System-Level Control Strategies For Multi-Stage Electrocaloric Cooling

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling represents a revolutionary approach to thermal management that leverages the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. This technology has evolved significantly since its initial discovery in the 1930s, with major breakthroughs occurring in the early 2000s when thin-film electrocaloric materials demonstrated temperature changes exceeding 10K, reigniting interest in this field.

The development trajectory of electrocaloric cooling has been characterized by progressive improvements in material properties, device architectures, and control systems. Early research focused primarily on ferroelectric ceramics, while recent advances have expanded to include relaxor ferroelectrics, polymers, and composite materials that offer enhanced electrocaloric responses and operational stability.

Multi-stage electrocaloric cooling represents the latest evolution in this technology, addressing the inherent limitations of single-stage systems by cascading multiple electrocaloric elements to achieve greater temperature differentials and improved cooling efficiency. This approach mirrors successful implementations in other cooling technologies such as thermoelectric and magnetocaloric systems.

The primary technical objective for multi-stage electrocaloric cooling is to develop robust system-level control strategies that optimize the coordination between stages, maximize energy efficiency, and ensure reliable operation across varying thermal loads. These control strategies must address the complex thermal dynamics, electrical requirements, and timing sequences necessary for effective heat pumping across multiple stages.

Current research aims to achieve coefficient of performance (COP) values exceeding 3.0 at practically useful temperature spans (>20K), making electrocaloric technology competitive with conventional vapor-compression refrigeration while eliminating environmentally harmful refrigerants. Additional objectives include reducing system complexity, minimizing response time, and extending operational lifetime.

The technology trend indicates a convergence toward integrated solutions that combine advanced materials science with sophisticated control algorithms. Machine learning approaches are increasingly being explored to optimize operational parameters in real-time, adapting to changing environmental conditions and usage patterns.

Looking forward, the field is moving toward miniaturization for electronics cooling applications while simultaneously scaling up for building climate control systems. The development of standardized testing protocols and performance metrics will be crucial for comparative evaluation of different control strategies and system architectures.

As global energy efficiency regulations become more stringent, electrocaloric cooling technology stands poised to address critical sustainability challenges in thermal management, with system-level control strategies representing the key enabler for practical implementation and commercial viability.

The development trajectory of electrocaloric cooling has been characterized by progressive improvements in material properties, device architectures, and control systems. Early research focused primarily on ferroelectric ceramics, while recent advances have expanded to include relaxor ferroelectrics, polymers, and composite materials that offer enhanced electrocaloric responses and operational stability.

Multi-stage electrocaloric cooling represents the latest evolution in this technology, addressing the inherent limitations of single-stage systems by cascading multiple electrocaloric elements to achieve greater temperature differentials and improved cooling efficiency. This approach mirrors successful implementations in other cooling technologies such as thermoelectric and magnetocaloric systems.

The primary technical objective for multi-stage electrocaloric cooling is to develop robust system-level control strategies that optimize the coordination between stages, maximize energy efficiency, and ensure reliable operation across varying thermal loads. These control strategies must address the complex thermal dynamics, electrical requirements, and timing sequences necessary for effective heat pumping across multiple stages.

Current research aims to achieve coefficient of performance (COP) values exceeding 3.0 at practically useful temperature spans (>20K), making electrocaloric technology competitive with conventional vapor-compression refrigeration while eliminating environmentally harmful refrigerants. Additional objectives include reducing system complexity, minimizing response time, and extending operational lifetime.

The technology trend indicates a convergence toward integrated solutions that combine advanced materials science with sophisticated control algorithms. Machine learning approaches are increasingly being explored to optimize operational parameters in real-time, adapting to changing environmental conditions and usage patterns.

Looking forward, the field is moving toward miniaturization for electronics cooling applications while simultaneously scaling up for building climate control systems. The development of standardized testing protocols and performance metrics will be crucial for comparative evaluation of different control strategies and system architectures.

As global energy efficiency regulations become more stringent, electrocaloric cooling technology stands poised to address critical sustainability challenges in thermal management, with system-level control strategies representing the key enabler for practical implementation and commercial viability.

Market Analysis for Advanced Thermal Management Solutions

The global thermal management market is experiencing significant growth, driven by increasing demands for efficient cooling solutions across various industries. The market for advanced thermal management technologies is projected to reach $20.7 billion by 2025, growing at a CAGR of 8.2% from 2020. Within this broader market, electrocaloric cooling represents an emerging segment with substantial growth potential due to its energy efficiency advantages over conventional vapor-compression refrigeration systems.

Multi-stage electrocaloric cooling systems are particularly gaining attention in high-value applications where precise temperature control and energy efficiency are paramount. The market for these advanced cooling technologies is primarily segmented across consumer electronics, automotive, healthcare, aerospace, and data centers, with each sector presenting unique requirements and growth trajectories.

In the consumer electronics segment, the miniaturization trend and increasing power densities in devices have created an urgent need for more efficient cooling solutions. Electrocaloric cooling systems offer significant advantages in this space due to their compact form factor and potential for integration into small devices. This segment is expected to grow at 9.5% annually through 2026.

The automotive industry represents another substantial market opportunity, particularly with the rapid expansion of electric vehicles. Thermal management for battery systems is critical for performance, safety, and longevity. The automotive thermal management market specific to electric vehicles is projected to grow at 12.3% annually, with electrocaloric solutions positioned to capture a significant portion of this growth.

Data centers constitute a particularly promising application area for multi-stage electrocaloric cooling. With global data center power consumption reaching approximately 1% of worldwide electricity use and cooling accounting for up to 40% of a data center's energy consumption, the potential energy savings from advanced electrocaloric systems could translate to billions in operational cost reductions.

Regional analysis indicates North America currently leads in adoption of advanced thermal management solutions, holding approximately 35% market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing electronics manufacturing, and growing data center infrastructure.

Key market drivers include stringent energy efficiency regulations, rising cooling demands in electronics, increasing awareness about carbon footprint reduction, and technological advancements in materials science enabling more efficient electrocaloric materials. Market restraints include high initial investment costs, technical challenges in system integration, and competition from established cooling technologies.

Multi-stage electrocaloric cooling systems are particularly gaining attention in high-value applications where precise temperature control and energy efficiency are paramount. The market for these advanced cooling technologies is primarily segmented across consumer electronics, automotive, healthcare, aerospace, and data centers, with each sector presenting unique requirements and growth trajectories.

In the consumer electronics segment, the miniaturization trend and increasing power densities in devices have created an urgent need for more efficient cooling solutions. Electrocaloric cooling systems offer significant advantages in this space due to their compact form factor and potential for integration into small devices. This segment is expected to grow at 9.5% annually through 2026.

The automotive industry represents another substantial market opportunity, particularly with the rapid expansion of electric vehicles. Thermal management for battery systems is critical for performance, safety, and longevity. The automotive thermal management market specific to electric vehicles is projected to grow at 12.3% annually, with electrocaloric solutions positioned to capture a significant portion of this growth.

Data centers constitute a particularly promising application area for multi-stage electrocaloric cooling. With global data center power consumption reaching approximately 1% of worldwide electricity use and cooling accounting for up to 40% of a data center's energy consumption, the potential energy savings from advanced electrocaloric systems could translate to billions in operational cost reductions.

Regional analysis indicates North America currently leads in adoption of advanced thermal management solutions, holding approximately 35% market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing electronics manufacturing, and growing data center infrastructure.

Key market drivers include stringent energy efficiency regulations, rising cooling demands in electronics, increasing awareness about carbon footprint reduction, and technological advancements in materials science enabling more efficient electrocaloric materials. Market restraints include high initial investment costs, technical challenges in system integration, and competition from established cooling technologies.

Current Status and Challenges in Multi-Stage Electrocaloric Systems

Electrocaloric (EC) cooling technology has gained significant attention as a promising alternative to conventional vapor compression refrigeration systems due to its potential for higher efficiency and environmental friendliness. Currently, multi-stage EC cooling systems represent the cutting edge of this technology, with research efforts spanning across North America, Europe, and Asia. The United States and China lead in patent filings, while European research institutions contribute substantially to fundamental research publications.

The current development status of multi-stage EC systems reveals several key advancements. Laboratory prototypes have demonstrated temperature spans of 15-20K in multi-stage configurations, significantly improving upon the 3-5K spans achievable in single-stage systems. Energy efficiency ratios (EER) have reached 3-4 in controlled environments, approaching but still below conventional cooling technologies. Material development has progressed with new EC materials showing improved temperature change capabilities, including relaxor ferroelectrics and polymer-based composites that exhibit ΔT values of 6-8K under moderate electric fields.

Despite these advancements, multi-stage EC cooling faces substantial technical challenges. System-level control integration remains problematic, with difficulties in synchronizing the operation of multiple EC stages to achieve optimal heat transfer and temperature regulation. Current control algorithms struggle to adapt to varying thermal loads and environmental conditions, resulting in efficiency losses during dynamic operation.

Heat transfer management presents another significant obstacle. The thermal interfaces between stages create bottlenecks that limit overall system performance, while heat rejection mechanisms often fail to efficiently dissipate heat during continuous operation. This leads to performance degradation over extended operating periods.

Material limitations continue to constrain system capabilities. Available EC materials exhibit fatigue and degradation under repeated electric field cycling, reducing lifetime reliability. Additionally, the temperature-dependent nature of the EC effect complicates control strategies, as material performance varies across the operating temperature range.

Power electronics integration poses challenges in delivering precise, high-voltage pulses to multiple EC elements while maintaining system efficiency. Current driver circuits struggle with energy recovery during field cycling, resulting in significant parasitic energy losses that reduce overall system efficiency.

Scalability remains a critical concern, as laboratory demonstrations have not yet translated effectively to commercially viable systems. Manufacturing complexities and cost factors inhibit mass production potential, while system complexity increases exponentially with additional cooling stages, complicating both fabrication and control.

The current development status of multi-stage EC systems reveals several key advancements. Laboratory prototypes have demonstrated temperature spans of 15-20K in multi-stage configurations, significantly improving upon the 3-5K spans achievable in single-stage systems. Energy efficiency ratios (EER) have reached 3-4 in controlled environments, approaching but still below conventional cooling technologies. Material development has progressed with new EC materials showing improved temperature change capabilities, including relaxor ferroelectrics and polymer-based composites that exhibit ΔT values of 6-8K under moderate electric fields.

Despite these advancements, multi-stage EC cooling faces substantial technical challenges. System-level control integration remains problematic, with difficulties in synchronizing the operation of multiple EC stages to achieve optimal heat transfer and temperature regulation. Current control algorithms struggle to adapt to varying thermal loads and environmental conditions, resulting in efficiency losses during dynamic operation.

Heat transfer management presents another significant obstacle. The thermal interfaces between stages create bottlenecks that limit overall system performance, while heat rejection mechanisms often fail to efficiently dissipate heat during continuous operation. This leads to performance degradation over extended operating periods.

Material limitations continue to constrain system capabilities. Available EC materials exhibit fatigue and degradation under repeated electric field cycling, reducing lifetime reliability. Additionally, the temperature-dependent nature of the EC effect complicates control strategies, as material performance varies across the operating temperature range.

Power electronics integration poses challenges in delivering precise, high-voltage pulses to multiple EC elements while maintaining system efficiency. Current driver circuits struggle with energy recovery during field cycling, resulting in significant parasitic energy losses that reduce overall system efficiency.

Scalability remains a critical concern, as laboratory demonstrations have not yet translated effectively to commercially viable systems. Manufacturing complexities and cost factors inhibit mass production potential, while system complexity increases exponentially with additional cooling stages, complicating both fabrication and control.

Current System-Level Control Architectures for Multi-Stage Cooling

01 Multi-stage electrocaloric cooling systems

Multi-stage electrocaloric cooling systems utilize cascaded electrocaloric elements arranged in series or parallel configurations to achieve enhanced cooling efficiency. These systems employ multiple electrocaloric materials that operate at different temperature ranges, allowing for a wider overall operating temperature span. The staged approach enables more efficient heat transfer between stages and can achieve higher temperature differentials than single-stage systems.- Multi-stage electrocaloric cooling system architecture: Multi-stage electrocaloric cooling systems utilize a cascade arrangement of electrocaloric materials to achieve enhanced cooling efficiency. These systems employ multiple electrocaloric elements arranged in series or parallel configurations to create temperature gradients across stages. The architecture allows for progressive cooling, where each stage contributes to the overall temperature reduction, enabling the system to reach lower temperatures than single-stage designs. This approach optimizes heat transfer between stages and improves the coefficient of performance of the cooling system.

- Control algorithms for electrocaloric cooling cycles: Advanced control algorithms are essential for optimizing the performance of multi-stage electrocaloric cooling systems. These algorithms manage the timing and sequencing of electric field application across different stages, ensuring synchronized operation of the cooling cycle. They incorporate feedback mechanisms that monitor temperature differentials and adjust the electric field strength accordingly. Adaptive control strategies can respond to varying cooling loads and environmental conditions, maintaining optimal efficiency across different operating scenarios while minimizing energy consumption.

- Heat transfer management in electrocaloric cooling systems: Effective heat transfer management is crucial for multi-stage electrocaloric cooling systems. This involves the strategic placement of heat exchangers between cooling stages and the implementation of thermal switches to control the direction and timing of heat flow. Various heat transfer fluids and mechanisms are employed to efficiently move thermal energy between the electrocaloric elements and heat sinks. Advanced designs incorporate regenerative heat recovery systems that capture and reuse thermal energy from one stage to enhance the efficiency of another, significantly improving the overall system performance.

- Electric field application strategies for electrocaloric materials: The application of electric fields to electrocaloric materials follows specific strategies to maximize cooling effect while minimizing energy consumption. These strategies include pulsed field application, variable field strength control, and phase-shifted field application across multiple stages. The timing of field application is synchronized with heat transfer cycles to optimize the electrocaloric effect. Advanced systems implement variable frequency control of the electric field to match the thermal response characteristics of different electrocaloric materials, enhancing energy efficiency and cooling performance.

- Integration of electrocaloric cooling with other technologies: Multi-stage electrocaloric cooling systems can be integrated with complementary technologies to enhance overall performance. These hybrid approaches combine electrocaloric cooling with other cooling methods such as thermoelectric, magnetocaloric, or conventional vapor compression systems. The integration allows for leveraging the strengths of each technology while mitigating their individual limitations. Smart control systems coordinate the operation of these hybrid systems, optimizing energy usage based on ambient conditions and cooling demands. This integration approach extends the application range of electrocaloric cooling to diverse scenarios from electronics cooling to building climate control.

02 Control strategies for electrocaloric cooling cycles

Advanced control strategies for electrocaloric cooling cycles involve precise timing of electric field application and removal synchronized with heat transfer phases. These control methods optimize the thermodynamic cycle by managing the timing of electric field pulses, controlling the duration of heat exchange periods, and adjusting field strength based on temperature feedback. Adaptive control algorithms can dynamically adjust operating parameters to maintain optimal performance under varying load conditions.Expand Specific Solutions03 Heat transfer mechanisms in electrocaloric cooling

Efficient heat transfer mechanisms are crucial for electrocaloric cooling systems, including active fluid circulation, thermal switches, and heat pipes. These mechanisms facilitate the movement of heat between the electrocaloric material and heat exchangers during the cooling cycle. Advanced designs incorporate phase-change materials, specialized heat transfer fluids, and optimized flow patterns to enhance thermal conductivity and reduce thermal resistance between system components.Expand Specific Solutions04 Integration of electrocaloric cooling with other technologies

Electrocaloric cooling systems can be integrated with complementary technologies such as thermoelectric, magnetocaloric, or conventional vapor compression systems to create hybrid cooling solutions. These integrated approaches leverage the strengths of each technology while mitigating their individual limitations. Hybrid systems can offer improved energy efficiency, wider operating temperature ranges, and enhanced reliability through redundancy and optimized operation across different ambient conditions.Expand Specific Solutions05 Energy management and efficiency optimization

Energy management strategies for electrocaloric cooling systems focus on minimizing power consumption while maintaining cooling performance. These include regenerative energy recovery circuits that capture and reuse electrical energy during field cycling, variable frequency operation that adjusts cycle speed based on cooling demand, and intelligent power management systems. Advanced algorithms optimize the electric field profile to maximize the electrocaloric effect while minimizing energy input, resulting in improved coefficient of performance.Expand Specific Solutions

Leading Organizations in Electrocaloric Cooling Research

The electrocaloric cooling technology market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size remains relatively small but is projected to expand significantly as energy-efficient cooling solutions gain traction. From a technical maturity perspective, multi-stage electrocaloric cooling systems are transitioning from laboratory research to early commercialization, with key players demonstrating varied levels of advancement. Companies like Intel, IBM, and Siemens are leading with sophisticated control strategies for thermal management systems, while specialized firms such as Advanced Liquid Cooling Technologies are developing targeted solutions. Chinese entities including China Mobile Group and Wuhan Haiyi are making significant investments in energy-efficient cooling technologies, particularly for telecommunications infrastructure. Academic institutions like Auburn University and SRM University are contributing fundamental research to advance system-level control methodologies for multi-stage implementations.

Hewlett Packard Enterprise Development LP

Technical Solution: Hewlett Packard Enterprise has developed a comprehensive system-level control strategy for multi-stage electrocaloric cooling specifically targeting data center thermal management applications. Their approach leverages machine learning algorithms to continuously optimize the operation of cascaded electrocaloric cooling stages based on server workload patterns and environmental conditions. HPE's system implements a hierarchical control architecture where high-level workload prediction algorithms determine optimal cooling requirements, while lower-level controllers manage the precise timing and magnitude of electric field application to each electrocaloric element. The system incorporates digital twin modeling of the entire cooling chain to enable real-time optimization and predictive maintenance capabilities. HPE has demonstrated energy efficiency improvements of approximately 30% compared to conventional cooling technologies in controlled data center environments, with their multi-stage approach allowing for precise temperature control within ±0.5°C across varying computational loads. The control system also features adaptive power management that balances cooling performance against energy consumption based on configurable efficiency targets.

Strengths: Integration with data center management systems provides holistic optimization; advanced machine learning capabilities enable continuous improvement; substantial R&D resources for ongoing development. Weaknesses: Solution primarily optimized for data center applications with limited focus on other cooling markets; high implementation complexity requires specialized expertise; significant initial investment costs.

Siemens AG

Technical Solution: Siemens has developed an integrated system-level control platform for multi-stage electrocaloric cooling applications that leverages their extensive expertise in industrial automation and control systems. Their approach implements a model-predictive control framework that optimizes the operation of cascaded electrocaloric stages based on comprehensive thermodynamic modeling and real-time performance feedback. Siemens' system features distributed intelligence architecture where local controllers manage individual stage operations while communicating with a central coordinator that optimizes overall system performance. The control strategy incorporates adaptive algorithms that continuously refine operational parameters based on measured performance metrics, enabling the system to maintain optimal efficiency despite component aging or environmental variations. Siemens has demonstrated successful implementation in industrial process cooling applications, achieving energy efficiency improvements of approximately 25-30% compared to conventional vapor-compression systems. Their control platform also integrates seamlessly with building management systems and industrial SCADA networks, enabling holistic energy optimization across entire facilities. The system incorporates comprehensive diagnostics and prognostics capabilities that predict potential component failures before they impact cooling performance.

Strengths: Extensive experience in industrial control systems provides robust implementation; seamless integration with existing building and industrial automation systems; comprehensive diagnostic capabilities enhance maintenance efficiency. Weaknesses: Industrial focus may limit optimization for consumer applications; relatively high implementation complexity requires specialized configuration; significant initial investment costs for full system deployment.

Key Patents and Research in Electrocaloric Control Strategies

Electrocaloric cooling with electrostatic actuation

PatentWO2018208680A1

Innovation

- A solid-state heat transporting device utilizing a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism, allowing for controlled heat transfer by changing the shape or position of the film to form uniform thermal contact with surfaces, thereby enhancing heat flux and reducing parasitic power consumption.

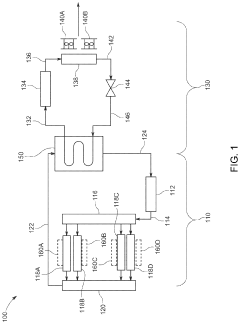

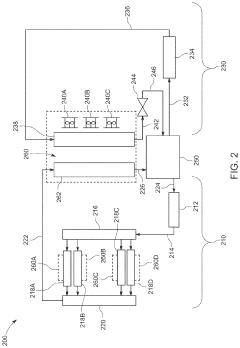

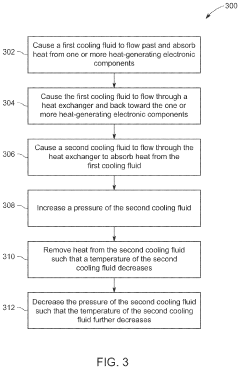

Multi-stage liquid cooling system

PatentActiveUS20240057284A1

Innovation

- A dual-stage cooling system that uses a first cooling fluid to absorb heat from electronic components, with a second cooling fluid undergoing pressure increase, heat removal, and pressure decrease to enhance heat transfer efficiency through a shared heat exchanger.

Energy Efficiency Considerations and Optimization Methods

Energy efficiency represents a critical dimension in the development and implementation of multi-stage electrocaloric cooling systems. The fundamental challenge lies in balancing cooling performance with energy consumption, as these systems must compete with conventional vapor compression technologies that have benefited from decades of optimization.

Current electrocaloric cooling systems typically demonstrate coefficients of performance (COP) ranging from 2 to 5, depending on operating conditions and system architecture. However, theoretical analyses suggest potential COPs exceeding 7 under optimized conditions, highlighting significant room for efficiency improvements through advanced control strategies.

Power consumption in multi-stage electrocaloric systems stems from two primary sources: the electrical energy required for polarizing the electrocaloric materials and the mechanical energy needed for fluid circulation and heat transfer. Control strategies must therefore address both components simultaneously to maximize overall efficiency.

Temporal coordination of voltage application across multiple stages presents a particularly promising optimization avenue. By implementing phase-shifted control sequences that activate different stages at precisely calculated intervals, energy recovery mechanisms can be employed where the depolarization energy from one stage partially powers the polarization of subsequent stages. This approach has demonstrated energy savings of 15-30% in experimental prototypes.

Adaptive control algorithms that respond to varying thermal loads represent another significant efficiency frontier. Machine learning approaches have shown particular promise, with reinforcement learning algorithms capable of developing control policies that dynamically adjust stage sequencing, voltage levels, and cycle timing based on both immediate performance feedback and predicted future demands.

Thermal management optimization within the system presents additional efficiency opportunities. Precise control of fluid flow rates between stages can minimize parasitic pumping losses while maintaining effective heat transfer. Variable speed drives coupled with pressure sensors enable dynamic adjustment of fluid circulation to match instantaneous cooling demands, reducing unnecessary energy expenditure during partial load operation.

System-level integration with renewable energy sources and smart grid capabilities further enhances efficiency potential. Control strategies that leverage time-of-use electricity pricing or available solar/wind generation can schedule intensive cooling cycles during periods of low electricity costs or high renewable availability, improving both economic and environmental performance metrics.

Current electrocaloric cooling systems typically demonstrate coefficients of performance (COP) ranging from 2 to 5, depending on operating conditions and system architecture. However, theoretical analyses suggest potential COPs exceeding 7 under optimized conditions, highlighting significant room for efficiency improvements through advanced control strategies.

Power consumption in multi-stage electrocaloric systems stems from two primary sources: the electrical energy required for polarizing the electrocaloric materials and the mechanical energy needed for fluid circulation and heat transfer. Control strategies must therefore address both components simultaneously to maximize overall efficiency.

Temporal coordination of voltage application across multiple stages presents a particularly promising optimization avenue. By implementing phase-shifted control sequences that activate different stages at precisely calculated intervals, energy recovery mechanisms can be employed where the depolarization energy from one stage partially powers the polarization of subsequent stages. This approach has demonstrated energy savings of 15-30% in experimental prototypes.

Adaptive control algorithms that respond to varying thermal loads represent another significant efficiency frontier. Machine learning approaches have shown particular promise, with reinforcement learning algorithms capable of developing control policies that dynamically adjust stage sequencing, voltage levels, and cycle timing based on both immediate performance feedback and predicted future demands.

Thermal management optimization within the system presents additional efficiency opportunities. Precise control of fluid flow rates between stages can minimize parasitic pumping losses while maintaining effective heat transfer. Variable speed drives coupled with pressure sensors enable dynamic adjustment of fluid circulation to match instantaneous cooling demands, reducing unnecessary energy expenditure during partial load operation.

System-level integration with renewable energy sources and smart grid capabilities further enhances efficiency potential. Control strategies that leverage time-of-use electricity pricing or available solar/wind generation can schedule intensive cooling cycles during periods of low electricity costs or high renewable availability, improving both economic and environmental performance metrics.

Integration Challenges with Existing HVAC Infrastructure

The integration of multi-stage electrocaloric cooling systems with existing HVAC infrastructure presents significant technical and operational challenges that must be addressed for successful implementation. Current HVAC systems are predominantly based on vapor-compression technology with established control mechanisms, distribution networks, and maintenance protocols. Introducing electrocaloric cooling requires careful consideration of compatibility issues at both hardware and software levels.

Physical integration constraints represent the first major hurdle. Existing ductwork, piping, and heat exchange systems are designed for specific thermal capacities and flow rates that may not align with electrocaloric cooling requirements. The dimensional and spatial characteristics of electrocaloric modules differ substantially from conventional cooling coils, necessitating redesign of air handling units or the development of specialized interface components to ensure proper thermal transfer.

Control system compatibility presents another critical challenge. Modern HVAC systems utilize sophisticated building management systems (BMS) with proprietary protocols and algorithms optimized for vapor-compression cycle dynamics. Electrocaloric cooling operates on fundamentally different thermodynamic principles with unique response characteristics, particularly in multi-stage configurations. This disparity requires either comprehensive BMS reprogramming or the development of middleware solutions to translate between electrocaloric control requirements and existing HVAC control frameworks.

Energy infrastructure adaptation must also be considered. While electrocaloric systems potentially offer energy efficiency advantages, they have different electrical load profiles compared to conventional compressor-based systems. Peak power demands during stage switching may require electrical system upgrades or load management strategies to prevent circuit overloading. Additionally, backup and redundancy systems must be reconsidered, as failure modes differ significantly between technologies.

Maintenance and serviceability represent practical implementation barriers. HVAC technicians are trained for conventional refrigerant-based systems, with established diagnostic procedures and repair techniques. Electrocaloric technology introduces unfamiliar components, different failure modes, and new maintenance requirements. This necessitates comprehensive training programs and the development of specialized diagnostic tools before widespread adoption becomes feasible.

Regulatory compliance and certification pathways present additional integration challenges. Existing HVAC systems operate within well-established regulatory frameworks for safety, efficiency, and environmental impact. Electrocaloric cooling systems must demonstrate compliance with these regulations through appropriate testing and certification, which may require the development of new standards specifically addressing the unique characteristics of this technology.

Physical integration constraints represent the first major hurdle. Existing ductwork, piping, and heat exchange systems are designed for specific thermal capacities and flow rates that may not align with electrocaloric cooling requirements. The dimensional and spatial characteristics of electrocaloric modules differ substantially from conventional cooling coils, necessitating redesign of air handling units or the development of specialized interface components to ensure proper thermal transfer.

Control system compatibility presents another critical challenge. Modern HVAC systems utilize sophisticated building management systems (BMS) with proprietary protocols and algorithms optimized for vapor-compression cycle dynamics. Electrocaloric cooling operates on fundamentally different thermodynamic principles with unique response characteristics, particularly in multi-stage configurations. This disparity requires either comprehensive BMS reprogramming or the development of middleware solutions to translate between electrocaloric control requirements and existing HVAC control frameworks.

Energy infrastructure adaptation must also be considered. While electrocaloric systems potentially offer energy efficiency advantages, they have different electrical load profiles compared to conventional compressor-based systems. Peak power demands during stage switching may require electrical system upgrades or load management strategies to prevent circuit overloading. Additionally, backup and redundancy systems must be reconsidered, as failure modes differ significantly between technologies.

Maintenance and serviceability represent practical implementation barriers. HVAC technicians are trained for conventional refrigerant-based systems, with established diagnostic procedures and repair techniques. Electrocaloric technology introduces unfamiliar components, different failure modes, and new maintenance requirements. This necessitates comprehensive training programs and the development of specialized diagnostic tools before widespread adoption becomes feasible.

Regulatory compliance and certification pathways present additional integration challenges. Existing HVAC systems operate within well-established regulatory frameworks for safety, efficiency, and environmental impact. Electrocaloric cooling systems must demonstrate compliance with these regulations through appropriate testing and certification, which may require the development of new standards specifically addressing the unique characteristics of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!