The Impact of Plate Heat Exchanger Geometry on Heat Transfer

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Geometry Evolution

The evolution of plate heat exchanger (PHE) geometry has been a critical factor in enhancing heat transfer efficiency over the years. Initially, PHEs featured simple flat plates with basic corrugations. These early designs provided limited heat transfer surface area and relatively low turbulence, resulting in modest heat transfer coefficients.

As research progressed, engineers recognized the potential for improvement through geometric modifications. The introduction of chevron patterns in the 1960s marked a significant milestone. These V-shaped corrugations increased turbulence and expanded the effective heat transfer area, leading to substantial performance gains. The angle and depth of chevron patterns became key parameters for optimization, with steeper angles generally promoting higher heat transfer rates at the cost of increased pressure drop.

In the 1980s and 1990s, more complex geometries emerged. Manufacturers began experimenting with asymmetrical plate designs, where the corrugation patterns on opposite sides of a plate differed. This approach allowed for fine-tuning of heat transfer and pressure drop characteristics. Additionally, mixed chevron angles within a single plate became common, offering a balance between heat transfer enhancement and manageable pressure losses.

The turn of the millennium saw the advent of advanced manufacturing techniques, enabling the creation of intricate surface textures. Dimpled surfaces, wavy patterns, and protrusions were incorporated to further disrupt fluid flow and promote local turbulence. These features, often on a micro-scale, proved effective in boosting heat transfer without excessive pressure penalties.

Recent years have witnessed the exploration of biomimetic designs, inspired by natural structures known for efficient heat exchange. Plate geometries mimicking the vascular networks of leaves or the gill structures of fish have shown promise in laboratory settings. These bio-inspired designs aim to optimize fluid distribution and maximize heat transfer surface area within compact volumes.

Computational fluid dynamics (CFD) and advanced simulation tools have played a crucial role in this evolutionary process. They have allowed designers to model and predict the performance of complex geometries before physical prototyping, accelerating the development cycle. Machine learning algorithms are now being employed to generate and evaluate novel plate geometries, pushing the boundaries of conventional design thinking.

The ongoing evolution of PHE geometry continues to focus on achieving an optimal balance between heat transfer enhancement, pressure drop minimization, and fouling resistance. As energy efficiency and compact design become increasingly important, the quest for innovative plate geometries remains a dynamic area of research and development in the field of heat exchanger technology.

As research progressed, engineers recognized the potential for improvement through geometric modifications. The introduction of chevron patterns in the 1960s marked a significant milestone. These V-shaped corrugations increased turbulence and expanded the effective heat transfer area, leading to substantial performance gains. The angle and depth of chevron patterns became key parameters for optimization, with steeper angles generally promoting higher heat transfer rates at the cost of increased pressure drop.

In the 1980s and 1990s, more complex geometries emerged. Manufacturers began experimenting with asymmetrical plate designs, where the corrugation patterns on opposite sides of a plate differed. This approach allowed for fine-tuning of heat transfer and pressure drop characteristics. Additionally, mixed chevron angles within a single plate became common, offering a balance between heat transfer enhancement and manageable pressure losses.

The turn of the millennium saw the advent of advanced manufacturing techniques, enabling the creation of intricate surface textures. Dimpled surfaces, wavy patterns, and protrusions were incorporated to further disrupt fluid flow and promote local turbulence. These features, often on a micro-scale, proved effective in boosting heat transfer without excessive pressure penalties.

Recent years have witnessed the exploration of biomimetic designs, inspired by natural structures known for efficient heat exchange. Plate geometries mimicking the vascular networks of leaves or the gill structures of fish have shown promise in laboratory settings. These bio-inspired designs aim to optimize fluid distribution and maximize heat transfer surface area within compact volumes.

Computational fluid dynamics (CFD) and advanced simulation tools have played a crucial role in this evolutionary process. They have allowed designers to model and predict the performance of complex geometries before physical prototyping, accelerating the development cycle. Machine learning algorithms are now being employed to generate and evaluate novel plate geometries, pushing the boundaries of conventional design thinking.

The ongoing evolution of PHE geometry continues to focus on achieving an optimal balance between heat transfer enhancement, pressure drop minimization, and fouling resistance. As energy efficiency and compact design become increasingly important, the quest for innovative plate geometries remains a dynamic area of research and development in the field of heat exchanger technology.

Heat Transfer Market Needs

The heat transfer market is experiencing significant growth driven by increasing demand for energy-efficient solutions across various industries. As environmental concerns and energy costs continue to rise, there is a growing need for advanced heat transfer technologies, particularly in plate heat exchangers. These devices are crucial in numerous applications, including HVAC systems, chemical processing, food and beverage production, and power generation.

The market for plate heat exchangers is expanding rapidly, with a projected compound annual growth rate of 7.8% from 2021 to 2026. This growth is fueled by the need for compact, efficient, and cost-effective heat transfer solutions. Industries are increasingly recognizing the benefits of plate heat exchangers over traditional shell and tube designs, including their ability to handle high-pressure applications and their superior heat transfer coefficients.

In the HVAC sector, there is a strong demand for plate heat exchangers that can improve energy efficiency in buildings. With stricter energy regulations and a focus on sustainable construction, HVAC systems require heat exchangers that can maximize heat recovery and minimize energy consumption. This has led to a surge in research and development efforts to optimize plate heat exchanger geometry for enhanced performance.

The food and beverage industry is another key driver of market growth, with increasing emphasis on food safety and process efficiency. Plate heat exchangers are preferred in this sector due to their ability to maintain product quality and extend shelf life through precise temperature control. There is a growing need for designs that can handle viscous fluids and particulate-laden streams while minimizing fouling and ensuring easy cleanability.

In the chemical processing industry, there is a demand for plate heat exchangers that can withstand corrosive environments and high temperatures. Manufacturers are seeking innovative geometries that can enhance heat transfer rates while maintaining structural integrity under extreme conditions. This has spurred research into advanced materials and surface treatments that can improve the durability and efficiency of plate heat exchangers.

The power generation sector is also driving market needs, particularly in renewable energy applications such as geothermal power plants. There is a growing demand for plate heat exchangers that can efficiently transfer heat from low-temperature geothermal fluids, necessitating designs that can maximize heat transfer even with small temperature differentials.

As industries strive for greater sustainability and energy efficiency, there is an increasing focus on the development of plate heat exchangers with reduced material usage and lower manufacturing costs. This has led to a surge in research on optimizing plate geometries to achieve higher heat transfer rates with less material, thereby reducing both production costs and environmental impact.

The market for plate heat exchangers is expanding rapidly, with a projected compound annual growth rate of 7.8% from 2021 to 2026. This growth is fueled by the need for compact, efficient, and cost-effective heat transfer solutions. Industries are increasingly recognizing the benefits of plate heat exchangers over traditional shell and tube designs, including their ability to handle high-pressure applications and their superior heat transfer coefficients.

In the HVAC sector, there is a strong demand for plate heat exchangers that can improve energy efficiency in buildings. With stricter energy regulations and a focus on sustainable construction, HVAC systems require heat exchangers that can maximize heat recovery and minimize energy consumption. This has led to a surge in research and development efforts to optimize plate heat exchanger geometry for enhanced performance.

The food and beverage industry is another key driver of market growth, with increasing emphasis on food safety and process efficiency. Plate heat exchangers are preferred in this sector due to their ability to maintain product quality and extend shelf life through precise temperature control. There is a growing need for designs that can handle viscous fluids and particulate-laden streams while minimizing fouling and ensuring easy cleanability.

In the chemical processing industry, there is a demand for plate heat exchangers that can withstand corrosive environments and high temperatures. Manufacturers are seeking innovative geometries that can enhance heat transfer rates while maintaining structural integrity under extreme conditions. This has spurred research into advanced materials and surface treatments that can improve the durability and efficiency of plate heat exchangers.

The power generation sector is also driving market needs, particularly in renewable energy applications such as geothermal power plants. There is a growing demand for plate heat exchangers that can efficiently transfer heat from low-temperature geothermal fluids, necessitating designs that can maximize heat transfer even with small temperature differentials.

As industries strive for greater sustainability and energy efficiency, there is an increasing focus on the development of plate heat exchangers with reduced material usage and lower manufacturing costs. This has led to a surge in research on optimizing plate geometries to achieve higher heat transfer rates with less material, thereby reducing both production costs and environmental impact.

PHE Design Challenges

Plate heat exchangers (PHEs) have become increasingly popular in various industries due to their compact design and high efficiency. However, designing an optimal PHE geometry presents several challenges that engineers must overcome to maximize heat transfer performance while minimizing pressure drop and fouling.

One of the primary challenges in PHE design is balancing the trade-off between heat transfer enhancement and pressure drop. As the plate geometry becomes more complex with features like corrugations, chevrons, or dimples, the heat transfer coefficient typically increases. However, these same features also lead to higher pressure drops, which can result in increased pumping power requirements and operational costs. Engineers must carefully optimize the plate geometry to find the sweet spot that provides the best overall performance for a given application.

Another significant challenge is the prevention of flow maldistribution within the PHE. Uneven flow distribution can lead to reduced thermal performance and increased fouling in certain areas of the exchanger. Designing inlet and outlet port configurations, as well as plate patterns that promote uniform flow distribution across the entire heat transfer surface, is crucial for maintaining high efficiency and prolonging the operational life of the PHE.

Fouling mitigation is also a critical aspect of PHE design. The accumulation of deposits on heat transfer surfaces can significantly reduce thermal performance and increase pressure drop over time. While certain geometries may enhance heat transfer, they may also promote fouling by creating low-velocity zones or increasing surface roughness. Designers must consider the trade-offs between heat transfer enhancement and fouling propensity when selecting plate geometries for specific applications.

Material selection and manufacturing constraints pose additional challenges in PHE design. The complex geometries required for optimal heat transfer often push the limits of manufacturing capabilities, especially for materials with high thermal conductivity but poor formability. Balancing the desired thermal performance with manufacturability and cost-effectiveness is a constant challenge for PHE designers.

Thermal stress and fatigue are also important considerations in PHE design, particularly for applications with large temperature differentials or frequent thermal cycling. The plate geometry must be designed to accommodate thermal expansion and contraction while maintaining structural integrity and preventing leaks at the gasket interfaces.

Lastly, the optimization of PHE geometry for specific fluid properties and flow regimes presents a significant challenge. Different fluids and operating conditions may require vastly different plate geometries for optimal performance. Developing flexible design methodologies that can adapt to a wide range of applications while maintaining high efficiency is an ongoing challenge in the field of PHE design.

One of the primary challenges in PHE design is balancing the trade-off between heat transfer enhancement and pressure drop. As the plate geometry becomes more complex with features like corrugations, chevrons, or dimples, the heat transfer coefficient typically increases. However, these same features also lead to higher pressure drops, which can result in increased pumping power requirements and operational costs. Engineers must carefully optimize the plate geometry to find the sweet spot that provides the best overall performance for a given application.

Another significant challenge is the prevention of flow maldistribution within the PHE. Uneven flow distribution can lead to reduced thermal performance and increased fouling in certain areas of the exchanger. Designing inlet and outlet port configurations, as well as plate patterns that promote uniform flow distribution across the entire heat transfer surface, is crucial for maintaining high efficiency and prolonging the operational life of the PHE.

Fouling mitigation is also a critical aspect of PHE design. The accumulation of deposits on heat transfer surfaces can significantly reduce thermal performance and increase pressure drop over time. While certain geometries may enhance heat transfer, they may also promote fouling by creating low-velocity zones or increasing surface roughness. Designers must consider the trade-offs between heat transfer enhancement and fouling propensity when selecting plate geometries for specific applications.

Material selection and manufacturing constraints pose additional challenges in PHE design. The complex geometries required for optimal heat transfer often push the limits of manufacturing capabilities, especially for materials with high thermal conductivity but poor formability. Balancing the desired thermal performance with manufacturability and cost-effectiveness is a constant challenge for PHE designers.

Thermal stress and fatigue are also important considerations in PHE design, particularly for applications with large temperature differentials or frequent thermal cycling. The plate geometry must be designed to accommodate thermal expansion and contraction while maintaining structural integrity and preventing leaks at the gasket interfaces.

Lastly, the optimization of PHE geometry for specific fluid properties and flow regimes presents a significant challenge. Different fluids and operating conditions may require vastly different plate geometries for optimal performance. Developing flexible design methodologies that can adapt to a wide range of applications while maintaining high efficiency is an ongoing challenge in the field of PHE design.

Current PHE Designs

01 Enhanced heat transfer efficiency

Plate heat exchangers are designed to improve heat transfer efficiency through various methods, such as optimizing plate geometry, increasing turbulence, and maximizing surface area. These designs aim to enhance the overall performance of the heat exchanger by promoting better fluid mixing and reducing thermal resistance.- Enhanced heat transfer efficiency in plate heat exchangers: Various design improvements and modifications are implemented to increase the heat transfer efficiency of plate heat exchangers. These include optimizing plate geometry, enhancing surface area, and improving fluid flow distribution. Such enhancements result in better thermal performance and overall system efficiency.

- Turbulence promotion in plate heat exchangers: Techniques are employed to promote turbulence within the fluid flow channels of plate heat exchangers. This may involve the use of corrugated plates, chevron patterns, or other surface features that disrupt laminar flow. Increased turbulence leads to improved heat transfer rates and overall exchanger performance.

- Plate design optimization for heat transfer: The design of heat exchanger plates is optimized to enhance heat transfer. This includes considerations such as plate thickness, material selection, and surface area maximization. Improved plate designs contribute to better thermal conductivity and overall heat exchange efficiency.

- Flow distribution improvements in plate heat exchangers: Methods are developed to improve fluid flow distribution within plate heat exchangers. This may involve the design of inlet and outlet manifolds, flow channel configurations, and the use of flow distributors. Enhanced flow distribution leads to more uniform heat transfer and reduced pressure drop across the exchanger.

- Fouling mitigation in plate heat exchangers: Strategies are implemented to mitigate fouling in plate heat exchangers, which can significantly impact heat transfer efficiency. These may include surface treatments, self-cleaning mechanisms, or design features that reduce the accumulation of deposits. Effective fouling mitigation helps maintain optimal heat transfer performance over time.

02 Plate design and configuration

The design and configuration of plates in heat exchangers play a crucial role in heat transfer. Innovations in plate patterns, corrugations, and arrangements can significantly impact the heat transfer rate. Some designs focus on creating specific flow patterns or increasing the contact area between fluids to maximize heat exchange.Expand Specific Solutions03 Flow distribution and turbulence

Improving flow distribution and creating controlled turbulence within plate heat exchangers can enhance heat transfer. This may involve the use of specially designed inlet and outlet ports, flow guides, or turbulence promoters to ensure uniform fluid distribution and increase the heat transfer coefficient.Expand Specific Solutions04 Material selection and surface treatment

The choice of materials for plates and surface treatments can significantly affect heat transfer in plate heat exchangers. Advanced materials with high thermal conductivity or specially treated surfaces can improve heat transfer rates and overall exchanger efficiency. Some innovations focus on developing coatings or surface modifications to enhance heat transfer properties.Expand Specific Solutions05 Compact and modular designs

Compact and modular plate heat exchanger designs aim to maximize heat transfer in limited spaces. These designs often focus on increasing the heat transfer area per unit volume, optimizing fluid flow paths, and improving overall system integration. Such innovations can lead to more efficient and space-saving heat exchange solutions.Expand Specific Solutions

Key PHE Manufacturers

The plate heat exchanger geometry market is in a growth phase, driven by increasing demand for energy-efficient heat transfer solutions across industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Alfa Laval, Vahterus, and Danfoss leading innovation. These firms are developing more compact, efficient designs and exploring new materials to enhance heat transfer performance. Emerging players such as Lanpec Technologies and Shanghai Lanbin Petrochemical Equipment are also contributing to technological advancements, particularly in specialized applications for the petrochemical industry. The competitive landscape is characterized by a mix of established global leaders and innovative regional players, fostering continuous improvement in plate heat exchanger technology.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed innovative plate heat exchanger geometries to enhance heat transfer efficiency. Their AlfaNova fusion-bonded plate heat exchangers utilize a unique corrugated plate design with optimized chevron angles and distribution patterns. This design creates turbulent flow and increases the effective heat transfer area, resulting in up to 25% higher thermal efficiency compared to conventional designs[1]. Additionally, Alfa Laval's PureBallast technology incorporates specially designed plate heat exchangers with enhanced flow distribution, reducing the risk of fouling and improving overall system performance in marine applications[2].

Strengths: Superior thermal efficiency, reduced fouling, and versatility across various industries. Weaknesses: Higher initial cost and potential complexity in maintenance compared to simpler designs.

Vahterus Oy

Technical Solution: Vahterus has pioneered the Plate & Shell heat exchanger technology, which combines the benefits of plate and shell-and-tube designs. Their unique circular plate geometry creates a fully countercurrent flow arrangement, maximizing heat transfer efficiency. The plates feature a dimpled surface pattern that induces turbulence and reduces fouling. This design allows for a more compact exchanger with up to 70% less footprint compared to traditional shell-and-tube units[3]. Vahterus has also developed specialized plate geometries for high-pressure applications, enabling their use in demanding processes such as LNG vaporization and refrigeration systems[4].

Strengths: Compact design, high-pressure capability, and excellent fouling resistance. Weaknesses: Limited flexibility in capacity adjustments and potentially higher manufacturing costs.

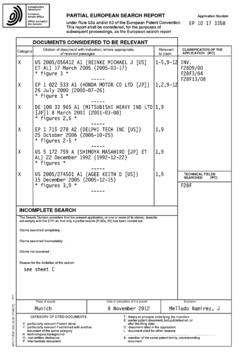

PHE Geometry Innovations

Apparatus and method for equalizing hot fluid exit plane plate temperatures in heat exchangers

PatentActiveEP2299228A3

Innovation

- The implementation of variable flow structures on the plates, such as protrusions and dimples, to manipulate gas velocities and heat transfer coefficients, ensuring that the metal plate temperatures are more evenly distributed by optimizing the velocity of hot and cold gas streams, thereby preventing condensation and corrosion.

CFD in PHE Development

Computational Fluid Dynamics (CFD) has become an indispensable tool in the development of Plate Heat Exchangers (PHEs), revolutionizing the design process and enhancing our understanding of heat transfer mechanisms. CFD simulations provide detailed insights into fluid flow patterns, temperature distributions, and pressure drops within the complex geometries of PHEs, enabling engineers to optimize designs without the need for extensive physical prototyping.

The application of CFD in PHE development typically involves creating a 3D model of the exchanger geometry, defining boundary conditions, and solving the governing equations of fluid dynamics and heat transfer. Advanced turbulence models, such as k-ε or SST k-ω, are often employed to accurately capture the flow characteristics in the narrow channels between plates.

One of the primary advantages of CFD in PHE development is its ability to visualize and quantify the impact of various geometric parameters on heat transfer performance. Engineers can easily modify plate corrugation patterns, chevron angles, or channel spacing in the virtual environment and observe the resulting changes in flow distribution and thermal efficiency. This parametric analysis capability significantly accelerates the design optimization process.

CFD simulations also play a crucial role in identifying and mitigating flow maldistribution issues, which can severely impact PHE performance. By analyzing velocity profiles and pressure distributions, designers can pinpoint areas of stagnation or excessive turbulence and make informed decisions to improve flow uniformity across the exchanger.

Furthermore, CFD enables the investigation of fouling phenomena in PHEs by simulating particle deposition and growth over time. This capability is particularly valuable for industries dealing with high-fouling fluids, as it allows for the development of plate geometries that minimize fouling propensity and extend operational intervals between cleaning cycles.

The integration of CFD with other computational tools, such as Finite Element Analysis (FEA), has further enhanced its utility in PHE development. Coupled CFD-FEA simulations can provide insights into thermal stresses and mechanical deformations under various operating conditions, ensuring the structural integrity of the exchanger design.

As computational power continues to increase, the role of CFD in PHE development is expected to expand. Advanced techniques like Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS) are becoming more feasible, offering even greater accuracy in predicting heat transfer and fluid flow behaviors in complex PHE geometries.

The application of CFD in PHE development typically involves creating a 3D model of the exchanger geometry, defining boundary conditions, and solving the governing equations of fluid dynamics and heat transfer. Advanced turbulence models, such as k-ε or SST k-ω, are often employed to accurately capture the flow characteristics in the narrow channels between plates.

One of the primary advantages of CFD in PHE development is its ability to visualize and quantify the impact of various geometric parameters on heat transfer performance. Engineers can easily modify plate corrugation patterns, chevron angles, or channel spacing in the virtual environment and observe the resulting changes in flow distribution and thermal efficiency. This parametric analysis capability significantly accelerates the design optimization process.

CFD simulations also play a crucial role in identifying and mitigating flow maldistribution issues, which can severely impact PHE performance. By analyzing velocity profiles and pressure distributions, designers can pinpoint areas of stagnation or excessive turbulence and make informed decisions to improve flow uniformity across the exchanger.

Furthermore, CFD enables the investigation of fouling phenomena in PHEs by simulating particle deposition and growth over time. This capability is particularly valuable for industries dealing with high-fouling fluids, as it allows for the development of plate geometries that minimize fouling propensity and extend operational intervals between cleaning cycles.

The integration of CFD with other computational tools, such as Finite Element Analysis (FEA), has further enhanced its utility in PHE development. Coupled CFD-FEA simulations can provide insights into thermal stresses and mechanical deformations under various operating conditions, ensuring the structural integrity of the exchanger design.

As computational power continues to increase, the role of CFD in PHE development is expected to expand. Advanced techniques like Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS) are becoming more feasible, offering even greater accuracy in predicting heat transfer and fluid flow behaviors in complex PHE geometries.

Energy Efficiency Impact

The energy efficiency impact of plate heat exchanger geometry on heat transfer is a critical consideration in the design and optimization of these devices. The geometry of plate heat exchangers significantly influences their thermal performance and overall energy efficiency. By carefully manipulating the plate design, manufacturers can enhance heat transfer rates, reduce pressure drops, and ultimately improve the energy efficiency of various industrial processes.

One of the primary geometric factors affecting energy efficiency is the plate corrugation pattern. Different corrugation designs, such as chevron, herringbone, or washboard patterns, create varying levels of turbulence and flow distribution within the exchanger. Enhanced turbulence promotes better mixing of fluids and increases the heat transfer coefficient, leading to improved thermal efficiency. However, this must be balanced against the increased pressure drop associated with higher turbulence, which can impact pumping energy requirements.

The plate spacing and gap width between plates also play crucial roles in energy efficiency. Narrower gaps generally result in higher heat transfer rates due to increased fluid velocity and reduced thermal resistance. However, excessively narrow gaps can lead to higher pressure drops and potential fouling issues, which may negatively impact long-term energy efficiency. Optimizing the plate spacing for specific applications is essential to achieve the best balance between heat transfer enhancement and pressure drop minimization.

The size and distribution of flow ports on the plates affect fluid distribution and, consequently, energy efficiency. Well-designed port configurations ensure uniform flow across the entire plate surface, maximizing the effective heat transfer area and reducing the likelihood of dead zones or short-circuiting. This uniform distribution contributes to better overall thermal performance and energy utilization.

Plate thickness and material selection also influence energy efficiency. Thinner plates generally offer lower thermal resistance, allowing for more efficient heat transfer between fluids. However, plate thickness must be balanced with mechanical strength requirements. Advanced materials with high thermal conductivity, such as titanium or high-grade stainless steel, can further enhance heat transfer efficiency, albeit at a higher cost.

The overall plate size and aspect ratio impact the heat transfer area and fluid flow characteristics. Larger plates increase the total heat transfer surface area but may lead to non-uniform flow distribution. Optimizing the plate aspect ratio can help maintain uniform flow while maximizing the heat transfer area, contributing to improved energy efficiency.

In conclusion, the geometry of plate heat exchangers has a profound impact on their energy efficiency. By carefully considering and optimizing various geometric parameters, engineers can design plate heat exchangers that achieve high thermal performance with minimal energy input, contributing to more sustainable and cost-effective industrial processes.

One of the primary geometric factors affecting energy efficiency is the plate corrugation pattern. Different corrugation designs, such as chevron, herringbone, or washboard patterns, create varying levels of turbulence and flow distribution within the exchanger. Enhanced turbulence promotes better mixing of fluids and increases the heat transfer coefficient, leading to improved thermal efficiency. However, this must be balanced against the increased pressure drop associated with higher turbulence, which can impact pumping energy requirements.

The plate spacing and gap width between plates also play crucial roles in energy efficiency. Narrower gaps generally result in higher heat transfer rates due to increased fluid velocity and reduced thermal resistance. However, excessively narrow gaps can lead to higher pressure drops and potential fouling issues, which may negatively impact long-term energy efficiency. Optimizing the plate spacing for specific applications is essential to achieve the best balance between heat transfer enhancement and pressure drop minimization.

The size and distribution of flow ports on the plates affect fluid distribution and, consequently, energy efficiency. Well-designed port configurations ensure uniform flow across the entire plate surface, maximizing the effective heat transfer area and reducing the likelihood of dead zones or short-circuiting. This uniform distribution contributes to better overall thermal performance and energy utilization.

Plate thickness and material selection also influence energy efficiency. Thinner plates generally offer lower thermal resistance, allowing for more efficient heat transfer between fluids. However, plate thickness must be balanced with mechanical strength requirements. Advanced materials with high thermal conductivity, such as titanium or high-grade stainless steel, can further enhance heat transfer efficiency, albeit at a higher cost.

The overall plate size and aspect ratio impact the heat transfer area and fluid flow characteristics. Larger plates increase the total heat transfer surface area but may lead to non-uniform flow distribution. Optimizing the plate aspect ratio can help maintain uniform flow while maximizing the heat transfer area, contributing to improved energy efficiency.

In conclusion, the geometry of plate heat exchangers has a profound impact on their energy efficiency. By carefully considering and optimizing various geometric parameters, engineers can design plate heat exchangers that achieve high thermal performance with minimal energy input, contributing to more sustainable and cost-effective industrial processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!