What Are The Testing Challenges For Automotive-Grade GaN HEMTs?

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GaN HEMT Evolution and Testing Objectives

Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have emerged as revolutionary power semiconductor devices, evolving significantly since their initial development in the early 1990s. The evolution trajectory of GaN HEMTs has been characterized by continuous improvements in material quality, device architecture, and manufacturing processes, leading to enhanced performance metrics such as higher breakdown voltage, lower on-resistance, and improved thermal management capabilities.

The automotive industry's transition toward electrification has accelerated the demand for more efficient power electronics, positioning GaN HEMTs as critical components in next-generation vehicle systems. This technological shift necessitates comprehensive testing methodologies specifically tailored for automotive-grade GaN HEMTs to ensure reliability under extreme operating conditions, including wide temperature ranges (-40°C to 175°C), high humidity, mechanical stress, and prolonged operational lifetimes exceeding 15 years.

Testing objectives for automotive-grade GaN HEMTs must align with the stringent requirements outlined in AEC-Q101 qualification standards, which were originally developed for silicon-based devices. However, GaN's unique material properties and failure mechanisms require adaptation and extension of these testing protocols. Primary testing objectives include verification of dynamic Ron performance, threshold voltage stability, gate leakage characteristics, and robustness against short-circuit events.

Long-term reliability assessment represents a paramount testing objective, focusing on mechanisms such as time-dependent dielectric breakdown (TDDB), hot electron effects, and current collapse phenomena. These reliability concerns are particularly critical in automotive applications where safety and dependability cannot be compromised. Testing must validate that GaN HEMTs can maintain consistent performance throughout the vehicle's operational lifetime without degradation that could compromise system functionality.

Another crucial testing objective involves evaluating GaN HEMTs under realistic application conditions that simulate actual automotive use cases. This includes power cycling tests, thermal cycling, and mission-profile based testing that replicates real-world driving scenarios. Such application-specific testing helps bridge the gap between laboratory qualification and field reliability, providing more accurate predictions of device behavior in deployed automotive systems.

The evolution of testing methodologies must keep pace with advancements in GaN HEMT technology, particularly as new device architectures and packaging solutions emerge. Testing objectives should therefore include provisions for evaluating novel structures such as vertical GaN devices, hybrid cascode configurations, and advanced packaging technologies that integrate multiple components for enhanced system performance and reliability.

Standardization of testing protocols represents another key objective, as the industry currently lacks consensus on GaN-specific testing standards. Collaborative efforts between semiconductor manufacturers, automotive OEMs, and standards organizations are essential to establish universally accepted qualification procedures that address the unique characteristics and failure modes of GaN HEMTs in automotive environments.

The automotive industry's transition toward electrification has accelerated the demand for more efficient power electronics, positioning GaN HEMTs as critical components in next-generation vehicle systems. This technological shift necessitates comprehensive testing methodologies specifically tailored for automotive-grade GaN HEMTs to ensure reliability under extreme operating conditions, including wide temperature ranges (-40°C to 175°C), high humidity, mechanical stress, and prolonged operational lifetimes exceeding 15 years.

Testing objectives for automotive-grade GaN HEMTs must align with the stringent requirements outlined in AEC-Q101 qualification standards, which were originally developed for silicon-based devices. However, GaN's unique material properties and failure mechanisms require adaptation and extension of these testing protocols. Primary testing objectives include verification of dynamic Ron performance, threshold voltage stability, gate leakage characteristics, and robustness against short-circuit events.

Long-term reliability assessment represents a paramount testing objective, focusing on mechanisms such as time-dependent dielectric breakdown (TDDB), hot electron effects, and current collapse phenomena. These reliability concerns are particularly critical in automotive applications where safety and dependability cannot be compromised. Testing must validate that GaN HEMTs can maintain consistent performance throughout the vehicle's operational lifetime without degradation that could compromise system functionality.

Another crucial testing objective involves evaluating GaN HEMTs under realistic application conditions that simulate actual automotive use cases. This includes power cycling tests, thermal cycling, and mission-profile based testing that replicates real-world driving scenarios. Such application-specific testing helps bridge the gap between laboratory qualification and field reliability, providing more accurate predictions of device behavior in deployed automotive systems.

The evolution of testing methodologies must keep pace with advancements in GaN HEMT technology, particularly as new device architectures and packaging solutions emerge. Testing objectives should therefore include provisions for evaluating novel structures such as vertical GaN devices, hybrid cascode configurations, and advanced packaging technologies that integrate multiple components for enhanced system performance and reliability.

Standardization of testing protocols represents another key objective, as the industry currently lacks consensus on GaN-specific testing standards. Collaborative efforts between semiconductor manufacturers, automotive OEMs, and standards organizations are essential to establish universally accepted qualification procedures that address the unique characteristics and failure modes of GaN HEMTs in automotive environments.

Automotive Market Demand for GaN Power Devices

The automotive industry is experiencing a significant shift towards electrification and advanced power electronics, creating substantial market demand for Gallium Nitride (GaN) High Electron Mobility Transistors (HEMTs). This demand is primarily driven by the superior performance characteristics of GaN devices compared to traditional silicon-based solutions, particularly in electric vehicle (EV) applications where efficiency, power density, and reliability are paramount.

Market analysis indicates that the global automotive power electronics market is projected to grow at a compound annual growth rate of 22% between 2023 and 2030, with GaN power devices representing an increasingly important segment. The transition to electric vehicles is accelerating this growth, as manufacturers seek more efficient power conversion solutions for onboard chargers, DC-DC converters, and traction inverters.

The automotive sector's specific requirements for GaN power devices stem from the need to maximize driving range while minimizing charging time in EVs. GaN HEMTs offer switching frequencies up to ten times higher than silicon alternatives, with significantly reduced switching losses. This translates to smaller, lighter, and more efficient power conversion systems - critical advantages in the weight and space-constrained automotive environment.

Vehicle manufacturers are particularly interested in GaN technology for onboard chargers, where the higher efficiency can reduce charging times by up to 40% compared to silicon-based solutions. Additionally, the reduced size and weight contribute to extended vehicle range, addressing a key consumer concern in EV adoption.

The demand for automotive-grade GaN devices is further intensified by the industry's push toward higher voltage systems (800V and beyond) to enable ultra-fast charging capabilities. In these applications, GaN's higher breakdown voltage and superior thermal performance provide significant advantages over silicon technologies.

Regional market analysis reveals that Asia-Pacific currently leads in automotive GaN adoption, followed by Europe and North America. This geographic distribution aligns with regional EV manufacturing concentrations and government initiatives promoting electric mobility.

Despite strong market potential, automotive adoption of GaN technology faces challenges related to cost premiums over silicon alternatives, supply chain maturity, and the stringent qualification requirements of the automotive industry. The automotive qualification process (AEC-Q101) demands extensive reliability testing under extreme conditions, creating a significant barrier to entry for new GaN device manufacturers.

Industry forecasts suggest that as production volumes increase and manufacturing processes mature, the cost differential between GaN and silicon devices will narrow, accelerating adoption across multiple automotive power applications and expanding the addressable market for GaN HEMTs in the automotive sector.

Market analysis indicates that the global automotive power electronics market is projected to grow at a compound annual growth rate of 22% between 2023 and 2030, with GaN power devices representing an increasingly important segment. The transition to electric vehicles is accelerating this growth, as manufacturers seek more efficient power conversion solutions for onboard chargers, DC-DC converters, and traction inverters.

The automotive sector's specific requirements for GaN power devices stem from the need to maximize driving range while minimizing charging time in EVs. GaN HEMTs offer switching frequencies up to ten times higher than silicon alternatives, with significantly reduced switching losses. This translates to smaller, lighter, and more efficient power conversion systems - critical advantages in the weight and space-constrained automotive environment.

Vehicle manufacturers are particularly interested in GaN technology for onboard chargers, where the higher efficiency can reduce charging times by up to 40% compared to silicon-based solutions. Additionally, the reduced size and weight contribute to extended vehicle range, addressing a key consumer concern in EV adoption.

The demand for automotive-grade GaN devices is further intensified by the industry's push toward higher voltage systems (800V and beyond) to enable ultra-fast charging capabilities. In these applications, GaN's higher breakdown voltage and superior thermal performance provide significant advantages over silicon technologies.

Regional market analysis reveals that Asia-Pacific currently leads in automotive GaN adoption, followed by Europe and North America. This geographic distribution aligns with regional EV manufacturing concentrations and government initiatives promoting electric mobility.

Despite strong market potential, automotive adoption of GaN technology faces challenges related to cost premiums over silicon alternatives, supply chain maturity, and the stringent qualification requirements of the automotive industry. The automotive qualification process (AEC-Q101) demands extensive reliability testing under extreme conditions, creating a significant barrier to entry for new GaN device manufacturers.

Industry forecasts suggest that as production volumes increase and manufacturing processes mature, the cost differential between GaN and silicon devices will narrow, accelerating adoption across multiple automotive power applications and expanding the addressable market for GaN HEMTs in the automotive sector.

Current Testing Limitations for Automotive-Grade GaN HEMTs

Current testing methodologies for automotive-grade Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) face significant limitations that impede their widespread adoption in the automotive industry. Traditional silicon-based testing protocols prove inadequate for GaN technology due to fundamental differences in material properties and operational characteristics, creating a substantial gap in reliability assessment.

The automotive qualification standard AEC-Q101, originally developed for silicon devices, lacks specific provisions for wide bandgap semiconductors like GaN. This misalignment results in either overly stringent or insufficiently comprehensive testing regimes that fail to accurately predict GaN HEMT performance under automotive conditions. The absence of standardized GaN-specific testing protocols creates inconsistency across the industry and complicates supplier qualification processes.

Dynamic switching behavior testing presents particular challenges, as GaN HEMTs operate at significantly higher frequencies and switching speeds than silicon counterparts. Current testing equipment often lacks sufficient bandwidth and resolution to accurately capture nanosecond-scale switching events and associated parasitic effects that are critical to understanding device reliability in automotive applications.

Temperature-dependent performance evaluation remains problematic, with existing test chambers struggling to simulate the rapid thermal cycling and extreme temperature gradients experienced in automotive environments. The unique thermal properties of GaN materials, including different coefficients of thermal expansion compared to packaging materials, create reliability concerns that current testing methodologies cannot adequately assess.

Gate reliability testing faces limitations in accurately replicating the complex stress conditions that automotive-grade GaN HEMTs encounter during operation. The threshold voltage instability mechanisms in GaN differ substantially from silicon devices, yet testing protocols have not evolved sufficiently to characterize these differences, leading to potential reliability blind spots.

Accelerated lifetime testing methodologies show significant limitations when applied to GaN technology. The acceleration factors derived from silicon-based devices do not translate directly to GaN HEMTs, making it difficult to extrapolate long-term reliability from accelerated tests. This creates uncertainty in lifetime predictions, a critical factor for automotive applications requiring 15+ years of operational life.

EMI/EMC testing infrastructure lacks the capability to fully characterize the unique electromagnetic signature of GaN-based power systems, which operate at higher frequencies and with faster switching transitions than silicon equivalents. This limitation creates uncertainty regarding compliance with automotive electromagnetic compatibility standards.

Finally, current testing approaches struggle to account for system-level interactions between GaN HEMTs and other automotive components. The lack of comprehensive testing that considers the entire power conversion system leads to unexpected failures when devices are deployed in real-world automotive applications.

The automotive qualification standard AEC-Q101, originally developed for silicon devices, lacks specific provisions for wide bandgap semiconductors like GaN. This misalignment results in either overly stringent or insufficiently comprehensive testing regimes that fail to accurately predict GaN HEMT performance under automotive conditions. The absence of standardized GaN-specific testing protocols creates inconsistency across the industry and complicates supplier qualification processes.

Dynamic switching behavior testing presents particular challenges, as GaN HEMTs operate at significantly higher frequencies and switching speeds than silicon counterparts. Current testing equipment often lacks sufficient bandwidth and resolution to accurately capture nanosecond-scale switching events and associated parasitic effects that are critical to understanding device reliability in automotive applications.

Temperature-dependent performance evaluation remains problematic, with existing test chambers struggling to simulate the rapid thermal cycling and extreme temperature gradients experienced in automotive environments. The unique thermal properties of GaN materials, including different coefficients of thermal expansion compared to packaging materials, create reliability concerns that current testing methodologies cannot adequately assess.

Gate reliability testing faces limitations in accurately replicating the complex stress conditions that automotive-grade GaN HEMTs encounter during operation. The threshold voltage instability mechanisms in GaN differ substantially from silicon devices, yet testing protocols have not evolved sufficiently to characterize these differences, leading to potential reliability blind spots.

Accelerated lifetime testing methodologies show significant limitations when applied to GaN technology. The acceleration factors derived from silicon-based devices do not translate directly to GaN HEMTs, making it difficult to extrapolate long-term reliability from accelerated tests. This creates uncertainty in lifetime predictions, a critical factor for automotive applications requiring 15+ years of operational life.

EMI/EMC testing infrastructure lacks the capability to fully characterize the unique electromagnetic signature of GaN-based power systems, which operate at higher frequencies and with faster switching transitions than silicon equivalents. This limitation creates uncertainty regarding compliance with automotive electromagnetic compatibility standards.

Finally, current testing approaches struggle to account for system-level interactions between GaN HEMTs and other automotive components. The lack of comprehensive testing that considers the entire power conversion system leads to unexpected failures when devices are deployed in real-world automotive applications.

Established Testing Methodologies for GaN HEMTs

01 High-frequency and high-power testing challenges

Testing GaN HEMTs at high frequencies and high power levels presents significant challenges due to their unique operational characteristics. These devices operate at frequencies up to several GHz and power levels that can exceed hundreds of watts, requiring specialized test equipment and methodologies. The testing must account for thermal management issues, as high power operation generates substantial heat that can affect measurement accuracy and device reliability. Advanced test fixtures and calibration techniques are necessary to ensure accurate characterization of these high-performance devices.- High-frequency and high-power testing challenges: Testing GaN HEMTs at high frequencies and high power levels presents significant challenges due to their unique operational characteristics. These devices operate at frequencies up to several GHz and power levels that can exceed hundreds of watts, requiring specialized test equipment and methodologies. The testing must account for thermal management issues, as high power operation generates substantial heat that can affect device performance and reliability measurements. Advanced test fixtures with proper impedance matching and heat dissipation capabilities are essential for accurate characterization.

- Reliability and lifetime testing methodologies: Developing effective reliability and lifetime testing methodologies for GaN HEMTs is challenging due to their complex failure mechanisms. These tests must evaluate device degradation under various stress conditions including high temperature, high voltage, and high current operation. Accelerated life testing protocols need to be carefully designed to accurately predict long-term reliability while maintaining correlation with real-world applications. Challenges include identifying appropriate acceleration factors, monitoring subtle parametric shifts that indicate degradation, and establishing standardized testing procedures that can be widely adopted across the industry.

- Dynamic performance and switching characterization: Characterizing the dynamic performance and switching behavior of GaN HEMTs presents unique testing challenges. These devices exhibit extremely fast switching speeds with transition times in the nanosecond range, requiring high-bandwidth measurement systems. Testing must account for dynamic Ron effects, current collapse phenomena, and gate lag that can significantly impact device performance in switching applications. Specialized test setups with minimal parasitic inductance and capacitance are needed to accurately capture transient behaviors without measurement artifacts. Additionally, testing under various temperature and bias conditions is necessary to fully understand switching performance limitations.

- Thermal management and temperature-dependent testing: Testing GaN HEMTs under controlled thermal conditions presents significant challenges due to their temperature-sensitive performance characteristics. Accurate temperature control and measurement during testing are essential as device parameters can vary significantly with temperature. Testing setups must incorporate precise thermal management solutions to maintain consistent junction temperatures during high-power operation. Infrared thermal imaging and specialized thermal test fixtures are often required to monitor temperature distribution across the device. Additionally, testing must evaluate the effectiveness of various cooling strategies and thermal interfaces that will be used in final applications.

- Wafer-level and production testing efficiency: Implementing efficient wafer-level and production testing for GaN HEMTs presents challenges in balancing thoroughness with throughput. These devices require comprehensive RF, DC, and thermal testing to ensure quality, but performing all tests on every device would be prohibitively time-consuming and expensive. Developing optimized test sequences that can quickly identify defective devices while ensuring reliability requires sophisticated statistical approaches and correlation studies. Automated test equipment must be capable of handling the unique requirements of GaN technology, including high voltages, high frequencies, and thermal considerations, while maintaining measurement accuracy and test throughput.

02 Reliability and lifetime testing methodologies

Developing effective reliability and lifetime testing methodologies for GaN HEMTs is challenging due to their complex failure mechanisms. These tests must evaluate device degradation under various stress conditions including high temperature, high voltage, and high current operation. Accelerated life testing protocols need to be carefully designed to accurately predict long-term reliability while maintaining correlation with real-world operating conditions. Testing must address specific GaN HEMT failure modes such as current collapse, gate leakage, and threshold voltage shifts that may not be present in other semiconductor technologies.Expand Specific Solutions03 Thermal management and characterization challenges

Thermal management presents a significant challenge in GaN HEMT testing due to the high power density and self-heating effects of these devices. Accurate temperature measurement during operation is difficult but critical for proper device characterization. Testing must account for thermal resistance, thermal transients, and hot spot formation that can affect device performance and reliability. Advanced thermal imaging techniques and specialized test fixtures are required to properly evaluate the thermal behavior of GaN HEMTs under various operating conditions.Expand Specific Solutions04 Dynamic performance and switching characterization

Testing the dynamic performance and switching characteristics of GaN HEMTs presents unique challenges due to their extremely fast switching speeds and complex transient behaviors. Specialized high-speed test equipment is required to accurately capture switching events that occur in nanoseconds or less. Testing must address phenomena such as dynamic on-resistance, current collapse, and gate bounce that are particularly relevant to GaN technology. Measurement setups must minimize parasitic inductances and capacitances that can mask the true device performance.Expand Specific Solutions05 Standardization and qualification testing issues

The lack of standardized testing protocols specifically designed for GaN HEMTs creates challenges in device qualification and comparison. Unlike silicon-based technologies with well-established testing standards, GaN HEMT testing often requires custom approaches. Testing must address unique aspects of GaN technology such as trapping effects, buffer leakage, and substrate-related issues. Developing industry-wide standards for GaN HEMT qualification is an ongoing challenge that impacts manufacturing quality control and device reliability assessment.Expand Specific Solutions

Leading Manufacturers and Test Equipment Providers

The automotive GaN HEMT testing landscape is evolving rapidly as the industry transitions from early adoption to commercial scaling. The market is projected to grow significantly with the electric vehicle revolution, though testing challenges remain a critical bottleneck. Leading semiconductor manufacturers like Wolfspeed, Innoscience, and Nexperia are advancing GaN HEMT technology with varying levels of maturity. Taiwan Semiconductor and UMC provide foundry support, while research institutions like Tsinghua University and Chinese Academy of Sciences contribute to fundamental testing methodologies. The competitive landscape features established power semiconductor players (ROHM, STMicroelectronics) alongside GaN specialists, with testing capabilities becoming a key differentiator as automotive qualification standards evolve for this relatively young technology.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has developed comprehensive testing methodologies specifically for automotive-grade GaN HEMTs that address reliability challenges in harsh automotive environments. Their approach includes accelerated lifetime testing protocols that simulate extreme temperature cycling (-40°C to 175°C), humidity conditions, and mechanical stress scenarios. Wolfspeed implements specialized gate stress testing to evaluate threshold voltage stability under continuous operation, which is critical for automotive applications requiring thousands of hours of reliable performance. Their testing framework incorporates dynamic Ron characterization to assess current collapse phenomena under switching conditions, using custom-designed test fixtures that can apply precise voltage waveforms while measuring on-resistance changes at nanosecond resolution. Additionally, Wolfspeed has pioneered advanced thermal resistance measurement techniques that more accurately reflect real-world automotive thermal management challenges, allowing for better prediction of device behavior in actual vehicle power systems.

Strengths: Industry-leading reliability testing infrastructure specifically optimized for automotive qualification standards; proprietary test methodologies for dynamic characterization that more accurately predict field performance. Weaknesses: Testing procedures may require longer qualification cycles compared to silicon devices, potentially impacting time-to-market for new automotive products.

Innoscience Suzhou Semiconductor Co. Ltd.

Technical Solution: Innoscience has developed a comprehensive testing methodology for automotive-grade GaN HEMTs that addresses the unique challenges of these devices in vehicle applications. Their approach includes specialized high-temperature reverse bias (HTRB) testing protocols that extend beyond standard qualification requirements, with testing durations exceeding 2,000 hours at elevated temperatures to better characterize long-term reliability. Innoscience implements advanced dynamic characterization techniques that evaluate switching performance under various inductive load conditions, with particular focus on measuring dynamic Ron degradation at different temperatures and humidity levels. Their testing framework incorporates specialized gate reliability assessment using both static and dynamic stress conditions to evaluate threshold voltage stability over extended operating periods. Innoscience has also developed proprietary accelerated life testing methods that combine electrical, thermal, and mechanical stresses to better simulate real-world automotive conditions. Additionally, their approach includes comprehensive parametric testing across production lots to ensure consistent performance and reliability in high-volume automotive applications.

Strengths: Extensive reliability database specific to automotive GaN applications; advanced correlation between accelerated testing and actual field reliability. Weaknesses: Testing methodology may be more focused on 650V applications, with less extensive data for lower voltage automotive applications like 100V devices used in 48V systems.

Critical Test Parameters and Reliability Assessment Techniques

High-voltage GAN high electron mobility transistors

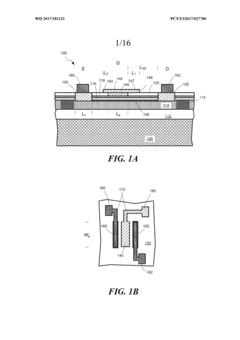

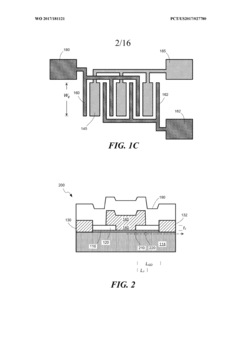

PatentWO2017181121A2

Innovation

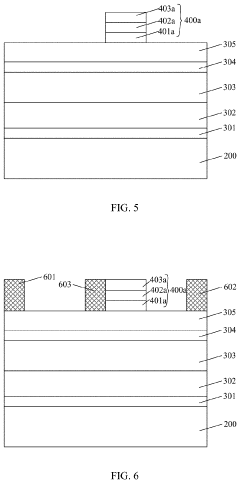

- The development of high-voltage HEMTs with a gallium-nitride material structure, including a buffer layer, conduction layer, barrier layer, gate, source, and drain, with a gate-connected field plate extending beyond the gate edges, and a thin gallium-oxide layer formed through oxygen plasma treatment, to enhance reverse-bias voltage withstand and reduce leakage currents.

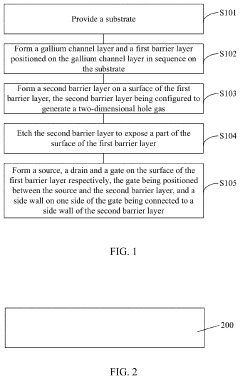

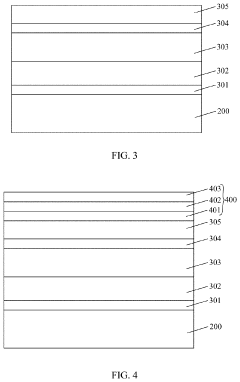

Gallium nitride high electron mobility transistor having high breakdown voltage and formation method therefor

PatentActiveUS20190393300A1

Innovation

- A gallium nitride high electron mobility transistor with a second barrier layer configured to generate two-dimensional hole gas, positioned between the gate and drain, and connected to the gate's side wall, which improves the breakdown voltage by smoothing electric field distribution and reducing current leakage.

Automotive Safety Standards and Compliance Requirements

The automotive industry's adoption of GaN HEMTs necessitates strict adherence to established safety standards and compliance requirements. The Automotive Safety Integrity Level (ASIL) classification system, defined by ISO 26262, categorizes components based on their safety criticality from ASIL A (least stringent) to ASIL D (most stringent). GaN HEMTs used in critical power systems typically require ASIL C or D certification, demanding comprehensive testing protocols and failure analysis.

The AEC-Q101 qualification standard specifically addresses discrete semiconductors in automotive applications, requiring GaN HEMTs to undergo rigorous environmental stress testing including temperature cycling (-55°C to +150°C), high temperature reverse bias (HTRB), and high temperature gate bias (HTGB) tests. These tests must demonstrate device reliability under extreme conditions for minimum 1,000-hour durations.

Beyond AEC-Q101, automotive GaN HEMTs must comply with electromagnetic compatibility (EMC) standards outlined in CISPR 25 and ISO 11452, addressing both emissions and immunity. The high switching frequencies of GaN devices (often exceeding 1 MHz) create unique EMI challenges requiring specialized testing methodologies and filtering solutions.

Functional safety requirements outlined in ISO 26262 mandate systematic failure analysis through techniques such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA). For GaN HEMTs, this includes characterizing unique failure modes like dynamic RON degradation and threshold voltage shifts that may not be adequately addressed in traditional silicon-based testing frameworks.

The automotive industry's zero-defect quality target imposes parts-per-billion (ppb) defect rate requirements, significantly more stringent than consumer electronics standards. This necessitates statistical process control and accelerated life testing methodologies specifically calibrated for GaN technology's unique degradation mechanisms.

Traceability requirements present another compliance challenge, with automotive standards requiring complete documentation of all testing procedures, results, and any deviations. For GaN HEMTs, this includes capturing baseline characteristics and monitoring parametric shifts throughout qualification testing, with data retention periods typically extending to 15 years or more.

As autonomous driving technologies advance, emerging standards like ISO/PAS 21448 (SOTIF - Safety Of The Intended Functionality) are beginning to address performance limitations beyond traditional hardware failures, potentially imposing additional verification requirements on power electronics including GaN HEMTs used in these systems.

The AEC-Q101 qualification standard specifically addresses discrete semiconductors in automotive applications, requiring GaN HEMTs to undergo rigorous environmental stress testing including temperature cycling (-55°C to +150°C), high temperature reverse bias (HTRB), and high temperature gate bias (HTGB) tests. These tests must demonstrate device reliability under extreme conditions for minimum 1,000-hour durations.

Beyond AEC-Q101, automotive GaN HEMTs must comply with electromagnetic compatibility (EMC) standards outlined in CISPR 25 and ISO 11452, addressing both emissions and immunity. The high switching frequencies of GaN devices (often exceeding 1 MHz) create unique EMI challenges requiring specialized testing methodologies and filtering solutions.

Functional safety requirements outlined in ISO 26262 mandate systematic failure analysis through techniques such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA). For GaN HEMTs, this includes characterizing unique failure modes like dynamic RON degradation and threshold voltage shifts that may not be adequately addressed in traditional silicon-based testing frameworks.

The automotive industry's zero-defect quality target imposes parts-per-billion (ppb) defect rate requirements, significantly more stringent than consumer electronics standards. This necessitates statistical process control and accelerated life testing methodologies specifically calibrated for GaN technology's unique degradation mechanisms.

Traceability requirements present another compliance challenge, with automotive standards requiring complete documentation of all testing procedures, results, and any deviations. For GaN HEMTs, this includes capturing baseline characteristics and monitoring parametric shifts throughout qualification testing, with data retention periods typically extending to 15 years or more.

As autonomous driving technologies advance, emerging standards like ISO/PAS 21448 (SOTIF - Safety Of The Intended Functionality) are beginning to address performance limitations beyond traditional hardware failures, potentially imposing additional verification requirements on power electronics including GaN HEMTs used in these systems.

Cost-Performance Analysis of GaN HEMT Testing Solutions

The economic aspects of testing solutions for automotive-grade GaN HEMTs present significant considerations for manufacturers and suppliers in the power electronics industry. When evaluating testing methodologies, organizations must balance initial capital expenditure against long-term operational costs. High-precision testing equipment for GaN HEMTs typically requires investments ranging from $500,000 to $2 million, depending on testing capabilities and throughput requirements.

Automated testing solutions, while demanding higher upfront investment, demonstrate superior cost-efficiency for high-volume production scenarios. Data indicates that automated systems can reduce per-unit testing costs by approximately 40-60% compared to manual testing approaches when production volumes exceed 100,000 units annually. This cost advantage becomes particularly relevant for automotive applications where production scales are substantial.

The performance metrics of testing solutions directly impact overall manufacturing economics. Testing systems with higher throughput capabilities (>200 units/hour) command premium pricing but deliver lower cost-per-test figures in volume production environments. Conversely, more flexible testing platforms that accommodate multiple device variants offer strategic advantages for manufacturers with diverse product portfolios, despite potentially higher per-unit testing costs.

Reliability testing represents a significant cost component, particularly for automotive-grade GaN HEMTs that must undergo extensive qualification procedures. Accelerated lifetime testing, which may require 1,000+ hours of continuous operation under stress conditions, constitutes approximately 25-30% of total testing costs. However, these investments correlate directly with reduced field failure rates and warranty claims, presenting a favorable long-term economic proposition.

Test data management systems introduce another cost-performance consideration. Advanced analytics platforms that enable comprehensive data collection and analysis typically add 15-20% to overall testing infrastructure costs but deliver substantial value through improved yield rates and process optimization. Manufacturers report yield improvements of 5-8% following implementation of advanced test data management systems, representing significant cost savings in high-volume production.

The geographical distribution of testing facilities also influences the cost structure. Localized testing capabilities near manufacturing centers reduce logistics expenses and cycle times but may require redundant capital investments. Centralized testing hubs offer economies of scale but introduce additional handling and transportation considerations that impact both cost and time-to-market parameters.

Automated testing solutions, while demanding higher upfront investment, demonstrate superior cost-efficiency for high-volume production scenarios. Data indicates that automated systems can reduce per-unit testing costs by approximately 40-60% compared to manual testing approaches when production volumes exceed 100,000 units annually. This cost advantage becomes particularly relevant for automotive applications where production scales are substantial.

The performance metrics of testing solutions directly impact overall manufacturing economics. Testing systems with higher throughput capabilities (>200 units/hour) command premium pricing but deliver lower cost-per-test figures in volume production environments. Conversely, more flexible testing platforms that accommodate multiple device variants offer strategic advantages for manufacturers with diverse product portfolios, despite potentially higher per-unit testing costs.

Reliability testing represents a significant cost component, particularly for automotive-grade GaN HEMTs that must undergo extensive qualification procedures. Accelerated lifetime testing, which may require 1,000+ hours of continuous operation under stress conditions, constitutes approximately 25-30% of total testing costs. However, these investments correlate directly with reduced field failure rates and warranty claims, presenting a favorable long-term economic proposition.

Test data management systems introduce another cost-performance consideration. Advanced analytics platforms that enable comprehensive data collection and analysis typically add 15-20% to overall testing infrastructure costs but deliver substantial value through improved yield rates and process optimization. Manufacturers report yield improvements of 5-8% following implementation of advanced test data management systems, representing significant cost savings in high-volume production.

The geographical distribution of testing facilities also influences the cost structure. Localized testing capabilities near manufacturing centers reduce logistics expenses and cycle times but may require redundant capital investments. Centralized testing hubs offer economies of scale but introduce additional handling and transportation considerations that impact both cost and time-to-market parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!