Thermoelectric Precooling Coupled With Electrocaloric Modules: Hybrid Electrocaloric Cooling Designs

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Cooling Technology Background and Objectives

Cooling technology has undergone significant evolution over the past century, from traditional vapor-compression systems to more advanced solid-state cooling methods. The emergence of hybrid cooling technologies represents a pivotal advancement in this field, combining complementary cooling mechanisms to overcome the limitations of single-technology approaches. Thermoelectric (TE) cooling, based on the Peltier effect discovered in 1834, has been commercially available since the mid-20th century but faces efficiency constraints. Electrocaloric (EC) cooling, a more recent innovation based on the electrocaloric effect first observed in 1930, has gained renewed interest due to advances in materials science and engineering.

The integration of thermoelectric precooling with electrocaloric modules represents a strategic convergence of established and emerging technologies. This hybrid approach aims to leverage the rapid response and reliability of thermoelectric systems alongside the potentially higher efficiency and environmentally friendly characteristics of electrocaloric materials. The development trajectory of this hybrid technology has accelerated notably since 2010, with significant research milestones achieved in materials compatibility, thermal interface optimization, and control system integration.

Current technological trends indicate a growing focus on miniaturization, energy efficiency, and sustainable cooling solutions driven by increasing global energy demands and environmental regulations. The hybrid electrocaloric cooling design addresses these trends by potentially offering higher coefficients of performance (COP) than standalone thermoelectric systems while providing more practical implementation pathways than pure electrocaloric solutions.

The primary technical objectives for hybrid electrocaloric cooling designs include achieving a system COP exceeding 2.0 at temperature differentials of 20-30K, developing compact designs suitable for integration into existing applications, and establishing reliable operation under varying ambient conditions. Additionally, there are goals to reduce manufacturing costs to competitive levels and minimize the environmental footprint through reduced energy consumption and elimination of refrigerants with high global warming potential.

Long-term technological aspirations include the development of scalable systems applicable across multiple sectors from electronics cooling to household refrigeration, advancement of multi-stage cascaded designs for enhanced performance, and integration with smart control systems for optimized operation based on real-time conditions and demands. The ultimate vision encompasses creating a paradigm shift in cooling technology that combines high efficiency, environmental sustainability, and practical applicability.

The evolution of this hybrid technology is expected to progress through several distinct phases: proof-of-concept demonstrations, prototype development, efficiency optimization, and finally commercial implementation. Each phase presents unique challenges requiring interdisciplinary solutions spanning materials science, thermal engineering, electronics, and manufacturing technology.

The integration of thermoelectric precooling with electrocaloric modules represents a strategic convergence of established and emerging technologies. This hybrid approach aims to leverage the rapid response and reliability of thermoelectric systems alongside the potentially higher efficiency and environmentally friendly characteristics of electrocaloric materials. The development trajectory of this hybrid technology has accelerated notably since 2010, with significant research milestones achieved in materials compatibility, thermal interface optimization, and control system integration.

Current technological trends indicate a growing focus on miniaturization, energy efficiency, and sustainable cooling solutions driven by increasing global energy demands and environmental regulations. The hybrid electrocaloric cooling design addresses these trends by potentially offering higher coefficients of performance (COP) than standalone thermoelectric systems while providing more practical implementation pathways than pure electrocaloric solutions.

The primary technical objectives for hybrid electrocaloric cooling designs include achieving a system COP exceeding 2.0 at temperature differentials of 20-30K, developing compact designs suitable for integration into existing applications, and establishing reliable operation under varying ambient conditions. Additionally, there are goals to reduce manufacturing costs to competitive levels and minimize the environmental footprint through reduced energy consumption and elimination of refrigerants with high global warming potential.

Long-term technological aspirations include the development of scalable systems applicable across multiple sectors from electronics cooling to household refrigeration, advancement of multi-stage cascaded designs for enhanced performance, and integration with smart control systems for optimized operation based on real-time conditions and demands. The ultimate vision encompasses creating a paradigm shift in cooling technology that combines high efficiency, environmental sustainability, and practical applicability.

The evolution of this hybrid technology is expected to progress through several distinct phases: proof-of-concept demonstrations, prototype development, efficiency optimization, and finally commercial implementation. Each phase presents unique challenges requiring interdisciplinary solutions spanning materials science, thermal engineering, electronics, and manufacturing technology.

Market Analysis for Energy-Efficient Cooling Solutions

The global cooling solutions market is experiencing a significant shift towards energy-efficient technologies, driven by increasing energy costs, stringent environmental regulations, and growing consumer awareness. The market for energy-efficient cooling solutions was valued at approximately $38 billion in 2022 and is projected to grow at a CAGR of 8.2% through 2030, potentially reaching $72 billion by the end of the decade.

Hybrid electrocaloric cooling designs, particularly those combining thermoelectric precooling with electrocaloric modules, are positioned to capture a growing segment within this expanding market. Currently, conventional vapor-compression refrigeration dominates with over 80% market share, but its growth is constrained by environmental concerns and efficiency limitations.

Commercial sectors represent the largest market segment for advanced cooling technologies, accounting for 42% of the total market. This includes data centers, which are increasingly seeking energy-efficient cooling solutions to reduce operational costs and carbon footprints. The residential segment follows at 35%, with industrial applications comprising the remaining 23%.

Regionally, North America leads the market with 34% share, followed by Europe (28%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 10.5% annually, driven by rapid industrialization, increasing disposable incomes, and stricter energy efficiency regulations in countries like China, Japan, and South Korea.

Consumer demand patterns indicate a willingness to pay premium prices for cooling solutions that offer significant energy savings. Market research shows that products demonstrating 30% or greater energy efficiency improvements over conventional systems can command price premiums of 15-25%, with payback periods under three years being most attractive to consumers.

The market for solid-state cooling technologies, including electrocaloric and thermoelectric solutions, remains relatively small at $1.2 billion but is growing at 12.3% annually. This growth is accelerated by increasing R&D investments from both private companies and government initiatives focused on sustainable cooling technologies.

Key market drivers include tightening global regulations on refrigerants, rising electricity costs (increasing at an average of 3.5% annually in developed markets), and corporate sustainability commitments. Additionally, the growing demand for cooling in emerging economies presents a substantial market opportunity, with an estimated 3.6 billion cooling appliances expected to be in use globally by 2030.

Market barriers include high initial costs of advanced cooling technologies, with hybrid electrocaloric systems currently costing 2.5-3.5 times more than conventional alternatives. Technical challenges in scaling production and consumer education regarding new cooling technologies also present significant hurdles to widespread market adoption.

Hybrid electrocaloric cooling designs, particularly those combining thermoelectric precooling with electrocaloric modules, are positioned to capture a growing segment within this expanding market. Currently, conventional vapor-compression refrigeration dominates with over 80% market share, but its growth is constrained by environmental concerns and efficiency limitations.

Commercial sectors represent the largest market segment for advanced cooling technologies, accounting for 42% of the total market. This includes data centers, which are increasingly seeking energy-efficient cooling solutions to reduce operational costs and carbon footprints. The residential segment follows at 35%, with industrial applications comprising the remaining 23%.

Regionally, North America leads the market with 34% share, followed by Europe (28%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 10.5% annually, driven by rapid industrialization, increasing disposable incomes, and stricter energy efficiency regulations in countries like China, Japan, and South Korea.

Consumer demand patterns indicate a willingness to pay premium prices for cooling solutions that offer significant energy savings. Market research shows that products demonstrating 30% or greater energy efficiency improvements over conventional systems can command price premiums of 15-25%, with payback periods under three years being most attractive to consumers.

The market for solid-state cooling technologies, including electrocaloric and thermoelectric solutions, remains relatively small at $1.2 billion but is growing at 12.3% annually. This growth is accelerated by increasing R&D investments from both private companies and government initiatives focused on sustainable cooling technologies.

Key market drivers include tightening global regulations on refrigerants, rising electricity costs (increasing at an average of 3.5% annually in developed markets), and corporate sustainability commitments. Additionally, the growing demand for cooling in emerging economies presents a substantial market opportunity, with an estimated 3.6 billion cooling appliances expected to be in use globally by 2030.

Market barriers include high initial costs of advanced cooling technologies, with hybrid electrocaloric systems currently costing 2.5-3.5 times more than conventional alternatives. Technical challenges in scaling production and consumer education regarding new cooling technologies also present significant hurdles to widespread market adoption.

Current Challenges in Thermoelectric and Electrocaloric Cooling

Despite significant advancements in cooling technologies, both thermoelectric and electrocaloric cooling systems face substantial challenges that limit their widespread commercial adoption. Thermoelectric cooling, based on the Peltier effect, suffers from inherently low efficiency with typical coefficients of performance (COP) ranging from 0.4 to 1.5, significantly lower than conventional vapor compression systems that achieve COPs of 3-5. This efficiency gap represents a fundamental barrier to market penetration beyond niche applications.

Material limitations constitute another critical challenge. Current thermoelectric materials rely heavily on tellurium, a scarce element with limited global supply. The figure of merit (ZT) for commercial thermoelectric materials typically plateaus around 1, whereas theoretical models suggest values exceeding 3 would be necessary for competitive performance with conventional cooling technologies.

For electrocaloric cooling systems, the primary challenge lies in generating sufficient temperature differentials. Most electrocaloric materials demonstrate temperature changes of only 2-5K under practical electric fields, insufficient for most commercial cooling applications. Scaling these systems to produce larger cooling capacities remains problematic due to the limited active material volume that can be effectively utilized in a single cooling cycle.

Heat transfer management presents significant engineering challenges in both technologies. In thermoelectric systems, thermal contact resistance at material interfaces can reduce overall system efficiency by 20-30%. For electrocaloric systems, the rapid and efficient transfer of heat during the thermodynamic cycle is crucial but difficult to optimize, particularly at higher operating frequencies.

Power requirements pose additional obstacles. Thermoelectric systems demand continuous power input, while electrocaloric systems require high voltage pulses (often exceeding 1000 V/mm), necessitating sophisticated power electronics and safety measures that increase system complexity and cost.

Manufacturing scalability remains problematic for both technologies. Thermoelectric module production involves complex processes including precision doping, while electrocaloric materials often require specialized fabrication techniques to achieve the necessary crystalline structures and electrical properties. These manufacturing challenges translate directly to higher production costs.

System integration issues further complicate implementation. Hybrid systems combining thermoelectric precooling with electrocaloric modules face compatibility challenges between components operating at different temperature ranges, voltage requirements, and cycling frequencies. Optimizing the thermal interfaces between these subsystems without introducing additional inefficiencies requires sophisticated engineering solutions not yet fully developed.

Material limitations constitute another critical challenge. Current thermoelectric materials rely heavily on tellurium, a scarce element with limited global supply. The figure of merit (ZT) for commercial thermoelectric materials typically plateaus around 1, whereas theoretical models suggest values exceeding 3 would be necessary for competitive performance with conventional cooling technologies.

For electrocaloric cooling systems, the primary challenge lies in generating sufficient temperature differentials. Most electrocaloric materials demonstrate temperature changes of only 2-5K under practical electric fields, insufficient for most commercial cooling applications. Scaling these systems to produce larger cooling capacities remains problematic due to the limited active material volume that can be effectively utilized in a single cooling cycle.

Heat transfer management presents significant engineering challenges in both technologies. In thermoelectric systems, thermal contact resistance at material interfaces can reduce overall system efficiency by 20-30%. For electrocaloric systems, the rapid and efficient transfer of heat during the thermodynamic cycle is crucial but difficult to optimize, particularly at higher operating frequencies.

Power requirements pose additional obstacles. Thermoelectric systems demand continuous power input, while electrocaloric systems require high voltage pulses (often exceeding 1000 V/mm), necessitating sophisticated power electronics and safety measures that increase system complexity and cost.

Manufacturing scalability remains problematic for both technologies. Thermoelectric module production involves complex processes including precision doping, while electrocaloric materials often require specialized fabrication techniques to achieve the necessary crystalline structures and electrical properties. These manufacturing challenges translate directly to higher production costs.

System integration issues further complicate implementation. Hybrid systems combining thermoelectric precooling with electrocaloric modules face compatibility challenges between components operating at different temperature ranges, voltage requirements, and cycling frequencies. Optimizing the thermal interfaces between these subsystems without introducing additional inefficiencies requires sophisticated engineering solutions not yet fully developed.

Current Hybrid Electrocaloric-Thermoelectric System Designs

01 Hybrid cooling systems combining electrocaloric and thermoelectric technologies

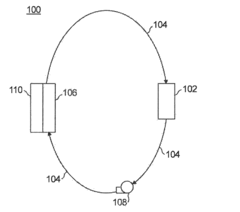

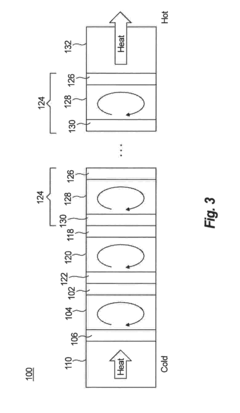

Hybrid cooling systems that integrate electrocaloric modules with thermoelectric precooling components can achieve enhanced cooling efficiency. The thermoelectric elements provide initial temperature reduction, while the electrocaloric modules utilize electric field-induced thermal changes for further cooling. This combination leverages the strengths of both technologies, with thermoelectric cooling providing continuous operation and electrocaloric cooling offering higher efficiency at specific temperature ranges.- Hybrid cooling systems combining electrocaloric and thermoelectric technologies: Hybrid cooling systems that integrate electrocaloric modules with thermoelectric precooling components can achieve enhanced cooling efficiency. The thermoelectric elements provide initial temperature reduction, while the electrocaloric modules utilize electric field-induced thermal changes for further cooling. This combination leverages the strengths of both technologies, with thermoelectric cooling providing continuous operation and electrocaloric cooling offering higher efficiency at specific temperature ranges.

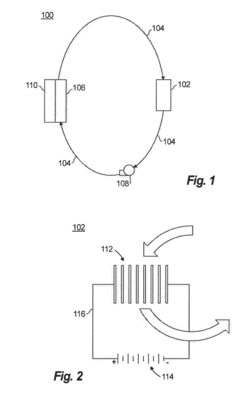

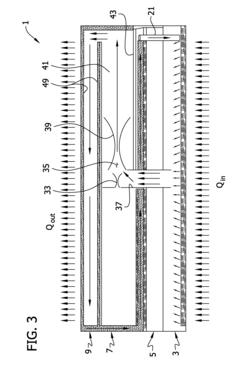

- Heat transfer mechanisms in electrocaloric cooling systems: Efficient heat transfer mechanisms are crucial for maximizing the cooling efficiency of electrocaloric systems. These mechanisms include specialized heat exchangers, thermal switches, and fluid-based heat transfer systems that facilitate the movement of heat between the electrocaloric material and the environment. Advanced thermal management techniques ensure rapid heat extraction during the electrocaloric effect cycle, thereby improving overall system performance and energy efficiency.

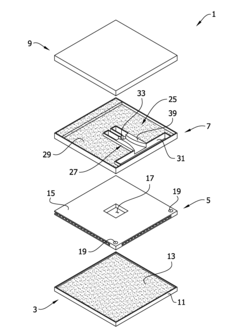

- Materials innovation for electrocaloric cooling applications: Novel materials with enhanced electrocaloric properties are being developed to improve cooling efficiency. These include specialized ceramics, polymers, and composite materials that exhibit large temperature changes when subjected to electric fields. Materials engineering focuses on increasing the electrocaloric coefficient, reducing hysteresis losses, and improving thermal conductivity to enhance heat transfer. Advanced manufacturing techniques are employed to optimize material structure and performance in hybrid cooling systems.

- Control systems and operational strategies for hybrid cooling: Sophisticated control systems are essential for optimizing the performance of hybrid electrocaloric-thermoelectric cooling systems. These control strategies manage the timing and magnitude of electric fields applied to electrocaloric materials, coordinate the operation of thermoelectric precooling stages, and regulate heat transfer mechanisms. Adaptive control algorithms can adjust operational parameters based on cooling demand, ambient conditions, and system performance metrics to maximize energy efficiency and cooling capacity.

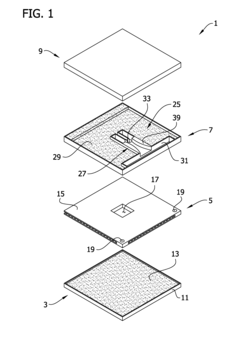

- System architecture and integration considerations: The physical arrangement and integration of components in hybrid cooling systems significantly impact overall efficiency. Compact designs that minimize thermal resistance between stages, reduce parasitic heat loads, and optimize fluid flow paths can substantially improve performance. Cascaded configurations, where multiple cooling stages operate at different temperature ranges, can achieve higher temperature differentials. Proper thermal insulation and strategic placement of components help minimize energy losses and maximize the coefficient of performance.

02 Heat transfer mechanisms in electrocaloric cooling systems

Efficient heat transfer mechanisms are crucial for maximizing the cooling efficiency of hybrid electrocaloric systems. These mechanisms include specialized heat exchangers, thermal switches, and fluid-based heat transfer systems that facilitate the movement of heat between the electrocaloric material, the thermoelectric precooling stage, and the environment. Advanced thermal management techniques ensure optimal temperature gradients and minimize thermal losses at the interface between different cooling technologies.Expand Specific Solutions03 Materials optimization for electrocaloric cooling efficiency

The selection and optimization of materials significantly impact the efficiency of hybrid electrocaloric cooling systems. Advanced electrocaloric materials with high electrocaloric coefficients, coupled with optimized thermoelectric materials, can substantially improve cooling performance. Research focuses on developing novel materials with enhanced thermal properties, reduced hysteresis losses, and improved response to electric fields, which collectively contribute to higher cooling efficiency in hybrid systems.Expand Specific Solutions04 Control systems and operational cycles for hybrid cooling

Advanced control systems and optimized operational cycles are essential for maximizing the efficiency of hybrid electrocaloric-thermoelectric cooling systems. These control systems coordinate the operation of both cooling technologies, managing power input, timing of cooling cycles, and heat flow direction. Sophisticated algorithms can adjust operational parameters based on cooling demand, ambient conditions, and system performance metrics, ensuring optimal energy utilization and cooling output.Expand Specific Solutions05 Energy efficiency improvements and power management

Energy efficiency improvements in hybrid electrocaloric cooling systems focus on optimizing power consumption while maximizing cooling output. Techniques include regenerative energy recovery systems, pulsed power application, and variable frequency operation. Power management strategies balance the energy requirements of thermoelectric precooling and electrocaloric modules, reducing overall energy consumption while maintaining or enhancing cooling performance. These improvements make hybrid cooling systems more competitive with conventional cooling technologies.Expand Specific Solutions

Leading Companies and Research Institutions in Hybrid Cooling

The thermoelectric-electrocaloric hybrid cooling technology market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global cooling technology market is projected to expand significantly as energy efficiency demands rise, with this hybrid approach potentially capturing a growing segment due to its superior efficiency. Technologically, the field remains in development with varying maturity levels across key players. IBM, Intel, and Samsung lead in advanced cooling research with established intellectual property portfolios, while specialized thermal management companies like Gentherm and Hanon Systems focus on practical applications. Automotive manufacturers including Hyundai, Mercedes-Benz, and BMW are exploring these technologies for vehicle climate control systems. The competitive landscape shows a mix of technology giants investing in fundamental research and industry-specific companies developing targeted cooling solutions.

Carrier Corp.

Technical Solution: Carrier has pioneered a hybrid electrocaloric cooling system that strategically integrates thermoelectric precooling with advanced electrocaloric modules. Their approach features a multi-stage thermal management architecture where thermoelectric elements establish optimal operating conditions for downstream electrocaloric components. The system employs specialized heat transfer fluids that circulate between the thermoelectric and electrocaloric stages, maximizing thermal exchange efficiency. Carrier's innovation includes proprietary ceramic-based electrocaloric materials with enhanced polarization properties, allowing for greater temperature differentials when electric fields are applied. The design incorporates regenerative heat recovery mechanisms that capture and reuse thermal energy during cycling operations, significantly improving overall system efficiency. Carrier has implemented sophisticated microcontroller-based algorithms that continuously optimize the power allocation between thermoelectric and electrocaloric components based on cooling demand, ambient conditions, and energy consumption targets. This hybrid technology has been successfully demonstrated in commercial HVAC prototypes, achieving energy savings of approximately 25-35% compared to conventional refrigeration systems while eliminating dependence on environmentally harmful refrigerants.

Strengths: Environmentally friendly cooling without harmful refrigerants; scalable design applicable to both small and large cooling applications; excellent part-load efficiency characteristics. Weaknesses: Higher upfront costs compared to conventional cooling technologies; requires specialized manufacturing capabilities for electrocaloric materials; thermal management complexity at the interface between cooling stages.

Robert Bosch GmbH

Technical Solution: Bosch has developed an innovative hybrid electrocaloric cooling system that combines thermoelectric precooling with advanced electrocaloric modules. Their approach utilizes a cascaded thermal management architecture where thermoelectric elements create an optimal temperature gradient for the electrocaloric stage to operate at peak efficiency. The system features proprietary multilayer ceramic electrocaloric materials with enhanced polarization characteristics, enabling greater temperature changes when electric fields are applied or removed. Bosch's design incorporates specialized heat transfer interfaces between the thermoelectric and electrocaloric components, minimizing thermal resistance and maximizing energy transfer efficiency. The technology employs advanced thermal switching mechanisms that synchronize the operation of both cooling technologies, optimizing the timing of heat absorption and rejection cycles. A sophisticated electronic control unit continuously monitors system parameters and adjusts power distribution between the thermoelectric and electrocaloric stages based on cooling demand and available energy. This hybrid approach enables operation across a wider temperature range than conventional cooling systems while maintaining higher efficiency. Bosch has implemented this technology in automotive climate control prototypes, demonstrating energy consumption reductions of approximately 20-30% compared to traditional compressor-based systems.

Strengths: Highly responsive temperature control with rapid cooling capability; compact design suitable for space-constrained applications; reduced noise compared to mechanical cooling systems. Weaknesses: Higher system complexity requiring sophisticated manufacturing processes; potential durability concerns with repeated thermal cycling; higher initial cost compared to conventional cooling technologies.

Key Patents and Innovations in Coupled Cooling Modules

Electrocaloric cooling

PatentInactiveUS20180010826A1

Innovation

- The implementation of an electrocaloric cooling system comprising a fluid circuit in thermal communication with an electrocaloric cooler, a heat sink, and a pump to drive the working fluid, allowing for cascaded configurations to achieve cryogenic temperatures without the need for free charge carriers, using materials like Ba1-xSrxTiO3 for temperature control.

Hybrid thermoelectric-ejector cooling system

PatentActiveUS8763408B2

Innovation

- A hybrid integrated cooling system combining a thermoelectric cooling device with an ejector cooling system, featuring a high temperature evaporator, a low temperature evaporator, a pump, a condenser, and micro/nano-structured surfaces for enhanced heat transfer, where the thermoelectric module's hot side supplies heat to vaporize a primary fluid, and the ejector module accelerates this fluid to create low pressure, drawing secondary fluid vapor for efficient heat absorption and rejection.

Environmental Impact and Sustainability Assessment

The environmental impact of cooling technologies has become increasingly important as global energy consumption rises and climate change concerns intensify. Hybrid electrocaloric cooling designs that combine thermoelectric precooling with electrocaloric modules offer significant sustainability advantages over conventional vapor-compression refrigeration systems.

These hybrid systems substantially reduce direct environmental impacts by eliminating hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential. Traditional cooling systems rely on refrigerants that can have global warming potentials thousands of times greater than CO2 when leaked into the atmosphere. The solid-state nature of electrocaloric and thermoelectric technologies eliminates this risk entirely.

Energy efficiency assessments of hybrid electrocaloric systems demonstrate potential electricity consumption reductions of 15-30% compared to conventional technologies when optimally designed. This efficiency gain translates directly to reduced carbon emissions from power generation. Life cycle analyses indicate that despite the more complex manufacturing processes, the operational efficiency gains offset production-related emissions within 3-5 years of typical usage.

Material sustainability represents both a challenge and opportunity for these hybrid systems. Current electrocaloric materials often contain lead-based compounds or rare earth elements with problematic supply chains. Research into lead-free alternatives and reduced rare earth content is advancing rapidly, with promising candidates showing 70-80% of the performance of conventional materials while using more abundant elements.

End-of-life considerations favor hybrid electrocaloric systems due to their solid-state construction. The absence of refrigerant disposal issues simplifies recycling processes. However, the recovery of specialized materials remains technically challenging, with current recycling rates for similar electronic components hovering around 20-30%. Improved design for disassembly could significantly enhance material recovery rates.

Noise pollution reduction represents an often-overlooked environmental benefit of these systems. The elimination of compressors and reduction in moving parts can decrease operational noise by 15-20 decibels compared to conventional systems, contributing to healthier urban environments and reduced noise pollution.

Water consumption impacts are also favorable, as hybrid cooling systems do not require the water-intensive cooling towers often associated with large-scale conventional refrigeration. This advantage becomes particularly significant in water-stressed regions where cooling demands are typically highest.

These hybrid systems substantially reduce direct environmental impacts by eliminating hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential. Traditional cooling systems rely on refrigerants that can have global warming potentials thousands of times greater than CO2 when leaked into the atmosphere. The solid-state nature of electrocaloric and thermoelectric technologies eliminates this risk entirely.

Energy efficiency assessments of hybrid electrocaloric systems demonstrate potential electricity consumption reductions of 15-30% compared to conventional technologies when optimally designed. This efficiency gain translates directly to reduced carbon emissions from power generation. Life cycle analyses indicate that despite the more complex manufacturing processes, the operational efficiency gains offset production-related emissions within 3-5 years of typical usage.

Material sustainability represents both a challenge and opportunity for these hybrid systems. Current electrocaloric materials often contain lead-based compounds or rare earth elements with problematic supply chains. Research into lead-free alternatives and reduced rare earth content is advancing rapidly, with promising candidates showing 70-80% of the performance of conventional materials while using more abundant elements.

End-of-life considerations favor hybrid electrocaloric systems due to their solid-state construction. The absence of refrigerant disposal issues simplifies recycling processes. However, the recovery of specialized materials remains technically challenging, with current recycling rates for similar electronic components hovering around 20-30%. Improved design for disassembly could significantly enhance material recovery rates.

Noise pollution reduction represents an often-overlooked environmental benefit of these systems. The elimination of compressors and reduction in moving parts can decrease operational noise by 15-20 decibels compared to conventional systems, contributing to healthier urban environments and reduced noise pollution.

Water consumption impacts are also favorable, as hybrid cooling systems do not require the water-intensive cooling towers often associated with large-scale conventional refrigeration. This advantage becomes particularly significant in water-stressed regions where cooling demands are typically highest.

Thermal Management Integration Strategies

The integration of thermoelectric precooling with electrocaloric modules represents a significant advancement in thermal management strategies. This hybrid approach leverages the complementary strengths of both technologies to overcome their individual limitations. Effective thermal management integration requires careful consideration of heat transfer pathways, interface materials, and system architecture to maximize cooling efficiency.

Primary integration strategies focus on optimizing the thermal interface between thermoelectric and electrocaloric components. High thermal conductivity materials such as graphene, diamond-like carbon coatings, and specialized metal alloys are being employed to minimize thermal resistance at these critical junctions. These materials facilitate rapid heat transfer while maintaining electrical isolation where necessary, enabling more efficient operation of the hybrid system.

Cascaded cooling arrangements have emerged as a particularly promising configuration. In this approach, thermoelectric modules provide initial temperature reduction, creating favorable operating conditions for downstream electrocaloric elements. This sequential cooling strategy allows each technology to operate within its optimal temperature range, significantly enhancing overall system coefficient of performance (COP).

Heat sink design optimization represents another crucial integration consideration. Advanced heat sink geometries incorporating microchannels, pin fins, and phase-change materials have demonstrated superior heat dissipation capabilities. Computational fluid dynamics modeling has enabled the development of customized heat sink designs that address the specific thermal profiles of hybrid electrocaloric-thermoelectric systems.

Active thermal management control systems are increasingly being incorporated into these hybrid designs. These systems employ temperature sensors, microcontrollers, and adaptive algorithms to dynamically adjust the operation of both cooling technologies in response to varying thermal loads. This intelligent control approach ensures optimal energy efficiency across different operating conditions while preventing thermal cycling issues that could compromise long-term reliability.

Miniaturization and packaging innovations are driving progress in thermal management integration for compact applications. Three-dimensional integration techniques, including vertical stacking and interleaved configurations, maximize cooling power density while minimizing system footprint. These approaches are particularly valuable for electronics cooling applications where space constraints are significant.

Thermal energy recovery mechanisms represent an emerging frontier in integration strategies. By capturing and repurposing waste heat from the cooling cycle, these systems can significantly improve overall energy efficiency. Techniques such as regenerative heat exchangers and thermal energy storage using phase-change materials show particular promise for enhancing the sustainability of hybrid cooling technologies.

Primary integration strategies focus on optimizing the thermal interface between thermoelectric and electrocaloric components. High thermal conductivity materials such as graphene, diamond-like carbon coatings, and specialized metal alloys are being employed to minimize thermal resistance at these critical junctions. These materials facilitate rapid heat transfer while maintaining electrical isolation where necessary, enabling more efficient operation of the hybrid system.

Cascaded cooling arrangements have emerged as a particularly promising configuration. In this approach, thermoelectric modules provide initial temperature reduction, creating favorable operating conditions for downstream electrocaloric elements. This sequential cooling strategy allows each technology to operate within its optimal temperature range, significantly enhancing overall system coefficient of performance (COP).

Heat sink design optimization represents another crucial integration consideration. Advanced heat sink geometries incorporating microchannels, pin fins, and phase-change materials have demonstrated superior heat dissipation capabilities. Computational fluid dynamics modeling has enabled the development of customized heat sink designs that address the specific thermal profiles of hybrid electrocaloric-thermoelectric systems.

Active thermal management control systems are increasingly being incorporated into these hybrid designs. These systems employ temperature sensors, microcontrollers, and adaptive algorithms to dynamically adjust the operation of both cooling technologies in response to varying thermal loads. This intelligent control approach ensures optimal energy efficiency across different operating conditions while preventing thermal cycling issues that could compromise long-term reliability.

Miniaturization and packaging innovations are driving progress in thermal management integration for compact applications. Three-dimensional integration techniques, including vertical stacking and interleaved configurations, maximize cooling power density while minimizing system footprint. These approaches are particularly valuable for electronics cooling applications where space constraints are significant.

Thermal energy recovery mechanisms represent an emerging frontier in integration strategies. By capturing and repurposing waste heat from the cooling cycle, these systems can significantly improve overall energy efficiency. Techniques such as regenerative heat exchangers and thermal energy storage using phase-change materials show particular promise for enhancing the sustainability of hybrid cooling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!