The Impact of Flame Stability on Gas Weld Integrity

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flame Stability Fundamentals and Objectives

Flame stability is a critical factor in gas welding processes, significantly influencing the quality and integrity of the resulting welds. The concept of flame stability encompasses the consistent and controlled combustion of fuel gases and oxygen, which is essential for maintaining a steady heat source during welding operations. Over the years, the understanding of flame stability has evolved from empirical observations to a more scientific approach, incorporating principles of fluid dynamics, thermodynamics, and combustion chemistry.

The primary objective in studying flame stability is to optimize welding processes for improved weld quality, increased productivity, and enhanced safety. By achieving a stable flame, welders can ensure uniform heat distribution, precise temperature control, and consistent penetration depth, all of which are crucial for producing high-integrity welds. Furthermore, a stable flame reduces the likelihood of defects such as porosity, lack of fusion, and inconsistent bead geometry.

Recent technological advancements have led to the development of sophisticated monitoring and control systems that can detect and adjust flame characteristics in real-time. These innovations aim to maintain optimal flame stability across various welding conditions, materials, and gas compositions. The integration of sensors, data analytics, and adaptive control algorithms represents a significant leap forward in addressing the challenges associated with flame stability.

One of the key trends in flame stability research is the exploration of alternative fuel gases and gas mixtures. This includes investigating the use of hydrogen-enriched fuels, which offer potential benefits in terms of flame temperature control and reduced environmental impact. Additionally, researchers are examining the effects of gas flow dynamics on flame stability, seeking to develop nozzle designs and gas delivery systems that promote more stable and efficient combustion.

The impact of flame stability on gas weld integrity extends beyond the immediate welding process. It influences the microstructure of the weld and heat-affected zone, affecting the mechanical properties and long-term performance of welded components. As industries push for lighter, stronger, and more complex structures, the demands on weld quality continue to increase, making flame stability an ever more critical area of study.

Looking ahead, the objectives in flame stability research include developing predictive models that can anticipate and prevent instabilities before they occur, creating adaptive welding systems that can maintain optimal flame characteristics across a wide range of operating conditions, and integrating flame stability control into broader manufacturing automation and Industry 4.0 initiatives. These advancements promise to enhance weld quality, reduce defects, and improve overall manufacturing efficiency in industries ranging from automotive and aerospace to energy and construction.

The primary objective in studying flame stability is to optimize welding processes for improved weld quality, increased productivity, and enhanced safety. By achieving a stable flame, welders can ensure uniform heat distribution, precise temperature control, and consistent penetration depth, all of which are crucial for producing high-integrity welds. Furthermore, a stable flame reduces the likelihood of defects such as porosity, lack of fusion, and inconsistent bead geometry.

Recent technological advancements have led to the development of sophisticated monitoring and control systems that can detect and adjust flame characteristics in real-time. These innovations aim to maintain optimal flame stability across various welding conditions, materials, and gas compositions. The integration of sensors, data analytics, and adaptive control algorithms represents a significant leap forward in addressing the challenges associated with flame stability.

One of the key trends in flame stability research is the exploration of alternative fuel gases and gas mixtures. This includes investigating the use of hydrogen-enriched fuels, which offer potential benefits in terms of flame temperature control and reduced environmental impact. Additionally, researchers are examining the effects of gas flow dynamics on flame stability, seeking to develop nozzle designs and gas delivery systems that promote more stable and efficient combustion.

The impact of flame stability on gas weld integrity extends beyond the immediate welding process. It influences the microstructure of the weld and heat-affected zone, affecting the mechanical properties and long-term performance of welded components. As industries push for lighter, stronger, and more complex structures, the demands on weld quality continue to increase, making flame stability an ever more critical area of study.

Looking ahead, the objectives in flame stability research include developing predictive models that can anticipate and prevent instabilities before they occur, creating adaptive welding systems that can maintain optimal flame characteristics across a wide range of operating conditions, and integrating flame stability control into broader manufacturing automation and Industry 4.0 initiatives. These advancements promise to enhance weld quality, reduce defects, and improve overall manufacturing efficiency in industries ranging from automotive and aerospace to energy and construction.

Gas Welding Market Analysis

The gas welding market has experienced steady growth over the past decade, driven by increasing demand in various industrial sectors. The global gas welding equipment market was valued at approximately $5.2 billion in 2020 and is projected to reach $7.1 billion by 2026, growing at a CAGR of 5.3% during the forecast period. This growth is primarily attributed to the expanding construction, automotive, and manufacturing industries, particularly in emerging economies.

The market for gas welding is segmented based on equipment type, application, and geography. Equipment types include cylinders, torches, regulators, and accessories. Applications span across construction, automotive, aerospace, shipbuilding, and general fabrication. Geographically, Asia-Pacific dominates the market, followed by North America and Europe.

Key factors driving market growth include the increasing adoption of automation in welding processes, rising demand for lightweight materials in automotive and aerospace industries, and ongoing infrastructure development projects worldwide. However, the market faces challenges such as stringent safety regulations, environmental concerns related to gas emissions, and competition from alternative welding technologies like arc welding and laser welding.

The impact of flame stability on gas weld integrity is a critical factor influencing market dynamics. As industries demand higher quality welds and improved productivity, there is a growing focus on developing advanced gas welding equipment that ensures consistent flame stability. This trend is driving innovation among manufacturers, leading to the introduction of new products with enhanced flame control features.

Market players are investing in research and development to address the challenges associated with flame stability. This includes the development of advanced gas mixing systems, improved nozzle designs, and intelligent control mechanisms. These innovations aim to minimize fluctuations in flame characteristics, resulting in more precise and reliable welds.

The emphasis on flame stability is also influencing customer preferences and purchasing decisions. End-users are increasingly prioritizing equipment that offers superior flame control and stability, even if it comes at a higher initial cost. This shift is reshaping the competitive landscape, with manufacturers focusing on product differentiation based on flame stability performance.

Furthermore, the growing awareness of the relationship between flame stability and weld integrity is driving demand for training and skill development programs in the gas welding industry. This trend is creating new opportunities for training service providers and contributing to the overall market growth.

The market for gas welding is segmented based on equipment type, application, and geography. Equipment types include cylinders, torches, regulators, and accessories. Applications span across construction, automotive, aerospace, shipbuilding, and general fabrication. Geographically, Asia-Pacific dominates the market, followed by North America and Europe.

Key factors driving market growth include the increasing adoption of automation in welding processes, rising demand for lightweight materials in automotive and aerospace industries, and ongoing infrastructure development projects worldwide. However, the market faces challenges such as stringent safety regulations, environmental concerns related to gas emissions, and competition from alternative welding technologies like arc welding and laser welding.

The impact of flame stability on gas weld integrity is a critical factor influencing market dynamics. As industries demand higher quality welds and improved productivity, there is a growing focus on developing advanced gas welding equipment that ensures consistent flame stability. This trend is driving innovation among manufacturers, leading to the introduction of new products with enhanced flame control features.

Market players are investing in research and development to address the challenges associated with flame stability. This includes the development of advanced gas mixing systems, improved nozzle designs, and intelligent control mechanisms. These innovations aim to minimize fluctuations in flame characteristics, resulting in more precise and reliable welds.

The emphasis on flame stability is also influencing customer preferences and purchasing decisions. End-users are increasingly prioritizing equipment that offers superior flame control and stability, even if it comes at a higher initial cost. This shift is reshaping the competitive landscape, with manufacturers focusing on product differentiation based on flame stability performance.

Furthermore, the growing awareness of the relationship between flame stability and weld integrity is driving demand for training and skill development programs in the gas welding industry. This trend is creating new opportunities for training service providers and contributing to the overall market growth.

Flame Stability Challenges in Gas Welding

Gas welding, a critical process in various industries, heavily relies on flame stability for ensuring weld integrity. However, achieving and maintaining stable flames presents significant challenges that can compromise the quality and reliability of welds. One of the primary issues is the sensitivity of flame stability to environmental factors such as wind, temperature fluctuations, and atmospheric pressure changes. These external influences can disrupt the delicate balance of fuel and oxidizer, leading to inconsistent flame characteristics.

Another challenge lies in the variability of gas flow rates and pressures. Fluctuations in gas supply can result in unstable flames, causing irregular heat distribution and potentially leading to defects in the weld. This issue is particularly pronounced in portable welding setups or in environments where gas supply infrastructure is not optimal. Additionally, the design and condition of welding nozzles play a crucial role in flame stability. Worn or improperly maintained nozzles can cause turbulent gas flow, resulting in erratic flame behavior.

The composition and purity of welding gases also present challenges to flame stability. Contaminants or variations in gas mixtures can alter flame characteristics, affecting both the temperature and the chemical reactions occurring at the weld site. This can lead to inconsistent weld quality and potentially introduce impurities into the weld pool. Furthermore, the skill level of the welder is a significant factor in maintaining flame stability. Proper technique and experience are essential for adjusting the flame and responding to changes in welding conditions.

Flame stability is also affected by the properties of the materials being welded. Different metals and alloys may require specific flame characteristics for optimal welding, and maintaining these precise conditions consistently throughout the welding process can be challenging. The geometry of the workpiece can further complicate flame stability, especially when welding in confined spaces or at awkward angles.

Technological limitations in current gas welding equipment contribute to flame stability challenges. Many systems lack advanced sensors and real-time adjustment capabilities that could help maintain optimal flame conditions. The development of more sophisticated control systems and adaptive technologies represents a significant area for improvement in addressing flame stability issues.

Lastly, the interaction between flame stability and weld pool dynamics presents complex challenges. An unstable flame can cause turbulence in the weld pool, leading to porosity, inclusions, and other defects that compromise weld integrity. Understanding and controlling these interactions requires advanced modeling and experimental techniques, which are areas of ongoing research and development in the field of gas welding.

Another challenge lies in the variability of gas flow rates and pressures. Fluctuations in gas supply can result in unstable flames, causing irregular heat distribution and potentially leading to defects in the weld. This issue is particularly pronounced in portable welding setups or in environments where gas supply infrastructure is not optimal. Additionally, the design and condition of welding nozzles play a crucial role in flame stability. Worn or improperly maintained nozzles can cause turbulent gas flow, resulting in erratic flame behavior.

The composition and purity of welding gases also present challenges to flame stability. Contaminants or variations in gas mixtures can alter flame characteristics, affecting both the temperature and the chemical reactions occurring at the weld site. This can lead to inconsistent weld quality and potentially introduce impurities into the weld pool. Furthermore, the skill level of the welder is a significant factor in maintaining flame stability. Proper technique and experience are essential for adjusting the flame and responding to changes in welding conditions.

Flame stability is also affected by the properties of the materials being welded. Different metals and alloys may require specific flame characteristics for optimal welding, and maintaining these precise conditions consistently throughout the welding process can be challenging. The geometry of the workpiece can further complicate flame stability, especially when welding in confined spaces or at awkward angles.

Technological limitations in current gas welding equipment contribute to flame stability challenges. Many systems lack advanced sensors and real-time adjustment capabilities that could help maintain optimal flame conditions. The development of more sophisticated control systems and adaptive technologies represents a significant area for improvement in addressing flame stability issues.

Lastly, the interaction between flame stability and weld pool dynamics presents complex challenges. An unstable flame can cause turbulence in the weld pool, leading to porosity, inclusions, and other defects that compromise weld integrity. Understanding and controlling these interactions requires advanced modeling and experimental techniques, which are areas of ongoing research and development in the field of gas welding.

Current Flame Stabilization Techniques

01 Non-destructive testing methods for gas weld integrity

Various non-destructive testing methods are employed to assess gas weld integrity without damaging the welded components. These methods include ultrasonic testing, radiographic inspection, and acoustic emission monitoring. These techniques allow for the detection of defects, cracks, or inconsistencies in the weld structure, ensuring the quality and safety of gas welds.- Non-destructive testing methods for gas weld integrity: Various non-destructive testing methods are employed to assess gas weld integrity without damaging the welded components. These methods include ultrasonic testing, radiographic inspection, and acoustic emission monitoring. These techniques allow for the detection of defects, cracks, or inconsistencies in the weld structure, ensuring the quality and safety of gas welds.

- Automated welding systems for improved gas weld integrity: Advanced automated welding systems are developed to enhance gas weld integrity. These systems incorporate precision control mechanisms, real-time monitoring, and adaptive algorithms to maintain consistent weld quality. By minimizing human error and optimizing welding parameters, automated systems significantly improve the reliability and integrity of gas welds.

- Weld joint design optimization for gas weld integrity: Optimizing weld joint designs is crucial for ensuring gas weld integrity. This involves careful consideration of factors such as joint geometry, material properties, and stress distribution. Advanced modeling and simulation techniques are used to analyze and improve joint designs, resulting in stronger and more durable gas welds.

- Post-weld heat treatment for enhancing gas weld integrity: Post-weld heat treatment processes are employed to improve the integrity of gas welds. These treatments help relieve residual stresses, refine grain structures, and enhance the overall mechanical properties of the welded joint. Proper heat treatment procedures can significantly increase the longevity and reliability of gas welds in various applications.

- In-situ monitoring and quality control for gas weld integrity: Advanced in-situ monitoring and quality control systems are developed to ensure gas weld integrity during the welding process. These systems utilize sensors, real-time data analysis, and machine learning algorithms to detect and correct potential issues as they occur. By providing immediate feedback and adjustments, these technologies significantly improve the consistency and reliability of gas welds.

02 Automated welding systems for improved gas weld integrity

Advanced automated welding systems are developed to enhance gas weld integrity. These systems incorporate precision control mechanisms, real-time monitoring, and adaptive algorithms to maintain consistent weld quality. By minimizing human error and optimizing welding parameters, automated systems significantly improve the reliability and integrity of gas welds.Expand Specific Solutions03 Weld joint design optimization for gas weld integrity

Optimizing weld joint design is crucial for ensuring gas weld integrity. This involves careful consideration of factors such as joint geometry, material properties, and stress distribution. Advanced modeling and simulation techniques are used to analyze and improve joint designs, resulting in stronger and more durable gas welds.Expand Specific Solutions04 Post-weld heat treatment for enhancing gas weld integrity

Post-weld heat treatment processes are employed to improve the integrity of gas welds. These treatments help relieve residual stresses, refine grain structure, and enhance the mechanical properties of the welded joint. Controlled heating and cooling cycles are applied to optimize the microstructure and overall strength of the gas weld.Expand Specific Solutions05 In-situ monitoring and quality control of gas welds

Advanced in-situ monitoring and quality control techniques are developed to ensure gas weld integrity during the welding process. These methods involve real-time data acquisition, analysis of welding parameters, and immediate feedback systems. By detecting and correcting deviations in real-time, these techniques significantly improve the consistency and reliability of gas welds.Expand Specific Solutions

Key Gas Welding Equipment Manufacturers

The flame stability in gas welding is a critical factor in the integrity of welds, with the market for related technologies and solutions evolving rapidly. The industry is in a growth phase, driven by increasing demand for high-quality welding in sectors like automotive, aerospace, and construction. The global market size for welding equipment and consumables is projected to reach significant figures in the coming years. Technologically, advancements are being made by key players such as Air Liquide SA, Siemens AG, and Daihen Corp., who are investing in research and development to improve flame stability and weld quality. These companies are focusing on innovative solutions like advanced gas mixtures, digital control systems, and AI-powered welding equipment to address the challenges of flame stability and enhance overall weld integrity.

Air Liquide SA

Technical Solution: Air Liquide SA has pioneered a comprehensive approach to flame stability in gas welding, focusing on both gas composition and delivery systems. Their ARCAL™ range of shielding gases is specifically engineered to provide superior arc stability and weld pool control[2]. For flame stability in gas welding, they have developed a proprietary gas mixing technology that ensures precise and consistent gas ratios. This system incorporates advanced flow controllers and real-time monitoring to maintain optimal flame characteristics. Additionally, Air Liquide has introduced smart gas management systems that can predict and prevent potential instabilities before they occur, significantly improving overall weld integrity[4].

Strengths: Comprehensive gas solutions, from composition to delivery systems, and predictive maintenance capabilities. Weaknesses: May require specialized training for operators to fully utilize the advanced features.

Siemens AG

Technical Solution: Siemens AG has developed advanced flame stability control systems for gas welding applications. Their technology utilizes real-time monitoring and adaptive control algorithms to maintain optimal flame characteristics throughout the welding process. The system employs high-precision sensors to measure key parameters such as gas flow rates, pressure, and temperature[1]. This data is then processed by a sophisticated control unit that dynamically adjusts the gas mixture and flow to ensure consistent flame stability. Siemens has also integrated machine learning capabilities into their system, allowing it to adapt to different welding conditions and materials over time, further enhancing weld integrity[3].

Strengths: Highly adaptive and precise control, integration with existing industrial systems, and continuous improvement through machine learning. Weaknesses: Potentially higher initial cost and complexity compared to traditional systems.

Innovative Flame Control Methods

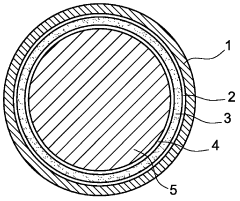

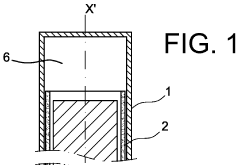

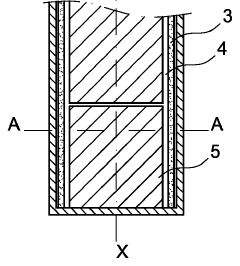

Solid interface joint with open porosity, for nuclear fuel rod

PatentWO2011157780A1

Innovation

- A solid interface gasket with open porosity is introduced, providing mechanical decoupling and high thermal conductivity while allowing for volume expansion and deformation under irradiation, ensuring efficient heat transfer and fission gas transport without excessive mechanical loading, and maintaining chemical compatibility with the cladding and fuel.

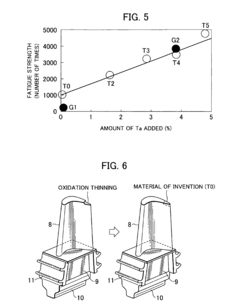

Ni-based alloy member, method of producing the alloy member, turbine engine part, welding material, and method of producing the welding material

PatentActiveEP1717326A2

Innovation

- A Ni-based alloy with specific compositions (15% Co or less, 18-22% Cr, 0.8-2.0% Al, 5.0% or less Ta, 0.5% or less Mo, 13-18% W, 0.05-0.13% C, 0.06% or less Zr, 0.015% or less B, 0.4-1.2% Mn, and 0.1-0.3% Si) is developed for the buildup-welded layer, which is produced using vacuum smelting and casting, followed by hot and cold plastic working, to enhance oxidation resistance and fatigue strength.

Safety Standards in Gas Welding

Safety standards in gas welding play a crucial role in ensuring the integrity of welds and protecting workers from potential hazards. These standards are developed and enforced by various regulatory bodies and industry organizations to establish best practices and minimize risks associated with gas welding processes.

One of the primary safety standards in gas welding focuses on proper equipment maintenance and inspection. Regular checks of welding torches, hoses, regulators, and cylinders are mandated to prevent leaks, malfunctions, or equipment failures that could compromise weld quality or worker safety. Specific guidelines are provided for the storage, handling, and transportation of gas cylinders to prevent accidents and ensure their proper use.

Personal protective equipment (PPE) requirements form another essential aspect of safety standards in gas welding. Welders are required to wear appropriate eye protection, such as welding helmets or goggles with the correct shade of filter lens, to shield their eyes from harmful radiation and flying debris. Heat-resistant gloves, flame-resistant clothing, and safety shoes are also mandatory to protect against burns and other injuries.

Ventilation standards are critical in gas welding operations to prevent the accumulation of harmful fumes and gases. Adequate ventilation systems or local exhaust ventilation must be in place to remove welding fumes and maintain air quality within acceptable limits. Regular air quality monitoring may be required in enclosed spaces to ensure compliance with exposure limits for various gases and particulates.

Fire prevention measures are integral to gas welding safety standards. Welding areas must be cleared of flammable materials, and fire-resistant screens or curtains should be used to contain sparks and spatter. Fire extinguishers must be readily available, and welders should be trained in their proper use. Some standards may require a fire watch to be present during and after welding operations in high-risk areas.

Training and certification requirements for welders are also outlined in safety standards. Welders must demonstrate proficiency in proper welding techniques, equipment operation, and safety procedures. Regular refresher training may be mandated to ensure ongoing compliance and awareness of updated safety protocols.

Emergency response procedures are another critical component of gas welding safety standards. Clear guidelines for handling gas leaks, fires, or other emergencies must be established and communicated to all personnel. This includes evacuation plans, emergency shut-off procedures, and protocols for contacting emergency services.

Compliance with these safety standards is essential not only for protecting workers but also for ensuring the quality and integrity of gas welds. By adhering to these guidelines, organizations can minimize the risk of accidents, improve weld quality, and maintain a safe and productive welding environment.

One of the primary safety standards in gas welding focuses on proper equipment maintenance and inspection. Regular checks of welding torches, hoses, regulators, and cylinders are mandated to prevent leaks, malfunctions, or equipment failures that could compromise weld quality or worker safety. Specific guidelines are provided for the storage, handling, and transportation of gas cylinders to prevent accidents and ensure their proper use.

Personal protective equipment (PPE) requirements form another essential aspect of safety standards in gas welding. Welders are required to wear appropriate eye protection, such as welding helmets or goggles with the correct shade of filter lens, to shield their eyes from harmful radiation and flying debris. Heat-resistant gloves, flame-resistant clothing, and safety shoes are also mandatory to protect against burns and other injuries.

Ventilation standards are critical in gas welding operations to prevent the accumulation of harmful fumes and gases. Adequate ventilation systems or local exhaust ventilation must be in place to remove welding fumes and maintain air quality within acceptable limits. Regular air quality monitoring may be required in enclosed spaces to ensure compliance with exposure limits for various gases and particulates.

Fire prevention measures are integral to gas welding safety standards. Welding areas must be cleared of flammable materials, and fire-resistant screens or curtains should be used to contain sparks and spatter. Fire extinguishers must be readily available, and welders should be trained in their proper use. Some standards may require a fire watch to be present during and after welding operations in high-risk areas.

Training and certification requirements for welders are also outlined in safety standards. Welders must demonstrate proficiency in proper welding techniques, equipment operation, and safety procedures. Regular refresher training may be mandated to ensure ongoing compliance and awareness of updated safety protocols.

Emergency response procedures are another critical component of gas welding safety standards. Clear guidelines for handling gas leaks, fires, or other emergencies must be established and communicated to all personnel. This includes evacuation plans, emergency shut-off procedures, and protocols for contacting emergency services.

Compliance with these safety standards is essential not only for protecting workers but also for ensuring the quality and integrity of gas welds. By adhering to these guidelines, organizations can minimize the risk of accidents, improve weld quality, and maintain a safe and productive welding environment.

Environmental Impact of Gas Welding Processes

Gas welding processes, while effective for many applications, have significant environmental impacts that warrant careful consideration. The combustion of fuel gases, typically acetylene or propane, with oxygen produces various emissions that can affect air quality and contribute to climate change. Carbon dioxide, a primary greenhouse gas, is a major byproduct of the welding flame. Additionally, nitrogen oxides and volatile organic compounds are released, which can lead to the formation of ground-level ozone and smog.

The welding process also generates particulate matter, including metal fumes and dust, which can have detrimental effects on both human health and the environment. These particles can remain suspended in the air for extended periods, potentially causing respiratory issues for workers and nearby communities. Moreover, the dispersion of these particles can lead to soil and water contamination, affecting local ecosystems.

Energy consumption is another critical environmental aspect of gas welding. The production and transportation of fuel gases and oxygen require substantial energy inputs, contributing to the overall carbon footprint of the welding process. Furthermore, the inefficient use of gases during welding, particularly when flame stability is compromised, can lead to increased fuel consumption and, consequently, higher emissions.

Waste generation is an often-overlooked environmental impact of gas welding. Spent welding rods, slag, and other consumables contribute to solid waste streams. Improper disposal of these materials can lead to soil and water pollution, particularly if they contain hazardous elements such as heavy metals.

The impact of flame stability on weld integrity is closely linked to environmental concerns. Unstable flames can result in incomplete combustion, leading to increased emissions of carbon monoxide and unburned hydrocarbons. Additionally, poor flame control may necessitate rework, which multiplies the environmental impact through increased material and energy consumption.

To mitigate these environmental impacts, the welding industry is exploring several avenues. The development of more efficient burner designs and improved gas flow control systems can enhance flame stability, reducing emissions and improving weld quality. Additionally, the adoption of alternative fuel gases with lower carbon content, such as hydrogen, is being investigated to reduce greenhouse gas emissions.

The welding process also generates particulate matter, including metal fumes and dust, which can have detrimental effects on both human health and the environment. These particles can remain suspended in the air for extended periods, potentially causing respiratory issues for workers and nearby communities. Moreover, the dispersion of these particles can lead to soil and water contamination, affecting local ecosystems.

Energy consumption is another critical environmental aspect of gas welding. The production and transportation of fuel gases and oxygen require substantial energy inputs, contributing to the overall carbon footprint of the welding process. Furthermore, the inefficient use of gases during welding, particularly when flame stability is compromised, can lead to increased fuel consumption and, consequently, higher emissions.

Waste generation is an often-overlooked environmental impact of gas welding. Spent welding rods, slag, and other consumables contribute to solid waste streams. Improper disposal of these materials can lead to soil and water pollution, particularly if they contain hazardous elements such as heavy metals.

The impact of flame stability on weld integrity is closely linked to environmental concerns. Unstable flames can result in incomplete combustion, leading to increased emissions of carbon monoxide and unburned hydrocarbons. Additionally, poor flame control may necessitate rework, which multiplies the environmental impact through increased material and energy consumption.

To mitigate these environmental impacts, the welding industry is exploring several avenues. The development of more efficient burner designs and improved gas flow control systems can enhance flame stability, reducing emissions and improving weld quality. Additionally, the adoption of alternative fuel gases with lower carbon content, such as hydrogen, is being investigated to reduce greenhouse gas emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!