The Application of Liquid Nitrogen in Sensor Technologies

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Nitrogen Sensor Technology Background and Objectives

Liquid nitrogen has emerged as a transformative element in sensor technology development, with its unique cryogenic properties enabling unprecedented advancements across multiple industries. The evolution of liquid nitrogen applications in sensing technologies can be traced back to the mid-20th century, when cryogenic cooling first demonstrated significant improvements in sensor performance. Over subsequent decades, this technology has progressed from specialized laboratory applications to widespread industrial and commercial implementation.

The fundamental advantage of liquid nitrogen in sensor technology stems from its extremely low temperature (-196°C), which dramatically reduces thermal noise and increases signal-to-noise ratios in various sensing devices. This characteristic has proven particularly valuable in high-precision measurement applications where ambient thermal interference would otherwise compromise data integrity.

Current technological trends indicate an accelerating integration of liquid nitrogen cooling systems with advanced sensor technologies, particularly in quantum sensing, superconducting devices, and ultra-sensitive detection systems. The miniaturization of cryogenic cooling systems represents a significant evolutionary step, enabling portable applications previously impossible with traditional bulky cooling apparatus.

The primary technical objectives in this field include developing more energy-efficient cooling systems, extending operational lifetimes between nitrogen refills, and creating more compact integration solutions that maintain performance while reducing size and weight constraints. Additionally, there is growing emphasis on developing sensors that can operate at intermediate temperatures, reducing the extreme cooling requirements while preserving performance benefits.

Another critical objective involves enhancing the reliability and safety of liquid nitrogen-based sensor systems for deployment in challenging environments, including space exploration, deep-sea applications, and hazardous industrial settings. This includes developing robust containment systems and fail-safe mechanisms to prevent system failures in critical applications.

The convergence of liquid nitrogen cooling with emerging technologies such as MEMS (Micro-Electro-Mechanical Systems), nanotechnology, and advanced materials science presents particularly promising avenues for innovation. Research indicates that novel composite materials specifically designed for cryogenic environments could potentially revolutionize sensor design by offering superior thermal management and mechanical stability.

Looking forward, the technology roadmap for liquid nitrogen in sensor applications points toward increasingly integrated systems where cooling technology becomes an intrinsic part of sensor design rather than an external addition. This holistic approach promises to overcome current limitations while opening new application domains previously considered impractical for cryogenic sensor technologies.

The fundamental advantage of liquid nitrogen in sensor technology stems from its extremely low temperature (-196°C), which dramatically reduces thermal noise and increases signal-to-noise ratios in various sensing devices. This characteristic has proven particularly valuable in high-precision measurement applications where ambient thermal interference would otherwise compromise data integrity.

Current technological trends indicate an accelerating integration of liquid nitrogen cooling systems with advanced sensor technologies, particularly in quantum sensing, superconducting devices, and ultra-sensitive detection systems. The miniaturization of cryogenic cooling systems represents a significant evolutionary step, enabling portable applications previously impossible with traditional bulky cooling apparatus.

The primary technical objectives in this field include developing more energy-efficient cooling systems, extending operational lifetimes between nitrogen refills, and creating more compact integration solutions that maintain performance while reducing size and weight constraints. Additionally, there is growing emphasis on developing sensors that can operate at intermediate temperatures, reducing the extreme cooling requirements while preserving performance benefits.

Another critical objective involves enhancing the reliability and safety of liquid nitrogen-based sensor systems for deployment in challenging environments, including space exploration, deep-sea applications, and hazardous industrial settings. This includes developing robust containment systems and fail-safe mechanisms to prevent system failures in critical applications.

The convergence of liquid nitrogen cooling with emerging technologies such as MEMS (Micro-Electro-Mechanical Systems), nanotechnology, and advanced materials science presents particularly promising avenues for innovation. Research indicates that novel composite materials specifically designed for cryogenic environments could potentially revolutionize sensor design by offering superior thermal management and mechanical stability.

Looking forward, the technology roadmap for liquid nitrogen in sensor applications points toward increasingly integrated systems where cooling technology becomes an intrinsic part of sensor design rather than an external addition. This holistic approach promises to overcome current limitations while opening new application domains previously considered impractical for cryogenic sensor technologies.

Market Demand Analysis for Cryogenic Sensor Applications

The global market for cryogenic sensor applications has been experiencing robust growth, driven primarily by advancements in quantum computing, medical diagnostics, and aerospace technologies. Current market valuations indicate that the cryogenic sensor market reached approximately $3.2 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028. This growth trajectory is particularly pronounced in regions with strong research infrastructure, notably North America, Europe, and parts of Asia.

The demand for liquid nitrogen-based sensor technologies is especially strong in the semiconductor industry, where ultra-low temperatures are essential for reducing thermal noise and enhancing measurement precision. Market research indicates that semiconductor testing applications alone account for nearly 28% of the total cryogenic sensor market, with demand increasing as chip architectures become more complex and sensitive.

Healthcare represents another significant market segment, with cryogenic sensors finding applications in magnetic resonance imaging (MRI), sample preservation, and advanced diagnostic equipment. The medical cryogenic sensor market segment has shown consistent annual growth of 7.5%, outpacing the overall market average, driven by increasing demand for high-resolution imaging technologies and precision medicine applications.

Quantum computing research has emerged as a particularly dynamic driver of market growth. As governments and private enterprises increase investments in quantum technologies, the demand for specialized cryogenic sensors capable of operating at near-absolute zero temperatures has surged. Market analysis reveals that funding for quantum computing research increased by 43% between 2020 and 2022, directly correlating with increased demand for advanced cryogenic sensing solutions.

The aerospace and defense sectors represent mature but steadily growing markets for cryogenic sensor technologies. Satellite systems, space exploration equipment, and advanced defense systems rely heavily on sensors that can operate reliably in extreme temperature environments. This sector accounts for approximately 18% of the total market share, with growth closely tied to government spending patterns and space exploration initiatives.

Emerging applications in energy storage, particularly in superconducting magnetic energy storage systems and advanced battery research, are creating new market opportunities. Though currently representing only 5% of the market, this segment shows the highest potential growth rate at 12.3% annually, as energy transition initiatives gain momentum globally.

Customer requirements across these markets consistently emphasize reliability, miniaturization, energy efficiency, and integration capabilities. Market surveys indicate that 76% of industrial customers prioritize long-term stability and calibration retention in cryogenic environments, while 64% seek solutions that minimize liquid nitrogen consumption through improved insulation and thermal management.

The demand for liquid nitrogen-based sensor technologies is especially strong in the semiconductor industry, where ultra-low temperatures are essential for reducing thermal noise and enhancing measurement precision. Market research indicates that semiconductor testing applications alone account for nearly 28% of the total cryogenic sensor market, with demand increasing as chip architectures become more complex and sensitive.

Healthcare represents another significant market segment, with cryogenic sensors finding applications in magnetic resonance imaging (MRI), sample preservation, and advanced diagnostic equipment. The medical cryogenic sensor market segment has shown consistent annual growth of 7.5%, outpacing the overall market average, driven by increasing demand for high-resolution imaging technologies and precision medicine applications.

Quantum computing research has emerged as a particularly dynamic driver of market growth. As governments and private enterprises increase investments in quantum technologies, the demand for specialized cryogenic sensors capable of operating at near-absolute zero temperatures has surged. Market analysis reveals that funding for quantum computing research increased by 43% between 2020 and 2022, directly correlating with increased demand for advanced cryogenic sensing solutions.

The aerospace and defense sectors represent mature but steadily growing markets for cryogenic sensor technologies. Satellite systems, space exploration equipment, and advanced defense systems rely heavily on sensors that can operate reliably in extreme temperature environments. This sector accounts for approximately 18% of the total market share, with growth closely tied to government spending patterns and space exploration initiatives.

Emerging applications in energy storage, particularly in superconducting magnetic energy storage systems and advanced battery research, are creating new market opportunities. Though currently representing only 5% of the market, this segment shows the highest potential growth rate at 12.3% annually, as energy transition initiatives gain momentum globally.

Customer requirements across these markets consistently emphasize reliability, miniaturization, energy efficiency, and integration capabilities. Market surveys indicate that 76% of industrial customers prioritize long-term stability and calibration retention in cryogenic environments, while 64% seek solutions that minimize liquid nitrogen consumption through improved insulation and thermal management.

Current State and Challenges in Liquid Nitrogen Sensor Integration

The integration of liquid nitrogen in sensor technologies has reached a significant level of maturity in specific applications while remaining experimental in others. Currently, liquid nitrogen is widely utilized in cooling infrared sensors for thermal imaging systems, particularly in military, aerospace, and high-precision industrial applications. These cryogenically cooled sensors demonstrate superior signal-to-noise ratios compared to their uncooled counterparts, enabling detection of minute temperature differences at extended ranges.

In the semiconductor industry, liquid nitrogen cooling has become standard practice for certain types of radiation detectors and specialized scientific instruments. The global market for cryogenic sensors was valued at approximately $2.1 billion in 2022, with a projected CAGR of 6.8% through 2028, indicating sustained growth in this technological domain.

Despite these advancements, significant challenges persist in the widespread adoption of liquid nitrogen-based sensor systems. The primary obstacle remains the complex infrastructure required for liquid nitrogen storage, handling, and delivery. Current systems necessitate bulky dewars and specialized insulation, limiting portability and increasing operational complexity. This infrastructure requirement creates substantial barriers to entry for many potential applications, particularly in consumer electronics and portable devices.

Thermal management presents another critical challenge. The extreme temperature differential between liquid nitrogen (-196°C) and ambient conditions creates thermal stress on sensor components and surrounding materials. This stress often leads to material fatigue, reduced operational lifespan, and potential system failures. Current materials science has not fully resolved these issues, particularly for miniaturized sensor applications.

Energy efficiency remains problematic as well. The production, transportation, and maintenance of liquid nitrogen cooling systems demand considerable energy input, reducing the overall efficiency of sensor operations. This energy requirement contradicts the growing industry trend toward sustainable and energy-efficient technologies.

Geographically, research and development in liquid nitrogen sensor technologies remain concentrated in North America, Western Europe, and East Asia, with the United States, Germany, Japan, and China leading innovation efforts. This concentration creates disparities in technological access and implementation capabilities across different regions.

The regulatory landscape presents additional complexities, with varying safety standards and handling requirements across jurisdictions. These regulatory inconsistencies complicate the development of standardized liquid nitrogen sensor solutions for global markets, further fragmenting the technological ecosystem and impeding widespread adoption.

In the semiconductor industry, liquid nitrogen cooling has become standard practice for certain types of radiation detectors and specialized scientific instruments. The global market for cryogenic sensors was valued at approximately $2.1 billion in 2022, with a projected CAGR of 6.8% through 2028, indicating sustained growth in this technological domain.

Despite these advancements, significant challenges persist in the widespread adoption of liquid nitrogen-based sensor systems. The primary obstacle remains the complex infrastructure required for liquid nitrogen storage, handling, and delivery. Current systems necessitate bulky dewars and specialized insulation, limiting portability and increasing operational complexity. This infrastructure requirement creates substantial barriers to entry for many potential applications, particularly in consumer electronics and portable devices.

Thermal management presents another critical challenge. The extreme temperature differential between liquid nitrogen (-196°C) and ambient conditions creates thermal stress on sensor components and surrounding materials. This stress often leads to material fatigue, reduced operational lifespan, and potential system failures. Current materials science has not fully resolved these issues, particularly for miniaturized sensor applications.

Energy efficiency remains problematic as well. The production, transportation, and maintenance of liquid nitrogen cooling systems demand considerable energy input, reducing the overall efficiency of sensor operations. This energy requirement contradicts the growing industry trend toward sustainable and energy-efficient technologies.

Geographically, research and development in liquid nitrogen sensor technologies remain concentrated in North America, Western Europe, and East Asia, with the United States, Germany, Japan, and China leading innovation efforts. This concentration creates disparities in technological access and implementation capabilities across different regions.

The regulatory landscape presents additional complexities, with varying safety standards and handling requirements across jurisdictions. These regulatory inconsistencies complicate the development of standardized liquid nitrogen sensor solutions for global markets, further fragmenting the technological ecosystem and impeding widespread adoption.

Current Technical Solutions for Liquid Nitrogen Sensing Applications

01 Storage and transportation systems for liquid nitrogen

Various systems and containers designed for the safe storage and transportation of liquid nitrogen. These include specialized vessels with vacuum insulation to minimize heat transfer, pressure relief mechanisms to prevent over-pressurization, and monitoring systems to track temperature and pressure levels. These systems are crucial for maintaining the cryogenic properties of liquid nitrogen during storage and transport.- Cryogenic storage and transportation systems: Specialized systems for storing and transporting liquid nitrogen at extremely low temperatures. These systems include insulated containers, dewars, and tanks designed to minimize heat transfer and maintain the cryogenic state of liquid nitrogen. Advanced insulation techniques and pressure management systems are employed to prevent rapid evaporation and ensure safe handling during transportation and storage.

- Cooling applications in industrial processes: Liquid nitrogen is widely used as a cooling agent in various industrial processes due to its extremely low temperature. Applications include rapid freezing of food products, cooling of electronic components during manufacturing, temperature control in chemical reactions, and material processing where precise temperature management is critical. The rapid cooling capability of liquid nitrogen makes it valuable for processes requiring quick temperature reduction.

- Medical and biological preservation techniques: Liquid nitrogen is essential in medical and biological fields for cryopreservation of biological samples, tissues, and cells. The ultra-low temperatures achieved with liquid nitrogen allow for long-term storage of biological materials with minimal degradation. These techniques are crucial for reproductive medicine, stem cell research, organ preservation, and biobanking applications where maintaining cellular viability is critical.

- Cryotherapy and dermatological applications: The use of liquid nitrogen in medical treatments, particularly in dermatology for cryotherapy procedures. Liquid nitrogen is applied to remove unwanted tissue such as warts, skin tags, and precancerous lesions through controlled freezing. The extreme cold causes cellular destruction of the targeted tissue while minimizing damage to surrounding healthy tissue. Specialized applicators and delivery systems have been developed for precise administration in these medical procedures.

- Safety systems and handling equipment: Specialized equipment and safety systems designed for the safe handling and use of liquid nitrogen. These include protective gear, automated dispensing systems, monitoring devices for oxygen levels, ventilation systems, and emergency response equipment. Safety innovations focus on preventing cold burns, asphyxiation hazards, and pressure-related accidents associated with liquid nitrogen handling in laboratory, industrial, and medical settings.

02 Cryogenic treatment applications

Applications of liquid nitrogen for cryogenic treatment of materials and components. Liquid nitrogen is used to subject materials to extremely low temperatures to modify their properties, such as increasing wear resistance, improving dimensional stability, and enhancing fatigue life. This process is commonly applied in manufacturing industries for tools, dies, and precision components.Expand Specific Solutions03 Medical and biological applications

Use of liquid nitrogen in medical and biological fields, particularly for cryopreservation and cryotherapy. Liquid nitrogen enables the preservation of biological samples, cells, tissues, and organs at ultra-low temperatures. In medical treatments, it's used for cryosurgery to remove abnormal tissues by freezing, particularly in dermatology and oncology applications.Expand Specific Solutions04 Industrial cooling and freezing systems

Systems utilizing liquid nitrogen for industrial cooling and freezing processes. These include food freezing applications, where liquid nitrogen provides rapid freezing capabilities that help preserve food quality and texture. Other industrial applications include cooling of electronic components during manufacturing, temperature control in chemical reactions, and creating inert atmospheres for sensitive processes.Expand Specific Solutions05 Liquid nitrogen production and purification methods

Methods and systems for the production, purification, and liquefaction of nitrogen from air. These include cryogenic air separation units that cool atmospheric air to separate nitrogen based on different boiling points, membrane separation technologies, and pressure swing adsorption systems. The processes focus on achieving high purity levels while optimizing energy efficiency in the production of liquid nitrogen.Expand Specific Solutions

Key Industry Players in Liquid Nitrogen Sensor Development

The application of liquid nitrogen in sensor technologies is currently in a growth phase, with the market expanding due to increasing demand for high-precision sensing in various industries. The global market is estimated to reach significant value as cryogenic technologies become more mainstream in sensing applications. Leading companies like Robert Bosch GmbH, Fujitsu Ltd., and Hitachi Ltd. are driving innovation with established R&D capabilities, while specialized players such as Cryofocus Medtech and Semiconductor Energy Laboratory are developing niche applications. Academic institutions including California Institute of Technology and Duke University are advancing fundamental research, creating a competitive ecosystem where commercial applications are emerging from laboratory breakthroughs. The technology is approaching maturity in certain applications but remains in development for others, with significant potential for growth as manufacturing processes improve.

Robert Bosch GmbH

Technical Solution: Robert Bosch has developed advanced cryogenic sensor systems utilizing liquid nitrogen cooling to achieve superior performance in automotive and industrial applications. Their technology employs liquid nitrogen as a coolant for temperature-sensitive sensors, particularly in their MEMS (Micro-Electro-Mechanical Systems) sensor portfolio. Bosch's approach involves hermetically sealed cryostats that maintain sensors at optimal operating temperatures (77K), significantly enhancing sensitivity and reducing thermal noise. Their patented thermal isolation techniques minimize liquid nitrogen consumption while maintaining stable temperatures. Bosch has particularly focused on applying this technology to magnetic field sensors, infrared detectors, and precision inertial measurement units where thermal noise reduction is critical for performance. Their systems incorporate automated refill mechanisms and advanced thermal management to extend cryogenic operation periods.

Strengths: Superior signal-to-noise ratio in harsh environments; extended sensor lifetime due to reduced thermal degradation; industry-leading thermal isolation efficiency. Weaknesses: Higher system complexity and cost compared to ambient temperature sensors; requires periodic liquid nitrogen replenishment; limited deployment in consumer applications due to maintenance requirements.

Cryofocus Medtech (Shanghai) Co. Ltd.

Technical Solution: Cryofocus Medtech has pioneered liquid nitrogen-based sensor technologies specifically for medical diagnostics and therapeutic applications. Their flagship platform integrates ultra-sensitive superconducting quantum interference device (SQUID) sensors cooled by liquid nitrogen to detect minute biomagnetic signals from the human body. The company's proprietary cryostat design maintains sensors at 77K while positioned just millimeters from body tissue, enabling unprecedented spatial resolution in magnetoencephalography and magnetocardiography applications. Their technology employs specialized thermal interfaces and vacuum insulation to minimize liquid nitrogen consumption while maintaining stable temperatures. Cryofocus has also developed novel microfluidic sensors that leverage the extreme temperature gradients possible with liquid nitrogen to achieve rapid, highly sensitive detection of biomarkers in small sample volumes.

Strengths: Exceptional sensitivity for medical diagnostics; compact cryostat design suitable for clinical environments; demonstrated clinical efficacy in early disease detection. Weaknesses: Relatively high operational costs; requires specialized training for clinical staff; limited portability due to liquid nitrogen handling requirements.

Core Patents and Innovations in Cryogenic Sensor Technology

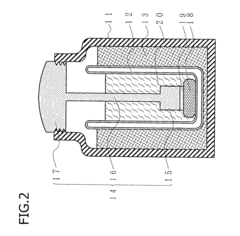

An indirect method and apparatus for cooling a silicon drift detector

PatentWO2008082678A1

Innovation

- An indirect cooling apparatus and method using a remote cooling engine, thermal conduction device, and heat removal device within a vacuum enclosure, where the cooling engine is thermally coupled to the silicon drift detector module via a thermal conduction device, allowing heat generated by the cooling engine to be dissipated externally, thereby maintaining the detector at lower temperatures without heat generation near the module.

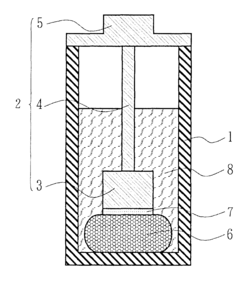

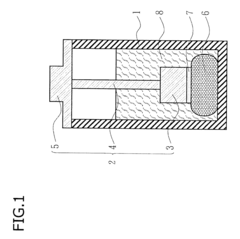

Liquid nitrogen cooling sensor device container and liquid nitrogen cooling sensor device

PatentActiveUS10113695B2

Innovation

- A liquid nitrogen cooling sensor device container with a sensor fixing member and a fixing buffer member, such as melamine foam or PVA sponge, that provides a buffering effect to absorb vibrations while allowing easy insertion and removal of the probe, ensuring stable measurements over long periods.

Safety Standards and Protocols for Cryogenic Sensor Implementation

The implementation of liquid nitrogen in sensor technologies necessitates rigorous safety standards and protocols due to the inherent hazards associated with cryogenic materials. International standards such as ISO 24490 and OSHA 29 CFR 1910.103 provide comprehensive guidelines for handling cryogenic liquids, specifically addressing temperature extremes, oxygen displacement risks, and material compatibility concerns.

Primary safety requirements for cryogenic sensor systems include proper ventilation systems to prevent nitrogen accumulation, which can lead to asphyxiation hazards in confined spaces. Oxygen monitoring systems must be installed in areas where liquid nitrogen is used, with automatic alarms triggered when oxygen levels fall below 19.5% by volume, as recommended by NIOSH and OSHA standards.

Personal protective equipment (PPE) protocols mandate the use of specialized cryogenic gloves, face shields, and aprons when handling liquid nitrogen-cooled sensors. These items must conform to EN 511 standards for protection against extreme cold, with materials tested to withstand temperatures as low as -196°C without compromising flexibility or protective qualities.

Equipment design standards for cryogenic sensor technologies require double-walled vacuum insulation for storage vessels and transfer lines, with pressure relief mechanisms calibrated to prevent over-pressurization. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides specific requirements for cryogenic pressure vessels used in sensor applications, including material selection criteria and stress analysis parameters.

Training and certification requirements constitute another critical component of safety protocols. Personnel working with liquid nitrogen-based sensor systems must complete specialized training programs covering cryogenic hazards, emergency response procedures, and proper handling techniques. The European Industrial Gases Association (EIGA) and the Compressed Gas Association (CGA) offer standardized training frameworks that have become industry benchmarks.

Emergency response protocols for cryogenic sensor installations must address potential scenarios including liquid nitrogen spills, oxygen-deficient atmospheres, and cold burns. These protocols typically include evacuation procedures, first aid measures for cryogenic injuries, and containment strategies for large-scale releases. The Chemical Safety Board recommends regular emergency drills and scenario-based training to ensure preparedness.

Documentation and risk assessment procedures require comprehensive hazard analyses before implementing liquid nitrogen-based sensor systems in any facility. This includes detailed process safety management documentation, regular equipment inspection schedules, and maintenance protocols that comply with ISO 31000 risk management standards and industry-specific requirements.

Primary safety requirements for cryogenic sensor systems include proper ventilation systems to prevent nitrogen accumulation, which can lead to asphyxiation hazards in confined spaces. Oxygen monitoring systems must be installed in areas where liquid nitrogen is used, with automatic alarms triggered when oxygen levels fall below 19.5% by volume, as recommended by NIOSH and OSHA standards.

Personal protective equipment (PPE) protocols mandate the use of specialized cryogenic gloves, face shields, and aprons when handling liquid nitrogen-cooled sensors. These items must conform to EN 511 standards for protection against extreme cold, with materials tested to withstand temperatures as low as -196°C without compromising flexibility or protective qualities.

Equipment design standards for cryogenic sensor technologies require double-walled vacuum insulation for storage vessels and transfer lines, with pressure relief mechanisms calibrated to prevent over-pressurization. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides specific requirements for cryogenic pressure vessels used in sensor applications, including material selection criteria and stress analysis parameters.

Training and certification requirements constitute another critical component of safety protocols. Personnel working with liquid nitrogen-based sensor systems must complete specialized training programs covering cryogenic hazards, emergency response procedures, and proper handling techniques. The European Industrial Gases Association (EIGA) and the Compressed Gas Association (CGA) offer standardized training frameworks that have become industry benchmarks.

Emergency response protocols for cryogenic sensor installations must address potential scenarios including liquid nitrogen spills, oxygen-deficient atmospheres, and cold burns. These protocols typically include evacuation procedures, first aid measures for cryogenic injuries, and containment strategies for large-scale releases. The Chemical Safety Board recommends regular emergency drills and scenario-based training to ensure preparedness.

Documentation and risk assessment procedures require comprehensive hazard analyses before implementing liquid nitrogen-based sensor systems in any facility. This includes detailed process safety management documentation, regular equipment inspection schedules, and maintenance protocols that comply with ISO 31000 risk management standards and industry-specific requirements.

Environmental Impact Assessment of Liquid Nitrogen Sensor Systems

The environmental impact of liquid nitrogen sensor systems requires comprehensive assessment due to their increasing deployment across various industries. While these systems offer significant technological advantages, their environmental footprint spans multiple dimensions that must be carefully evaluated.

The production and transportation of liquid nitrogen represent significant sources of environmental concern. The cryogenic distillation process used to produce liquid nitrogen is energy-intensive, consuming approximately 0.5-0.7 kWh of electricity per kilogram of nitrogen produced. This energy demand contributes to indirect carbon emissions when non-renewable energy sources power production facilities. Additionally, the specialized insulated containers required for transportation add to the embodied carbon footprint of these systems.

Operational impacts of liquid nitrogen sensor systems present both challenges and benefits. During operation, these systems release nitrogen gas back into the atmosphere, which constitutes approximately 78% of air naturally and is generally considered environmentally benign. However, the rapid expansion of liquid nitrogen during warming can displace oxygen in confined spaces, creating potential safety hazards that require proper ventilation systems, which themselves consume energy.

The cooling efficiency of liquid nitrogen systems offers environmental advantages compared to traditional electrical cooling methods. Studies indicate that for certain applications, liquid nitrogen cooling can reduce energy consumption by 20-30% compared to conventional refrigeration systems, potentially offsetting some production-related impacts when evaluated on a lifecycle basis.

End-of-life considerations reveal additional environmental dimensions. The specialized materials used in cryogenic sensors, including rare earth elements and specialized alloys, present recycling challenges. Current recovery rates for these materials remain below 35%, indicating significant room for improvement in circular economy practices for these technologies.

Water usage represents another environmental consideration, as nitrogen liquefaction plants require substantial water for cooling processes. A typical medium-sized facility may consume 2,000-3,000 gallons of water daily, with potential thermal pollution impacts on local water bodies if cooling water is not properly managed before discharge.

Comparative lifecycle assessments indicate that liquid nitrogen sensor systems generally demonstrate lower global warming potential than conventional electronic sensor systems over a 10-year operational period, primarily due to their reduced operational energy requirements and longer service intervals. However, these advantages must be weighed against higher initial environmental costs during production and end-of-life management challenges.

The production and transportation of liquid nitrogen represent significant sources of environmental concern. The cryogenic distillation process used to produce liquid nitrogen is energy-intensive, consuming approximately 0.5-0.7 kWh of electricity per kilogram of nitrogen produced. This energy demand contributes to indirect carbon emissions when non-renewable energy sources power production facilities. Additionally, the specialized insulated containers required for transportation add to the embodied carbon footprint of these systems.

Operational impacts of liquid nitrogen sensor systems present both challenges and benefits. During operation, these systems release nitrogen gas back into the atmosphere, which constitutes approximately 78% of air naturally and is generally considered environmentally benign. However, the rapid expansion of liquid nitrogen during warming can displace oxygen in confined spaces, creating potential safety hazards that require proper ventilation systems, which themselves consume energy.

The cooling efficiency of liquid nitrogen systems offers environmental advantages compared to traditional electrical cooling methods. Studies indicate that for certain applications, liquid nitrogen cooling can reduce energy consumption by 20-30% compared to conventional refrigeration systems, potentially offsetting some production-related impacts when evaluated on a lifecycle basis.

End-of-life considerations reveal additional environmental dimensions. The specialized materials used in cryogenic sensors, including rare earth elements and specialized alloys, present recycling challenges. Current recovery rates for these materials remain below 35%, indicating significant room for improvement in circular economy practices for these technologies.

Water usage represents another environmental consideration, as nitrogen liquefaction plants require substantial water for cooling processes. A typical medium-sized facility may consume 2,000-3,000 gallons of water daily, with potential thermal pollution impacts on local water bodies if cooling water is not properly managed before discharge.

Comparative lifecycle assessments indicate that liquid nitrogen sensor systems generally demonstrate lower global warming potential than conventional electronic sensor systems over a 10-year operational period, primarily due to their reduced operational energy requirements and longer service intervals. However, these advantages must be weighed against higher initial environmental costs during production and end-of-life management challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!