory compliance represents another critical dimension, with operations adhering to OSHA standards, ASME pressure vessel codes, and CGA (Compressed Gas Association) guidelines. Regular third-party audits should verify compliance and identify improvement opportunities. For international operations, country-specific regulations must be incorporated into the safety framework.

Advanced monitoring technologies enhance safety through real-time tracking of testing parameters, with automated shutdown systems triggered by anomalous conditions. Modern facilities increasingly employ IoT sensors to monitor oxygen levels, temperature gradients, and structural integrity of testing apparatus, with data analytics identifying potential safety issues before they manifest.

The integration of these safety protocols with quality management systems ensures consistent application across all testing operations, with clear documentation of responsibilities and regular review cycles to incorporate lessons learned and technological advances.

Personal Protective Equipment (PPE) requirements are non-negotiable and include insulated gloves, face shields, closed-toe shoes, and cryogenic aprons. Laboratory infrastructure must feature adequate ventilation systems to prevent nitrogen accumulation, oxygen level monitors with automated alarms, and clearly marked emergency exits. Storage protocols should mandate double-walled vacuum-insulated containers placed in well-ventilated areas away from heat sources.

Risk assessment methodologies specific to high stress testing environments must be implemented, identifying potential failure points when liquid nitrogen interacts with materials under extreme mechanical stress. This includes analyzing material embrittlement risks, pressure vessel integrity, and potential for catastrophic releases during testing. Formal documentation systems should track all near-misses and incidents, enabling continuous improvement of safety protocols.

Emergency response procedures require special attention, with clearly defined evacuation routes, readily accessible emergency equipment, and regular drills simulating various scenarios including large-scale spills and oxygen depletion events. Medical response protocols must address frostbite, asphyxiation, and other cryogenic injuries with designated first responders trained in specialized treatment techniques.

Regulatory compliance represents another critical dimension, with operations adhering to OSHA standards, ASME pressure vessel codes, and CGA (Compressed Gas Association) guidelines. Regular third-party audits should verify compliance and identify improvement opportunities. For international operations, country-specific regulations must be incorporated into the safety framework.

Advanced monitoring technologies enhance safety through real-time tracking of testing parameters, with automated shutdown systems triggered by anomalous conditions. Modern facilities increasingly employ IoT sensors to monitor oxygen levels, temperature gradients, and structural integrity of testing apparatus, with data analytics identifying potential safety issues before they manifest.

The integration of these safety protocols with quality management systems ensures consistent application across all testing operations, with clear documentation of responsibilities and regular review cycles to incorporate lessons learned and technological advances.

Material Compatibility and Performance Standards

Material compatibility is a critical consideration when designing systems for liquid nitrogen testing in high stress environments. Different materials exhibit varying behaviors when exposed to cryogenic temperatures, with some becoming brittle and susceptible to fracture. Metals such as austenitic stainless steels (304, 316), aluminum alloys (6061, 5083), and copper alloys maintain good ductility at liquid nitrogen temperatures (-196°C), making them preferred choices for cryogenic applications. Conversely, carbon steels and many plastics typically experience severe embrittlement, limiting their applicability in such extreme conditions.

Performance standards for materials in liquid nitrogen environments must address thermal cycling effects, which can lead to fatigue failure due to repeated expansion and contraction. ASTM E1450 and ASTM D2137 provide standardized testing methodologies for evaluating material performance under cryogenic conditions, while ISO 21010 specifically addresses compatibility requirements for cryogenic vessels and associated equipment.

Sealing materials present particular challenges, as traditional elastomers harden and lose flexibility at extremely low temperatures. Specialized materials such as PTFE, PCTFE, and certain fluoroelastomers maintain better sealing properties at cryogenic temperatures, though their performance characteristics must be carefully evaluated against application requirements. The selection of appropriate sealing materials often involves trade-offs between low-temperature flexibility and permeability to nitrogen gas.

Surface treatments and coatings can significantly enhance material performance in liquid nitrogen environments. Techniques such as nitriding, carburizing, and the application of specialized cryogenic coatings can improve wear resistance and reduce thermal stress concentrations at critical interfaces. These treatments must be validated through rigorous testing to ensure they maintain integrity under the combined effects of cryogenic temperatures and mechanical stress.

Standardized testing protocols for material qualification typically include impact testing (Charpy V-notch), tensile testing at cryogenic temperatures, and thermal cycling evaluations. These tests must be conducted in accordance with established standards such as ASTM A370 and ASTM E23, with particular attention to specimen preparation and testing methodology to ensure reliable results.

Composite materials represent an emerging area of interest for cryogenic applications, with carbon fiber reinforced polymers (CFRPs) and glass fiber reinforced polymers (GFRPs) offering potential advantages in terms of strength-to-weight ratio and thermal insulation properties. However, these materials present unique challenges related to differential thermal contraction between fibers and matrix materials, requiring specialized design approaches and comprehensive testing regimes to validate their performance under combined thermal and mechanical stresses.

Performance standards for materials in liquid nitrogen environments must address thermal cycling effects, which can lead to fatigue failure due to repeated expansion and contraction. ASTM E1450 and ASTM D2137 provide standardized testing methodologies for evaluating material performance under cryogenic conditions, while ISO 21010 specifically addresses compatibility requirements for cryogenic vessels and associated equipment.

Sealing materials present particular challenges, as traditional elastomers harden and lose flexibility at extremely low temperatures. Specialized materials such as PTFE, PCTFE, and certain fluoroelastomers maintain better sealing properties at cryogenic temperatures, though their performance characteristics must be carefully evaluated against application requirements. The selection of appropriate sealing materials often involves trade-offs between low-temperature flexibility and permeability to nitrogen gas.

Surface treatments and coatings can significantly enhance material performance in liquid nitrogen environments. Techniques such as nitriding, carburizing, and the application of specialized cryogenic coatings can improve wear resistance and reduce thermal stress concentrations at critical interfaces. These treatments must be validated through rigorous testing to ensure they maintain integrity under the combined effects of cryogenic temperatures and mechanical stress.

Standardized testing protocols for material qualification typically include impact testing (Charpy V-notch), tensile testing at cryogenic temperatures, and thermal cycling evaluations. These tests must be conducted in accordance with established standards such as ASTM A370 and ASTM E23, with particular attention to specimen preparation and testing methodology to ensure reliable results.

Composite materials represent an emerging area of interest for cryogenic applications, with carbon fiber reinforced polymers (CFRPs) and glass fiber reinforced polymers (GFRPs) offering potential advantages in terms of strength-to-weight ratio and thermal insulation properties. However, these materials present unique challenges related to differential thermal contraction between fibers and matrix materials, requiring specialized design approaches and comprehensive testing regimes to validate their performance under combined thermal and mechanical stresses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!