Plate Heat Exchanger in Eco-Friendly Refrigeration Systems

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE in Green Cooling: Background and Objectives

Plate heat exchangers (PHEs) have emerged as a crucial component in the evolution of eco-friendly refrigeration systems. The background of this technology dates back to the early 20th century, with significant advancements in design and efficiency occurring over the past few decades. As global concerns about environmental sustainability and energy efficiency have intensified, the role of PHEs in green cooling solutions has become increasingly prominent.

The development of PHEs has been driven by the need for more compact, efficient, and environmentally friendly heat transfer solutions. Traditional shell-and-tube heat exchangers, while effective, often fall short in meeting the stringent requirements of modern, eco-conscious cooling systems. PHEs offer superior heat transfer efficiency, reduced refrigerant charge, and greater flexibility in system design, making them ideal for applications in green cooling technologies.

The evolution of PHE technology has been closely tied to advancements in manufacturing processes, materials science, and computational fluid dynamics. These developments have enabled the creation of more intricate plate designs, optimized flow patterns, and enhanced thermal performance. Concurrently, the refrigeration industry has been undergoing a paradigm shift towards natural refrigerants and low-GWP (Global Warming Potential) alternatives, further emphasizing the importance of efficient heat exchange solutions.

The primary objective of research on PHEs in eco-friendly refrigeration systems is to maximize energy efficiency while minimizing environmental impact. This involves optimizing heat transfer characteristics, reducing pressure drop, and enhancing overall system performance. Researchers aim to develop innovative plate geometries, explore novel materials with superior thermal properties, and improve manufacturing techniques to reduce costs and increase reliability.

Another critical goal is to adapt PHE technology to work effectively with next-generation refrigerants, particularly natural options like CO2, ammonia, and hydrocarbons. These refrigerants present unique challenges in terms of operating pressures, thermodynamic properties, and safety considerations, necessitating specialized PHE designs and configurations.

Furthermore, the research seeks to expand the application range of PHEs in various cooling systems, from small-scale residential units to large industrial installations. This includes exploring hybrid systems that combine PHEs with other heat exchange technologies to achieve optimal performance across diverse operating conditions.

Ultimately, the overarching aim of PHE research in green cooling is to contribute significantly to global efforts in reducing energy consumption and greenhouse gas emissions associated with refrigeration and air conditioning. By pushing the boundaries of heat exchanger technology, researchers and engineers strive to create more sustainable cooling solutions that align with international environmental agreements and regulations.

The development of PHEs has been driven by the need for more compact, efficient, and environmentally friendly heat transfer solutions. Traditional shell-and-tube heat exchangers, while effective, often fall short in meeting the stringent requirements of modern, eco-conscious cooling systems. PHEs offer superior heat transfer efficiency, reduced refrigerant charge, and greater flexibility in system design, making them ideal for applications in green cooling technologies.

The evolution of PHE technology has been closely tied to advancements in manufacturing processes, materials science, and computational fluid dynamics. These developments have enabled the creation of more intricate plate designs, optimized flow patterns, and enhanced thermal performance. Concurrently, the refrigeration industry has been undergoing a paradigm shift towards natural refrigerants and low-GWP (Global Warming Potential) alternatives, further emphasizing the importance of efficient heat exchange solutions.

The primary objective of research on PHEs in eco-friendly refrigeration systems is to maximize energy efficiency while minimizing environmental impact. This involves optimizing heat transfer characteristics, reducing pressure drop, and enhancing overall system performance. Researchers aim to develop innovative plate geometries, explore novel materials with superior thermal properties, and improve manufacturing techniques to reduce costs and increase reliability.

Another critical goal is to adapt PHE technology to work effectively with next-generation refrigerants, particularly natural options like CO2, ammonia, and hydrocarbons. These refrigerants present unique challenges in terms of operating pressures, thermodynamic properties, and safety considerations, necessitating specialized PHE designs and configurations.

Furthermore, the research seeks to expand the application range of PHEs in various cooling systems, from small-scale residential units to large industrial installations. This includes exploring hybrid systems that combine PHEs with other heat exchange technologies to achieve optimal performance across diverse operating conditions.

Ultimately, the overarching aim of PHE research in green cooling is to contribute significantly to global efforts in reducing energy consumption and greenhouse gas emissions associated with refrigeration and air conditioning. By pushing the boundaries of heat exchanger technology, researchers and engineers strive to create more sustainable cooling solutions that align with international environmental agreements and regulations.

Market Analysis for Eco-Friendly Refrigeration

The eco-friendly refrigeration market has experienced significant growth in recent years, driven by increasing environmental concerns and stringent regulations on greenhouse gas emissions. This sector encompasses a wide range of technologies and products designed to minimize energy consumption and reduce the use of harmful refrigerants. Plate heat exchangers, as a key component in these systems, play a crucial role in enhancing overall efficiency and sustainability.

The global market for eco-friendly refrigeration systems is projected to expand rapidly, with a particular focus on commercial and industrial applications. Key sectors driving demand include food and beverage processing, pharmaceuticals, and data centers. The adoption of plate heat exchangers in these systems is expected to grow in tandem with the broader market, as they offer superior heat transfer efficiency and compact design compared to traditional heat exchange technologies.

Consumer awareness and preferences are shifting towards more environmentally responsible products, creating a favorable market environment for eco-friendly refrigeration solutions. Governments worldwide are implementing stricter energy efficiency standards and phasing out high-global warming potential (GWP) refrigerants, further propelling market growth. These regulatory pressures are encouraging manufacturers to invest in research and development of advanced plate heat exchanger designs optimized for use with natural refrigerants and low-GWP alternatives.

The Asia-Pacific region is emerging as a significant market for eco-friendly refrigeration systems, driven by rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe continue to be major markets, with a strong focus on retrofitting existing systems to meet new environmental standards. This geographical distribution of demand is influencing the strategic decisions of plate heat exchanger manufacturers, who are expanding their production capacities and distribution networks to serve these diverse markets.

Despite the positive outlook, the market faces challenges such as high initial costs and the need for specialized technical expertise in system design and maintenance. However, these barriers are gradually being overcome through technological advancements, economies of scale, and increasing awareness of long-term cost savings and environmental benefits. The integration of smart technologies and IoT capabilities in plate heat exchangers is expected to further enhance their appeal in the eco-friendly refrigeration market, offering improved monitoring, control, and predictive maintenance features.

The global market for eco-friendly refrigeration systems is projected to expand rapidly, with a particular focus on commercial and industrial applications. Key sectors driving demand include food and beverage processing, pharmaceuticals, and data centers. The adoption of plate heat exchangers in these systems is expected to grow in tandem with the broader market, as they offer superior heat transfer efficiency and compact design compared to traditional heat exchange technologies.

Consumer awareness and preferences are shifting towards more environmentally responsible products, creating a favorable market environment for eco-friendly refrigeration solutions. Governments worldwide are implementing stricter energy efficiency standards and phasing out high-global warming potential (GWP) refrigerants, further propelling market growth. These regulatory pressures are encouraging manufacturers to invest in research and development of advanced plate heat exchanger designs optimized for use with natural refrigerants and low-GWP alternatives.

The Asia-Pacific region is emerging as a significant market for eco-friendly refrigeration systems, driven by rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe continue to be major markets, with a strong focus on retrofitting existing systems to meet new environmental standards. This geographical distribution of demand is influencing the strategic decisions of plate heat exchanger manufacturers, who are expanding their production capacities and distribution networks to serve these diverse markets.

Despite the positive outlook, the market faces challenges such as high initial costs and the need for specialized technical expertise in system design and maintenance. However, these barriers are gradually being overcome through technological advancements, economies of scale, and increasing awareness of long-term cost savings and environmental benefits. The integration of smart technologies and IoT capabilities in plate heat exchangers is expected to further enhance their appeal in the eco-friendly refrigeration market, offering improved monitoring, control, and predictive maintenance features.

PHE Technology Status and Challenges

Plate Heat Exchangers (PHEs) have emerged as a crucial component in eco-friendly refrigeration systems, offering significant advantages in terms of energy efficiency and environmental sustainability. However, the current state of PHE technology in this application faces several challenges that require addressing for wider adoption and improved performance.

The global push towards more sustainable cooling solutions has accelerated the development and implementation of PHEs in refrigeration systems. These exchangers have demonstrated superior heat transfer capabilities compared to traditional shell-and-tube heat exchangers, resulting in more compact designs and reduced refrigerant charge. This aligns well with the industry's goals of minimizing environmental impact and improving energy efficiency.

Despite the progress, PHEs in eco-friendly refrigeration systems still encounter technical hurdles. One of the primary challenges is the optimization of PHE designs for various refrigerants, particularly natural refrigerants like CO2 and ammonia. These refrigerants, while environmentally friendly, often operate at higher pressures and have different thermodynamic properties compared to conventional refrigerants, necessitating specialized PHE designs to ensure optimal performance and safety.

Another significant challenge lies in mitigating fouling and scaling issues in PHEs. The narrow channels and complex flow patterns in these exchangers can lead to increased susceptibility to fouling, which can significantly reduce heat transfer efficiency over time. This is particularly problematic in applications where water quality may be poor or in systems with high mineral content.

The manufacturing processes for PHEs also present challenges, especially when it comes to producing units capable of withstanding high pressures and maintaining tight tolerances. The need for advanced materials and precision manufacturing techniques to meet these requirements can drive up costs, potentially limiting widespread adoption in cost-sensitive markets.

Geographically, the development and adoption of PHE technology in eco-friendly refrigeration systems show notable variations. European countries, particularly in Scandinavia, have been at the forefront of PHE innovation and implementation in sustainable cooling applications. This is largely due to stringent environmental regulations and a strong focus on energy efficiency. In contrast, adoption rates in developing economies have been slower, often hampered by cost considerations and lack of technical expertise.

In the United States and Japan, there has been growing interest in PHE technology for eco-friendly refrigeration, driven by both regulatory pressures and market demand for more sustainable solutions. However, the transition from traditional heat exchanger technologies to PHEs in these markets has been gradual, with many industries still in the process of evaluating and implementing these systems.

Looking ahead, overcoming these challenges will require concerted efforts in research and development. Focus areas include developing new materials and coatings to enhance corrosion resistance and reduce fouling, improving manufacturing techniques to reduce costs while maintaining high quality, and optimizing PHE designs for specific refrigerants and operating conditions. Additionally, there is a need for more comprehensive standards and guidelines for the design and operation of PHEs in eco-friendly refrigeration systems to ensure consistent performance and safety across different applications and regions.

The global push towards more sustainable cooling solutions has accelerated the development and implementation of PHEs in refrigeration systems. These exchangers have demonstrated superior heat transfer capabilities compared to traditional shell-and-tube heat exchangers, resulting in more compact designs and reduced refrigerant charge. This aligns well with the industry's goals of minimizing environmental impact and improving energy efficiency.

Despite the progress, PHEs in eco-friendly refrigeration systems still encounter technical hurdles. One of the primary challenges is the optimization of PHE designs for various refrigerants, particularly natural refrigerants like CO2 and ammonia. These refrigerants, while environmentally friendly, often operate at higher pressures and have different thermodynamic properties compared to conventional refrigerants, necessitating specialized PHE designs to ensure optimal performance and safety.

Another significant challenge lies in mitigating fouling and scaling issues in PHEs. The narrow channels and complex flow patterns in these exchangers can lead to increased susceptibility to fouling, which can significantly reduce heat transfer efficiency over time. This is particularly problematic in applications where water quality may be poor or in systems with high mineral content.

The manufacturing processes for PHEs also present challenges, especially when it comes to producing units capable of withstanding high pressures and maintaining tight tolerances. The need for advanced materials and precision manufacturing techniques to meet these requirements can drive up costs, potentially limiting widespread adoption in cost-sensitive markets.

Geographically, the development and adoption of PHE technology in eco-friendly refrigeration systems show notable variations. European countries, particularly in Scandinavia, have been at the forefront of PHE innovation and implementation in sustainable cooling applications. This is largely due to stringent environmental regulations and a strong focus on energy efficiency. In contrast, adoption rates in developing economies have been slower, often hampered by cost considerations and lack of technical expertise.

In the United States and Japan, there has been growing interest in PHE technology for eco-friendly refrigeration, driven by both regulatory pressures and market demand for more sustainable solutions. However, the transition from traditional heat exchanger technologies to PHEs in these markets has been gradual, with many industries still in the process of evaluating and implementing these systems.

Looking ahead, overcoming these challenges will require concerted efforts in research and development. Focus areas include developing new materials and coatings to enhance corrosion resistance and reduce fouling, improving manufacturing techniques to reduce costs while maintaining high quality, and optimizing PHE designs for specific refrigerants and operating conditions. Additionally, there is a need for more comprehensive standards and guidelines for the design and operation of PHEs in eco-friendly refrigeration systems to ensure consistent performance and safety across different applications and regions.

Current PHE Solutions for Eco-Cooling

01 Plate design and configuration

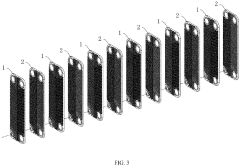

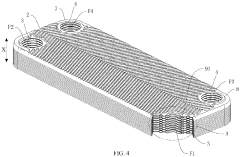

Innovations in plate design and configuration for heat exchangers focus on improving heat transfer efficiency and reducing pressure drop. This includes optimizing plate patterns, corrugations, and spacing to enhance fluid flow and thermal performance. Advanced designs may incorporate asymmetrical patterns or variable plate thicknesses to address specific heat transfer requirements.- Plate design and configuration: Innovations in plate design and configuration for heat exchangers, including improvements in plate geometry, corrugation patterns, and stacking arrangements to enhance heat transfer efficiency and reduce pressure drop. These designs aim to optimize fluid flow distribution and increase the overall performance of the heat exchanger.

- Sealing and gasket systems: Advancements in sealing and gasket systems for plate heat exchangers, focusing on improved leak prevention, durability, and ease of maintenance. These innovations include new gasket materials, designs, and attachment methods to ensure reliable operation under various operating conditions.

- Flow distribution and turbulence enhancement: Techniques for improving flow distribution and enhancing turbulence within plate heat exchangers. These innovations aim to minimize flow maldistribution, reduce fouling, and increase heat transfer coefficients through the use of novel flow channel designs, turbulators, and other flow-modifying structures.

- Material selection and surface treatments: Developments in material selection and surface treatments for plate heat exchangers, focusing on corrosion resistance, fouling mitigation, and thermal conductivity enhancement. These innovations include the use of advanced alloys, coatings, and surface modification techniques to improve performance and longevity.

- Modular and customizable designs: Innovations in modular and customizable plate heat exchanger designs, allowing for easier scalability, maintenance, and adaptation to specific application requirements. These designs focus on flexibility in plate arrangement, connection configurations, and the ability to modify heat transfer capacity without complete system replacement.

02 Sealing and gasket improvements

Developments in sealing technology and gasket design aim to enhance the reliability and longevity of plate heat exchangers. This includes novel gasket materials, improved sealing mechanisms, and innovative gasket profiles that can withstand high temperatures and pressures while preventing leakage between fluid channels.Expand Specific Solutions03 Material selection and coatings

Advancements in material science contribute to the development of more durable and efficient plate heat exchangers. This includes the use of corrosion-resistant alloys, composite materials, and specialized coatings that improve heat transfer properties, reduce fouling, and extend the operational life of the equipment.Expand Specific Solutions04 Modular and customizable designs

Innovations in modular and customizable plate heat exchanger designs allow for greater flexibility in application and easier maintenance. These designs feature interchangeable components, scalable configurations, and adaptable flow arrangements to meet specific industrial requirements and facilitate on-site modifications or expansions.Expand Specific Solutions05 Integration of smart technologies

The incorporation of smart technologies and sensors into plate heat exchangers enables real-time monitoring, predictive maintenance, and performance optimization. This includes the integration of IoT devices, advanced control systems, and data analytics to enhance operational efficiency, reduce downtime, and improve overall system management.Expand Specific Solutions

Key Players in Green Cooling Industry

The research on plate heat exchangers in eco-friendly refrigeration systems is in a growth phase, driven by increasing demand for energy-efficient and environmentally friendly cooling solutions. The market size is expanding, with a projected CAGR of 7-8% over the next five years. Technologically, the field is advancing rapidly, with companies like Alfa Laval, SWEP International, and Kelvion leading innovation. These firms are developing more compact, efficient, and sustainable heat exchanger designs. Other key players such as Danfoss, Mitsubishi Electric, and Daikin are integrating advanced materials and smart controls to enhance performance and reduce environmental impact. The technology's maturity varies across applications, with some sectors like HVAC seeing widespread adoption, while others like automotive thermal management are still evolving.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchangers specifically designed for eco-friendly refrigeration systems. Their technology utilizes asymmetric plate designs and optimized flow distribution to enhance heat transfer efficiency. The company's AlfaNova fusion-bonded plate heat exchangers are made of 100% stainless steel, making them suitable for high-pressure applications with natural refrigerants like CO2[1]. These exchangers feature a compact design that reduces refrigerant charge by up to 90% compared to traditional shell-and-tube heat exchangers[2]. Alfa Laval's plate heat exchangers also incorporate innovative corrugation patterns that minimize fouling and improve overall system performance, leading to energy savings of up to 30% in refrigeration applications[3].

Strengths: High efficiency, compact design, compatibility with natural refrigerants, and reduced environmental impact. Weaknesses: Higher initial cost compared to traditional heat exchangers, potential for increased maintenance in certain applications.

Midea Group Co. Ltd.

Technical Solution: Midea Group has invested heavily in research and development of plate heat exchangers for eco-friendly refrigeration systems. Their technology focuses on optimizing heat transfer through innovative plate designs and distribution systems. Midea's plate heat exchangers feature a patented dimple pattern that enhances turbulence and heat transfer while minimizing pressure drop. The company has also developed a range of heat exchangers specifically designed for use with low-GWP refrigerants such as R290 and R32. Midea's eco-friendly heat exchangers have demonstrated energy efficiency improvements of up to 20% in air conditioning applications and up to 15% in refrigeration systems compared to traditional technologies[10]. Additionally, Midea has implemented advanced manufacturing processes, including automated brazing and leak detection, to ensure high quality and reliability of their heat exchangers.

Strengths: Innovative plate design, compatibility with low-GWP refrigerants, improved energy efficiency, and high manufacturing quality. Weaknesses: Limited experience in very large industrial applications and potential for higher costs in some market segments.

Innovative PHE Designs for Sustainability

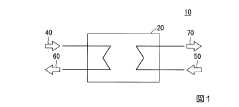

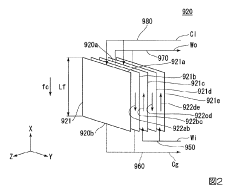

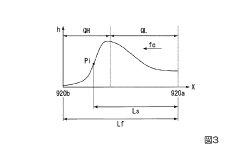

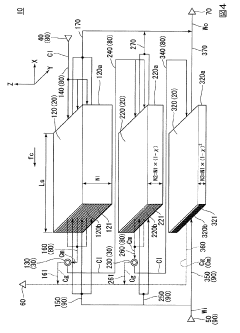

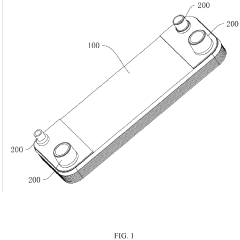

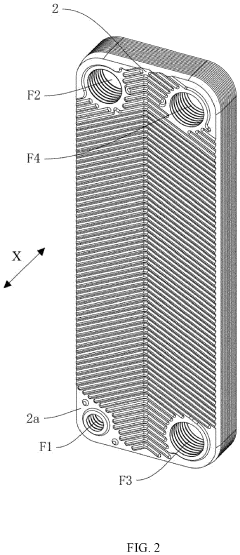

Heat exchange system

PatentActiveJP2017156040A

Innovation

- A heat exchange system with stacked plates that alternate between coolant and cold water flow paths, incorporating gas-liquid separation units to manage refrigerant phase change and reduce the number of plates, ensuring efficient heat transfer across multiple exchangers.

Plate heat exchanger with improved connection strength

PatentActiveEP4357716A1

Innovation

- The design incorporates a connection portion that connects the front surface of one flat joint portion with an adjacent flat joint portion, enhancing the connection strength between plates and including features like bosses and connection blocks to improve structural integrity and prevent refrigerant bypass, while also ensuring the heat exchange medium does not freeze at the corner holes.

Environmental Impact Assessment

The environmental impact assessment of plate heat exchangers in eco-friendly refrigeration systems reveals significant potential for reducing the carbon footprint of cooling technologies. These systems, when compared to traditional vapor compression refrigeration, demonstrate a marked decrease in direct greenhouse gas emissions due to the elimination of harmful refrigerants. The use of natural refrigerants or low-global warming potential (GWP) fluids in conjunction with plate heat exchangers contributes to a substantial reduction in the overall environmental impact.

Plate heat exchangers in eco-friendly refrigeration systems exhibit improved energy efficiency, leading to lower indirect emissions associated with power consumption. The compact design and high heat transfer coefficients of plate heat exchangers result in reduced material usage and smaller system footprints, further minimizing the environmental impact during manufacturing and installation processes.

Life cycle assessments of these systems indicate a notable decrease in cumulative energy demand and global warming potential over their operational lifespan. The durability and corrosion resistance of plate heat exchangers contribute to extended service life, reducing the frequency of replacements and associated environmental costs of production and disposal.

Water consumption in eco-friendly refrigeration systems utilizing plate heat exchangers is generally lower compared to conventional cooling towers, addressing water scarcity concerns in various regions. Additionally, the potential for heat recovery and integration with renewable energy sources further enhances the environmental benefits of these systems.

The recyclability of materials used in plate heat exchangers, such as stainless steel and copper, aligns with circular economy principles, reducing waste and promoting resource conservation. However, the environmental impact of manufacturing processes and material sourcing for specialized plate designs requires ongoing assessment and optimization.

Noise pollution, often associated with traditional refrigeration systems, is significantly reduced in eco-friendly systems employing plate heat exchangers. This aspect contributes to improved urban environments and workplace conditions, indirectly benefiting human health and well-being.

While the overall environmental impact of plate heat exchangers in eco-friendly refrigeration systems is predominantly positive, considerations must be given to the end-of-life management and proper disposal of components. Developing comprehensive recycling programs and promoting responsible decommissioning practices are essential to maximizing the environmental benefits throughout the entire lifecycle of these systems.

Plate heat exchangers in eco-friendly refrigeration systems exhibit improved energy efficiency, leading to lower indirect emissions associated with power consumption. The compact design and high heat transfer coefficients of plate heat exchangers result in reduced material usage and smaller system footprints, further minimizing the environmental impact during manufacturing and installation processes.

Life cycle assessments of these systems indicate a notable decrease in cumulative energy demand and global warming potential over their operational lifespan. The durability and corrosion resistance of plate heat exchangers contribute to extended service life, reducing the frequency of replacements and associated environmental costs of production and disposal.

Water consumption in eco-friendly refrigeration systems utilizing plate heat exchangers is generally lower compared to conventional cooling towers, addressing water scarcity concerns in various regions. Additionally, the potential for heat recovery and integration with renewable energy sources further enhances the environmental benefits of these systems.

The recyclability of materials used in plate heat exchangers, such as stainless steel and copper, aligns with circular economy principles, reducing waste and promoting resource conservation. However, the environmental impact of manufacturing processes and material sourcing for specialized plate designs requires ongoing assessment and optimization.

Noise pollution, often associated with traditional refrigeration systems, is significantly reduced in eco-friendly systems employing plate heat exchangers. This aspect contributes to improved urban environments and workplace conditions, indirectly benefiting human health and well-being.

While the overall environmental impact of plate heat exchangers in eco-friendly refrigeration systems is predominantly positive, considerations must be given to the end-of-life management and proper disposal of components. Developing comprehensive recycling programs and promoting responsible decommissioning practices are essential to maximizing the environmental benefits throughout the entire lifecycle of these systems.

Regulatory Framework for Green Refrigeration

The regulatory framework for green refrigeration systems, particularly those incorporating plate heat exchangers, has been evolving rapidly in response to global environmental concerns. At the international level, the Montreal Protocol and its subsequent amendments have played a crucial role in phasing out ozone-depleting substances, including many traditional refrigerants. This has led to a shift towards more environmentally friendly alternatives, such as natural refrigerants and low global warming potential (GWP) synthetic refrigerants.

In the European Union, the F-Gas Regulation (EU No 517/2014) has been instrumental in driving the adoption of eco-friendly refrigeration systems. This regulation sets strict quotas on the use of hydrofluorocarbons (HFCs) and promotes the use of alternative refrigerants with lower GWP. The regulation also mandates regular leak checks and the proper recovery of refrigerants at the end of equipment life, which has implications for the design and maintenance of plate heat exchangers in refrigeration systems.

The United States Environmental Protection Agency (EPA) has implemented the Significant New Alternatives Policy (SNAP) program, which evaluates and regulates substitutes for ozone-depleting substances. This program has approved several low-GWP refrigerants for use in various applications, including those involving plate heat exchangers. Additionally, the Department of Energy (DOE) has established energy efficiency standards for refrigeration equipment, which indirectly promotes the use of more efficient heat exchange technologies.

In Asia, countries like Japan and South Korea have introduced their own regulations to promote green refrigeration. Japan's Act on Rational Use and Proper Management of Fluorocarbons sets targets for reducing HFC emissions and encourages the use of natural refrigerants. South Korea has implemented a cap-and-trade system for HFCs, creating economic incentives for businesses to adopt more environmentally friendly refrigeration solutions.

The regulatory landscape also includes standards and certifications that impact the design and operation of plate heat exchangers in eco-friendly refrigeration systems. For instance, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides guidelines and standards for the safe use of refrigerants, including those applicable to plate heat exchangers. The International Organization for Standardization (ISO) has developed standards such as ISO 5149, which addresses safety and environmental requirements for refrigerating systems and heat pumps.

As the global community continues to prioritize environmental protection and energy efficiency, it is likely that regulations will become increasingly stringent. This may lead to further restrictions on high-GWP refrigerants and more stringent requirements for the design and operation of refrigeration systems, including those utilizing plate heat exchangers. Manufacturers and operators of these systems will need to stay abreast of these regulatory changes and adapt their technologies accordingly to ensure compliance and maintain market competitiveness.

In the European Union, the F-Gas Regulation (EU No 517/2014) has been instrumental in driving the adoption of eco-friendly refrigeration systems. This regulation sets strict quotas on the use of hydrofluorocarbons (HFCs) and promotes the use of alternative refrigerants with lower GWP. The regulation also mandates regular leak checks and the proper recovery of refrigerants at the end of equipment life, which has implications for the design and maintenance of plate heat exchangers in refrigeration systems.

The United States Environmental Protection Agency (EPA) has implemented the Significant New Alternatives Policy (SNAP) program, which evaluates and regulates substitutes for ozone-depleting substances. This program has approved several low-GWP refrigerants for use in various applications, including those involving plate heat exchangers. Additionally, the Department of Energy (DOE) has established energy efficiency standards for refrigeration equipment, which indirectly promotes the use of more efficient heat exchange technologies.

In Asia, countries like Japan and South Korea have introduced their own regulations to promote green refrigeration. Japan's Act on Rational Use and Proper Management of Fluorocarbons sets targets for reducing HFC emissions and encourages the use of natural refrigerants. South Korea has implemented a cap-and-trade system for HFCs, creating economic incentives for businesses to adopt more environmentally friendly refrigeration solutions.

The regulatory landscape also includes standards and certifications that impact the design and operation of plate heat exchangers in eco-friendly refrigeration systems. For instance, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides guidelines and standards for the safe use of refrigerants, including those applicable to plate heat exchangers. The International Organization for Standardization (ISO) has developed standards such as ISO 5149, which addresses safety and environmental requirements for refrigerating systems and heat pumps.

As the global community continues to prioritize environmental protection and energy efficiency, it is likely that regulations will become increasingly stringent. This may lead to further restrictions on high-GWP refrigerants and more stringent requirements for the design and operation of refrigeration systems, including those utilizing plate heat exchangers. Manufacturers and operators of these systems will need to stay abreast of these regulatory changes and adapt their technologies accordingly to ensure compliance and maintain market competitiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!