The Role of Computational Fluid Dynamics in Plate Heat Exchanger Design

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFD in PHE Design: Background and Objectives

Computational Fluid Dynamics (CFD) has emerged as a pivotal tool in the design and optimization of plate heat exchangers (PHEs), revolutionizing the approach to thermal management and fluid flow analysis. The evolution of CFD in PHE design can be traced back to the late 20th century, coinciding with advancements in computational power and numerical methods. Initially, CFD applications in PHE design were limited to simple geometries and steady-state simulations. However, as technology progressed, so did the complexity and accuracy of CFD models.

The primary objective of incorporating CFD in PHE design is to enhance heat transfer efficiency while minimizing pressure drop, ultimately leading to more compact and cost-effective heat exchanger designs. CFD enables engineers to visualize and analyze complex flow patterns, temperature distributions, and pressure fields within the intricate channels of plate heat exchangers. This level of insight was previously unattainable through traditional experimental methods alone.

As the field has matured, CFD has become an indispensable tool for addressing key challenges in PHE design. These challenges include optimizing plate geometries, reducing fouling, and improving overall thermal-hydraulic performance. The ability to simulate various operating conditions and geometrical configurations without the need for physical prototypes has significantly accelerated the design process and reduced development costs.

The technological trajectory of CFD in PHE design has been marked by several key milestones. Early simulations focused on laminar flow regimes and simplified plate geometries. Subsequent advancements allowed for the modeling of turbulent flows, which are more representative of real-world PHE operations. The introduction of multiphase flow models further expanded the applicability of CFD to a wider range of heat transfer fluids and operating conditions.

Recent trends in CFD for PHE design include the integration of optimization algorithms, enabling automated design processes that can rapidly explore vast design spaces. Machine learning techniques are also being incorporated to enhance the predictive capabilities of CFD models and to accelerate simulation times. Furthermore, the development of high-fidelity models that can accurately capture phenomena such as flow maldistribution and local heat transfer coefficients has pushed the boundaries of what is possible in PHE design.

Looking ahead, the future of CFD in PHE design is poised for continued growth and innovation. Emerging areas of focus include the development of multi-scale modeling approaches that can bridge the gap between microscopic and macroscopic phenomena, as well as the integration of CFD with other simulation tools for holistic system-level optimization. As computational resources continue to expand, the scope and complexity of CFD simulations in PHE design are expected to reach new heights, further cementing its role as an essential tool in the heat exchanger industry.

The primary objective of incorporating CFD in PHE design is to enhance heat transfer efficiency while minimizing pressure drop, ultimately leading to more compact and cost-effective heat exchanger designs. CFD enables engineers to visualize and analyze complex flow patterns, temperature distributions, and pressure fields within the intricate channels of plate heat exchangers. This level of insight was previously unattainable through traditional experimental methods alone.

As the field has matured, CFD has become an indispensable tool for addressing key challenges in PHE design. These challenges include optimizing plate geometries, reducing fouling, and improving overall thermal-hydraulic performance. The ability to simulate various operating conditions and geometrical configurations without the need for physical prototypes has significantly accelerated the design process and reduced development costs.

The technological trajectory of CFD in PHE design has been marked by several key milestones. Early simulations focused on laminar flow regimes and simplified plate geometries. Subsequent advancements allowed for the modeling of turbulent flows, which are more representative of real-world PHE operations. The introduction of multiphase flow models further expanded the applicability of CFD to a wider range of heat transfer fluids and operating conditions.

Recent trends in CFD for PHE design include the integration of optimization algorithms, enabling automated design processes that can rapidly explore vast design spaces. Machine learning techniques are also being incorporated to enhance the predictive capabilities of CFD models and to accelerate simulation times. Furthermore, the development of high-fidelity models that can accurately capture phenomena such as flow maldistribution and local heat transfer coefficients has pushed the boundaries of what is possible in PHE design.

Looking ahead, the future of CFD in PHE design is poised for continued growth and innovation. Emerging areas of focus include the development of multi-scale modeling approaches that can bridge the gap between microscopic and macroscopic phenomena, as well as the integration of CFD with other simulation tools for holistic system-level optimization. As computational resources continue to expand, the scope and complexity of CFD simulations in PHE design are expected to reach new heights, further cementing its role as an essential tool in the heat exchanger industry.

Market Demand for Advanced PHE Solutions

The market demand for advanced Plate Heat Exchanger (PHE) solutions has been steadily increasing, driven by the growing need for energy-efficient and compact heat transfer systems across various industries. As environmental regulations become more stringent and energy costs continue to rise, companies are actively seeking innovative PHE designs that can optimize thermal performance while minimizing space requirements and operational costs.

In the oil and gas sector, there is a significant demand for high-performance PHEs capable of handling extreme temperatures and pressures. These advanced solutions are crucial for processes such as liquefied natural gas (LNG) production, where efficient heat transfer is essential for maximizing output and reducing energy consumption. The petrochemical industry also requires specialized PHEs that can withstand corrosive fluids and maintain high thermal efficiency in complex chemical processes.

The food and beverage industry represents another key market for advanced PHE solutions. With increasing emphasis on food safety and product quality, there is a growing demand for PHEs that offer superior hygienic design and ease of cleaning. Additionally, the industry requires PHEs that can handle viscous fluids and provide precise temperature control for sensitive processes such as pasteurization and sterilization.

In the HVAC sector, the push for energy-efficient buildings has led to a surge in demand for compact and high-performance PHEs. These advanced solutions are essential for optimizing heat recovery systems, reducing energy consumption, and minimizing the carbon footprint of commercial and residential buildings. The ability of modern PHEs to handle low-temperature differentials efficiently makes them particularly attractive for applications in district heating and cooling systems.

The pharmaceutical industry is another significant driver of demand for advanced PHE solutions. The need for precise temperature control in drug manufacturing processes, coupled with stringent regulatory requirements, has created a market for specialized PHEs that offer exceptional cleanliness, reliability, and traceability. These advanced solutions play a crucial role in ensuring product quality and consistency in pharmaceutical production.

As industries continue to prioritize sustainability and operational efficiency, the demand for PHEs with enhanced fouling resistance and extended operational lifespans has increased. This trend has led to the development of innovative surface treatments and materials that can significantly reduce maintenance requirements and improve long-term performance. The market is also seeing growing interest in modular and customizable PHE designs that can be easily adapted to specific process requirements, offering greater flexibility and cost-effectiveness for end-users.

In the oil and gas sector, there is a significant demand for high-performance PHEs capable of handling extreme temperatures and pressures. These advanced solutions are crucial for processes such as liquefied natural gas (LNG) production, where efficient heat transfer is essential for maximizing output and reducing energy consumption. The petrochemical industry also requires specialized PHEs that can withstand corrosive fluids and maintain high thermal efficiency in complex chemical processes.

The food and beverage industry represents another key market for advanced PHE solutions. With increasing emphasis on food safety and product quality, there is a growing demand for PHEs that offer superior hygienic design and ease of cleaning. Additionally, the industry requires PHEs that can handle viscous fluids and provide precise temperature control for sensitive processes such as pasteurization and sterilization.

In the HVAC sector, the push for energy-efficient buildings has led to a surge in demand for compact and high-performance PHEs. These advanced solutions are essential for optimizing heat recovery systems, reducing energy consumption, and minimizing the carbon footprint of commercial and residential buildings. The ability of modern PHEs to handle low-temperature differentials efficiently makes them particularly attractive for applications in district heating and cooling systems.

The pharmaceutical industry is another significant driver of demand for advanced PHE solutions. The need for precise temperature control in drug manufacturing processes, coupled with stringent regulatory requirements, has created a market for specialized PHEs that offer exceptional cleanliness, reliability, and traceability. These advanced solutions play a crucial role in ensuring product quality and consistency in pharmaceutical production.

As industries continue to prioritize sustainability and operational efficiency, the demand for PHEs with enhanced fouling resistance and extended operational lifespans has increased. This trend has led to the development of innovative surface treatments and materials that can significantly reduce maintenance requirements and improve long-term performance. The market is also seeing growing interest in modular and customizable PHE designs that can be easily adapted to specific process requirements, offering greater flexibility and cost-effectiveness for end-users.

Current CFD Challenges in PHE Modeling

Computational Fluid Dynamics (CFD) has become an indispensable tool in the design and optimization of Plate Heat Exchangers (PHEs). However, several challenges persist in accurately modeling these complex systems. One of the primary difficulties lies in capturing the intricate geometry of PHEs, which typically consist of numerous thin, corrugated plates with complex flow patterns. The small-scale features and irregular surfaces pose significant meshing challenges, often requiring high computational resources and advanced meshing techniques.

Another major hurdle is the accurate representation of turbulence in PHE channels. The flow within these narrow passages is characterized by complex, three-dimensional turbulent structures that are difficult to model using standard turbulence models. While Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS) offer higher fidelity, they are computationally expensive and often impractical for industrial-scale simulations. Consequently, researchers are continuously working on developing and refining turbulence models specifically tailored for PHE applications.

The multiphase nature of many PHE applications presents additional modeling challenges. Accurately capturing phase change phenomena, such as boiling or condensation, requires sophisticated models that can handle the complex heat and mass transfer processes at the interface. Moreover, the presence of non-Newtonian fluids in certain applications further complicates the modeling process, necessitating advanced rheological models to accurately predict fluid behavior.

Scale formation and fouling are critical issues in PHE operation that significantly impact performance. However, incorporating these phenomena into CFD models remains a significant challenge. Current models struggle to accurately predict the initiation and growth of fouling layers, as well as their impact on heat transfer and fluid flow. Developing more robust fouling models that can account for various operating conditions and fluid properties is an active area of research.

The validation of CFD models for PHEs also presents unique challenges. Obtaining accurate experimental data for complex geometries and flow conditions is often difficult and expensive. Furthermore, the discrepancies between idealized CFD models and real-world PHE performance can be substantial, necessitating careful validation and calibration processes. Researchers are exploring novel experimental techniques and uncertainty quantification methods to bridge this gap and improve the reliability of CFD predictions for PHE design.

Another major hurdle is the accurate representation of turbulence in PHE channels. The flow within these narrow passages is characterized by complex, three-dimensional turbulent structures that are difficult to model using standard turbulence models. While Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS) offer higher fidelity, they are computationally expensive and often impractical for industrial-scale simulations. Consequently, researchers are continuously working on developing and refining turbulence models specifically tailored for PHE applications.

The multiphase nature of many PHE applications presents additional modeling challenges. Accurately capturing phase change phenomena, such as boiling or condensation, requires sophisticated models that can handle the complex heat and mass transfer processes at the interface. Moreover, the presence of non-Newtonian fluids in certain applications further complicates the modeling process, necessitating advanced rheological models to accurately predict fluid behavior.

Scale formation and fouling are critical issues in PHE operation that significantly impact performance. However, incorporating these phenomena into CFD models remains a significant challenge. Current models struggle to accurately predict the initiation and growth of fouling layers, as well as their impact on heat transfer and fluid flow. Developing more robust fouling models that can account for various operating conditions and fluid properties is an active area of research.

The validation of CFD models for PHEs also presents unique challenges. Obtaining accurate experimental data for complex geometries and flow conditions is often difficult and expensive. Furthermore, the discrepancies between idealized CFD models and real-world PHE performance can be substantial, necessitating careful validation and calibration processes. Researchers are exploring novel experimental techniques and uncertainty quantification methods to bridge this gap and improve the reliability of CFD predictions for PHE design.

Existing CFD Approaches for PHE Design

01 CFD modeling and simulation techniques

Advanced computational fluid dynamics modeling and simulation techniques are used to analyze and optimize fluid flow in various systems. These methods involve creating digital representations of physical systems, applying mathematical models, and running simulations to predict fluid behavior and performance under different conditions.- CFD modeling and simulation techniques: Advanced computational fluid dynamics modeling and simulation techniques are used to analyze and optimize fluid flow in various systems. These methods involve creating digital representations of physical systems, applying mathematical models, and running simulations to predict fluid behavior and performance under different conditions.

- Integration of CFD with other design tools: Computational fluid dynamics is integrated with other design tools and processes, such as computer-aided design (CAD) and finite element analysis (FEA). This integration allows for more comprehensive and efficient product development, enabling designers to optimize both fluid dynamics and structural aspects simultaneously.

- Machine learning and AI in CFD design: Machine learning and artificial intelligence techniques are applied to computational fluid dynamics to enhance prediction accuracy, reduce computational time, and automate design optimization processes. These advanced algorithms can identify patterns and relationships in complex fluid systems that may not be apparent through traditional methods.

- Real-time CFD analysis for dynamic systems: Real-time computational fluid dynamics analysis techniques are developed for dynamic systems, such as vehicles in motion or industrial processes with changing conditions. These methods allow for continuous monitoring and adjustment of fluid systems to optimize performance and efficiency in real-world applications.

- Multi-physics CFD simulations: Multi-physics computational fluid dynamics simulations are employed to analyze complex systems involving interactions between fluid dynamics and other physical phenomena, such as heat transfer, chemical reactions, or structural mechanics. These comprehensive simulations provide a more accurate representation of real-world scenarios and enable better design decisions.

02 Integration of CFD with other design tools

Computational fluid dynamics is integrated with other design tools and methodologies, such as computer-aided design (CAD) and finite element analysis (FEA), to create more comprehensive and efficient design processes. This integration allows for better optimization of fluid systems within the context of overall product design.Expand Specific Solutions03 Machine learning and AI in CFD design

Machine learning and artificial intelligence techniques are applied to computational fluid dynamics to enhance prediction accuracy, reduce computational time, and automate certain aspects of the design process. These advanced algorithms can help identify optimal design parameters and improve overall system performance.Expand Specific Solutions04 Real-time CFD analysis for dynamic systems

Real-time computational fluid dynamics analysis techniques are developed for dynamic systems, allowing for continuous monitoring and adjustment of fluid flow in applications such as automotive engines, aerospace systems, and industrial processes. These methods enable more responsive and adaptive fluid system designs.Expand Specific Solutions05 Multi-physics CFD simulations

Multi-physics computational fluid dynamics simulations are employed to analyze complex systems involving interactions between fluid flow and other physical phenomena, such as heat transfer, structural mechanics, and chemical reactions. These comprehensive simulations provide more accurate predictions of system behavior in real-world conditions.Expand Specific Solutions

Key Players in CFD and PHE Industries

The computational fluid dynamics (CFD) market in plate heat exchanger design is in a growth phase, driven by increasing demand for energy-efficient solutions across industries. The global market size for CFD software is projected to reach several billion dollars by 2025, with a significant portion attributed to heat exchanger applications. Technologically, CFD for plate heat exchangers is maturing, with companies like Swep International AB, Alfa Laval Corporate AB, and Hangzhou Sanhua Research Institute Co., Ltd. leading innovation. These firms are developing advanced simulation tools and integrating machine learning to enhance design accuracy and efficiency. Academic institutions such as Xi'an Jiaotong University and Shandong University are also contributing to research advancements, fostering industry-academia collaborations to push the boundaries of CFD applications in heat exchanger design.

Hangzhou Sanhua Research Institute Co., Ltd.

Technical Solution: Hangzhou Sanhua Research Institute has developed a comprehensive CFD approach for plate heat exchanger design, focusing on microchannel heat exchangers and compact designs. Their methodology incorporates advanced meshing techniques to accurately represent complex plate geometries and small-scale flow features[7]. The institute utilizes multi-scale modeling, combining CFD with heat transfer correlations to optimize performance across different scales[9]. Sanhua's approach also includes the integration of phase change models for applications involving refrigerants and two-phase flows. The institute has developed in-house CFD codes tailored for plate heat exchanger analysis, allowing for rapid design iterations and parameter studies[11].

Strengths: Expertise in microchannel and compact heat exchangers, in-house CFD code development, and multi-scale modeling capabilities. Weaknesses: Potential limitations in very large-scale industrial applications and possible over-specialization in compact designs.

Swep International AB

Technical Solution: Swep International AB employs CFD in their plate heat exchanger design process, focusing on optimizing flow distribution and heat transfer efficiency. Their approach involves creating detailed 3D models of plate geometries and simulating fluid flow patterns using advanced turbulence models[2]. Swep's CFD methodology incorporates both single-phase and two-phase flow simulations, allowing for accurate prediction of heat exchanger performance across various operating conditions[4]. The company has developed proprietary algorithms to analyze CFD results and automatically suggest design improvements, streamlining the iterative design process[6]. Swep also utilizes CFD for virtual prototyping, reducing the need for physical prototypes and accelerating time-to-market for new heat exchanger designs.

Strengths: Specialized in brazed plate heat exchangers, automated design optimization, and reduced physical prototyping. Weaknesses: Potential limitations in handling very large-scale industrial applications.

Innovative CFD Methods for PHE Optimization

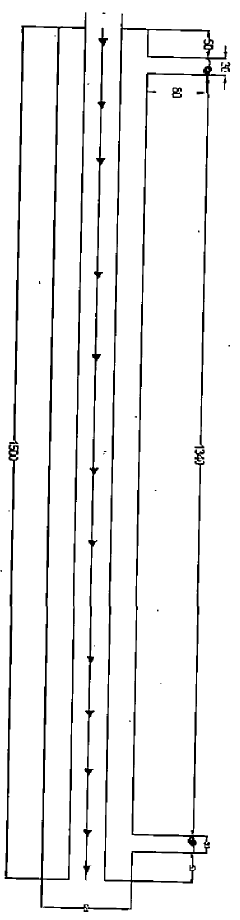

Design fabrication and computation of temperature reduction in counter flow heat exchanger using cfd

PatentInactiveIN201841018437A

Innovation

- A counter-flow heat exchanger design using a concentric copper and galvanized iron pipe setup with computational fluid dynamics (CFD) simulation to enhance heat transfer, employing water at atmospheric temperature to effectively reduce exhaust gas temperature, while ensuring no corrosion issues.

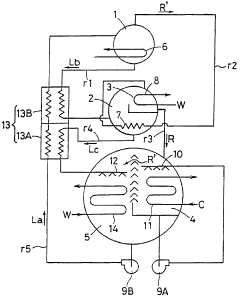

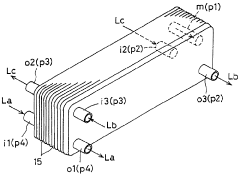

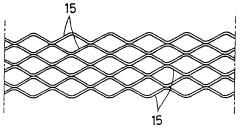

Plate type heat exchanger for three fluids and method of manufacturing the heat exchanger

PatentWO2000034729A1

Innovation

- The design integrates the front-stage and rear-stage heat exchange sections in a three-dimensional configuration with alternating fluid passages, incorporates a heat-insulating layer between the sections, and uses a vacuum insulation layer to minimize heat transfer between the sections, reducing overall size and heat loss.

Energy Efficiency and Sustainability Aspects

Computational Fluid Dynamics (CFD) plays a crucial role in enhancing the energy efficiency and sustainability of plate heat exchanger designs. By providing detailed insights into fluid flow and heat transfer processes, CFD enables engineers to optimize exchanger configurations for maximum performance while minimizing energy consumption and environmental impact.

One of the primary contributions of CFD to energy efficiency is its ability to identify and mitigate flow maldistribution within plate heat exchangers. Uneven flow distribution can lead to reduced heat transfer effectiveness and increased pressure drop, both of which negatively impact overall energy efficiency. Through CFD simulations, designers can visualize flow patterns and make informed decisions on plate geometry, corrugation patterns, and port designs to ensure uniform fluid distribution across the exchanger.

CFD analysis also aids in the optimization of heat transfer surface area. By simulating various plate configurations and corrugation designs, engineers can maximize the heat transfer coefficient while minimizing the required material and fluid inventory. This approach not only improves energy efficiency but also contributes to sustainability by reducing raw material consumption and minimizing the environmental footprint of the exchanger.

Furthermore, CFD simulations enable the evaluation of different working fluids and their impact on exchanger performance. This capability is particularly valuable in the context of sustainability, as it allows for the assessment of environmentally friendly refrigerants and heat transfer fluids. By comparing the thermodynamic and transport properties of various fluids in simulated exchanger conditions, designers can select options that offer the best balance between performance and environmental impact.

The role of CFD in reducing fouling and improving long-term performance is another critical aspect of sustainability in plate heat exchanger design. By accurately modeling fluid dynamics and particle transport, CFD helps in predicting fouling patterns and developing strategies to mitigate deposit formation. This proactive approach extends the operational life of heat exchangers, reduces maintenance requirements, and maintains high energy efficiency over time, all of which contribute to improved sustainability.

Lastly, CFD contributes to the development of novel plate heat exchanger designs that push the boundaries of energy efficiency. By enabling rapid virtual prototyping and performance evaluation, CFD accelerates the innovation cycle, allowing for the exploration of unconventional geometries and flow arrangements that may offer significant improvements in heat transfer efficiency and pressure drop characteristics.

One of the primary contributions of CFD to energy efficiency is its ability to identify and mitigate flow maldistribution within plate heat exchangers. Uneven flow distribution can lead to reduced heat transfer effectiveness and increased pressure drop, both of which negatively impact overall energy efficiency. Through CFD simulations, designers can visualize flow patterns and make informed decisions on plate geometry, corrugation patterns, and port designs to ensure uniform fluid distribution across the exchanger.

CFD analysis also aids in the optimization of heat transfer surface area. By simulating various plate configurations and corrugation designs, engineers can maximize the heat transfer coefficient while minimizing the required material and fluid inventory. This approach not only improves energy efficiency but also contributes to sustainability by reducing raw material consumption and minimizing the environmental footprint of the exchanger.

Furthermore, CFD simulations enable the evaluation of different working fluids and their impact on exchanger performance. This capability is particularly valuable in the context of sustainability, as it allows for the assessment of environmentally friendly refrigerants and heat transfer fluids. By comparing the thermodynamic and transport properties of various fluids in simulated exchanger conditions, designers can select options that offer the best balance between performance and environmental impact.

The role of CFD in reducing fouling and improving long-term performance is another critical aspect of sustainability in plate heat exchanger design. By accurately modeling fluid dynamics and particle transport, CFD helps in predicting fouling patterns and developing strategies to mitigate deposit formation. This proactive approach extends the operational life of heat exchangers, reduces maintenance requirements, and maintains high energy efficiency over time, all of which contribute to improved sustainability.

Lastly, CFD contributes to the development of novel plate heat exchanger designs that push the boundaries of energy efficiency. By enabling rapid virtual prototyping and performance evaluation, CFD accelerates the innovation cycle, allowing for the exploration of unconventional geometries and flow arrangements that may offer significant improvements in heat transfer efficiency and pressure drop characteristics.

Integration with Digital Twin Technology

The integration of Computational Fluid Dynamics (CFD) with Digital Twin technology represents a significant advancement in plate heat exchanger design. This synergy enables real-time monitoring, predictive maintenance, and optimization of heat exchanger performance throughout its lifecycle. Digital Twin technology creates a virtual replica of the physical heat exchanger, continuously updated with operational data from sensors and IoT devices.

By incorporating CFD simulations into the Digital Twin framework, engineers can achieve a more comprehensive understanding of the fluid dynamics and heat transfer processes within the plate heat exchanger. This integration allows for dynamic modeling of various operating conditions, including changes in flow rates, temperatures, and fluid properties. The CFD-enhanced Digital Twin can predict performance under different scenarios, enabling proactive decision-making and optimization of operating parameters.

One of the key benefits of this integration is the ability to perform virtual testing and optimization without disrupting the physical system. Engineers can simulate various design modifications and operational strategies, assessing their impact on heat transfer efficiency, pressure drop, and overall performance. This approach significantly reduces the time and cost associated with physical prototyping and testing.

The combination of CFD and Digital Twin technology also enhances predictive maintenance capabilities. By analyzing the simulated fluid flow patterns and heat transfer characteristics, potential issues such as fouling, uneven flow distribution, or thermal stress can be identified early. This proactive approach allows for timely maintenance interventions, minimizing downtime and extending the operational life of the heat exchanger.

Furthermore, the integration facilitates continuous improvement of the plate heat exchanger design. As the Digital Twin accumulates operational data and CFD simulation results over time, machine learning algorithms can be applied to identify patterns and optimize design parameters. This data-driven approach leads to iterative improvements in heat exchanger efficiency and performance.

The implementation of this integrated approach requires a robust data infrastructure and advanced computational resources. However, the long-term benefits in terms of improved design accuracy, operational efficiency, and maintenance planning justify the initial investment. As both CFD and Digital Twin technologies continue to evolve, their integration is expected to become an indispensable tool in the design and management of plate heat exchangers across various industries.

By incorporating CFD simulations into the Digital Twin framework, engineers can achieve a more comprehensive understanding of the fluid dynamics and heat transfer processes within the plate heat exchanger. This integration allows for dynamic modeling of various operating conditions, including changes in flow rates, temperatures, and fluid properties. The CFD-enhanced Digital Twin can predict performance under different scenarios, enabling proactive decision-making and optimization of operating parameters.

One of the key benefits of this integration is the ability to perform virtual testing and optimization without disrupting the physical system. Engineers can simulate various design modifications and operational strategies, assessing their impact on heat transfer efficiency, pressure drop, and overall performance. This approach significantly reduces the time and cost associated with physical prototyping and testing.

The combination of CFD and Digital Twin technology also enhances predictive maintenance capabilities. By analyzing the simulated fluid flow patterns and heat transfer characteristics, potential issues such as fouling, uneven flow distribution, or thermal stress can be identified early. This proactive approach allows for timely maintenance interventions, minimizing downtime and extending the operational life of the heat exchanger.

Furthermore, the integration facilitates continuous improvement of the plate heat exchanger design. As the Digital Twin accumulates operational data and CFD simulation results over time, machine learning algorithms can be applied to identify patterns and optimize design parameters. This data-driven approach leads to iterative improvements in heat exchanger efficiency and performance.

The implementation of this integrated approach requires a robust data infrastructure and advanced computational resources. However, the long-term benefits in terms of improved design accuracy, operational efficiency, and maintenance planning justify the initial investment. As both CFD and Digital Twin technologies continue to evolve, their integration is expected to become an indispensable tool in the design and management of plate heat exchangers across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!