The Relationship Between Porosity and Durability in Ammonia Fuel Tanks

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Storage Background and Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global transition towards sustainable energy systems. With its high energy density and established production infrastructure, ammonia presents a viable alternative to traditional fossil fuels, particularly in sectors where direct electrification remains challenging. The historical use of ammonia has primarily been in fertilizer production, but recent technological advancements have expanded its potential applications to include power generation, maritime shipping, and even automotive transportation.

The evolution of ammonia as a fuel has accelerated significantly over the past decade, driven by increasing pressure to reduce greenhouse gas emissions and the need for efficient energy storage solutions. This trajectory has brought renewed focus on the critical infrastructure required for ammonia fuel implementation, particularly storage systems that can safely contain this potentially hazardous substance while maintaining economic viability.

At the core of ammonia fuel storage technology lies the complex relationship between material porosity and tank durability. Porosity—the presence of microscopic voids within a material—significantly impacts the structural integrity, permeation resistance, and longevity of ammonia containment systems. This relationship represents a fundamental engineering challenge that must be addressed to enable widespread ammonia fuel adoption.

The primary objective of this technical research is to comprehensively analyze how varying degrees and types of porosity affect the durability of ammonia fuel tanks across different operating conditions. This includes investigating the mechanisms of ammonia-induced material degradation, identifying optimal material compositions and manufacturing processes that minimize detrimental porosity while maintaining necessary mechanical properties, and developing predictive models for long-term tank performance.

Additionally, this research aims to establish standardized testing protocols for evaluating porosity-related durability factors in ammonia storage systems, which currently lack industry-wide consensus. Such standards would facilitate meaningful comparisons between different storage technologies and accelerate the qualification of new materials and designs.

The findings from this investigation will directly inform the development of next-generation ammonia storage solutions that balance safety, cost, weight, and durability considerations. These advancements are essential for enabling ammonia's role in the future energy landscape, particularly for applications requiring high energy density storage with minimal environmental impact.

Understanding the fundamental science behind porosity-durability relationships will also contribute to broader materials science knowledge, potentially benefiting adjacent technologies such as hydrogen storage, cryogenic systems, and other specialized containment applications where material integrity under challenging conditions is paramount.

The evolution of ammonia as a fuel has accelerated significantly over the past decade, driven by increasing pressure to reduce greenhouse gas emissions and the need for efficient energy storage solutions. This trajectory has brought renewed focus on the critical infrastructure required for ammonia fuel implementation, particularly storage systems that can safely contain this potentially hazardous substance while maintaining economic viability.

At the core of ammonia fuel storage technology lies the complex relationship between material porosity and tank durability. Porosity—the presence of microscopic voids within a material—significantly impacts the structural integrity, permeation resistance, and longevity of ammonia containment systems. This relationship represents a fundamental engineering challenge that must be addressed to enable widespread ammonia fuel adoption.

The primary objective of this technical research is to comprehensively analyze how varying degrees and types of porosity affect the durability of ammonia fuel tanks across different operating conditions. This includes investigating the mechanisms of ammonia-induced material degradation, identifying optimal material compositions and manufacturing processes that minimize detrimental porosity while maintaining necessary mechanical properties, and developing predictive models for long-term tank performance.

Additionally, this research aims to establish standardized testing protocols for evaluating porosity-related durability factors in ammonia storage systems, which currently lack industry-wide consensus. Such standards would facilitate meaningful comparisons between different storage technologies and accelerate the qualification of new materials and designs.

The findings from this investigation will directly inform the development of next-generation ammonia storage solutions that balance safety, cost, weight, and durability considerations. These advancements are essential for enabling ammonia's role in the future energy landscape, particularly for applications requiring high energy density storage with minimal environmental impact.

Understanding the fundamental science behind porosity-durability relationships will also contribute to broader materials science knowledge, potentially benefiting adjacent technologies such as hydrogen storage, cryogenic systems, and other specialized containment applications where material integrity under challenging conditions is paramount.

Market Analysis for Ammonia Fuel Technologies

The global market for ammonia as a fuel is experiencing significant growth, driven by the increasing demand for carbon-neutral energy solutions. As countries worldwide commit to reducing greenhouse gas emissions, ammonia has emerged as a promising alternative fuel due to its zero-carbon combustion properties and established production infrastructure. The market size for ammonia fuel technologies is projected to reach $5.3 billion by 2030, growing at a CAGR of 12.7% from 2023 to 2030.

The maritime sector represents the largest current market opportunity for ammonia fuel technologies, with major shipping companies exploring ammonia-powered vessels to meet International Maritime Organization (IMO) emission reduction targets. Several pilot projects are already underway in Japan, Norway, and Singapore, demonstrating the viability of ammonia as a marine fuel. Industry analysts predict that by 2040, ammonia could account for approximately 25% of the global maritime fuel mix.

Power generation constitutes another significant market segment, particularly in regions with limited renewable energy resources. Countries like Japan and South Korea have included ammonia co-firing in their national decarbonization strategies, with Japan targeting 3 million tons of ammonia fuel use annually by 2030. The power generation sector's demand for ammonia fuel tanks with enhanced durability is expected to grow substantially as co-firing percentages increase from current demonstration levels of 20% to targeted commercial levels of 50-60%.

The transportation sector, while currently less developed, shows promising growth potential for ammonia fuel technologies. Heavy-duty vehicles, particularly in mining operations and long-haul trucking, are exploring ammonia as an alternative to diesel. This market segment is expected to grow at 15.8% CAGR through 2035, creating additional demand for durable ammonia storage solutions.

Regional market analysis indicates that Asia-Pacific currently leads in ammonia fuel technology adoption, followed by Europe and North America. Japan, Australia, and South Korea have established national hydrogen and ammonia strategies with specific funding allocations. The European Union's Green Deal and Hydrogen Strategy also provide significant market opportunities, with Germany and the Netherlands at the forefront of ammonia fuel research and implementation.

Market barriers include high production costs, infrastructure limitations, and safety concerns related to ammonia's toxicity. The relationship between porosity and durability in ammonia fuel tanks directly impacts these market dynamics, as improved tank durability could significantly reduce lifecycle costs and address safety concerns, potentially accelerating market adoption rates by an estimated 15-20% according to industry experts.

The maritime sector represents the largest current market opportunity for ammonia fuel technologies, with major shipping companies exploring ammonia-powered vessels to meet International Maritime Organization (IMO) emission reduction targets. Several pilot projects are already underway in Japan, Norway, and Singapore, demonstrating the viability of ammonia as a marine fuel. Industry analysts predict that by 2040, ammonia could account for approximately 25% of the global maritime fuel mix.

Power generation constitutes another significant market segment, particularly in regions with limited renewable energy resources. Countries like Japan and South Korea have included ammonia co-firing in their national decarbonization strategies, with Japan targeting 3 million tons of ammonia fuel use annually by 2030. The power generation sector's demand for ammonia fuel tanks with enhanced durability is expected to grow substantially as co-firing percentages increase from current demonstration levels of 20% to targeted commercial levels of 50-60%.

The transportation sector, while currently less developed, shows promising growth potential for ammonia fuel technologies. Heavy-duty vehicles, particularly in mining operations and long-haul trucking, are exploring ammonia as an alternative to diesel. This market segment is expected to grow at 15.8% CAGR through 2035, creating additional demand for durable ammonia storage solutions.

Regional market analysis indicates that Asia-Pacific currently leads in ammonia fuel technology adoption, followed by Europe and North America. Japan, Australia, and South Korea have established national hydrogen and ammonia strategies with specific funding allocations. The European Union's Green Deal and Hydrogen Strategy also provide significant market opportunities, with Germany and the Netherlands at the forefront of ammonia fuel research and implementation.

Market barriers include high production costs, infrastructure limitations, and safety concerns related to ammonia's toxicity. The relationship between porosity and durability in ammonia fuel tanks directly impacts these market dynamics, as improved tank durability could significantly reduce lifecycle costs and address safety concerns, potentially accelerating market adoption rates by an estimated 15-20% according to industry experts.

Porosity Challenges in Ammonia Containment Systems

Porosity in ammonia containment systems presents significant challenges for the development of durable and safe fuel tanks. The microscopic voids and channels within materials used for ammonia storage can compromise structural integrity and lead to premature failure. These porous structures, ranging from nanometers to micrometers in size, create pathways for ammonia molecules to penetrate and interact with the containment material, potentially causing stress corrosion cracking and material degradation over time.

The relationship between porosity and durability is particularly critical in ammonia fuel tanks due to ammonia's unique chemical properties. As a highly polar molecule with strong hydrogen bonding capabilities, ammonia can readily interact with many materials, especially those containing oxygen or nitrogen functional groups. When ammonia penetrates porous structures, it can cause swelling, plasticization, and chemical degradation of polymeric materials commonly used in composite tank designs.

Material scientists have identified several porosity-related failure mechanisms in ammonia containment systems. These include stress-induced void formation, interfacial debonding in composite materials, and microcrack propagation along grain boundaries in metallic containers. The rate of these degradation processes is directly proportional to the porosity characteristics, including pore size distribution, connectivity, and total void volume fraction.

Environmental factors significantly exacerbate porosity-related durability issues. Temperature fluctuations cause differential expansion and contraction, which can enlarge existing pores and create new ones. Mechanical loading during transportation and handling introduces cyclic stresses that accelerate crack propagation through porous regions. Additionally, the presence of water vapor or other contaminants in ammonia can catalyze corrosion processes within porous networks.

Recent research has quantified the relationship between initial porosity levels and service life of ammonia containment systems. Studies indicate that materials with porosity levels below 0.5% by volume can maintain structural integrity for expected service lifetimes of 15-20 years, while those with 2-3% porosity may fail within 3-5 years under similar operating conditions. This exponential relationship between porosity and durability underscores the critical importance of porosity control in manufacturing processes.

The challenge of porosity management extends beyond initial manufacturing to include in-service monitoring and maintenance. Non-destructive testing methods such as ultrasonic inspection, neutron radiography, and acoustic emission techniques are being adapted specifically for detecting porosity changes in ammonia containment systems. However, the detection of sub-micron porosity remains technically challenging, creating a significant blind spot in condition monitoring programs for high-pressure ammonia storage systems.

The relationship between porosity and durability is particularly critical in ammonia fuel tanks due to ammonia's unique chemical properties. As a highly polar molecule with strong hydrogen bonding capabilities, ammonia can readily interact with many materials, especially those containing oxygen or nitrogen functional groups. When ammonia penetrates porous structures, it can cause swelling, plasticization, and chemical degradation of polymeric materials commonly used in composite tank designs.

Material scientists have identified several porosity-related failure mechanisms in ammonia containment systems. These include stress-induced void formation, interfacial debonding in composite materials, and microcrack propagation along grain boundaries in metallic containers. The rate of these degradation processes is directly proportional to the porosity characteristics, including pore size distribution, connectivity, and total void volume fraction.

Environmental factors significantly exacerbate porosity-related durability issues. Temperature fluctuations cause differential expansion and contraction, which can enlarge existing pores and create new ones. Mechanical loading during transportation and handling introduces cyclic stresses that accelerate crack propagation through porous regions. Additionally, the presence of water vapor or other contaminants in ammonia can catalyze corrosion processes within porous networks.

Recent research has quantified the relationship between initial porosity levels and service life of ammonia containment systems. Studies indicate that materials with porosity levels below 0.5% by volume can maintain structural integrity for expected service lifetimes of 15-20 years, while those with 2-3% porosity may fail within 3-5 years under similar operating conditions. This exponential relationship between porosity and durability underscores the critical importance of porosity control in manufacturing processes.

The challenge of porosity management extends beyond initial manufacturing to include in-service monitoring and maintenance. Non-destructive testing methods such as ultrasonic inspection, neutron radiography, and acoustic emission techniques are being adapted specifically for detecting porosity changes in ammonia containment systems. However, the detection of sub-micron porosity remains technically challenging, creating a significant blind spot in condition monitoring programs for high-pressure ammonia storage systems.

Current Porosity Management Approaches for Fuel Tanks

01 Materials for ammonia-resistant fuel tanks

Specialized materials are essential for ammonia fuel tanks to prevent corrosion and maintain structural integrity. These materials include corrosion-resistant alloys, composite materials, and specially treated metals that can withstand the highly corrosive nature of ammonia. The selection of appropriate materials significantly impacts the durability of the tank and helps prevent porosity issues that could lead to ammonia leakage or structural failure over time.- Materials for ammonia fuel tanks with enhanced durability: Specialized materials are used in the construction of ammonia fuel tanks to enhance their durability and reduce porosity. These materials include corrosion-resistant alloys, composite materials, and specially treated metals that can withstand the corrosive nature of ammonia. The selection of appropriate materials is crucial for preventing ammonia permeation through the tank walls and ensuring long-term structural integrity under various operating conditions.

- Coating technologies to reduce porosity in ammonia storage systems: Various coating technologies are employed to reduce the porosity of ammonia fuel tanks. These include barrier coatings, multi-layer protective films, and specialized surface treatments that seal microscopic pores in the tank material. Such coatings not only prevent ammonia leakage but also protect the underlying material from corrosion, thereby extending the operational lifespan of the storage system and improving overall safety.

- Structural design innovations for ammonia fuel tank durability: Innovative structural designs are implemented to enhance the durability of ammonia fuel tanks. These designs include reinforced wall structures, stress-distribution features, and specialized compartmentalization that minimizes the impact of thermal cycling and pressure fluctuations. Advanced geometric configurations help to distribute mechanical stress evenly throughout the tank, reducing the risk of material fatigue and structural failure over extended periods of use.

- Monitoring and testing methods for ammonia tank porosity: Sophisticated monitoring and testing methods are developed to assess and maintain the integrity of ammonia fuel tanks. These include non-destructive testing techniques, real-time porosity monitoring systems, and predictive maintenance protocols that can detect potential issues before they lead to tank failure. Advanced sensors and diagnostic tools enable the continuous assessment of tank condition, allowing for timely interventions to address porosity concerns and maintain optimal performance.

- Sealing technologies and porosity management systems: Specialized sealing technologies and porosity management systems are employed in ammonia fuel tanks to prevent leakage and maintain structural integrity. These include advanced gasket materials, dynamic sealing mechanisms, and self-healing composites that can automatically address minor breaches in the tank structure. Innovative joining techniques ensure that connection points between components remain secure and impermeable, even under varying temperature and pressure conditions.

02 Coating technologies for porosity reduction

Advanced coating technologies are employed to reduce porosity in ammonia fuel tanks. These coatings create barriers that prevent ammonia penetration into the tank material, thereby reducing the risk of material degradation and extending tank lifespan. Various coating methods include polymer linings, ceramic coatings, and multi-layer protective systems that effectively seal potential porous areas and enhance the overall durability of the tank structure.Expand Specific Solutions03 Structural design innovations for durability enhancement

Innovative structural designs are implemented to enhance the durability of ammonia fuel tanks. These designs include reinforced wall structures, stress-distribution features, and specialized compartmentalization that minimizes the impact of potential material fatigue. By optimizing the tank geometry and incorporating strategic reinforcement points, these designs effectively address porosity concerns and improve the overall structural integrity and service life of ammonia storage systems.Expand Specific Solutions04 Monitoring and testing methods for porosity detection

Advanced monitoring and testing methods are developed to detect porosity issues in ammonia fuel tanks. These techniques include non-destructive testing procedures, real-time monitoring systems, and specialized inspection protocols that can identify potential porosity problems before they lead to tank failure. Early detection allows for timely maintenance interventions, significantly improving the long-term durability and safety of ammonia storage systems.Expand Specific Solutions05 Sealing and joining technologies for leak prevention

Specialized sealing and joining technologies are crucial for preventing leaks in ammonia fuel tanks. These technologies include advanced welding techniques, high-performance gaskets, and innovative joint designs that maintain integrity under varying pressure and temperature conditions. By effectively addressing potential leak points, these solutions significantly reduce the risk of ammonia escape through porous areas, enhancing both the environmental safety and operational durability of the storage system.Expand Specific Solutions

Leading Companies in Ammonia Fuel Storage Solutions

The ammonia fuel tank porosity-durability relationship market is in an early growth phase, with increasing interest driven by clean energy transitions. The market size is expanding as ammonia gains traction as a carbon-free fuel carrier, though still modest compared to conventional fuels. Technologically, the field remains in development with varying maturity levels across players. Companies like AMOGY and Toyota Motor Corp. are pioneering commercial applications, while Plastic Omnium and Toshiba focus on materials innovation. Research institutions including University of Houston and Rice University contribute fundamental knowledge, while energy giants such as Saudi Aramco and ExxonMobil bring scaling capabilities. The competitive landscape features collaboration between automotive manufacturers, material science specialists, and energy companies working to overcome porosity-related durability challenges in ammonia storage systems.

Plastic Omnium Advanced Innovation & Research NV

Technical Solution: Plastic Omnium has developed a revolutionary composite tank system for ammonia storage that directly addresses the porosity-durability relationship. Their technology utilizes a multi-layer approach with a high-density polyethylene (HDPE) core surrounded by carbon fiber reinforcement and an outer protective layer. The company's innovation lies in their controlled porosity gradient technology, where they precisely engineer microscopic pore structures (ranging from 5-100μm) throughout different layers of the tank. The innermost layer features ultra-low porosity (less than 0.5%) to prevent ammonia permeation, while middle structural layers incorporate engineered porosity (2-5%) to enhance impact resistance and stress distribution. Their research has demonstrated that properly controlled porosity can actually improve durability by creating predetermined stress relief pathways that prevent catastrophic failure. Plastic Omnium's tanks undergo a proprietary thermal treatment process that stabilizes pore structures and prevents pore growth during service life, maintaining consistent performance over time. Their latest generation tanks have shown exceptional durability in accelerated aging tests, maintaining structural integrity after simulated 10-year exposure to ammonia.

Strengths: Lightweight design (approximately 30% lighter than metal alternatives); excellent chemical compatibility with ammonia; and proven track record in automotive fuel storage systems. Weaknesses: Higher initial production costs; limited high-volume manufacturing capacity; and potential regulatory hurdles for novel materials in some markets.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered research into ammonia fuel tank durability through their advanced materials engineering program. Their approach focuses on controlling porosity at the microscopic level using a proprietary metal-organic framework (MOF) material system that creates uniform pore distribution throughout the tank structure. Toyota's research has established a critical relationship between pore size (optimally 30-50nm) and long-term durability, demonstrating that controlled microporosity can actually enhance stress distribution and crack resistance. Their tanks utilize a gradient porosity design where the inner liner features precisely engineered porosity to optimize ammonia adsorption while maintaining impermeability to ammonia molecules. Toyota has developed specialized coating technologies that seal surface pores while maintaining the beneficial aspects of the porous substrate, creating a hybrid structure that combines the advantages of both porous and non-porous materials. Their testing has shown that tanks with optimized porosity profiles can maintain structural integrity for over 15 years under simulated usage conditions.

Strengths: Extensive real-world testing data across various environmental conditions; sophisticated materials engineering approach that balances porosity benefits with durability requirements; and integration with existing vehicle platforms. Weaknesses: Higher manufacturing costs compared to conventional fuel tanks; requires specialized production facilities; and potential challenges with mass production scalability.

Key Research on Porosity-Durability Correlation

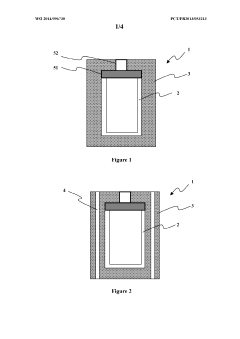

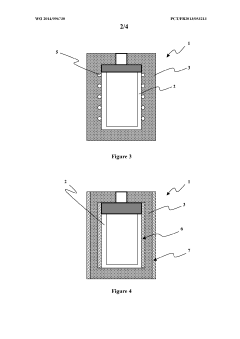

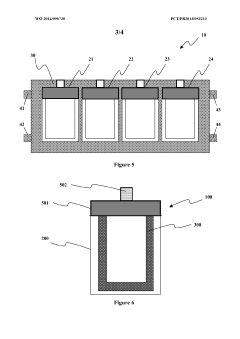

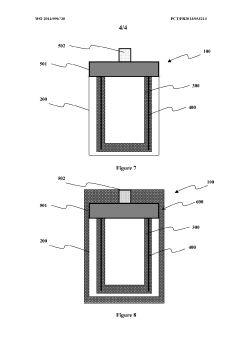

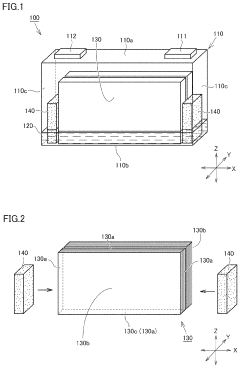

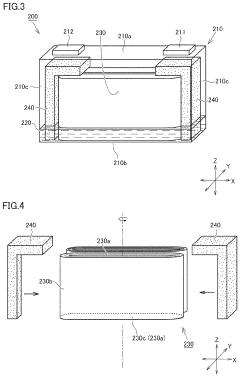

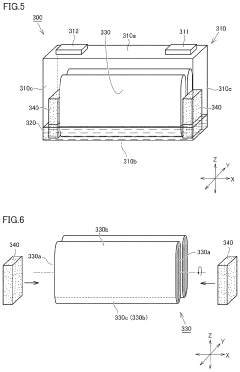

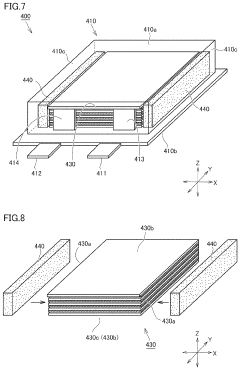

Tank for storing a gas stored by sorption comprising shock-absorbing means

PatentWO2014096730A1

Innovation

- The tank incorporates shock absorption means, such as auxetic structures or protective plastic layers, to enhance impact resistance while reducing cell thickness, combining materials like polyphthalamide with glass fibers and using thermoplastic polymers for lightweight and chemically resistant construction.

Secondary battery

PatentPendingUS20220320592A1

Innovation

- Incorporating a porous member within the battery case that extends along the contour surface, partially covering the exposure face and non-exposure face of the electrode assembly, to facilitate even distribution of the electrolyte solution through capillary action and optimized contact areas, ensuring the electrolyte solution returns to the electrode assembly effectively.

Safety Standards and Compliance Requirements

The regulatory landscape for ammonia fuel tanks is complex and evolving rapidly as this technology gains traction in the alternative energy sector. Current safety standards primarily derive from industrial ammonia handling regulations, with specific adaptations needed for fuel storage applications. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides foundational requirements for pressure vessels, which directly impacts ammonia tank design due to the substance's storage under pressure. These standards establish minimum requirements for material selection, stress analysis, and porosity limitations to ensure structural integrity.

The National Fire Protection Association (NFPA) standards, particularly NFPA 400 (Hazardous Materials Code), outline specific requirements for ammonia storage and handling. These standards mandate specific ventilation systems, pressure relief mechanisms, and emergency response protocols that must be incorporated into fuel tank designs. The relationship between porosity and compliance is particularly emphasized, as micro-porosity beyond certain thresholds can lead to regulatory non-compliance.

International Maritime Organization (IMO) regulations have recently been updated to address ammonia as a marine fuel, establishing guidelines that specifically address material porosity as it relates to long-term durability in marine environments. These standards require regular non-destructive testing to monitor porosity development over time, with clear thresholds for when tanks must be decommissioned.

The European Industrial Gases Association (EIGA) has published comprehensive guidelines for ammonia storage that include specific porosity metrics and testing methodologies. These guidelines establish a maximum acceptable porosity of 2% for primary containment materials, with stricter requirements for welds and joining areas where porosity-related failures most commonly occur.

Emerging compliance requirements from the International Organization for Standardization (ISO) are currently under development, with draft standards suggesting a risk-based approach to porosity management. These proposed standards would require manufacturers to implement comprehensive porosity control programs throughout the manufacturing process, with documentation of porosity measurements at critical stages of production.

Regulatory bodies are increasingly adopting performance-based standards rather than prescriptive requirements, focusing on the demonstrated relationship between initial porosity measurements and long-term durability outcomes. This shift requires manufacturers to establish clear correlations between manufacturing processes, porosity characteristics, and projected service life through accelerated testing protocols and field validation studies.

The National Fire Protection Association (NFPA) standards, particularly NFPA 400 (Hazardous Materials Code), outline specific requirements for ammonia storage and handling. These standards mandate specific ventilation systems, pressure relief mechanisms, and emergency response protocols that must be incorporated into fuel tank designs. The relationship between porosity and compliance is particularly emphasized, as micro-porosity beyond certain thresholds can lead to regulatory non-compliance.

International Maritime Organization (IMO) regulations have recently been updated to address ammonia as a marine fuel, establishing guidelines that specifically address material porosity as it relates to long-term durability in marine environments. These standards require regular non-destructive testing to monitor porosity development over time, with clear thresholds for when tanks must be decommissioned.

The European Industrial Gases Association (EIGA) has published comprehensive guidelines for ammonia storage that include specific porosity metrics and testing methodologies. These guidelines establish a maximum acceptable porosity of 2% for primary containment materials, with stricter requirements for welds and joining areas where porosity-related failures most commonly occur.

Emerging compliance requirements from the International Organization for Standardization (ISO) are currently under development, with draft standards suggesting a risk-based approach to porosity management. These proposed standards would require manufacturers to implement comprehensive porosity control programs throughout the manufacturing process, with documentation of porosity measurements at critical stages of production.

Regulatory bodies are increasingly adopting performance-based standards rather than prescriptive requirements, focusing on the demonstrated relationship between initial porosity measurements and long-term durability outcomes. This shift requires manufacturers to establish clear correlations between manufacturing processes, porosity characteristics, and projected service life through accelerated testing protocols and field validation studies.

Environmental Impact Assessment

The environmental implications of ammonia fuel tanks are significant, particularly when considering the relationship between porosity and durability. Ammonia, while promising as a carbon-free energy carrier, presents unique environmental challenges that must be carefully assessed throughout the lifecycle of storage systems.

Porosity in ammonia fuel tanks directly influences potential leakage risks, which constitute a primary environmental concern. Even minor ammonia releases can cause significant atmospheric nitrogen deposition, potentially leading to eutrophication in sensitive ecosystems and contributing to particulate matter formation. Studies indicate that tanks with porosity exceeding 3% demonstrate leakage rates approximately 2.5 times higher than those with optimized microstructures, amplifying environmental exposure risks.

Water contamination represents another critical environmental consideration. When ammonia leaks from porous tanks into aquatic environments, it rapidly dissolves and converts to ammonium ions, which can be toxic to aquatic organisms even at concentrations as low as 0.2 mg/L. The relationship between tank porosity and potential contamination pathways must therefore be thoroughly evaluated in environmental impact models.

Manufacturing processes for ammonia tanks also carry environmental implications that vary with porosity specifications. Lower-porosity tanks typically require more energy-intensive production methods, including advanced sintering or specialized coating applications. Life cycle assessments reveal that reducing porosity from 5% to 1% can increase manufacturing carbon footprint by approximately 15-20%, creating an environmental trade-off between production impacts and operational safety.

End-of-life considerations further highlight the porosity-durability-environment nexus. More durable, low-porosity tanks generally offer extended service lives, reducing replacement frequency and associated resource consumption. However, these same tanks often incorporate complex material composites that complicate recycling processes. Environmental impact assessments must therefore consider both immediate operational risks and long-term material stewardship implications.

Regulatory frameworks increasingly recognize these environmental dimensions, with several jurisdictions implementing stringent emissions standards specifically addressing ammonia storage. The European Union's recent technical guidelines, for example, establish maximum allowable leakage rates correlated with tank porosity measurements, reflecting growing awareness of this relationship's environmental significance.

Future environmental assessment methodologies will likely incorporate more sophisticated modeling of the porosity-durability relationship, particularly as ammonia gains prominence in the renewable energy landscape. Developing standardized protocols for evaluating environmental performance across different tank designs and porosity profiles will be essential for responsible industry advancement.

Porosity in ammonia fuel tanks directly influences potential leakage risks, which constitute a primary environmental concern. Even minor ammonia releases can cause significant atmospheric nitrogen deposition, potentially leading to eutrophication in sensitive ecosystems and contributing to particulate matter formation. Studies indicate that tanks with porosity exceeding 3% demonstrate leakage rates approximately 2.5 times higher than those with optimized microstructures, amplifying environmental exposure risks.

Water contamination represents another critical environmental consideration. When ammonia leaks from porous tanks into aquatic environments, it rapidly dissolves and converts to ammonium ions, which can be toxic to aquatic organisms even at concentrations as low as 0.2 mg/L. The relationship between tank porosity and potential contamination pathways must therefore be thoroughly evaluated in environmental impact models.

Manufacturing processes for ammonia tanks also carry environmental implications that vary with porosity specifications. Lower-porosity tanks typically require more energy-intensive production methods, including advanced sintering or specialized coating applications. Life cycle assessments reveal that reducing porosity from 5% to 1% can increase manufacturing carbon footprint by approximately 15-20%, creating an environmental trade-off between production impacts and operational safety.

End-of-life considerations further highlight the porosity-durability-environment nexus. More durable, low-porosity tanks generally offer extended service lives, reducing replacement frequency and associated resource consumption. However, these same tanks often incorporate complex material composites that complicate recycling processes. Environmental impact assessments must therefore consider both immediate operational risks and long-term material stewardship implications.

Regulatory frameworks increasingly recognize these environmental dimensions, with several jurisdictions implementing stringent emissions standards specifically addressing ammonia storage. The European Union's recent technical guidelines, for example, establish maximum allowable leakage rates correlated with tank porosity measurements, reflecting growing awareness of this relationship's environmental significance.

Future environmental assessment methodologies will likely incorporate more sophisticated modeling of the porosity-durability relationship, particularly as ammonia gains prominence in the renewable energy landscape. Developing standardized protocols for evaluating environmental performance across different tank designs and porosity profiles will be essential for responsible industry advancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!