The Role of Power Steering Fluid in Air Suspension System Performance

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Fluid Background and Objectives

Power steering fluid has played a crucial role in automotive systems for decades, primarily facilitating smooth and effortless steering in vehicles. However, its application in air suspension systems represents a relatively recent technological advancement. The evolution of this technology stems from the increasing demand for enhanced vehicle performance, comfort, and adaptability across various driving conditions.

The primary objective of incorporating power steering fluid in air suspension systems is to optimize the overall performance and responsiveness of the suspension. This integration aims to achieve a more precise control over the vehicle's ride height, stability, and handling characteristics. By leveraging the hydraulic properties of power steering fluid, engineers seek to create a more dynamic and adaptive suspension system that can respond rapidly to changing road conditions and driver inputs.

Historically, air suspension systems have relied solely on compressed air to adjust vehicle height and damping characteristics. While effective, these systems often faced limitations in terms of response time and precision. The introduction of power steering fluid into this equation marks a significant step towards addressing these challenges and pushing the boundaries of suspension technology.

The development of this hybrid system also aligns with the broader trend of vehicle electrification and the pursuit of more energy-efficient automotive solutions. By potentially reducing the reliance on air compressors and utilizing existing hydraulic systems, this approach may offer benefits in terms of energy consumption and overall system efficiency.

As the automotive industry continues to evolve, with an increasing focus on autonomous vehicles and advanced driver assistance systems, the role of suspension systems becomes even more critical. The integration of power steering fluid in air suspension systems is expected to contribute to the development of more intelligent and responsive vehicle dynamics, capable of adapting to a wide range of driving scenarios and user preferences.

This technological advancement also presents opportunities for cross-disciplinary innovation, combining expertise from hydraulic systems, pneumatics, and electronic control systems. The synergy between these fields could potentially lead to breakthroughs in suspension design and performance, setting new standards for ride quality and vehicle handling across various automotive segments.

The primary objective of incorporating power steering fluid in air suspension systems is to optimize the overall performance and responsiveness of the suspension. This integration aims to achieve a more precise control over the vehicle's ride height, stability, and handling characteristics. By leveraging the hydraulic properties of power steering fluid, engineers seek to create a more dynamic and adaptive suspension system that can respond rapidly to changing road conditions and driver inputs.

Historically, air suspension systems have relied solely on compressed air to adjust vehicle height and damping characteristics. While effective, these systems often faced limitations in terms of response time and precision. The introduction of power steering fluid into this equation marks a significant step towards addressing these challenges and pushing the boundaries of suspension technology.

The development of this hybrid system also aligns with the broader trend of vehicle electrification and the pursuit of more energy-efficient automotive solutions. By potentially reducing the reliance on air compressors and utilizing existing hydraulic systems, this approach may offer benefits in terms of energy consumption and overall system efficiency.

As the automotive industry continues to evolve, with an increasing focus on autonomous vehicles and advanced driver assistance systems, the role of suspension systems becomes even more critical. The integration of power steering fluid in air suspension systems is expected to contribute to the development of more intelligent and responsive vehicle dynamics, capable of adapting to a wide range of driving scenarios and user preferences.

This technological advancement also presents opportunities for cross-disciplinary innovation, combining expertise from hydraulic systems, pneumatics, and electronic control systems. The synergy between these fields could potentially lead to breakthroughs in suspension design and performance, setting new standards for ride quality and vehicle handling across various automotive segments.

Market Analysis for Air Suspension Systems

The air suspension system market has been experiencing significant growth in recent years, driven by increasing demand for enhanced vehicle comfort, improved handling, and better load-carrying capabilities. This market segment is primarily fueled by the automotive industry, with applications spanning across passenger vehicles, commercial trucks, and off-road vehicles.

In the passenger vehicle segment, luxury car manufacturers have been at the forefront of adopting air suspension systems, offering them as standard features or premium options in high-end models. This trend has gradually trickled down to mid-range vehicles, expanding the market reach. The commercial vehicle sector, particularly heavy-duty trucks and buses, has also shown a growing interest in air suspension systems due to their ability to provide a smoother ride and better load distribution.

The global air suspension market size was valued at approximately $4.3 billion in 2020 and is projected to reach $8.4 billion by 2026, growing at a CAGR of 6.5% during the forecast period. This growth is attributed to several factors, including increasing vehicle production, rising demand for luxury vehicles, and growing awareness about vehicle comfort and safety.

Geographically, North America and Europe have been the dominant markets for air suspension systems, owing to the high adoption rate in luxury vehicles and commercial trucks. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing vehicle production, rising disposable incomes, and growing demand for premium vehicles in countries like China and India.

The market is characterized by the presence of several key players, including Continental AG, ThyssenKrupp AG, Wabco Holdings Inc., and Hendrickson USA LLC. These companies are focusing on research and development to introduce innovative products and gain a competitive edge. For instance, recent advancements include the integration of electronic controls and sensors to provide adaptive suspension capabilities, further enhancing vehicle performance and comfort.

One of the emerging trends in the air suspension market is the increasing adoption of electronically controlled air suspension (ECAS) systems. These systems offer real-time adjustments to vehicle height and damping characteristics, providing optimal performance across various driving conditions. This trend is expected to drive market growth, particularly in the premium vehicle segment.

The role of power steering fluid in air suspension system performance, while not directly related to the core air suspension technology, highlights the interconnected nature of vehicle systems. As vehicles become more complex, the integration and optimization of various subsystems, including power steering and air suspension, become crucial for overall vehicle performance and efficiency.

In the passenger vehicle segment, luxury car manufacturers have been at the forefront of adopting air suspension systems, offering them as standard features or premium options in high-end models. This trend has gradually trickled down to mid-range vehicles, expanding the market reach. The commercial vehicle sector, particularly heavy-duty trucks and buses, has also shown a growing interest in air suspension systems due to their ability to provide a smoother ride and better load distribution.

The global air suspension market size was valued at approximately $4.3 billion in 2020 and is projected to reach $8.4 billion by 2026, growing at a CAGR of 6.5% during the forecast period. This growth is attributed to several factors, including increasing vehicle production, rising demand for luxury vehicles, and growing awareness about vehicle comfort and safety.

Geographically, North America and Europe have been the dominant markets for air suspension systems, owing to the high adoption rate in luxury vehicles and commercial trucks. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing vehicle production, rising disposable incomes, and growing demand for premium vehicles in countries like China and India.

The market is characterized by the presence of several key players, including Continental AG, ThyssenKrupp AG, Wabco Holdings Inc., and Hendrickson USA LLC. These companies are focusing on research and development to introduce innovative products and gain a competitive edge. For instance, recent advancements include the integration of electronic controls and sensors to provide adaptive suspension capabilities, further enhancing vehicle performance and comfort.

One of the emerging trends in the air suspension market is the increasing adoption of electronically controlled air suspension (ECAS) systems. These systems offer real-time adjustments to vehicle height and damping characteristics, providing optimal performance across various driving conditions. This trend is expected to drive market growth, particularly in the premium vehicle segment.

The role of power steering fluid in air suspension system performance, while not directly related to the core air suspension technology, highlights the interconnected nature of vehicle systems. As vehicles become more complex, the integration and optimization of various subsystems, including power steering and air suspension, become crucial for overall vehicle performance and efficiency.

Current Challenges in Air Suspension Technology

Air suspension systems have revolutionized vehicle comfort and performance, but they are not without their challenges. One of the primary issues facing air suspension technology is the complexity of integrating various components, including power steering fluid systems, to achieve optimal performance. The interaction between power steering fluid and air suspension components can lead to unexpected behaviors and potential system failures if not properly managed.

A significant challenge lies in maintaining the delicate balance between the air suspension system's pressure and the power steering fluid's hydraulic pressure. Fluctuations in either system can cause instability, affecting ride quality and vehicle handling. Engineers must develop sophisticated control algorithms to ensure seamless coordination between these two critical systems, accounting for various driving conditions and vehicle loads.

Another pressing concern is the potential for contamination of the air suspension system by power steering fluid leaks. Even minor leaks can compromise the integrity of air springs and valves, leading to reduced performance and increased maintenance costs. This issue is exacerbated by the fact that many modern vehicles utilize shared fluid reservoirs or closely positioned components, increasing the risk of cross-contamination.

The temperature sensitivity of both air suspension components and power steering fluid presents an additional challenge. Extreme temperatures can affect the viscosity of the power steering fluid and the elasticity of air suspension seals, potentially leading to system inefficiencies or failures. Developing materials and fluids that can maintain consistent performance across a wide temperature range remains an ongoing challenge for engineers in the automotive industry.

Durability and longevity of air suspension systems when integrated with power steering systems are also areas of concern. The constant interaction between these systems, coupled with the dynamic forces experienced during vehicle operation, can lead to accelerated wear on components. Designing robust interfaces and selecting appropriate materials that can withstand prolonged use without degradation is crucial for ensuring long-term reliability.

Moreover, the increasing demand for electronic control and integration of vehicle systems adds another layer of complexity. Engineers must develop sophisticated electronic control units (ECUs) capable of managing both air suspension and power steering systems simultaneously, while also interfacing with other vehicle subsystems. This integration challenge requires advanced software development and rigorous testing to ensure seamless operation under all conditions.

A significant challenge lies in maintaining the delicate balance between the air suspension system's pressure and the power steering fluid's hydraulic pressure. Fluctuations in either system can cause instability, affecting ride quality and vehicle handling. Engineers must develop sophisticated control algorithms to ensure seamless coordination between these two critical systems, accounting for various driving conditions and vehicle loads.

Another pressing concern is the potential for contamination of the air suspension system by power steering fluid leaks. Even minor leaks can compromise the integrity of air springs and valves, leading to reduced performance and increased maintenance costs. This issue is exacerbated by the fact that many modern vehicles utilize shared fluid reservoirs or closely positioned components, increasing the risk of cross-contamination.

The temperature sensitivity of both air suspension components and power steering fluid presents an additional challenge. Extreme temperatures can affect the viscosity of the power steering fluid and the elasticity of air suspension seals, potentially leading to system inefficiencies or failures. Developing materials and fluids that can maintain consistent performance across a wide temperature range remains an ongoing challenge for engineers in the automotive industry.

Durability and longevity of air suspension systems when integrated with power steering systems are also areas of concern. The constant interaction between these systems, coupled with the dynamic forces experienced during vehicle operation, can lead to accelerated wear on components. Designing robust interfaces and selecting appropriate materials that can withstand prolonged use without degradation is crucial for ensuring long-term reliability.

Moreover, the increasing demand for electronic control and integration of vehicle systems adds another layer of complexity. Engineers must develop sophisticated electronic control units (ECUs) capable of managing both air suspension and power steering systems simultaneously, while also interfacing with other vehicle subsystems. This integration challenge requires advanced software development and rigorous testing to ensure seamless operation under all conditions.

Existing Power Steering Fluid Solutions for Air Suspension

01 Fluid composition for improved performance

Power steering fluid compositions are designed to enhance performance by incorporating specific additives and base oils. These formulations aim to improve lubrication, reduce wear, and maintain viscosity under various operating conditions. The compositions may include anti-wear agents, viscosity modifiers, and friction modifiers to optimize the fluid's performance in power steering systems.- Fluid composition for improved performance: Power steering fluid compositions are designed to enhance performance by incorporating specific additives and base oils. These formulations aim to improve lubrication, reduce wear, and maintain viscosity under various operating conditions. The optimized compositions contribute to smoother steering operation and increased system longevity.

- Hydraulic system design for enhanced steering performance: Innovations in hydraulic system design focus on improving power steering performance. These designs may include optimized pump configurations, valve arrangements, and fluid flow paths. Such enhancements contribute to more responsive steering, reduced power consumption, and improved overall system efficiency.

- Temperature management for fluid performance: Managing the temperature of power steering fluid is crucial for maintaining optimal performance. This may involve cooling systems, heat exchangers, or temperature-responsive components that help regulate fluid temperature. Proper temperature control ensures consistent fluid viscosity and prevents degradation, leading to improved steering performance and system longevity.

- Fluid filtration and contamination control: Effective filtration and contamination control systems are essential for maintaining power steering fluid performance. These systems may include advanced filter designs, contaminant sensors, or self-cleaning mechanisms. By keeping the fluid clean and free from particles, the overall performance and lifespan of the power steering system can be significantly improved.

- Adaptive steering systems for performance optimization: Adaptive steering systems utilize advanced sensors and control algorithms to optimize power steering fluid performance. These systems can adjust fluid pressure, flow rates, and other parameters based on driving conditions and user input. By dynamically optimizing fluid performance, these systems provide enhanced steering feel, improved efficiency, and better overall vehicle handling.

02 Hydraulic system design for enhanced steering performance

Innovations in hydraulic system design focus on improving power steering performance. These designs may include optimized pump configurations, valve arrangements, and fluid flow paths to enhance steering responsiveness and efficiency. Advanced hydraulic systems can reduce power consumption, minimize fluid leakage, and provide smoother steering operation.Expand Specific Solutions03 Electronic control systems for power steering

Integration of electronic control systems in power steering enhances fluid performance by optimizing fluid pressure and flow based on driving conditions. These systems can adjust steering assistance, reduce energy consumption, and improve overall steering feel. Electronic controls may also monitor fluid temperature and pressure to maintain optimal performance.Expand Specific Solutions04 Fluid reservoir and circulation improvements

Advancements in power steering fluid reservoirs and circulation systems contribute to improved fluid performance. These innovations may include better fluid cooling mechanisms, enhanced filtration systems, and optimized reservoir designs to maintain fluid cleanliness and temperature. Improved circulation can lead to more consistent steering performance and extended fluid life.Expand Specific Solutions05 Maintenance and monitoring of power steering fluid

Techniques for maintaining and monitoring power steering fluid performance have been developed to ensure optimal system operation. These may include fluid condition sensors, automated fluid exchange systems, and improved sealing technologies to prevent contamination. Regular maintenance and monitoring can extend the life of power steering components and maintain consistent performance.Expand Specific Solutions

Key Players in Automotive Suspension Industry

The power steering fluid's role in air suspension system performance is an emerging field within automotive technology, currently in its early development stages. The market size is relatively small but growing, driven by increasing demand for advanced suspension systems in luxury and high-performance vehicles. The technology's maturity is still evolving, with key players like Ford Global Technologies, ZF Friedrichshafen, and Hitachi Automotive Systems leading research and development efforts. These companies are leveraging their expertise in automotive systems to integrate power steering fluid technology with air suspension, aiming to enhance vehicle handling and comfort. As the technology progresses, we can expect increased competition and innovation from other major automotive manufacturers and suppliers.

Eaton Corp.

Technical Solution: Eaton Corporation has developed a dual-function fluid system for air suspension and power steering applications. Their technology utilizes a specially formulated fluid that meets the requirements of both systems, featuring high thermal stability and low compressibility. Eaton's system employs a central pump that supplies fluid to both the air suspension and power steering components, with electronically controlled valves managing fluid distribution[3]. The company has also implemented advanced filtration technology to ensure fluid cleanliness and longevity, crucial for maintaining system performance over time. Eaton's solution includes adaptive control algorithms that optimize fluid pressure and flow based on vehicle speed, load, and steering input[4].

Strengths: Efficient use of a single fluid for dual purposes, potentially reducing maintenance complexity. Weaknesses: May require more frequent fluid changes due to increased stress on the fluid.

ZF Friedrichshafen AG

Technical Solution: ZF Friedrichshafen AG has developed an innovative integrated air suspension and power steering system that utilizes a common fluid reservoir. This system combines the functions of air suspension and power steering, using a specialized fluid that serves both purposes. The fluid is designed to maintain optimal viscosity across a wide temperature range, ensuring consistent performance in various climatic conditions. ZF's system incorporates advanced sensors and electronic control units to dynamically adjust fluid pressure and flow based on driving conditions and steering input[1]. This integration results in a more compact and efficient system, reducing overall weight and complexity compared to traditional separate systems[2].

Strengths: Reduced system complexity, weight savings, and improved packaging. Weaknesses: Potential for increased cost due to specialized components and fluid requirements.

Core Innovations in Fluid-Based Suspension Systems

Power steering fluid refining device

PatentPendingIN202211077346A

Innovation

- A power steering fluid refining device equipped with omnidirectional wheels, an AI-based image capturing module, a robotic arm, a telescopic gripper, a viscosity sensor, and a motorized gripper, which autonomously locates the fluid chamber, unfastens it, and determines the fluid's usability, refining the fluid without manual effort and storing it in a filtered receptacle.

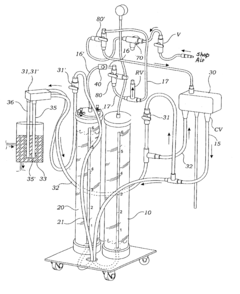

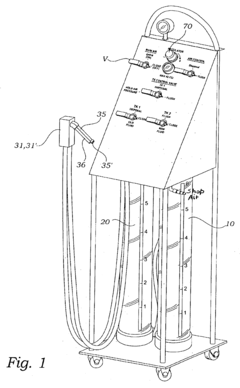

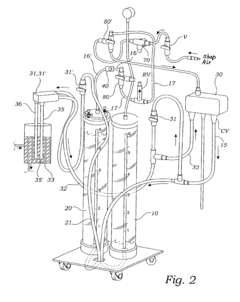

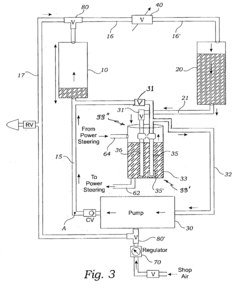

Power steering fluid exchange system and method of use

PatentInactiveUS6772803B2

Innovation

- An apparatus comprising a fluid receiving container, a fluid supply container, a utility fluid pump, and a pressure actuated fluid valve, where air is compressed by spent fluid to open the valve when 80-90% of spent fluid is removed, allowing replacement fluid to enter the power steering system, ensuring minimal mixing with the spent fluid.

Environmental Impact of Suspension Fluids

The environmental impact of suspension fluids, particularly power steering fluid used in air suspension systems, is a growing concern in the automotive industry. These fluids, while essential for system performance, can have significant ecological consequences if not properly managed throughout their lifecycle. The production, use, and disposal of suspension fluids contribute to various environmental issues, including resource depletion, pollution, and potential harm to ecosystems.

During the manufacturing process of suspension fluids, the extraction and refinement of raw materials, primarily petroleum-based compounds, contribute to greenhouse gas emissions and energy consumption. The production facilities themselves may also generate air and water pollution if not properly regulated. Additionally, the transportation of these fluids from production sites to distribution centers and end-users further increases the carbon footprint associated with their use.

In the operational phase, the environmental impact of suspension fluids is primarily related to leaks and improper maintenance. Air suspension systems, while generally sealed, can develop leaks over time, leading to the release of power steering fluid into the environment. These leaks can contaminate soil and water sources, potentially harming plant and animal life. Moreover, the frequent need for fluid replacement in some systems results in increased waste generation and disposal challenges.

The disposal of used suspension fluids presents another significant environmental concern. Improper disposal, such as pouring used fluid down drains or onto the ground, can lead to severe contamination of water sources and soil. Many suspension fluids contain toxic compounds that can persist in the environment for extended periods, bioaccumulate in organisms, and disrupt ecosystems. Proper recycling and disposal methods are crucial to mitigate these risks, but they are not always followed due to lack of awareness or inadequate infrastructure.

To address these environmental challenges, the automotive industry is exploring more sustainable alternatives. Research is being conducted on bio-based suspension fluids derived from renewable resources, which could reduce the reliance on petroleum-based products and potentially offer improved biodegradability. Additionally, advancements in air suspension system design are focusing on reducing fluid requirements and improving leak prevention, thereby minimizing the overall environmental footprint of these systems.

Regulatory bodies are also playing a crucial role in mitigating the environmental impact of suspension fluids. Stricter regulations on fluid composition, handling, and disposal are being implemented in many regions. These regulations aim to reduce the use of harmful chemicals in suspension fluids and promote more environmentally friendly practices throughout the fluid's lifecycle. Furthermore, extended producer responsibility programs are being considered to ensure manufacturers take a more active role in the proper disposal and recycling of used suspension fluids.

During the manufacturing process of suspension fluids, the extraction and refinement of raw materials, primarily petroleum-based compounds, contribute to greenhouse gas emissions and energy consumption. The production facilities themselves may also generate air and water pollution if not properly regulated. Additionally, the transportation of these fluids from production sites to distribution centers and end-users further increases the carbon footprint associated with their use.

In the operational phase, the environmental impact of suspension fluids is primarily related to leaks and improper maintenance. Air suspension systems, while generally sealed, can develop leaks over time, leading to the release of power steering fluid into the environment. These leaks can contaminate soil and water sources, potentially harming plant and animal life. Moreover, the frequent need for fluid replacement in some systems results in increased waste generation and disposal challenges.

The disposal of used suspension fluids presents another significant environmental concern. Improper disposal, such as pouring used fluid down drains or onto the ground, can lead to severe contamination of water sources and soil. Many suspension fluids contain toxic compounds that can persist in the environment for extended periods, bioaccumulate in organisms, and disrupt ecosystems. Proper recycling and disposal methods are crucial to mitigate these risks, but they are not always followed due to lack of awareness or inadequate infrastructure.

To address these environmental challenges, the automotive industry is exploring more sustainable alternatives. Research is being conducted on bio-based suspension fluids derived from renewable resources, which could reduce the reliance on petroleum-based products and potentially offer improved biodegradability. Additionally, advancements in air suspension system design are focusing on reducing fluid requirements and improving leak prevention, thereby minimizing the overall environmental footprint of these systems.

Regulatory bodies are also playing a crucial role in mitigating the environmental impact of suspension fluids. Stricter regulations on fluid composition, handling, and disposal are being implemented in many regions. These regulations aim to reduce the use of harmful chemicals in suspension fluids and promote more environmentally friendly practices throughout the fluid's lifecycle. Furthermore, extended producer responsibility programs are being considered to ensure manufacturers take a more active role in the proper disposal and recycling of used suspension fluids.

Safety Regulations for Automotive Suspension Systems

Safety regulations for automotive suspension systems play a crucial role in ensuring the overall safety and performance of vehicles on the road. These regulations are designed to establish minimum standards for suspension system design, manufacturing, and maintenance, with the ultimate goal of protecting drivers, passengers, and other road users from potential hazards.

One of the primary focuses of safety regulations in this area is the structural integrity of suspension components. Manufacturers are required to adhere to strict guidelines regarding the materials used, manufacturing processes, and quality control measures to ensure that suspension parts can withstand the various stresses and loads encountered during normal vehicle operation. This includes regulations on the strength and durability of components such as control arms, springs, shock absorbers, and mounting points.

Another key aspect of safety regulations for automotive suspension systems is the requirement for regular inspections and maintenance. Many jurisdictions mandate periodic safety inspections that include a thorough examination of the suspension system. These inspections are designed to identify worn or damaged components that could compromise vehicle stability, handling, or braking performance.

Regulations also address the performance characteristics of suspension systems, particularly in terms of vehicle stability and handling. For instance, there are specific requirements for the maximum allowable body roll during cornering, as well as guidelines for the suspension's ability to maintain proper wheel alignment under various driving conditions. These performance standards help ensure that vehicles remain controllable and predictable, even in challenging driving situations.

In recent years, safety regulations have expanded to encompass advanced suspension technologies, such as electronic stability control (ESC) systems and adaptive suspensions. These regulations outline the minimum performance criteria for such systems and often require manufacturers to include these technologies as standard equipment on new vehicles.

Furthermore, safety regulations for automotive suspension systems often include provisions for crash safety. This involves requirements for the suspension's behavior during impact scenarios, ensuring that it contributes to the overall crashworthiness of the vehicle by absorbing and dissipating energy in a controlled manner.

Compliance with these safety regulations is typically enforced through a combination of manufacturer self-certification and government oversight. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) conduct rigorous testing to verify compliance and provide consumers with safety ratings.

As vehicle technology continues to evolve, safety regulations for automotive suspension systems are regularly updated to address new challenges and opportunities. This ongoing process ensures that suspension systems continue to contribute to the overall safety and performance of modern vehicles, adapting to changing road conditions, driving habits, and technological advancements.

One of the primary focuses of safety regulations in this area is the structural integrity of suspension components. Manufacturers are required to adhere to strict guidelines regarding the materials used, manufacturing processes, and quality control measures to ensure that suspension parts can withstand the various stresses and loads encountered during normal vehicle operation. This includes regulations on the strength and durability of components such as control arms, springs, shock absorbers, and mounting points.

Another key aspect of safety regulations for automotive suspension systems is the requirement for regular inspections and maintenance. Many jurisdictions mandate periodic safety inspections that include a thorough examination of the suspension system. These inspections are designed to identify worn or damaged components that could compromise vehicle stability, handling, or braking performance.

Regulations also address the performance characteristics of suspension systems, particularly in terms of vehicle stability and handling. For instance, there are specific requirements for the maximum allowable body roll during cornering, as well as guidelines for the suspension's ability to maintain proper wheel alignment under various driving conditions. These performance standards help ensure that vehicles remain controllable and predictable, even in challenging driving situations.

In recent years, safety regulations have expanded to encompass advanced suspension technologies, such as electronic stability control (ESC) systems and adaptive suspensions. These regulations outline the minimum performance criteria for such systems and often require manufacturers to include these technologies as standard equipment on new vehicles.

Furthermore, safety regulations for automotive suspension systems often include provisions for crash safety. This involves requirements for the suspension's behavior during impact scenarios, ensuring that it contributes to the overall crashworthiness of the vehicle by absorbing and dissipating energy in a controlled manner.

Compliance with these safety regulations is typically enforced through a combination of manufacturer self-certification and government oversight. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) conduct rigorous testing to verify compliance and provide consumers with safety ratings.

As vehicle technology continues to evolve, safety regulations for automotive suspension systems are regularly updated to address new challenges and opportunities. This ongoing process ensures that suspension systems continue to contribute to the overall safety and performance of modern vehicles, adapting to changing road conditions, driving habits, and technological advancements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!