Testing Injector Spray Patterns in GDI Engines

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Injector Technology Background and Objectives

Gasoline Direct Injection (GDI) technology represents a significant advancement in internal combustion engine design, emerging in the early 1990s as a commercial solution but with roots dating back to the 1930s. This technology directly injects fuel into the combustion chamber rather than the intake port, offering superior fuel atomization, precise control over injection timing, and enhanced combustion efficiency. The evolution of GDI systems has been driven by increasingly stringent emissions regulations and the automotive industry's pursuit of improved fuel economy without sacrificing performance.

The primary objective of GDI injector spray pattern testing is to optimize fuel distribution within the combustion chamber, which directly impacts engine performance, emissions, and efficiency. As regulatory frameworks like Euro 7, China 7, and US EPA Tier 3 standards continue to tighten, the precision of fuel delivery systems becomes increasingly critical. Testing methodologies must evolve to ensure injectors meet these demanding requirements across various operating conditions.

Current technological trends in GDI systems include the development of multi-hole injectors with increasingly complex spray patterns, higher injection pressures (now commonly exceeding 350 bar), and more sophisticated electronic control systems. These advancements aim to address challenges such as particulate matter formation, combustion stability at lean operation, and cold-start emissions performance.

The industry is witnessing a convergence of computational fluid dynamics (CFD) simulation capabilities with advanced optical measurement techniques, creating more comprehensive testing protocols that can characterize spray dynamics with unprecedented detail. This integration of virtual and physical testing methodologies represents a significant trend in development processes, reducing time-to-market while improving design outcomes.

From a historical perspective, GDI technology has progressed through several distinct phases: early mechanical systems, first-generation electronic systems with limited pressure capabilities, second-generation systems with improved atomization, and current advanced systems featuring multiple injection events per cycle and adaptive spray patterns. Each evolutionary step has required more sophisticated testing capabilities to validate performance.

The technical goals for GDI injector spray pattern testing include quantifying spatial and temporal fuel distribution characteristics, evaluating droplet size distribution and velocity profiles, assessing spray penetration and cone angle consistency, and measuring cycle-to-cycle variations. Additionally, testing must evaluate injector performance under varying ambient conditions, including different temperatures, pressures, and backpressures that simulate real-world operating environments.

As electrification trends accelerate, GDI technology must adapt to hybrid powertrains where combustion events may be less frequent but equally critical for overall vehicle efficiency. This creates new testing challenges related to deposit formation during extended idle periods and cold-start optimization in hybrid operational modes.

The primary objective of GDI injector spray pattern testing is to optimize fuel distribution within the combustion chamber, which directly impacts engine performance, emissions, and efficiency. As regulatory frameworks like Euro 7, China 7, and US EPA Tier 3 standards continue to tighten, the precision of fuel delivery systems becomes increasingly critical. Testing methodologies must evolve to ensure injectors meet these demanding requirements across various operating conditions.

Current technological trends in GDI systems include the development of multi-hole injectors with increasingly complex spray patterns, higher injection pressures (now commonly exceeding 350 bar), and more sophisticated electronic control systems. These advancements aim to address challenges such as particulate matter formation, combustion stability at lean operation, and cold-start emissions performance.

The industry is witnessing a convergence of computational fluid dynamics (CFD) simulation capabilities with advanced optical measurement techniques, creating more comprehensive testing protocols that can characterize spray dynamics with unprecedented detail. This integration of virtual and physical testing methodologies represents a significant trend in development processes, reducing time-to-market while improving design outcomes.

From a historical perspective, GDI technology has progressed through several distinct phases: early mechanical systems, first-generation electronic systems with limited pressure capabilities, second-generation systems with improved atomization, and current advanced systems featuring multiple injection events per cycle and adaptive spray patterns. Each evolutionary step has required more sophisticated testing capabilities to validate performance.

The technical goals for GDI injector spray pattern testing include quantifying spatial and temporal fuel distribution characteristics, evaluating droplet size distribution and velocity profiles, assessing spray penetration and cone angle consistency, and measuring cycle-to-cycle variations. Additionally, testing must evaluate injector performance under varying ambient conditions, including different temperatures, pressures, and backpressures that simulate real-world operating environments.

As electrification trends accelerate, GDI technology must adapt to hybrid powertrains where combustion events may be less frequent but equally critical for overall vehicle efficiency. This creates new testing challenges related to deposit formation during extended idle periods and cold-start optimization in hybrid operational modes.

Market Demand Analysis for Advanced GDI Systems

The global market for Gasoline Direct Injection (GDI) systems continues to experience robust growth, driven primarily by increasingly stringent emission regulations and the automotive industry's pursuit of improved fuel efficiency. Current market analysis indicates that the GDI systems market is expected to grow at a compound annual growth rate of 8.7% between 2023 and 2028, reaching a market value of approximately 12.3 billion USD by the end of the forecast period.

Automotive manufacturers are facing mounting pressure to reduce carbon emissions while maintaining or improving vehicle performance. This has created substantial demand for advanced GDI systems that can deliver precise fuel atomization and optimal spray patterns. The European market leads this demand due to the EU's aggressive CO2 emission targets, followed closely by North America and rapidly developing Asian markets, particularly China and India.

Consumer preferences are simultaneously shifting toward vehicles that offer better fuel economy without sacrificing performance. This trend is particularly evident in emerging markets where fuel costs represent a significant portion of vehicle operating expenses. Advanced GDI systems that can optimize combustion efficiency through improved spray patterns directly address this consumer need, creating a strong market pull for innovation in this space.

The aftermarket segment for GDI components is also experiencing significant growth as the installed base of GDI-equipped vehicles ages. This creates additional demand for testing equipment and methodologies that can accurately evaluate injector spray patterns for maintenance and replacement purposes.

Fleet operators and commercial vehicle manufacturers represent another significant market segment, with their focus on total cost of ownership driving interest in fuel-efficient technologies. The potential fuel savings offered by optimized GDI systems with properly tested spray patterns directly impacts their operational costs, making this technology particularly attractive.

Original Equipment Manufacturers (OEMs) are increasingly investing in research and development of next-generation GDI systems, with particular emphasis on spray pattern optimization. This has created a parallel demand for sophisticated testing equipment and methodologies that can accurately characterize injector performance under various operating conditions.

The market for testing equipment specifically designed for GDI injector spray pattern analysis is projected to grow at 9.3% annually, outpacing the overall GDI market. This reflects the critical importance of spray pattern optimization in achieving the performance and efficiency goals that drive GDI adoption in the first place.

Automotive manufacturers are facing mounting pressure to reduce carbon emissions while maintaining or improving vehicle performance. This has created substantial demand for advanced GDI systems that can deliver precise fuel atomization and optimal spray patterns. The European market leads this demand due to the EU's aggressive CO2 emission targets, followed closely by North America and rapidly developing Asian markets, particularly China and India.

Consumer preferences are simultaneously shifting toward vehicles that offer better fuel economy without sacrificing performance. This trend is particularly evident in emerging markets where fuel costs represent a significant portion of vehicle operating expenses. Advanced GDI systems that can optimize combustion efficiency through improved spray patterns directly address this consumer need, creating a strong market pull for innovation in this space.

The aftermarket segment for GDI components is also experiencing significant growth as the installed base of GDI-equipped vehicles ages. This creates additional demand for testing equipment and methodologies that can accurately evaluate injector spray patterns for maintenance and replacement purposes.

Fleet operators and commercial vehicle manufacturers represent another significant market segment, with their focus on total cost of ownership driving interest in fuel-efficient technologies. The potential fuel savings offered by optimized GDI systems with properly tested spray patterns directly impacts their operational costs, making this technology particularly attractive.

Original Equipment Manufacturers (OEMs) are increasingly investing in research and development of next-generation GDI systems, with particular emphasis on spray pattern optimization. This has created a parallel demand for sophisticated testing equipment and methodologies that can accurately characterize injector performance under various operating conditions.

The market for testing equipment specifically designed for GDI injector spray pattern analysis is projected to grow at 9.3% annually, outpacing the overall GDI market. This reflects the critical importance of spray pattern optimization in achieving the performance and efficiency goals that drive GDI adoption in the first place.

Current Spray Pattern Testing Challenges

Despite significant advancements in GDI (Gasoline Direct Injection) engine technology, testing and characterizing injector spray patterns remains fraught with technical challenges. Current optical measurement systems struggle to capture the complete dynamic behavior of fuel sprays under realistic engine operating conditions. High-speed cameras and laser-based systems, while advanced, often fail to provide sufficient temporal and spatial resolution to fully characterize the microsecond-level events occurring during injection.

The extreme operating conditions of modern GDI engines present substantial measurement difficulties. With injection pressures exceeding 350 bar and in-cylinder temperatures and pressures constantly fluctuating, creating test environments that accurately replicate these conditions while maintaining optical access is exceedingly complex. Most laboratory setups represent compromises that may not fully reflect real-world engine behavior.

Quantitative analysis of spray characteristics faces significant hurdles in data processing and interpretation. Current image processing algorithms struggle with the complex, three-dimensional nature of spray patterns, particularly when attempting to quantify parameters such as droplet size distribution, penetration depth, and cone angle simultaneously across the entire spray event. The sheer volume of data generated during high-speed imaging creates computational bottlenecks in analysis pipelines.

Standardization remains an industry-wide challenge. Different manufacturers employ varied testing methodologies and evaluation criteria, making direct comparisons between injector technologies difficult. This lack of standardized testing protocols hampers collaborative research efforts and slows the pace of innovation in the field.

The transient nature of GDI sprays introduces additional complexity. Initial spray formation, primary and secondary breakup mechanisms, and late-stage atomization all occur within milliseconds, requiring sophisticated triggering and synchronization systems that are prone to timing errors. Even minor synchronization issues can lead to significant mischaracterization of spray behavior.

Fuel property variations further complicate testing procedures. Modern fuels contain various additives and can vary in composition seasonally and regionally. These variations affect spray formation and atomization characteristics, yet most testing protocols fail to account for these differences adequately. Additionally, alternative fuels and fuel blends introduce new variables that current testing methodologies are not fully equipped to evaluate.

Wall-wetting phenomena and spray-wall interactions remain particularly difficult to quantify with existing technologies. These interactions significantly impact emissions and efficiency, yet current optical methods provide limited insight into the complex fluid dynamics occurring at these interfaces.

The extreme operating conditions of modern GDI engines present substantial measurement difficulties. With injection pressures exceeding 350 bar and in-cylinder temperatures and pressures constantly fluctuating, creating test environments that accurately replicate these conditions while maintaining optical access is exceedingly complex. Most laboratory setups represent compromises that may not fully reflect real-world engine behavior.

Quantitative analysis of spray characteristics faces significant hurdles in data processing and interpretation. Current image processing algorithms struggle with the complex, three-dimensional nature of spray patterns, particularly when attempting to quantify parameters such as droplet size distribution, penetration depth, and cone angle simultaneously across the entire spray event. The sheer volume of data generated during high-speed imaging creates computational bottlenecks in analysis pipelines.

Standardization remains an industry-wide challenge. Different manufacturers employ varied testing methodologies and evaluation criteria, making direct comparisons between injector technologies difficult. This lack of standardized testing protocols hampers collaborative research efforts and slows the pace of innovation in the field.

The transient nature of GDI sprays introduces additional complexity. Initial spray formation, primary and secondary breakup mechanisms, and late-stage atomization all occur within milliseconds, requiring sophisticated triggering and synchronization systems that are prone to timing errors. Even minor synchronization issues can lead to significant mischaracterization of spray behavior.

Fuel property variations further complicate testing procedures. Modern fuels contain various additives and can vary in composition seasonally and regionally. These variations affect spray formation and atomization characteristics, yet most testing protocols fail to account for these differences adequately. Additionally, alternative fuels and fuel blends introduce new variables that current testing methodologies are not fully equipped to evaluate.

Wall-wetting phenomena and spray-wall interactions remain particularly difficult to quantify with existing technologies. These interactions significantly impact emissions and efficiency, yet current optical methods provide limited insight into the complex fluid dynamics occurring at these interfaces.

Current Spray Pattern Visualization Solutions

01 Fuel injector spray pattern optimization

Optimization of fuel injector spray patterns involves designing specific spray geometries to enhance combustion efficiency. This includes controlling droplet size distribution, spray angle, and penetration depth to ensure proper fuel-air mixing. Advanced injector designs can produce multiple spray patterns tailored to different engine operating conditions, resulting in improved fuel economy and reduced emissions.- Optimization of fuel injector spray patterns: Fuel injector spray patterns can be optimized through specific nozzle designs and configurations to improve combustion efficiency and reduce emissions. Various spray pattern geometries, such as cone-shaped, fan-shaped, or multi-stream patterns, can be tailored to match specific engine requirements. The optimization involves controlling parameters like droplet size distribution, spray angle, and penetration depth to ensure proper fuel-air mixing.

- Measurement and analysis of spray patterns: Advanced techniques and systems for measuring and analyzing spray patterns help in quality control and development of injection systems. These methods include optical imaging, laser-based measurements, and computational analysis to characterize spray properties such as cone angle, droplet size, velocity, and distribution uniformity. Real-time monitoring systems can detect deviations from desired spray patterns and provide feedback for adjustments.

- Multi-hole injector designs for controlled spray patterns: Multi-hole injector designs feature multiple orifices arranged in specific patterns to create customized spray distributions. The number, size, angle, and arrangement of these holes can be engineered to produce desired spray characteristics for different applications. These designs allow for precise control over fuel distribution, atomization quality, and spray targeting, resulting in improved combustion efficiency and reduced emissions.

- Adaptive and variable spray pattern technologies: Adaptive injection systems can modify spray patterns in response to changing operating conditions. These technologies incorporate electronically controlled actuators, variable orifice geometries, or multiple injection modes to optimize spray characteristics across different engine loads, speeds, and environmental conditions. The ability to dynamically adjust spray patterns improves performance across a wide operating range and enhances fuel economy.

- Specialized spray patterns for specific applications: Different applications require customized spray patterns to meet specific performance requirements. For example, direct injection engines may use wall-guided or air-guided spray patterns, while agricultural sprayers might employ flat fan patterns for even coverage. Medical injectors require fine, controlled spray patterns for proper medication delivery. The spray pattern design is tailored to the specific needs of each application, considering factors like target surface geometry, environmental conditions, and desired outcome.

02 Spray pattern testing and measurement techniques

Various methods and apparatus are used to test and measure injector spray patterns. These include optical measurement systems, laser-based diagnostics, and specialized test chambers that allow visualization and quantification of spray characteristics. These techniques help in evaluating spray uniformity, droplet size distribution, and spray angle consistency, which are critical parameters for injector performance assessment.Expand Specific Solutions03 Multi-pattern injector designs

Injectors capable of producing multiple spray patterns offer versatility for different operating conditions. These designs incorporate mechanisms to switch between different spray configurations based on engine load, speed, or other parameters. Some advanced injectors can dynamically adjust spray patterns during operation to optimize combustion throughout the engine's operating range.Expand Specific Solutions04 Spray pattern control mechanisms

Various mechanisms are employed to control injector spray patterns, including mechanical valves, electronic actuators, and specialized nozzle geometries. These control systems can adjust spray characteristics such as cone angle, droplet size, and spray distribution in response to operating conditions. Advanced control algorithms optimize spray patterns based on real-time feedback from engine sensors.Expand Specific Solutions05 Specialized spray patterns for specific applications

Different applications require customized spray patterns to meet specific performance requirements. For example, direct injection engines may use stratified charge spray patterns, while agricultural sprayers might employ patterns optimized for crop coverage. Medical injectors require precise patterns for medication delivery. These specialized patterns are achieved through careful nozzle design and flow control strategies.Expand Specific Solutions

Key Industry Players in GDI Technology

The GDI engine injector spray pattern testing market is in a growth phase, with increasing adoption driven by stringent emission regulations and fuel efficiency demands. The market is expected to reach significant value as automotive manufacturers prioritize cleaner combustion technologies. Leading players include established OEMs like Hyundai Motor, Ford Global Technologies, and Mercedes-Benz Group, who are actively developing proprietary GDI technologies. Specialized component suppliers such as Hyundai KEFICO, Delphi, and AVL List provide testing equipment and technical expertise. The technology is approaching maturity in developed markets but continues to evolve with innovations in high-precision testing methods, real-time analysis capabilities, and integration with advanced engine management systems to optimize fuel delivery and combustion efficiency.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed advanced optical visualization techniques for GDI injector spray pattern analysis, combining high-speed imaging with laser-induced fluorescence (LIF) to capture both macroscopic spray development and microscopic droplet characteristics. Their system employs pressure chambers that simulate various engine operating conditions, allowing for spray pattern evaluation across different pressures (up to 200 bar) and temperatures. Hyundai's approach integrates computational fluid dynamics (CFD) modeling with experimental validation, creating a comprehensive testing methodology that correlates spray characteristics with engine performance metrics. Their patented multi-hole injector designs undergo rigorous testing to optimize spray angle, penetration depth, and atomization quality, with particular focus on reducing particulate emissions while maintaining combustion efficiency.

Strengths: Comprehensive integration of optical diagnostics with computational modeling provides superior validation capabilities. Their testing protocols effectively bridge laboratory findings with real-world engine performance. Weaknesses: System complexity requires significant technical expertise and specialized equipment, potentially limiting deployment across all development facilities.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a multi-faceted approach to GDI injector spray pattern testing through their patented Spray Visualization and Analysis System (SVAS). This technology combines high-resolution imaging at up to 100,000 frames per second with advanced image processing algorithms to quantify spray characteristics including cone angle, penetration length, and droplet size distribution. Ford's methodology incorporates both constant volume chambers for fundamental spray characterization and optical access engines for in-situ visualization under firing conditions. Their system features automated test sequences that systematically vary injection timing, pressure (ranging from 50-300 bar), and ambient conditions to create comprehensive spray pattern maps. Ford has particularly focused on correlating spray patterns with particulate formation mechanisms, developing specialized testing protocols that identify conditions leading to pool fires and wall wetting phenomena.

Strengths: Exceptional correlation between spray visualization data and engine-out emissions through comprehensive testing protocols. Robust automation enables high-throughput testing across numerous operating conditions. Weaknesses: Heavy reliance on expensive optical equipment limits widespread implementation across all development teams and manufacturing facilities.

Critical Patents in Injector Testing Technology

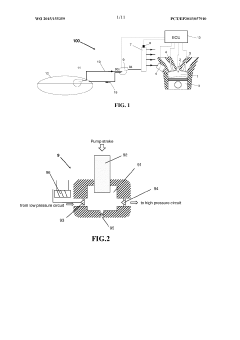

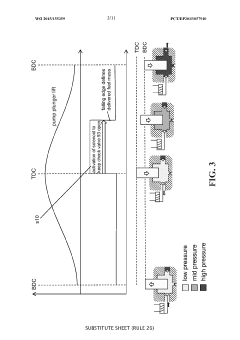

LPG direct injection engine

PatentWO2015155359A1

Innovation

- An LPG direct injection engine with a high-pressure pump and electronic control unit for precise liquefied petroleum gas injection between 360° and 60° BTDC, optimized valve overlap, and cylinder deactivation system to reduce emissions and improve efficiency.

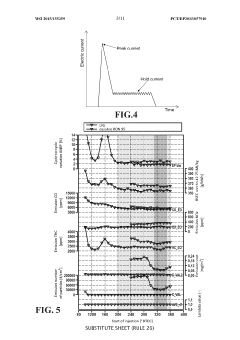

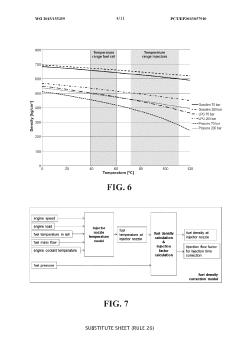

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Emissions Regulations Impact on GDI Development

The evolution of emissions regulations has been a primary driver for Gasoline Direct Injection (GDI) engine development over the past two decades. Since the introduction of Euro 3 standards in 2000 and subsequent tightening through Euro 6d and beyond, automotive manufacturers have faced increasingly stringent requirements for particulate matter (PM) and NOx emissions. These regulations have directly influenced the development of injector spray pattern testing methodologies, as optimal fuel atomization and distribution are critical for emissions compliance.

The California Air Resources Board (CARB) and the Environmental Protection Agency (EPA) in the United States have similarly implemented progressively stricter standards, with the EPA Tier 3 regulations requiring a 70% reduction in particulate emissions compared to previous standards. This regulatory pressure has accelerated research into advanced spray visualization techniques and quantitative measurement methods for GDI injectors.

China's implementation of China 6 standards, which are comparable to Euro 6 in stringency, has expanded the global market demand for precise injector testing technologies. These regulations specifically target particulate number (PN) emissions, which are directly affected by fuel atomization quality and spray pattern uniformity in GDI systems.

Real Driving Emissions (RDE) testing, introduced as part of Euro 6d, has further complicated compliance by requiring engines to perform efficiently across a wider range of operating conditions than traditional laboratory cycles. This has necessitated the development of more sophisticated spray pattern testing that can evaluate injector performance under variable pressure, temperature, and engine load conditions.

The introduction of Gasoline Particulate Filters (GPFs) as an emissions control technology has somewhat mitigated the immediate pressure on injector design but has simultaneously increased focus on optimizing combustion to reduce filter loading and regeneration frequency. Testing methodologies now increasingly incorporate evaluation of spray patterns that minimize wall wetting and optimize air-fuel mixing to reduce particulate formation at the source.

Future regulatory frameworks, including Euro 7 and EPA post-2026 standards, are expected to further reduce allowable emission limits and introduce additional regulated pollutants. This regulatory trajectory is driving investment in advanced optical diagnostics, high-speed imaging, and computational fluid dynamics (CFD) validation techniques for injector spray pattern characterization.

The correlation between emissions compliance and economic viability has elevated injector spray pattern testing from a technical development activity to a strategic business imperative, with manufacturers investing significantly in both in-house testing capabilities and partnerships with specialized testing facilities.

The California Air Resources Board (CARB) and the Environmental Protection Agency (EPA) in the United States have similarly implemented progressively stricter standards, with the EPA Tier 3 regulations requiring a 70% reduction in particulate emissions compared to previous standards. This regulatory pressure has accelerated research into advanced spray visualization techniques and quantitative measurement methods for GDI injectors.

China's implementation of China 6 standards, which are comparable to Euro 6 in stringency, has expanded the global market demand for precise injector testing technologies. These regulations specifically target particulate number (PN) emissions, which are directly affected by fuel atomization quality and spray pattern uniformity in GDI systems.

Real Driving Emissions (RDE) testing, introduced as part of Euro 6d, has further complicated compliance by requiring engines to perform efficiently across a wider range of operating conditions than traditional laboratory cycles. This has necessitated the development of more sophisticated spray pattern testing that can evaluate injector performance under variable pressure, temperature, and engine load conditions.

The introduction of Gasoline Particulate Filters (GPFs) as an emissions control technology has somewhat mitigated the immediate pressure on injector design but has simultaneously increased focus on optimizing combustion to reduce filter loading and regeneration frequency. Testing methodologies now increasingly incorporate evaluation of spray patterns that minimize wall wetting and optimize air-fuel mixing to reduce particulate formation at the source.

Future regulatory frameworks, including Euro 7 and EPA post-2026 standards, are expected to further reduce allowable emission limits and introduce additional regulated pollutants. This regulatory trajectory is driving investment in advanced optical diagnostics, high-speed imaging, and computational fluid dynamics (CFD) validation techniques for injector spray pattern characterization.

The correlation between emissions compliance and economic viability has elevated injector spray pattern testing from a technical development activity to a strategic business imperative, with manufacturers investing significantly in both in-house testing capabilities and partnerships with specialized testing facilities.

Cost-Benefit Analysis of Testing Technologies

When evaluating testing technologies for GDI injector spray patterns, a comprehensive cost-benefit analysis reveals significant financial implications across different methodologies. Traditional optical testing methods such as high-speed imaging and laser-based techniques require substantial initial investment, with specialized cameras costing between $20,000-$50,000 and laser systems potentially exceeding $100,000. However, these technologies offer exceptional precision in visualizing spray patterns, potentially reducing engine development cycles by 15-20%, which translates to millions in accelerated time-to-market value.

Emerging automated spray pattern recognition systems present a compelling middle-ground option, with implementation costs ranging from $30,000-$75,000 depending on sophistication levels. These systems demonstrate ROI within 12-18 months through reduced labor costs and increased testing throughput, processing up to 200% more injectors per day compared to manual inspection methods.

The operational expenses also vary significantly across technologies. While traditional mechanical testing methods have lower acquisition costs ($5,000-$15,000), they incur higher long-term expenses through increased labor requirements and lower accuracy rates, resulting in approximately 7-10% higher warranty claims related to fuel system issues. This represents a hidden cost that can exceed $500,000 annually for medium-volume manufacturers.

Maintenance considerations further impact the cost-benefit equation. Advanced optical systems typically require annual calibration and maintenance representing 8-12% of initial investment, while mechanical systems need more frequent maintenance but at lower individual service costs. Cloud-based analysis platforms offer subscription models ($2,000-$5,000 monthly) that eliminate major capital expenditures but introduce ongoing operational costs.

The economic impact of testing accuracy cannot be overstated. Enhanced testing precision correlates directly with reduced warranty claims and improved fuel efficiency. Studies indicate that advanced testing technologies detecting subtle spray pattern anomalies can improve fleet fuel economy by 1.2-2.5%, representing substantial lifetime fuel savings across production volumes and significant emissions reductions that may help manufacturers meet increasingly stringent regulatory requirements.

When factoring in scalability, advanced automated systems demonstrate superior economies of scale, with per-unit testing costs decreasing by approximately 40% when production volumes triple, compared to just 15% for manual methods. This makes sophisticated testing technologies particularly attractive for high-volume manufacturing operations despite their higher initial investment requirements.

Emerging automated spray pattern recognition systems present a compelling middle-ground option, with implementation costs ranging from $30,000-$75,000 depending on sophistication levels. These systems demonstrate ROI within 12-18 months through reduced labor costs and increased testing throughput, processing up to 200% more injectors per day compared to manual inspection methods.

The operational expenses also vary significantly across technologies. While traditional mechanical testing methods have lower acquisition costs ($5,000-$15,000), they incur higher long-term expenses through increased labor requirements and lower accuracy rates, resulting in approximately 7-10% higher warranty claims related to fuel system issues. This represents a hidden cost that can exceed $500,000 annually for medium-volume manufacturers.

Maintenance considerations further impact the cost-benefit equation. Advanced optical systems typically require annual calibration and maintenance representing 8-12% of initial investment, while mechanical systems need more frequent maintenance but at lower individual service costs. Cloud-based analysis platforms offer subscription models ($2,000-$5,000 monthly) that eliminate major capital expenditures but introduce ongoing operational costs.

The economic impact of testing accuracy cannot be overstated. Enhanced testing precision correlates directly with reduced warranty claims and improved fuel efficiency. Studies indicate that advanced testing technologies detecting subtle spray pattern anomalies can improve fleet fuel economy by 1.2-2.5%, representing substantial lifetime fuel savings across production volumes and significant emissions reductions that may help manufacturers meet increasingly stringent regulatory requirements.

When factoring in scalability, advanced automated systems demonstrate superior economies of scale, with per-unit testing costs decreasing by approximately 40% when production volumes triple, compared to just 15% for manual methods. This makes sophisticated testing technologies particularly attractive for high-volume manufacturing operations despite their higher initial investment requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!