The Effects of Alloy Composition on Amorphous Metal Properties

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metal Development History and Objectives

Amorphous metals, also known as metallic glasses, were first discovered in 1960 when Pol Duwez and colleagues at Caltech developed a rapid cooling technique that prevented crystallization in a gold-silicon alloy. This breakthrough marked the beginning of a new era in metallurgy, challenging the conventional understanding that metals must possess crystalline structures. Throughout the 1960s and 1970s, research primarily focused on binary alloy systems with limited practical applications due to their small critical dimensions.

The 1980s witnessed significant advancement with the development of multicomponent alloy systems, particularly those based on zirconium, palladium, and iron. These compositions demonstrated enhanced glass-forming ability, allowing for the production of amorphous metals with larger dimensions. The introduction of bulk metallic glasses (BMGs) in the late 1980s by Akihisa Inoue's group at Tohoku University represented a pivotal moment, as these materials could be cast with thicknesses exceeding 1mm while maintaining their amorphous structure.

The 1990s saw the emergence of systematic approaches to alloy design, with researchers identifying key principles for creating stable amorphous structures. The "confusion principle" and the development of empirical rules relating atomic size differences, negative heats of mixing, and multi-component systems to glass-forming ability provided a framework for rational alloy design. During this period, researchers began to understand how specific elemental additions could dramatically alter the properties and processing windows of amorphous metals.

Since 2000, research has increasingly focused on establishing clear relationships between alloy composition and resulting properties. Scientists have developed sophisticated models to predict how variations in elemental constituents affect glass transition temperature, mechanical strength, corrosion resistance, and magnetic properties. High-throughput experimental methods and computational materials science approaches have accelerated this understanding, enabling the design of tailored compositions for specific applications.

The current objectives in amorphous metal research center on several key areas. First, developing compositions with improved thermal stability to prevent crystallization during processing and service. Second, enhancing mechanical properties, particularly ductility, which remains a significant limitation for many amorphous metal systems. Third, creating cost-effective formulations by reducing or eliminating expensive elements like palladium while maintaining desirable properties. Fourth, establishing predictive models that can accurately relate composition to processability and final properties, reducing the need for extensive empirical testing.

Looking forward, researchers aim to develop "designer" amorphous metals with precisely tailored property combinations for specific applications, from biomedical implants to energy storage systems. This goal requires a comprehensive understanding of how each element in complex alloy systems contributes to the overall property profile of the resulting amorphous metal.

The 1980s witnessed significant advancement with the development of multicomponent alloy systems, particularly those based on zirconium, palladium, and iron. These compositions demonstrated enhanced glass-forming ability, allowing for the production of amorphous metals with larger dimensions. The introduction of bulk metallic glasses (BMGs) in the late 1980s by Akihisa Inoue's group at Tohoku University represented a pivotal moment, as these materials could be cast with thicknesses exceeding 1mm while maintaining their amorphous structure.

The 1990s saw the emergence of systematic approaches to alloy design, with researchers identifying key principles for creating stable amorphous structures. The "confusion principle" and the development of empirical rules relating atomic size differences, negative heats of mixing, and multi-component systems to glass-forming ability provided a framework for rational alloy design. During this period, researchers began to understand how specific elemental additions could dramatically alter the properties and processing windows of amorphous metals.

Since 2000, research has increasingly focused on establishing clear relationships between alloy composition and resulting properties. Scientists have developed sophisticated models to predict how variations in elemental constituents affect glass transition temperature, mechanical strength, corrosion resistance, and magnetic properties. High-throughput experimental methods and computational materials science approaches have accelerated this understanding, enabling the design of tailored compositions for specific applications.

The current objectives in amorphous metal research center on several key areas. First, developing compositions with improved thermal stability to prevent crystallization during processing and service. Second, enhancing mechanical properties, particularly ductility, which remains a significant limitation for many amorphous metal systems. Third, creating cost-effective formulations by reducing or eliminating expensive elements like palladium while maintaining desirable properties. Fourth, establishing predictive models that can accurately relate composition to processability and final properties, reducing the need for extensive empirical testing.

Looking forward, researchers aim to develop "designer" amorphous metals with precisely tailored property combinations for specific applications, from biomedical implants to energy storage systems. This goal requires a comprehensive understanding of how each element in complex alloy systems contributes to the overall property profile of the resulting amorphous metal.

Market Applications and Demand Analysis for Amorphous Alloys

The global market for amorphous metals, also known as metallic glasses, has been experiencing significant growth driven by their exceptional mechanical, magnetic, and corrosion-resistant properties. Current market valuations place the amorphous metals sector at approximately 14.2 billion USD in 2023, with projections indicating a compound annual growth rate of 7.8% through 2030. This growth trajectory is primarily fueled by increasing demand across multiple high-value industries seeking materials with superior performance characteristics.

The electronics sector represents the largest application segment, accounting for roughly 32% of the total market share. Amorphous metal transformers and inductors are particularly sought after due to their low core losses and high magnetic permeability, resulting in energy efficiency improvements of 40-80% compared to conventional silicon steel alternatives. This efficiency gain translates to substantial operational cost savings in power distribution systems.

Aerospace and defense applications constitute another rapidly expanding market segment, growing at 9.3% annually. The exceptional strength-to-weight ratio of amorphous alloys makes them ideal for structural components in aircraft and military equipment. Specifically, iron-based amorphous alloys with boron and silicon additions have demonstrated tensile strengths exceeding 3 GPa while maintaining good ductility, properties highly valued in this sector.

The medical device industry has emerged as a promising frontier for amorphous metals, particularly zirconium-based compositions. These alloys exhibit excellent biocompatibility, wear resistance, and corrosion resistance in physiological environments. Surgical instruments, orthopedic implants, and dental prosthetics manufactured from these materials show improved performance and longevity compared to traditional titanium alloys.

Renewable energy systems represent another significant growth area, with amorphous metal components increasingly incorporated into wind turbines, solar panel frameworks, and energy storage systems. The superior magnetic properties of iron-based amorphous alloys enable the development of more efficient generators and transformers, directly contributing to improved energy conversion efficiency in renewable power systems.

Regional market analysis reveals that Asia-Pacific dominates the global amorphous metals market with 45% share, followed by North America (28%) and Europe (22%). China and Japan lead manufacturing capacity, while significant research and development activities are concentrated in the United States and Germany. The concentration of manufacturing in Asia has created supply chain vulnerabilities for Western markets, prompting initiatives to develop domestic production capabilities for these strategic materials.

The electronics sector represents the largest application segment, accounting for roughly 32% of the total market share. Amorphous metal transformers and inductors are particularly sought after due to their low core losses and high magnetic permeability, resulting in energy efficiency improvements of 40-80% compared to conventional silicon steel alternatives. This efficiency gain translates to substantial operational cost savings in power distribution systems.

Aerospace and defense applications constitute another rapidly expanding market segment, growing at 9.3% annually. The exceptional strength-to-weight ratio of amorphous alloys makes them ideal for structural components in aircraft and military equipment. Specifically, iron-based amorphous alloys with boron and silicon additions have demonstrated tensile strengths exceeding 3 GPa while maintaining good ductility, properties highly valued in this sector.

The medical device industry has emerged as a promising frontier for amorphous metals, particularly zirconium-based compositions. These alloys exhibit excellent biocompatibility, wear resistance, and corrosion resistance in physiological environments. Surgical instruments, orthopedic implants, and dental prosthetics manufactured from these materials show improved performance and longevity compared to traditional titanium alloys.

Renewable energy systems represent another significant growth area, with amorphous metal components increasingly incorporated into wind turbines, solar panel frameworks, and energy storage systems. The superior magnetic properties of iron-based amorphous alloys enable the development of more efficient generators and transformers, directly contributing to improved energy conversion efficiency in renewable power systems.

Regional market analysis reveals that Asia-Pacific dominates the global amorphous metals market with 45% share, followed by North America (28%) and Europe (22%). China and Japan lead manufacturing capacity, while significant research and development activities are concentrated in the United States and Germany. The concentration of manufacturing in Asia has created supply chain vulnerabilities for Western markets, prompting initiatives to develop domestic production capabilities for these strategic materials.

Current Challenges in Alloy Composition Engineering

Despite significant advancements in amorphous metal development, several critical challenges persist in alloy composition engineering that impede broader industrial applications. The primary challenge remains the limited glass-forming ability (GFA) of many potentially valuable compositions. While certain alloy systems like Zr-based and Pd-based compositions demonstrate excellent GFA, many others, particularly those containing lightweight elements such as Al and Ti, exhibit restricted critical casting dimensions, typically below 10mm.

Compositional precision presents another formidable obstacle. Minor variations in elemental ratios, sometimes as small as 0.5 atomic percent, can dramatically alter an alloy's ability to form amorphous structures. This extreme sensitivity necessitates unprecedented manufacturing precision that exceeds current industrial capabilities, particularly for mass production scenarios where compositional control becomes increasingly difficult to maintain.

The cost-performance balance remains problematic for commercial applications. High-GFA compositions often rely on expensive elements like palladium, platinum, or rare earth metals. Attempts to substitute these with more economical alternatives frequently compromise the material's amorphous-forming capabilities or degrade critical performance properties such as corrosion resistance or mechanical strength.

Reproducibility issues further complicate alloy development efforts. Researchers frequently encounter difficulties replicating published results due to unidentified processing variables or undisclosed minor elements that significantly impact amorphous formation. This "hidden variable" problem slows scientific progress and technology transfer from laboratory to industry.

The multi-property optimization challenge represents perhaps the most complex barrier. Engineering alloy compositions requires simultaneous optimization across numerous properties including GFA, mechanical strength, ductility, thermal stability, corrosion resistance, and magnetic characteristics. These properties often exhibit competing relationships, creating complex trade-offs that defy straightforward optimization approaches.

Computational modeling limitations also hinder progress. Current simulation tools struggle to accurately predict amorphous phase formation and properties from first principles, particularly for complex multi-component systems. The absence of reliable predictive models forces researchers to rely heavily on empirical approaches and high-throughput experimentation, which are both time-consuming and resource-intensive.

Finally, processing-composition interdependence creates additional complexity. The optimal composition for amorphous formation varies significantly depending on processing conditions such as cooling rate, pressure, and environmental factors. This interdependence necessitates a holistic approach to alloy design that considers both composition and processing parameters simultaneously.

Compositional precision presents another formidable obstacle. Minor variations in elemental ratios, sometimes as small as 0.5 atomic percent, can dramatically alter an alloy's ability to form amorphous structures. This extreme sensitivity necessitates unprecedented manufacturing precision that exceeds current industrial capabilities, particularly for mass production scenarios where compositional control becomes increasingly difficult to maintain.

The cost-performance balance remains problematic for commercial applications. High-GFA compositions often rely on expensive elements like palladium, platinum, or rare earth metals. Attempts to substitute these with more economical alternatives frequently compromise the material's amorphous-forming capabilities or degrade critical performance properties such as corrosion resistance or mechanical strength.

Reproducibility issues further complicate alloy development efforts. Researchers frequently encounter difficulties replicating published results due to unidentified processing variables or undisclosed minor elements that significantly impact amorphous formation. This "hidden variable" problem slows scientific progress and technology transfer from laboratory to industry.

The multi-property optimization challenge represents perhaps the most complex barrier. Engineering alloy compositions requires simultaneous optimization across numerous properties including GFA, mechanical strength, ductility, thermal stability, corrosion resistance, and magnetic characteristics. These properties often exhibit competing relationships, creating complex trade-offs that defy straightforward optimization approaches.

Computational modeling limitations also hinder progress. Current simulation tools struggle to accurately predict amorphous phase formation and properties from first principles, particularly for complex multi-component systems. The absence of reliable predictive models forces researchers to rely heavily on empirical approaches and high-throughput experimentation, which are both time-consuming and resource-intensive.

Finally, processing-composition interdependence creates additional complexity. The optimal composition for amorphous formation varies significantly depending on processing conditions such as cooling rate, pressure, and environmental factors. This interdependence necessitates a holistic approach to alloy design that considers both composition and processing parameters simultaneously.

Current Methodologies for Alloy Composition Optimization

01 Mechanical properties of amorphous metals

Amorphous metals exhibit exceptional mechanical properties compared to their crystalline counterparts. They typically demonstrate high strength, hardness, and elastic limit due to the absence of grain boundaries and dislocations. These materials also show excellent wear resistance and fatigue strength, making them suitable for applications requiring durability. The unique atomic structure of amorphous metals contributes to their superior mechanical behavior, though they may exhibit limited ductility at room temperature.- Mechanical properties of amorphous metals: Amorphous metals exhibit exceptional mechanical properties including high strength, hardness, and elasticity compared to their crystalline counterparts. The absence of grain boundaries and crystal defects contributes to their superior wear resistance and mechanical durability. These materials can withstand significant deformation without permanent damage, making them suitable for applications requiring high mechanical performance and reliability.

- Magnetic properties of amorphous metals: Amorphous metals possess unique magnetic properties, including high magnetic permeability, low coercivity, and reduced core losses. The disordered atomic structure results in soft magnetic behavior that is advantageous for electromagnetic applications. These materials exhibit excellent response to changing magnetic fields with minimal energy loss, making them ideal for transformers, inductors, and magnetic shielding applications.

- Thermal and chemical stability of amorphous metals: Amorphous metals demonstrate remarkable thermal stability within specific temperature ranges and excellent resistance to chemical corrosion. Their homogeneous structure without grain boundaries provides superior resistance to oxidation and chemical attack compared to conventional metals. However, they may undergo crystallization when heated above their glass transition temperature, which can significantly alter their properties. Various alloying elements can be added to enhance thermal stability and corrosion resistance.

- Manufacturing processes for amorphous metals: Various specialized manufacturing techniques are employed to produce amorphous metals, including rapid solidification, melt spinning, and vapor deposition. These processes involve cooling the molten metal at extremely high rates (typically 10^4-10^6 K/s) to prevent crystallization. The processing parameters significantly influence the resulting properties of the amorphous metals. Recent advancements have enabled the production of bulk amorphous metals with increased dimensions and improved property control.

- Applications of amorphous metals based on their properties: The unique combination of properties exhibited by amorphous metals makes them suitable for diverse applications across multiple industries. Their exceptional magnetic properties are utilized in transformer cores and electronic devices. The superior mechanical properties and corrosion resistance make them ideal for cutting tools, sporting equipment, and biomedical implants. Additionally, their unique atomic structure enables applications in hydrogen storage, electronic components, and high-performance structural materials.

02 Magnetic properties of amorphous metals

Amorphous metals possess distinctive magnetic properties that make them valuable in electromagnetic applications. They typically exhibit soft magnetic characteristics with low coercivity, high permeability, and reduced core losses compared to conventional magnetic materials. The absence of crystalline anisotropy and magnetocrystalline structure contributes to their superior magnetic performance. These properties make amorphous metals particularly suitable for transformer cores, magnetic sensors, and other electromagnetic devices requiring efficient magnetic response.Expand Specific Solutions03 Thermal stability and processing of amorphous metals

The thermal stability of amorphous metals is a critical property that affects their processing and application. These materials exist in a metastable state and can crystallize when heated above their crystallization temperature. Rapid cooling techniques such as melt spinning are essential for producing amorphous structures by preventing atomic rearrangement into crystalline patterns. The glass transition temperature and crystallization kinetics are important parameters that determine the processing window for these materials. Various thermal treatments can be applied to control the microstructure and enhance specific properties.Expand Specific Solutions04 Chemical properties and corrosion resistance

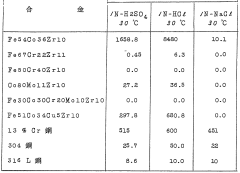

Amorphous metals demonstrate exceptional corrosion resistance compared to their crystalline counterparts due to their homogeneous structure and absence of grain boundaries. The uniform atomic distribution creates a passive surface layer that provides protection against various corrosive environments. These materials show excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. The chemical composition can be tailored to enhance specific corrosion resistance properties for applications in aggressive environments such as marine settings, chemical processing, and biomedical implants.Expand Specific Solutions05 Electrical and thermal conductivity properties

Amorphous metals exhibit distinctive electrical and thermal conductivity characteristics that differ from crystalline metals. The disordered atomic structure typically results in higher electrical resistivity compared to crystalline counterparts, making them suitable for applications requiring reduced eddy current losses. Their thermal conductivity is generally lower than crystalline metals due to increased phonon scattering in the amorphous structure. These properties can be advantageous in specific applications such as electronic components, resistive heating elements, and thermal barriers where controlled electrical and thermal transport is desired.Expand Specific Solutions

Leading Research Institutions and Manufacturers Analysis

The amorphous metal properties market is currently in a growth phase, with increasing applications across automotive, electronics, and industrial sectors. The global market size is expanding rapidly due to superior mechanical and magnetic properties these materials offer. Technologically, the field shows varying maturity levels, with established players like Metglas, Inc. and VACUUMSCHMELZE leading commercial applications, while research institutions such as Institute of Metal Research Chinese Academy of Sciences and Zhejiang University drive fundamental innovation. Companies like BYD, Samsung Electronics, and NIPPON STEEL are integrating amorphous metals into their product lines, particularly for energy-efficient applications. Newer entrants like Scoperta and Heraeus Amloy Technologies are developing specialized alloy compositions for targeted applications, indicating a competitive landscape balancing established manufacturing expertise with emerging materials science breakthroughs.

VACUUMSCHMELZE GmbH & Co. KG

Technical Solution: VACUUMSCHMELZE (VAC) has developed proprietary cobalt-based amorphous alloys under their VITROVAC® brand, with compositions primarily in the Co-Fe-Si-B system. Their manufacturing process utilizes precision-controlled rapid solidification techniques to produce amorphous ribbons with thicknesses ranging from 15-35μm and widths up to 213mm. The flagship Co67Fe4Mo1.5Si16.5B11 composition exhibits exceptional magnetic properties including initial permeability exceeding 100,000, saturation induction of 0.55-0.58 T, and extremely low coercivity (0.5-2.0 A/m)[8]. VAC has pioneered specialized annealing treatments under magnetic fields that induce controlled magnetic anisotropy, enabling precise tailoring of magnetic properties for specific applications. Their recent innovations include multi-layer amorphous/nanocrystalline composite materials that combine the high saturation of nanocrystalline phases with the low losses of amorphous structures. VAC has also developed specialized surface passivation techniques that enhance the corrosion resistance of their amorphous alloys by creating nanoscale oxide layers that protect against environmental degradation while maintaining the core magnetic properties[9].

Strengths: Exceptional magnetic stability across wide temperature ranges; industry-leading magnetic field annealing capabilities; extensive experience in mass production of consistent quality materials. Weaknesses: Lower saturation magnetization compared to Fe-based alternatives; relatively higher material costs; limited mechanical flexibility in certain applications requiring complex forming operations.

Advanced Technology & Materials Co., Ltd.

Technical Solution: Advanced Technology & Materials Co. has developed a comprehensive portfolio of amorphous and nanocrystalline alloys with compositions spanning Fe-based, Co-based, and Ni-based systems. Their Fe-based amorphous alloys (Fe78Si9B13 with additions of Cu and Nb) are produced using planar flow casting technology, achieving cooling rates of 10^6 K/s and ribbon thicknesses of 20-30μm with widths up to 250mm. These materials exhibit exceptional soft magnetic properties with core losses below 0.12 W/kg at 50Hz/1.4T[6]. The company has pioneered the development of Co-based amorphous alloys (Co68Fe4Ni1Si14B13) specifically engineered for high-frequency applications, demonstrating stable permeability up to 10 MHz and resistivity exceeding 130 μΩ·cm. Their recent innovations include amorphous powder metallurgy techniques that enable the production of complex 3D components while maintaining over 95% of the amorphous structure's inherent properties. AT&M has also developed specialized surface treatments that enhance wear and corrosion resistance of amorphous components by creating nanoscale surface modifications without inducing bulk crystallization.

Strengths: Diverse portfolio covering multiple alloy systems; established large-scale production capabilities; advanced processing techniques for creating complex components. Weaknesses: Relatively higher production costs compared to conventional crystalline materials; challenges in joining and welding amorphous components; limited thermal stability restricting high-temperature applications.

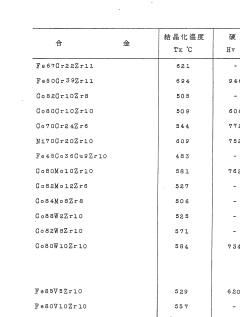

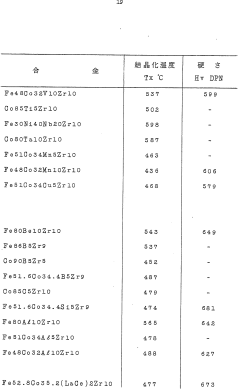

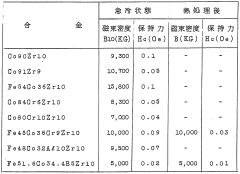

Key Composition-Property Relationships in Amorphous Metals

Amorphous alloy containing iron family element and zirconium,and articles obtained therefrom

PatentWO1980002159A1

Innovation

- Development of amorphous alloys with specific compositions involving iron group elements, zirconia, and additional elements like Cr, Mo, W, Ti, V, and lanthanides, which enhance ductility, toughness, and corrosion resistance while maintaining magnetic properties, and can be produced through rapid solidification techniques.

Amorphous metal alloy having high tensile strength and electrical resistivity

PatentActiveUS7771545B2

Innovation

- Development of amorphous metal alloys with specific compositions, such as (Co1-aFea)100-b-c-dCrbTcXd, incorporating elements like Cr, Mn, Mo, V, B, and Si, which enhance electrical resistivity and tensile strength by increasing structural disorder and preventing shear band formation, resulting in wires with high tensile strength and electrical resistivity.

Manufacturing Processes Impact on Amorphous Properties

The manufacturing process of amorphous metals significantly influences their final properties, often to a degree comparable with alloy composition itself. Rapid solidification techniques, particularly melt spinning, remain the dominant industrial method for producing amorphous metal ribbons. This process involves ejecting molten metal onto a rapidly rotating copper wheel, achieving cooling rates of 10^4-10^6 K/s, which is critical for preventing crystallization. The precise control of wheel speed, ejection pressure, and nozzle-to-wheel distance directly affects the thickness uniformity and amorphous structure quality.

Alternative manufacturing methods have emerged to overcome size limitations inherent in rapid quenching. Powder metallurgy approaches, including mechanical alloying and hot isostatic pressing, enable the production of bulk amorphous metals with complex geometries. These techniques introduce different stress states and potential contamination issues that can alter the glass-forming ability and subsequent properties of the alloy.

Additive manufacturing represents a revolutionary approach for amorphous metal production. Selective laser melting and electron beam melting create localized melt pools with extremely high cooling rates, potentially enabling the direct printing of amorphous structures. Recent studies demonstrate that layer-by-layer deposition can induce beneficial heterogeneities that enhance fracture toughness while maintaining the desirable amorphous character.

Post-processing treatments significantly modify amorphous metal properties. Controlled annealing below the crystallization temperature can relieve internal stresses without inducing crystallization, improving ductility while maintaining strength. Surface treatments such as shot peening introduce compressive stresses that enhance fatigue resistance by up to 30% in certain zirconium-based amorphous alloys.

The manufacturing environment itself introduces variables that affect final properties. Oxygen content during processing has been shown to dramatically influence the glass-forming ability of iron-based amorphous alloys, with even 100 ppm differences altering the critical cooling rate by an order of magnitude. Similarly, trace contaminants from production equipment can serve as heterogeneous nucleation sites, promoting unwanted crystallization.

Scale-up challenges remain significant in amorphous metal manufacturing. The critical cooling rate requirement creates fundamental limitations on section thickness, with most commercial amorphous metals restricted to thicknesses below 10mm. Recent innovations in electromagnetic levitation melting show promise for producing larger amorphous components by eliminating container-induced nucleation sites, potentially expanding industrial applications beyond current limitations.

Alternative manufacturing methods have emerged to overcome size limitations inherent in rapid quenching. Powder metallurgy approaches, including mechanical alloying and hot isostatic pressing, enable the production of bulk amorphous metals with complex geometries. These techniques introduce different stress states and potential contamination issues that can alter the glass-forming ability and subsequent properties of the alloy.

Additive manufacturing represents a revolutionary approach for amorphous metal production. Selective laser melting and electron beam melting create localized melt pools with extremely high cooling rates, potentially enabling the direct printing of amorphous structures. Recent studies demonstrate that layer-by-layer deposition can induce beneficial heterogeneities that enhance fracture toughness while maintaining the desirable amorphous character.

Post-processing treatments significantly modify amorphous metal properties. Controlled annealing below the crystallization temperature can relieve internal stresses without inducing crystallization, improving ductility while maintaining strength. Surface treatments such as shot peening introduce compressive stresses that enhance fatigue resistance by up to 30% in certain zirconium-based amorphous alloys.

The manufacturing environment itself introduces variables that affect final properties. Oxygen content during processing has been shown to dramatically influence the glass-forming ability of iron-based amorphous alloys, with even 100 ppm differences altering the critical cooling rate by an order of magnitude. Similarly, trace contaminants from production equipment can serve as heterogeneous nucleation sites, promoting unwanted crystallization.

Scale-up challenges remain significant in amorphous metal manufacturing. The critical cooling rate requirement creates fundamental limitations on section thickness, with most commercial amorphous metals restricted to thicknesses below 10mm. Recent innovations in electromagnetic levitation melting show promise for producing larger amorphous components by eliminating container-induced nucleation sites, potentially expanding industrial applications beyond current limitations.

Sustainability Aspects of Amorphous Metal Production

The production of amorphous metals presents both environmental challenges and sustainability opportunities that warrant careful consideration in industrial applications. Traditional metal manufacturing processes are energy-intensive, with high carbon footprints due to the extreme temperatures required for melting and processing. In contrast, amorphous metal production can offer significant energy savings, particularly when utilizing rapid solidification techniques that require less thermal energy than conventional crystalline metal processing.

The composition of alloys directly impacts the sustainability profile of amorphous metals. Research indicates that zirconium-based bulk metallic glasses can be produced with lower melting temperatures than their crystalline counterparts, reducing energy consumption by up to 30% in some manufacturing scenarios. Similarly, iron-based amorphous alloys containing phosphorus, boron, and silicon demonstrate improved energy efficiency during production while maintaining exceptional magnetic properties.

Material efficiency represents another critical sustainability aspect. Amorphous metals typically exhibit superior wear resistance and corrosion resistance compared to crystalline alternatives, potentially extending product lifecycles and reducing replacement frequency. For instance, iron-aluminum-based amorphous alloys show corrosion rates approximately 100 times lower than conventional stainless steels in certain environments, significantly reducing material consumption over time.

Recycling considerations are increasingly important in amorphous metal production. The homogeneous structure of these materials can theoretically facilitate recycling processes, though specialized techniques may be required due to their unique properties. Recent studies demonstrate that palladium-based bulk metallic glasses can be recycled multiple times while maintaining over 90% of their original mechanical properties, presenting opportunities for closed-loop manufacturing systems.

Environmental toxicity concerns arise with certain amorphous metal compositions. Beryllium-containing alloys, while offering exceptional glass-forming ability, present significant health and environmental hazards. Alternative compositions utilizing less toxic elements like titanium and zirconium are being developed to address these concerns while maintaining desirable material properties.

Water usage in amorphous metal production presents another sustainability challenge. Rapid quenching techniques often require substantial cooling resources, though innovations in gas-atomization processes have reduced water requirements by up to 40% compared to traditional methods. Additionally, closed-loop cooling systems are increasingly being implemented to minimize water consumption and prevent contamination of local water sources.

The composition of alloys directly impacts the sustainability profile of amorphous metals. Research indicates that zirconium-based bulk metallic glasses can be produced with lower melting temperatures than their crystalline counterparts, reducing energy consumption by up to 30% in some manufacturing scenarios. Similarly, iron-based amorphous alloys containing phosphorus, boron, and silicon demonstrate improved energy efficiency during production while maintaining exceptional magnetic properties.

Material efficiency represents another critical sustainability aspect. Amorphous metals typically exhibit superior wear resistance and corrosion resistance compared to crystalline alternatives, potentially extending product lifecycles and reducing replacement frequency. For instance, iron-aluminum-based amorphous alloys show corrosion rates approximately 100 times lower than conventional stainless steels in certain environments, significantly reducing material consumption over time.

Recycling considerations are increasingly important in amorphous metal production. The homogeneous structure of these materials can theoretically facilitate recycling processes, though specialized techniques may be required due to their unique properties. Recent studies demonstrate that palladium-based bulk metallic glasses can be recycled multiple times while maintaining over 90% of their original mechanical properties, presenting opportunities for closed-loop manufacturing systems.

Environmental toxicity concerns arise with certain amorphous metal compositions. Beryllium-containing alloys, while offering exceptional glass-forming ability, present significant health and environmental hazards. Alternative compositions utilizing less toxic elements like titanium and zirconium are being developed to address these concerns while maintaining desirable material properties.

Water usage in amorphous metal production presents another sustainability challenge. Rapid quenching techniques often require substantial cooling resources, though innovations in gas-atomization processes have reduced water requirements by up to 40% compared to traditional methods. Additionally, closed-loop cooling systems are increasingly being implemented to minimize water consumption and prevent contamination of local water sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!