TIM Adhesion Testing: Peel, Shear, And Aging Procedures

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Adhesion Testing Background and Objectives

Thermal Interface Materials (TIMs) have become increasingly critical components in modern electronics as thermal management challenges continue to grow with higher power densities and miniaturization trends. The adhesion properties of TIMs directly impact their thermal performance and long-term reliability in electronic assemblies. The evolution of TIM adhesion testing methodologies has paralleled the development of electronics cooling solutions, with significant advancements occurring over the past three decades.

Initially, TIM adhesion testing was primarily borrowed from general adhesive industry standards, but these methods often failed to address the unique requirements of thermal management applications. The thermal cycling, constant heat exposure, and mechanical stresses that TIMs experience in electronic devices necessitated the development of specialized testing protocols that could accurately predict field performance.

The primary objective of TIM adhesion testing is to quantitatively evaluate the bonding strength between thermal interface materials and various substrate surfaces under conditions that simulate actual application environments. This includes assessing both initial adhesion properties and long-term reliability after exposure to environmental stressors such as temperature cycling, humidity, and mechanical vibration.

Peel testing emerged as one of the earliest standardized methods for evaluating TIM adhesion strength, providing a quantitative measure of the force required to separate the TIM from a substrate at a controlled angle and rate. Shear testing subsequently developed as a complementary methodology that better represents certain in-service stress conditions, particularly for die-attach applications where lateral forces can be significant.

Aging procedures have evolved to address the critical need for predicting long-term reliability. These procedures typically involve exposing TIM samples to accelerated environmental conditions—including elevated temperatures, temperature cycling, and high humidity—to simulate years of service in compressed timeframes. The development of standardized aging protocols has been crucial for enabling meaningful comparisons between different TIM formulations.

The technological goals for TIM adhesion testing continue to evolve toward greater precision, reproducibility, and correlation with actual field performance. Current objectives include developing testing methodologies that can accurately predict adhesion behavior across the full range of operating conditions, standardizing procedures across the industry to enable direct comparisons between different materials, and reducing testing time while maintaining predictive accuracy.

As electronic devices continue to push thermal boundaries with higher power densities and more challenging form factors, the importance of robust TIM adhesion testing methodologies will only increase, driving further innovation in this specialized field of materials characterization.

Initially, TIM adhesion testing was primarily borrowed from general adhesive industry standards, but these methods often failed to address the unique requirements of thermal management applications. The thermal cycling, constant heat exposure, and mechanical stresses that TIMs experience in electronic devices necessitated the development of specialized testing protocols that could accurately predict field performance.

The primary objective of TIM adhesion testing is to quantitatively evaluate the bonding strength between thermal interface materials and various substrate surfaces under conditions that simulate actual application environments. This includes assessing both initial adhesion properties and long-term reliability after exposure to environmental stressors such as temperature cycling, humidity, and mechanical vibration.

Peel testing emerged as one of the earliest standardized methods for evaluating TIM adhesion strength, providing a quantitative measure of the force required to separate the TIM from a substrate at a controlled angle and rate. Shear testing subsequently developed as a complementary methodology that better represents certain in-service stress conditions, particularly for die-attach applications where lateral forces can be significant.

Aging procedures have evolved to address the critical need for predicting long-term reliability. These procedures typically involve exposing TIM samples to accelerated environmental conditions—including elevated temperatures, temperature cycling, and high humidity—to simulate years of service in compressed timeframes. The development of standardized aging protocols has been crucial for enabling meaningful comparisons between different TIM formulations.

The technological goals for TIM adhesion testing continue to evolve toward greater precision, reproducibility, and correlation with actual field performance. Current objectives include developing testing methodologies that can accurately predict adhesion behavior across the full range of operating conditions, standardizing procedures across the industry to enable direct comparisons between different materials, and reducing testing time while maintaining predictive accuracy.

As electronic devices continue to push thermal boundaries with higher power densities and more challenging form factors, the importance of robust TIM adhesion testing methodologies will only increase, driving further innovation in this specialized field of materials characterization.

Market Demand Analysis for TIM Adhesion Solutions

The global market for Thermal Interface Materials (TIMs) is experiencing robust growth driven by increasing thermal management requirements across multiple industries. Current market analysis indicates that the TIM market is projected to reach $4.5 billion by 2027, with a compound annual growth rate of approximately 8-10%. This growth is primarily fueled by the expanding electronics sector, particularly in high-performance computing, telecommunications, and automotive electronics, where efficient heat dissipation has become critical for product reliability and performance.

The demand for advanced TIM adhesion testing methods is particularly pronounced in the semiconductor industry, where chip miniaturization continues to increase power densities. As electronic components become smaller yet more powerful, the heat generated per unit area has increased dramatically, creating unprecedented thermal management challenges. Industry data shows that over 55% of electronic device failures are temperature-related, highlighting the critical importance of reliable TIM solutions.

Consumer electronics manufacturers are increasingly seeking TIMs that maintain consistent adhesion properties throughout product lifecycles. Market research indicates that smartphones, tablets, and wearable devices collectively represent over 40% of TIM application demand, with manufacturers requiring materials that can withstand repeated thermal cycling without degradation of adhesive properties.

The automotive sector presents another significant market opportunity, particularly with the rapid growth of electric vehicles (EVs). The global EV market is expanding at over 25% annually, creating substantial demand for TIMs with superior adhesion characteristics for battery thermal management systems. These applications require materials that can maintain performance under extreme temperature variations and extended operational periods.

Aerospace and defense applications represent a premium segment of the market, where reliability under harsh environmental conditions is paramount. These sectors demand rigorous adhesion testing protocols that can accurately predict long-term performance in extreme environments.

Geographically, Asia-Pacific dominates the TIM market with approximately 45% share, driven by the concentration of electronics manufacturing in countries like China, Taiwan, and South Korea. North America and Europe follow with significant market shares, particularly in high-performance computing and automotive applications.

The market is also witnessing increased demand for environmentally sustainable TIM solutions with reliable adhesion properties, as regulatory pressures and corporate sustainability initiatives drive manufacturers to reduce environmental impacts while maintaining thermal performance. This trend is creating new market opportunities for bio-based and recyclable TIM formulations that can meet stringent adhesion requirements.

The demand for advanced TIM adhesion testing methods is particularly pronounced in the semiconductor industry, where chip miniaturization continues to increase power densities. As electronic components become smaller yet more powerful, the heat generated per unit area has increased dramatically, creating unprecedented thermal management challenges. Industry data shows that over 55% of electronic device failures are temperature-related, highlighting the critical importance of reliable TIM solutions.

Consumer electronics manufacturers are increasingly seeking TIMs that maintain consistent adhesion properties throughout product lifecycles. Market research indicates that smartphones, tablets, and wearable devices collectively represent over 40% of TIM application demand, with manufacturers requiring materials that can withstand repeated thermal cycling without degradation of adhesive properties.

The automotive sector presents another significant market opportunity, particularly with the rapid growth of electric vehicles (EVs). The global EV market is expanding at over 25% annually, creating substantial demand for TIMs with superior adhesion characteristics for battery thermal management systems. These applications require materials that can maintain performance under extreme temperature variations and extended operational periods.

Aerospace and defense applications represent a premium segment of the market, where reliability under harsh environmental conditions is paramount. These sectors demand rigorous adhesion testing protocols that can accurately predict long-term performance in extreme environments.

Geographically, Asia-Pacific dominates the TIM market with approximately 45% share, driven by the concentration of electronics manufacturing in countries like China, Taiwan, and South Korea. North America and Europe follow with significant market shares, particularly in high-performance computing and automotive applications.

The market is also witnessing increased demand for environmentally sustainable TIM solutions with reliable adhesion properties, as regulatory pressures and corporate sustainability initiatives drive manufacturers to reduce environmental impacts while maintaining thermal performance. This trend is creating new market opportunities for bio-based and recyclable TIM formulations that can meet stringent adhesion requirements.

Current Challenges in TIM Adhesion Testing Methods

Despite significant advancements in thermal interface materials (TIMs) development, the testing methodologies for adhesion properties face several critical challenges that impede standardization and reliable performance prediction. Current peel testing methods often suffer from inconsistent results due to variations in peel angle, speed, and substrate preparation. The 90° and 180° peel tests commonly employed show significant result variability when conducted by different operators or laboratories, making cross-comparison of data problematic.

Shear testing methodologies present their own set of complications. The industry lacks consensus on optimal fixture designs, leading to non-uniform stress distribution during testing. This fundamental issue creates discrepancies in reported shear strength values, with variations exceeding 25% between different testing setups for identical materials. Furthermore, the rate-dependent behavior of many TIMs means that shear test results are highly sensitive to loading rates, yet standardized protocols for rate selection remain inadequate.

Accelerated aging procedures represent perhaps the most significant challenge in the field. Current methods fail to accurately simulate real-world conditions where TIMs experience complex combinations of thermal cycling, humidity, and mechanical stress simultaneously. Most aging protocols address these factors in isolation, leading to poor correlation between laboratory predictions and field performance. The industry has documented numerous cases where materials passing standard aging tests subsequently failed prematurely in actual applications.

Temperature range limitations in existing test equipment constitute another substantial obstacle. Many modern electronics operate in extreme environments, yet standard testing equipment typically covers only -40°C to 150°C, insufficient for emerging applications in automotive, aerospace, and industrial sectors where temperature extremes can be significantly more severe.

Sample preparation inconsistencies further complicate testing reliability. The thickness control of TIM application, curing conditions, and surface preparation all significantly impact adhesion test results. Current protocols provide insufficient guidance on these critical parameters, leading to poor reproducibility between testing facilities.

Data interpretation frameworks also remain underdeveloped. The complex viscoelastic behavior of many TIMs means that simple pass/fail criteria based on single-point measurements are inadequate for predicting long-term reliability. More sophisticated models incorporating time-temperature superposition principles and failure mode analysis are needed but not yet widely implemented in standard testing procedures.

Shear testing methodologies present their own set of complications. The industry lacks consensus on optimal fixture designs, leading to non-uniform stress distribution during testing. This fundamental issue creates discrepancies in reported shear strength values, with variations exceeding 25% between different testing setups for identical materials. Furthermore, the rate-dependent behavior of many TIMs means that shear test results are highly sensitive to loading rates, yet standardized protocols for rate selection remain inadequate.

Accelerated aging procedures represent perhaps the most significant challenge in the field. Current methods fail to accurately simulate real-world conditions where TIMs experience complex combinations of thermal cycling, humidity, and mechanical stress simultaneously. Most aging protocols address these factors in isolation, leading to poor correlation between laboratory predictions and field performance. The industry has documented numerous cases where materials passing standard aging tests subsequently failed prematurely in actual applications.

Temperature range limitations in existing test equipment constitute another substantial obstacle. Many modern electronics operate in extreme environments, yet standard testing equipment typically covers only -40°C to 150°C, insufficient for emerging applications in automotive, aerospace, and industrial sectors where temperature extremes can be significantly more severe.

Sample preparation inconsistencies further complicate testing reliability. The thickness control of TIM application, curing conditions, and surface preparation all significantly impact adhesion test results. Current protocols provide insufficient guidance on these critical parameters, leading to poor reproducibility between testing facilities.

Data interpretation frameworks also remain underdeveloped. The complex viscoelastic behavior of many TIMs means that simple pass/fail criteria based on single-point measurements are inadequate for predicting long-term reliability. More sophisticated models incorporating time-temperature superposition principles and failure mode analysis are needed but not yet widely implemented in standard testing procedures.

Standard Peel and Shear Testing Methodologies

01 Adhesion testing methods for thermal interface materials

Various methods are employed to test the adhesion strength of thermal interface materials (TIMs) to substrates. These include peel tests, shear tests, and pull-off tests that measure the force required to separate the TIM from the substrate. Advanced testing equipment can provide quantitative measurements of adhesion strength under different environmental conditions, helping to evaluate the reliability and durability of TIM applications in electronic devices.- Adhesion testing methods for thermal interface materials: Various methods are used to test the adhesion properties of thermal interface materials (TIMs). These methods include peel tests, shear tests, and pull-off tests that measure the force required to separate the TIM from the substrate. Advanced testing equipment can provide quantitative measurements of adhesion strength under different environmental conditions, helping to evaluate the reliability and durability of TIM applications in electronic devices.

- TIM formulations for enhanced adhesion properties: Specific formulations of thermal interface materials are designed to improve adhesion while maintaining thermal conductivity. These formulations may include adhesion promoters, coupling agents, and specialized polymers that create strong bonds with various substrate materials. The balance between adhesive properties and thermal performance is critical for applications in semiconductor packaging and electronic cooling solutions.

- Temperature and environmental effects on TIM adhesion: The adhesion properties of thermal interface materials can be significantly affected by temperature cycling, humidity, and other environmental factors. Testing protocols often include thermal cycling tests, high-temperature storage tests, and humidity exposure to evaluate how these conditions impact the long-term adhesion reliability of TIMs in electronic assemblies. Understanding these effects is crucial for predicting the service life of TIM applications in various operating environments.

- Surface preparation techniques for improved TIM adhesion: Surface preparation methods significantly impact the adhesion performance of thermal interface materials. Techniques such as plasma treatment, chemical cleaning, surface roughening, and application of primers can enhance the bonding between TIMs and substrates. Proper surface preparation protocols are essential for achieving consistent and reliable adhesion in high-performance electronic cooling applications.

- Novel TIM adhesion technologies for advanced electronics: Emerging technologies for thermal interface materials focus on addressing adhesion challenges in advanced electronic applications. These include reworkable adhesives, phase-change materials with enhanced adhesion properties, and nanostructured interfaces that improve both thermal conductivity and bonding strength. These innovations are particularly important for applications in 3D packaging, high-power electronics, and miniaturized devices where traditional TIMs may face limitations.

02 TIM formulations for enhanced adhesion properties

Specific formulations of thermal interface materials are designed to improve adhesion while maintaining thermal conductivity. These formulations may include adhesion promoters, coupling agents, and specialized polymers that create stronger bonds with various substrate materials. The balance between adhesion strength and thermal performance is critical, as excessive adhesion can sometimes lead to difficulties in rework or component replacement in electronic assemblies.Expand Specific Solutions03 Environmental reliability testing of TIM adhesion

Thermal interface materials must maintain adhesion under various environmental stresses. Testing protocols include thermal cycling, humidity exposure, and aging tests to evaluate long-term reliability. These tests simulate real-world conditions that electronic devices might encounter during their operational lifetime, ensuring that the TIM adhesion remains stable over time and through temperature fluctuations, which is critical for maintaining thermal management efficiency.Expand Specific Solutions04 Semiconductor package applications requiring specific TIM adhesion properties

In semiconductor packaging, thermal interface materials with tailored adhesion properties are essential for specific applications. Different package types (such as flip-chip, BGA, or stacked die configurations) require varying degrees of TIM adhesion strength. The adhesion requirements must balance thermal performance with mechanical stability while accommodating the coefficient of thermal expansion mismatches between different materials in the package assembly.Expand Specific Solutions05 Novel TIM compositions with improved adhesion-thermal conductivity balance

Innovative thermal interface material compositions are being developed to achieve an optimal balance between adhesion and thermal conductivity. These include nanoparticle-enhanced formulations, phase-change materials with adhesive properties, and hybrid organic-inorganic composites. These advanced materials aim to address the growing thermal management challenges in high-performance electronics while providing sufficient adhesion to maintain contact under mechanical stresses and vibration.Expand Specific Solutions

Key Industry Players in TIM Testing Equipment

The TIM (Thermal Interface Material) adhesion testing market is currently in a growth phase, with increasing demand driven by electronics, automotive, and aerospace applications. The market size is expanding due to the rising need for efficient thermal management in miniaturized electronic devices. Technologically, the field is moderately mature but evolving, with companies like 3M Innovative Properties, Nitto Denko, and LINTEC leading standardization efforts in peel, shear, and aging test procedures. Major players such as Shin-Etsu Chemical, Air Products & Chemicals, and Bostik are advancing testing methodologies to meet higher performance requirements. Academic institutions like MIT and Kyoto University contribute fundamental research, while electronics manufacturers including Sony and Boeing represent key end-users driving testing protocol development to ensure reliability in mission-critical applications.

3M Innovative Properties Co.

Technical Solution: 3M has developed comprehensive TIM adhesion testing protocols that combine multiple methodologies for thorough characterization. Their approach includes standardized 90° and 180° peel tests using automated testing equipment with precise control of peel angle and speed. For shear testing, 3M employs both static and dynamic methods, including lap shear tests at various temperatures (-40°C to 150°C) to simulate real-world conditions. Their aging procedures incorporate temperature cycling (-65°C to 200°C), high humidity exposure (85% RH at 85°C), and thermal shock testing. 3M has pioneered accelerated aging protocols that correlate with long-term field performance, allowing for rapid qualification of new TIM formulations while maintaining reliability predictions. Their testing methodology includes specialized fixtures designed to minimize edge effects and ensure uniform stress distribution during testing.

Strengths: Industry-leading correlation between accelerated testing and real-world performance; comprehensive multi-parameter testing capabilities; extensive historical database for benchmarking. Weaknesses: Proprietary testing methodologies may not align perfectly with industry standards; testing equipment requires significant capital investment; some accelerated aging protocols may overestimate performance in specific applications.

Nitto Denko Corp.

Technical Solution: Nitto Denko has established a sophisticated TIM adhesion testing framework specifically optimized for electronics applications. Their methodology incorporates modified ASTM D903 and D3330 procedures for peel testing, with custom sample preparation techniques to account for the unique properties of thermal interface materials. For shear testing, they utilize dynamic mechanical analysis (DMA) alongside traditional shear fixtures to characterize viscoelastic behavior under varying temperatures and frequencies. Nitto's aging procedures are particularly noteworthy, featuring power cycling tests that simulate actual device operation with precise thermal profiles and power densities. Their testing includes specialized high-temperature storage tests (up to 175°C) and temperature-humidity-bias (THB) testing to evaluate electrical and mechanical reliability simultaneously. Nitto has developed proprietary image analysis software to quantify adhesive failure modes and surface characteristics after testing.

Strengths: Specialized testing protocols for electronics and semiconductor applications; advanced failure analysis capabilities; excellent correlation between lab testing and field reliability. Weaknesses: Testing methodologies heavily focused on electronics applications with less emphasis on other industries; some specialized equipment not widely available outside Nitto facilities; testing protocols may require longer timeframes than competitors.

Critical Analysis of Aging Test Protocols

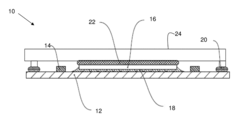

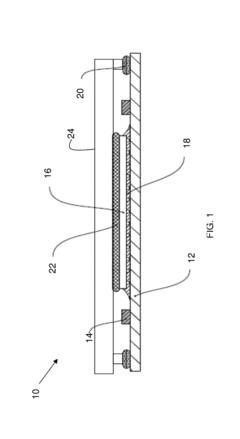

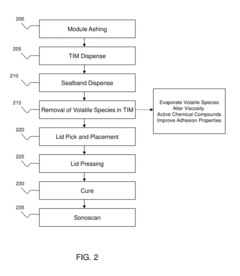

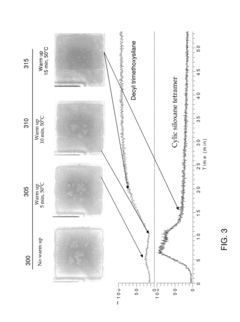

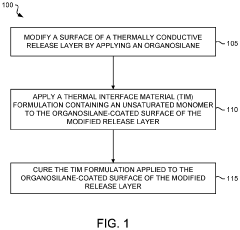

Thermal interface material on package

PatentActiveUS20180047655A1

Innovation

- A method involving the removal of volatile species from TIM through processes like extended delay, low-temperature heating, or vacuum outgassing, followed by lid placement and pressing, to enhance adhesion and minimize voiding, optimizing process parameters for improved thermal performance.

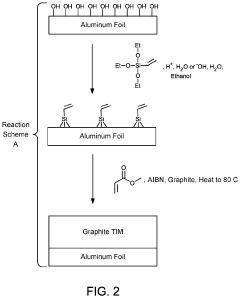

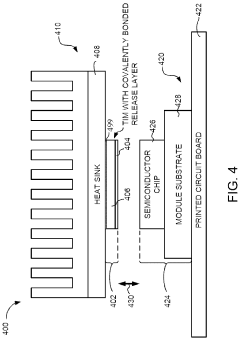

Thermal interface material (TIM) with thermally conductive integrated release layer

PatentActiveUS11621210B2

Innovation

- A TIM with a covalently attached thermally conductive release layer is developed by modifying the aluminum foil surface with organosilanes, allowing for a strong bond with the TIM formulation, which includes unsaturated monomers and thermally conductive fillers like graphite, ensuring durable attachment without residue.

Reliability Standards and Certification Requirements

Thermal Interface Materials (TIMs) must adhere to stringent reliability standards and certification requirements to ensure their performance in electronic applications. The International Electrotechnical Commission (IEC) has established several standards specifically for TIM reliability testing, including IEC 60068 for environmental testing and IEC 61189 for test methods for electrical materials and structures. These standards provide comprehensive guidelines for conducting peel, shear, and aging tests under controlled conditions.

In the United States, Underwriters Laboratories (UL) certification is often required for TIMs used in consumer electronics. UL 746C specifically addresses polymeric materials used in electrical equipment, including adhesion requirements after exposure to various environmental conditions. Similarly, the JEDEC standards, particularly JEDEC JESD22-A103 for high-temperature storage and JESD22-B106 for resistance to soldering heat, are widely recognized in the semiconductor industry for reliability testing.

The automotive industry imposes particularly rigorous standards through the Automotive Electronics Council (AEC). The AEC-Q100 qualification for integrated circuits includes specific requirements for TIM adhesion testing under temperature cycling (Test Method 1010) and high-temperature storage (Test Method 1008). These tests typically require TIMs to maintain at least 80% of their original adhesion strength after exposure to extreme conditions.

Military and aerospace applications follow MIL-STD-810 for environmental engineering considerations, with specific protocols for adhesion testing after exposure to temperature extremes, humidity, and mechanical shock. The standard requires extensive documentation of test procedures and results, with statistical analysis to ensure reliability.

For telecommunications equipment, the Telcordia GR-63-CORE standard outlines specific requirements for thermal management materials, including adhesion testing after exposure to temperature cycling, humidity, and vibration. These tests are designed to simulate real-world conditions in telecommunications infrastructure.

Certification processes typically involve third-party testing laboratories that verify compliance with these standards. Major certification bodies include TÜV, SGS, and Intertek, which provide independent verification of TIM reliability. The certification process generally includes initial type testing, factory production control assessment, and ongoing surveillance testing to ensure continued compliance.

Recent developments in reliability standards have begun to address the specific challenges of new TIM applications in emerging technologies such as electric vehicles, 5G telecommunications, and high-performance computing, where thermal management requirements are increasingly demanding. These updated standards often include more stringent requirements for long-term reliability under dynamic thermal cycling conditions.

In the United States, Underwriters Laboratories (UL) certification is often required for TIMs used in consumer electronics. UL 746C specifically addresses polymeric materials used in electrical equipment, including adhesion requirements after exposure to various environmental conditions. Similarly, the JEDEC standards, particularly JEDEC JESD22-A103 for high-temperature storage and JESD22-B106 for resistance to soldering heat, are widely recognized in the semiconductor industry for reliability testing.

The automotive industry imposes particularly rigorous standards through the Automotive Electronics Council (AEC). The AEC-Q100 qualification for integrated circuits includes specific requirements for TIM adhesion testing under temperature cycling (Test Method 1010) and high-temperature storage (Test Method 1008). These tests typically require TIMs to maintain at least 80% of their original adhesion strength after exposure to extreme conditions.

Military and aerospace applications follow MIL-STD-810 for environmental engineering considerations, with specific protocols for adhesion testing after exposure to temperature extremes, humidity, and mechanical shock. The standard requires extensive documentation of test procedures and results, with statistical analysis to ensure reliability.

For telecommunications equipment, the Telcordia GR-63-CORE standard outlines specific requirements for thermal management materials, including adhesion testing after exposure to temperature cycling, humidity, and vibration. These tests are designed to simulate real-world conditions in telecommunications infrastructure.

Certification processes typically involve third-party testing laboratories that verify compliance with these standards. Major certification bodies include TÜV, SGS, and Intertek, which provide independent verification of TIM reliability. The certification process generally includes initial type testing, factory production control assessment, and ongoing surveillance testing to ensure continued compliance.

Recent developments in reliability standards have begun to address the specific challenges of new TIM applications in emerging technologies such as electric vehicles, 5G telecommunications, and high-performance computing, where thermal management requirements are increasingly demanding. These updated standards often include more stringent requirements for long-term reliability under dynamic thermal cycling conditions.

Environmental Impact of TIM Materials and Testing

The environmental impact of Thermal Interface Materials (TIMs) and their testing procedures represents a growing concern in the electronics industry. As electronic devices become more prevalent, the cumulative environmental footprint of TIMs throughout their lifecycle—from production to disposal—demands critical examination. Traditional TIM materials often contain environmentally problematic components such as silicones, metal particles, and various synthetic compounds that pose challenges for biodegradability and recycling efforts.

Adhesion testing procedures, including peel, shear, and aging tests, contribute to environmental concerns through multiple pathways. These tests frequently require specialized equipment that consumes significant energy during operation. Additionally, the testing process often necessitates the use of chemical solvents and cleaning agents that may contain volatile organic compounds (VOCs) and other hazardous substances, which can contribute to air and water pollution when improperly managed.

The aging procedures in particular present environmental challenges, as accelerated aging tests typically employ elevated temperatures and humidity levels, requiring climate-controlled chambers that consume substantial energy. Furthermore, these tests generate waste materials that may contain degraded TIMs with potentially harmful leachates if disposed of improperly.

Recent industry trends show increasing attention to developing environmentally friendly TIM alternatives, including bio-based materials and recyclable compounds. These innovations aim to reduce the environmental impact while maintaining thermal performance requirements. However, testing protocols for these newer materials often still follow conventional methodologies that may not adequately address their unique environmental characteristics.

Regulatory frameworks worldwide are evolving to address these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly impact TIM formulations and testing requirements. Similarly, electronic waste (e-waste) regulations are becoming more stringent, affecting end-of-life considerations for TIMs.

Life cycle assessment (LCA) studies indicate that the environmental impact of TIMs extends beyond their operational phase. The extraction of raw materials for TIM production, particularly metals like silver and copper used in thermally conductive adhesives, contributes significantly to resource depletion and habitat disruption. Manufacturing processes for TIMs often involve energy-intensive mixing and curing steps that generate greenhouse gas emissions.

Industry stakeholders are now exploring more sustainable testing methodologies that minimize waste generation and energy consumption while still providing reliable performance data. These include non-destructive testing techniques and standardized protocols that reduce the number of samples required, thereby decreasing material waste from testing procedures.

Adhesion testing procedures, including peel, shear, and aging tests, contribute to environmental concerns through multiple pathways. These tests frequently require specialized equipment that consumes significant energy during operation. Additionally, the testing process often necessitates the use of chemical solvents and cleaning agents that may contain volatile organic compounds (VOCs) and other hazardous substances, which can contribute to air and water pollution when improperly managed.

The aging procedures in particular present environmental challenges, as accelerated aging tests typically employ elevated temperatures and humidity levels, requiring climate-controlled chambers that consume substantial energy. Furthermore, these tests generate waste materials that may contain degraded TIMs with potentially harmful leachates if disposed of improperly.

Recent industry trends show increasing attention to developing environmentally friendly TIM alternatives, including bio-based materials and recyclable compounds. These innovations aim to reduce the environmental impact while maintaining thermal performance requirements. However, testing protocols for these newer materials often still follow conventional methodologies that may not adequately address their unique environmental characteristics.

Regulatory frameworks worldwide are evolving to address these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly impact TIM formulations and testing requirements. Similarly, electronic waste (e-waste) regulations are becoming more stringent, affecting end-of-life considerations for TIMs.

Life cycle assessment (LCA) studies indicate that the environmental impact of TIMs extends beyond their operational phase. The extraction of raw materials for TIM production, particularly metals like silver and copper used in thermally conductive adhesives, contributes significantly to resource depletion and habitat disruption. Manufacturing processes for TIMs often involve energy-intensive mixing and curing steps that generate greenhouse gas emissions.

Industry stakeholders are now exploring more sustainable testing methodologies that minimize waste generation and energy consumption while still providing reliable performance data. These include non-destructive testing techniques and standardized protocols that reduce the number of samples required, thereby decreasing material waste from testing procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!