TIM For PCB Level Heat Spreading: Pads Versus Gap Fillers Performance Guide

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Technology Background and Objectives

Thermal Interface Materials (TIMs) have evolved significantly over the past three decades, transitioning from basic thermal greases to sophisticated engineered materials designed to address the increasing thermal management challenges in electronic devices. The fundamental purpose of TIMs remains consistent: to minimize thermal resistance at interfaces between heat-generating components and heat dissipation systems by filling microscopic air gaps that would otherwise impede efficient heat transfer.

The evolution of TIM technology has been primarily driven by the exponential growth in power densities of electronic components, particularly in computing, telecommunications, and power electronics sectors. Early TIMs focused primarily on basic thermal conductivity, while modern solutions must balance multiple properties including thermal performance, reliability, ease of application, reworkability, and long-term stability under various environmental conditions.

In the specific context of PCB-level heat spreading applications, the industry has witnessed a bifurcation in TIM solutions: thermal pads (phase change materials and gap pads) versus gap fillers (thermal compounds and pastes). This divergence represents different approaches to the fundamental challenge of creating optimal thermal interfaces in increasingly complex and miniaturized electronic assemblies.

The current technological landscape shows a clear trend toward higher thermal conductivity materials, with innovations in particle fillers, matrix materials, and interface engineering. Recent advancements include the incorporation of novel materials such as graphene, carbon nanotubes, and ceramic-metallic composites to enhance thermal performance while maintaining other critical properties such as compliance and reliability.

The primary objective of this technical research is to comprehensively evaluate the performance characteristics, application scenarios, and technical trade-offs between thermal pads and gap fillers specifically for PCB-level heat spreading applications. This analysis aims to establish clear guidelines for material selection based on specific application requirements, thermal loads, mechanical constraints, and reliability expectations.

Secondary objectives include identifying emerging trends in TIM technology that may influence future PCB thermal management strategies, evaluating the impact of manufacturing processes on TIM performance, and developing a framework for quantitative comparison of different TIM solutions across varied application scenarios. This research will also explore how recent innovations in material science might reshape the traditional boundaries between pad-type and filler-type TIMs in PCB applications.

The evolution of TIM technology has been primarily driven by the exponential growth in power densities of electronic components, particularly in computing, telecommunications, and power electronics sectors. Early TIMs focused primarily on basic thermal conductivity, while modern solutions must balance multiple properties including thermal performance, reliability, ease of application, reworkability, and long-term stability under various environmental conditions.

In the specific context of PCB-level heat spreading applications, the industry has witnessed a bifurcation in TIM solutions: thermal pads (phase change materials and gap pads) versus gap fillers (thermal compounds and pastes). This divergence represents different approaches to the fundamental challenge of creating optimal thermal interfaces in increasingly complex and miniaturized electronic assemblies.

The current technological landscape shows a clear trend toward higher thermal conductivity materials, with innovations in particle fillers, matrix materials, and interface engineering. Recent advancements include the incorporation of novel materials such as graphene, carbon nanotubes, and ceramic-metallic composites to enhance thermal performance while maintaining other critical properties such as compliance and reliability.

The primary objective of this technical research is to comprehensively evaluate the performance characteristics, application scenarios, and technical trade-offs between thermal pads and gap fillers specifically for PCB-level heat spreading applications. This analysis aims to establish clear guidelines for material selection based on specific application requirements, thermal loads, mechanical constraints, and reliability expectations.

Secondary objectives include identifying emerging trends in TIM technology that may influence future PCB thermal management strategies, evaluating the impact of manufacturing processes on TIM performance, and developing a framework for quantitative comparison of different TIM solutions across varied application scenarios. This research will also explore how recent innovations in material science might reshape the traditional boundaries between pad-type and filler-type TIMs in PCB applications.

Market Analysis for PCB Thermal Management Solutions

The global market for PCB thermal management solutions has been experiencing robust growth, driven by the increasing power density and miniaturization trends in electronic devices. The market was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2027, representing a compound annual growth rate (CAGR) of 8.5%. This growth trajectory is primarily fueled by the expanding applications in consumer electronics, automotive electronics, telecommunications, and industrial equipment sectors.

Thermal Interface Materials (TIMs) constitute a significant segment within this market, accounting for roughly 35% of the total PCB thermal management solutions. Within the TIM category, thermal pads and gap fillers collectively represent about 60% of the market share, with thermal pads holding a slight edge at 32% compared to gap fillers at 28%. The remaining market is distributed among thermal greases, phase change materials, and other emerging solutions.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 45% share, followed by North America (28%) and Europe (20%). This distribution aligns with the concentration of electronics manufacturing facilities in countries like China, Taiwan, South Korea, and Japan. However, North America leads in terms of innovation and high-performance TIM development, particularly for specialized applications in aerospace, defense, and high-end computing.

The competitive landscape features both established players and innovative startups. Key market participants include Henkel, 3M, Parker Chomerics, Laird Technologies, and Dow Corning, collectively controlling about 65% of the global market. These companies are increasingly focusing on developing environmentally friendly and higher-performance TIM solutions to address the growing thermal challenges in modern electronics.

Customer segmentation analysis indicates that OEMs in the consumer electronics sector constitute the largest end-user group (38%), followed by automotive electronics manufacturers (25%), telecommunications equipment producers (18%), and industrial electronics companies (12%). The remaining 7% is distributed among various niche applications including medical devices and aerospace systems.

Market trends suggest a growing preference for gap fillers in applications requiring conformability to irregular surfaces and the ability to fill larger gaps, while thermal pads continue to dominate in applications where defined thickness, ease of application, and reworkability are prioritized. The market is also witnessing increased demand for TIMs with higher thermal conductivity values, with premium solutions offering conductivity exceeding 10 W/mK gaining traction in high-performance computing and automotive applications.

Thermal Interface Materials (TIMs) constitute a significant segment within this market, accounting for roughly 35% of the total PCB thermal management solutions. Within the TIM category, thermal pads and gap fillers collectively represent about 60% of the market share, with thermal pads holding a slight edge at 32% compared to gap fillers at 28%. The remaining market is distributed among thermal greases, phase change materials, and other emerging solutions.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 45% share, followed by North America (28%) and Europe (20%). This distribution aligns with the concentration of electronics manufacturing facilities in countries like China, Taiwan, South Korea, and Japan. However, North America leads in terms of innovation and high-performance TIM development, particularly for specialized applications in aerospace, defense, and high-end computing.

The competitive landscape features both established players and innovative startups. Key market participants include Henkel, 3M, Parker Chomerics, Laird Technologies, and Dow Corning, collectively controlling about 65% of the global market. These companies are increasingly focusing on developing environmentally friendly and higher-performance TIM solutions to address the growing thermal challenges in modern electronics.

Customer segmentation analysis indicates that OEMs in the consumer electronics sector constitute the largest end-user group (38%), followed by automotive electronics manufacturers (25%), telecommunications equipment producers (18%), and industrial electronics companies (12%). The remaining 7% is distributed among various niche applications including medical devices and aerospace systems.

Market trends suggest a growing preference for gap fillers in applications requiring conformability to irregular surfaces and the ability to fill larger gaps, while thermal pads continue to dominate in applications where defined thickness, ease of application, and reworkability are prioritized. The market is also witnessing increased demand for TIMs with higher thermal conductivity values, with premium solutions offering conductivity exceeding 10 W/mK gaining traction in high-performance computing and automotive applications.

Current TIM Technologies and Implementation Challenges

Thermal Interface Materials (TIMs) have evolved significantly over the past decades, with current technologies broadly categorized into several types including thermal greases, phase change materials, thermal pads, gap fillers, and metal-based solutions. Each technology addresses specific thermal management challenges in electronic systems, particularly at the PCB level where heat dissipation is critical for component reliability and performance.

Thermal greases, one of the earliest TIM solutions, offer good thermal conductivity but face challenges related to pump-out effects and long-term reliability. These materials typically consist of silicone or hydrocarbon oils filled with thermally conductive particles such as aluminum oxide, zinc oxide, or silver. While cost-effective, their application process requires precision and they tend to dry out over time.

Phase change materials (PCMs) represent an advancement that addresses some limitations of thermal greases. These materials exist as solids at room temperature but transition to a semi-liquid state at operating temperatures, allowing them to fill microscopic surface irregularities. PCMs offer improved reliability and reduced thermal resistance compared to greases, but may require mechanical clamping pressure to maintain optimal performance.

Thermal pads, or gap pads, have gained significant market share due to their ease of application and consistent performance. These pre-formed, elastomeric materials filled with ceramic particles provide reliable thermal interfaces with minimal compression requirements. However, they typically offer lower thermal conductivity compared to high-performance greases and may require greater thickness to accommodate surface irregularities.

Gap fillers represent a more recent innovation, designed specifically to address larger gaps between heat sources and heat sinks. These dispensable, paste-like materials can fill spaces ranging from 0.25mm to several millimeters while maintaining good thermal performance. Their ability to conform to irregular surfaces makes them particularly valuable in applications with significant tolerance variations.

The implementation of these technologies faces several key challenges. First, the increasing power densities in modern electronic components demand ever-higher thermal conductivity from TIMs. Second, reliability requirements have become more stringent, with expectations for TIMs to maintain performance over product lifetimes of 10+ years despite thermal cycling and environmental stresses.

Manufacturing challenges also persist, particularly in high-volume production environments where application consistency, cure times, and rework capabilities significantly impact production efficiency. The industry continues to seek solutions that balance thermal performance with manufacturability, reliability, and cost-effectiveness.

Recent developments have focused on novel fillers including graphene, carbon nanotubes, and ceramic-metal hybrid particles to enhance thermal conductivity while maintaining other desirable properties. These advancements show promise but often face commercialization barriers related to cost, scalability, and long-term reliability validation.

Thermal greases, one of the earliest TIM solutions, offer good thermal conductivity but face challenges related to pump-out effects and long-term reliability. These materials typically consist of silicone or hydrocarbon oils filled with thermally conductive particles such as aluminum oxide, zinc oxide, or silver. While cost-effective, their application process requires precision and they tend to dry out over time.

Phase change materials (PCMs) represent an advancement that addresses some limitations of thermal greases. These materials exist as solids at room temperature but transition to a semi-liquid state at operating temperatures, allowing them to fill microscopic surface irregularities. PCMs offer improved reliability and reduced thermal resistance compared to greases, but may require mechanical clamping pressure to maintain optimal performance.

Thermal pads, or gap pads, have gained significant market share due to their ease of application and consistent performance. These pre-formed, elastomeric materials filled with ceramic particles provide reliable thermal interfaces with minimal compression requirements. However, they typically offer lower thermal conductivity compared to high-performance greases and may require greater thickness to accommodate surface irregularities.

Gap fillers represent a more recent innovation, designed specifically to address larger gaps between heat sources and heat sinks. These dispensable, paste-like materials can fill spaces ranging from 0.25mm to several millimeters while maintaining good thermal performance. Their ability to conform to irregular surfaces makes them particularly valuable in applications with significant tolerance variations.

The implementation of these technologies faces several key challenges. First, the increasing power densities in modern electronic components demand ever-higher thermal conductivity from TIMs. Second, reliability requirements have become more stringent, with expectations for TIMs to maintain performance over product lifetimes of 10+ years despite thermal cycling and environmental stresses.

Manufacturing challenges also persist, particularly in high-volume production environments where application consistency, cure times, and rework capabilities significantly impact production efficiency. The industry continues to seek solutions that balance thermal performance with manufacturability, reliability, and cost-effectiveness.

Recent developments have focused on novel fillers including graphene, carbon nanotubes, and ceramic-metal hybrid particles to enhance thermal conductivity while maintaining other desirable properties. These advancements show promise but often face commercialization barriers related to cost, scalability, and long-term reliability validation.

Comparative Analysis: Thermal Pads vs Gap Fillers

01 Carbon-based TIM for enhanced heat spreading

Carbon-based materials such as graphene, carbon nanotubes, and graphite are utilized in thermal interface materials to significantly improve heat spreading capabilities. These materials offer exceptional thermal conductivity and can be incorporated into various matrix materials to create composite TIMs. The unique structure of carbon allotropes allows for efficient heat transfer across interfaces, making them ideal for high-performance electronic cooling applications.- Carbon-based materials for thermal interface applications: Carbon-based materials such as graphene, carbon nanotubes, and graphite have excellent thermal conductivity properties making them ideal for thermal interface materials. These materials can be incorporated into polymer matrices to create composite TIMs with enhanced heat spreading capabilities. The high aspect ratio and intrinsic thermal conductivity of these carbon allotropes facilitate efficient heat transfer across interfaces in electronic devices, reducing thermal resistance and improving overall thermal management.

- Metal-based thermal interface materials: Metal-based thermal interface materials utilize metals and metal alloys with high thermal conductivity to enhance heat spreading in electronic devices. These materials include indium, gallium, tin, and their alloys, which can be formulated as liquid metal TIMs or metal-polymer composites. The advantage of metal-based TIMs is their ability to conform to surface irregularities while maintaining excellent thermal conductivity, thus reducing thermal resistance at interfaces between heat sources and heat sinks.

- Phase change materials for thermal management: Phase change materials (PCMs) are designed to change from solid to liquid at specific temperatures, allowing them to absorb heat during the phase transition. When incorporated into thermal interface materials, PCMs can provide excellent wetting of contact surfaces and fill microscopic air gaps, resulting in reduced thermal resistance. These materials are particularly effective in applications with thermal cycling, as they can repeatedly melt and solidify while maintaining their thermal performance characteristics.

- Ceramic-filled polymer composites for heat dissipation: Ceramic-filled polymer composites combine thermally conductive ceramic particles such as aluminum oxide, boron nitride, or aluminum nitride with polymer matrices to create effective thermal interface materials. These composites offer a balance between thermal conductivity and mechanical properties, including conformability and ease of application. The ceramic fillers create thermal conduction pathways through the otherwise insulating polymer matrix, enhancing the overall heat spreading capability while maintaining electrical insulation properties.

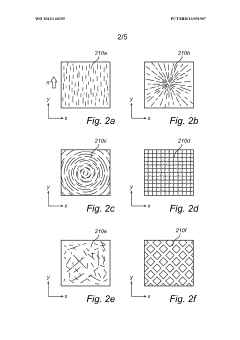

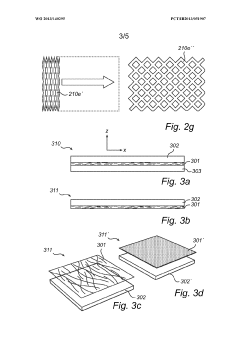

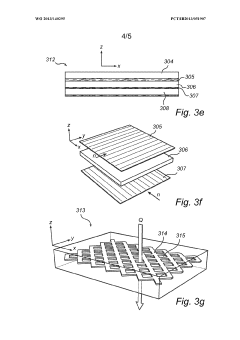

- Novel manufacturing techniques for advanced TIMs: Advanced manufacturing techniques are being developed to enhance the performance of thermal interface materials. These include 3D printing of custom TIM structures, sintering processes for metal-based TIMs, and alignment techniques for anisotropic fillers to create preferential heat conduction pathways. These manufacturing innovations allow for the creation of TIMs with tailored properties for specific applications, optimized contact pressure requirements, and reduced thermal resistance at critical interfaces in electronic assemblies.

02 Metal-based thermal interface materials

Metal-based TIMs utilize materials such as indium, gallium, or other metal alloys to provide superior thermal conductivity for heat spreading applications. These materials can be formulated as liquid metal compounds, sintered metal matrices, or metal-polymer composites. The high thermal conductivity of metals enables efficient heat transfer from heat-generating components to heat sinks, making them particularly effective in high-power density applications where thermal management is critical.Expand Specific Solutions03 Phase change materials for thermal management

Phase change materials (PCMs) in thermal interface applications utilize the latent heat of phase transition to absorb and release thermal energy, providing effective heat spreading. These materials change from solid to liquid at specific temperatures, filling microscopic gaps between surfaces and improving thermal contact. PCM-based TIMs offer advantages including conformability to surface irregularities, reduced thermal resistance, and the ability to manage transient thermal loads in electronic devices.Expand Specific Solutions04 Polymer-based composite TIMs

Polymer-based composite TIMs incorporate thermally conductive fillers within polymer matrices to create flexible, conformable materials with enhanced heat spreading capabilities. These composites combine the processability and mechanical properties of polymers with the thermal conductivity of fillers such as ceramic particles, metal flakes, or carbon materials. The polymer matrix provides flexibility and ease of application while the fillers create thermal pathways for efficient heat dissipation in electronic assemblies.Expand Specific Solutions05 Novel manufacturing techniques for advanced TIMs

Advanced manufacturing techniques are being developed to create next-generation thermal interface materials with superior heat spreading capabilities. These include 3D printing of custom TIM structures, sintering processes for metal-based TIMs, chemical vapor deposition for carbon-based materials, and novel curing methods for polymer composites. These manufacturing innovations enable precise control over material properties, interface geometry, and thermal pathways, resulting in TIMs with significantly improved performance for demanding thermal management applications.Expand Specific Solutions

Leading Manufacturers and Suppliers in TIM Industry

The thermal interface materials (TIM) market for PCB level heat spreading is evolving rapidly, currently transitioning from early maturity to growth phase. The market is expanding due to increasing thermal management demands in electronics, with an estimated global value exceeding $2 billion. Leading technology players demonstrate varying levels of technical maturity: Intel, IBM, and 3M showcase advanced gap filler and thermal pad solutions with proven performance metrics, while companies like Indium Corporation and Henkel focus on specialized formulations. Asian manufacturers including TSMC, Samsung, and Huawei are rapidly advancing their thermal management capabilities, particularly in high-density applications. The competitive landscape reveals a technical divergence between established players optimizing existing solutions and emerging companies developing novel materials with enhanced thermal conductivity and reliability.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced thermal interface materials for PCB-level heat spreading that include both gap fillers and thermal pads. Their gap filler portfolio features compressible, conformable materials with thermal conductivity ranging from 1.5 to 5 W/m-K, designed to minimize contact resistance between heat-generating components and heat sinks. Their thermal pads utilize proprietary boron nitride-filled silicone technology that maintains performance over multiple compression cycles. 3M's solutions incorporate phase-change materials that melt at specific temperatures (typically 45-65°C) to fill microscopic surface irregularities, reducing thermal resistance by up to 30% compared to standard gap fillers. Their manufacturing process ensures uniform particle distribution throughout the material matrix, preventing thermal conductivity inconsistencies that could lead to hotspots.

Strengths: Superior conformability to irregular surfaces, excellent compression set resistance, and consistent performance over thermal cycling. Their materials maintain gap-filling properties while providing electrical isolation where needed. Weaknesses: Higher cost compared to generic solutions, and some formulations may require specific handling procedures during assembly to achieve optimal thermal performance.

Henkel IP & Holding GmbH

Technical Solution: Henkel has pioneered hybrid thermal interface materials that combine the benefits of both pads and gap fillers for PCB-level heat spreading. Their BERGQUIST Gap Pad TGP 10000ULM series achieves thermal conductivity of 10.0 W/m-K while maintaining a low compression force (under 35 psi at 30% deflection), addressing the traditional trade-off between thermal performance and mechanical stress on components. Henkel's liquid gap fillers utilize a patented dual-cure mechanism that allows initial placement via UV curing followed by complete thermal curing, enabling precise application in high-volume manufacturing environments. Their materials incorporate specially treated ceramic fillers with optimized particle size distribution to maximize packing density while maintaining spreadability. Henkel's research has demonstrated that their gap fillers can reduce junction temperatures by up to 15°C compared to traditional thermal pads when used in high-power density applications with uneven surface topographies.

Strengths: Excellent balance between thermal conductivity and compressibility, automated dispensing compatibility for high-volume manufacturing, and long-term reliability with minimal pump-out or dry-out effects. Weaknesses: Some formulations require specific curing conditions that may extend manufacturing cycle times, and the highest performance materials come with premium pricing that may impact overall product cost structures.

Technical Deep Dive: Heat Transfer Mechanisms in PCB-Level TIMs

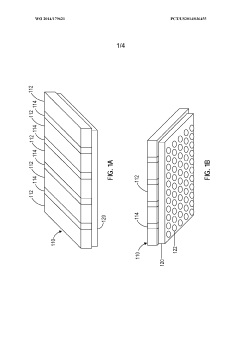

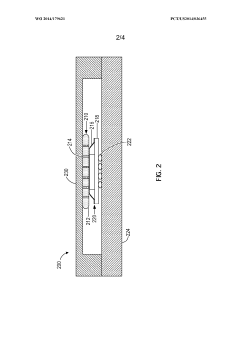

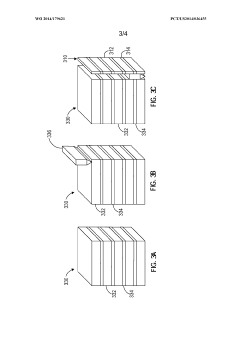

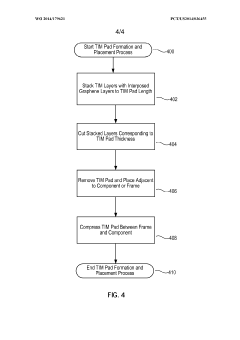

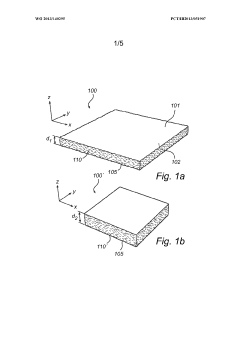

Thermal interface material pad and method of forming the same

PatentWO2014179621A1

Innovation

- Incorporating graphene layers into the TIM structure, which significantly increases thermal conductivity by interposing them between TIM layers, allowing for both high thermal transfer and compressibility to fill air gaps.

Thermal interface material

PatentWO2013140295A2

Innovation

- A TIM with an activable shrinkage material that increases in thickness upon activation, providing controllable physical dimensions and enhancing contact pressure between heat generating and conducting components, thereby eliminating the need for external pressure and improving robustness against surface curvature and roughness.

Environmental Impact and Sustainability of TIM Solutions

The environmental impact of Thermal Interface Materials (TIMs) has become increasingly significant as electronics manufacturing scales globally. Traditional TIM solutions often contain substances that pose environmental concerns, including silicones with volatile organic compounds (VOCs), heavy metals as fillers, and halogenated flame retardants. These components can contribute to pollution during manufacturing, use, and disposal phases of electronic products.

Gap fillers typically require larger material volumes compared to thermal pads, potentially increasing the environmental footprint through raw material extraction and processing. However, recent advancements have introduced bio-based alternatives and recyclable formulations that reduce environmental impact. Several manufacturers now offer silicone-free gap fillers derived from renewable resources, achieving comparable thermal performance while minimizing ecological harm.

Thermal pads present different sustainability considerations. Their pre-formed nature often results in material waste during application, as excess portions must be trimmed to fit specific PCB geometries. This manufacturing inefficiency contributes to resource wastage. However, thermal pads generally have longer operational lifespans than many gap fillers, reducing replacement frequency and associated environmental costs over product lifecycles.

Life cycle assessment (LCA) studies indicate that the environmental impact of TIMs extends beyond manufacturing to include energy consumption during use. TIMs that maintain optimal thermal performance throughout product life contribute to energy efficiency by preventing thermal throttling and extending component lifespan, thereby reducing electronic waste generation.

The disposal phase presents significant environmental challenges for both TIM types. Most conventional thermal interface materials are not biodegradable and contain compounds that can leach into soil and water systems. Recent industry initiatives have focused on developing TIM solutions with end-of-life considerations, including thermally conductive materials that can be more easily separated from electronic components during recycling processes.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic components, including TIMs. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have prompted manufacturers to develop compliant formulations with reduced environmental impact. These regulatory pressures have accelerated innovation in environmentally friendly TIM solutions that maintain or exceed the thermal performance of conventional materials.

Gap fillers typically require larger material volumes compared to thermal pads, potentially increasing the environmental footprint through raw material extraction and processing. However, recent advancements have introduced bio-based alternatives and recyclable formulations that reduce environmental impact. Several manufacturers now offer silicone-free gap fillers derived from renewable resources, achieving comparable thermal performance while minimizing ecological harm.

Thermal pads present different sustainability considerations. Their pre-formed nature often results in material waste during application, as excess portions must be trimmed to fit specific PCB geometries. This manufacturing inefficiency contributes to resource wastage. However, thermal pads generally have longer operational lifespans than many gap fillers, reducing replacement frequency and associated environmental costs over product lifecycles.

Life cycle assessment (LCA) studies indicate that the environmental impact of TIMs extends beyond manufacturing to include energy consumption during use. TIMs that maintain optimal thermal performance throughout product life contribute to energy efficiency by preventing thermal throttling and extending component lifespan, thereby reducing electronic waste generation.

The disposal phase presents significant environmental challenges for both TIM types. Most conventional thermal interface materials are not biodegradable and contain compounds that can leach into soil and water systems. Recent industry initiatives have focused on developing TIM solutions with end-of-life considerations, including thermally conductive materials that can be more easily separated from electronic components during recycling processes.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic components, including TIMs. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have prompted manufacturers to develop compliant formulations with reduced environmental impact. These regulatory pressures have accelerated innovation in environmentally friendly TIM solutions that maintain or exceed the thermal performance of conventional materials.

Cost-Performance Optimization Strategies for TIM Selection

When selecting Thermal Interface Materials (TIMs) for PCB-level heat spreading applications, organizations must balance performance requirements with cost constraints. This optimization process requires a systematic approach that considers both technical specifications and financial implications.

The cost structure of TIMs varies significantly between thermal pads and gap fillers. Thermal pads typically have higher initial material costs but offer simplified application processes that reduce labor expenses and minimize waste. Gap fillers, while often less expensive per unit volume, may require specialized dispensing equipment and trained personnel, increasing implementation costs.

Performance-to-cost ratio analysis reveals that high-end thermal pads deliver superior thermal conductivity per dollar spent in applications with minimal gap variations. Conversely, gap fillers demonstrate better cost efficiency in scenarios with irregular surfaces or varying bond line thicknesses, as they eliminate the need for multiple pad thickness inventories.

Lifecycle cost considerations further complicate the selection process. Thermal pads generally exhibit longer operational lifespans with minimal performance degradation, reducing replacement frequency and associated maintenance costs. Gap fillers may require more frequent reapplication in high-stress environments but offer easier rework capabilities that can offset these expenses in products requiring frequent servicing.

Volume scaling presents another critical optimization factor. For high-volume production, automated dispensing systems for gap fillers become increasingly cost-effective as initial equipment investments are distributed across larger production runs. Thermal pads maintain relatively consistent per-unit costs regardless of volume, making them potentially more economical for low to medium production scales.

Application-specific optimization strategies suggest that consumer electronics with short product lifecycles may benefit from lower-cost gap fillers despite marginally reduced thermal performance. In contrast, industrial or automotive applications with extended service requirements and harsh operating conditions often justify the premium cost of high-performance thermal pads due to their reliability and longevity advantages.

Risk mitigation must also factor into cost-performance calculations. The higher consistency and predictability of pre-formed thermal pads reduce quality control costs and minimize the risk of thermal failures in the field. Gap fillers introduce greater process variability but offer superior adaptability to design changes, potentially reducing redesign costs during product development cycles.

The cost structure of TIMs varies significantly between thermal pads and gap fillers. Thermal pads typically have higher initial material costs but offer simplified application processes that reduce labor expenses and minimize waste. Gap fillers, while often less expensive per unit volume, may require specialized dispensing equipment and trained personnel, increasing implementation costs.

Performance-to-cost ratio analysis reveals that high-end thermal pads deliver superior thermal conductivity per dollar spent in applications with minimal gap variations. Conversely, gap fillers demonstrate better cost efficiency in scenarios with irregular surfaces or varying bond line thicknesses, as they eliminate the need for multiple pad thickness inventories.

Lifecycle cost considerations further complicate the selection process. Thermal pads generally exhibit longer operational lifespans with minimal performance degradation, reducing replacement frequency and associated maintenance costs. Gap fillers may require more frequent reapplication in high-stress environments but offer easier rework capabilities that can offset these expenses in products requiring frequent servicing.

Volume scaling presents another critical optimization factor. For high-volume production, automated dispensing systems for gap fillers become increasingly cost-effective as initial equipment investments are distributed across larger production runs. Thermal pads maintain relatively consistent per-unit costs regardless of volume, making them potentially more economical for low to medium production scales.

Application-specific optimization strategies suggest that consumer electronics with short product lifecycles may benefit from lower-cost gap fillers despite marginally reduced thermal performance. In contrast, industrial or automotive applications with extended service requirements and harsh operating conditions often justify the premium cost of high-performance thermal pads due to their reliability and longevity advantages.

Risk mitigation must also factor into cost-performance calculations. The higher consistency and predictability of pre-formed thermal pads reduce quality control costs and minimize the risk of thermal failures in the field. Gap fillers introduce greater process variability but offer superior adaptability to design changes, potentially reducing redesign costs during product development cycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!