TIM Measurement Uncertainty: Reporting Format And Calibration Requirements

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Measurement Background and Objectives

Thermal Interface Materials (TIMs) have evolved significantly over the past three decades, transitioning from simple thermal greases to advanced composite materials engineered at the nanoscale. These materials play a critical role in electronic thermal management by filling microscopic air gaps between heat-generating components and heat dissipation systems, thereby facilitating efficient heat transfer across interfaces.

The measurement of TIM thermal performance has become increasingly important as electronic devices continue to miniaturize while generating more heat. Historically, thermal conductivity was the primary metric of interest, but industry understanding has evolved to recognize that thermal interface resistance (or thermal impedance) provides a more comprehensive and application-relevant performance indicator.

Current measurement methodologies for TIMs include steady-state techniques such as ASTM D5470, transient methods like laser flash analysis, and modified hot wire methods. Each approach offers distinct advantages but also presents unique challenges regarding accuracy, repeatability, and correlation to real-world performance. The diversity of measurement techniques has led to significant variability in reported thermal performance values across the industry.

The primary objective of TIM measurement standardization is to establish consistent protocols for quantifying measurement uncertainty, ensuring that thermal performance data can be meaningfully compared across different materials, manufacturers, and application scenarios. This standardization effort aims to address the current challenges in the industry where performance claims often lack proper uncertainty quantification, making it difficult for engineers to make informed material selection decisions.

Calibration requirements represent a critical component of this standardization effort. Current practices vary widely, with inconsistent reference materials, calibration intervals, and verification procedures. The establishment of traceable calibration standards and procedures is essential for ensuring measurement reliability and facilitating meaningful cross-laboratory comparisons.

The reporting format for TIM measurement data presents another significant challenge. Current industry practices lack uniformity in how thermal performance data is presented, particularly regarding the disclosure of test conditions, sample preparation methods, and uncertainty quantification. A standardized reporting format would enable more transparent communication of material performance and support more effective material selection processes.

As electronic devices continue to advance in complexity and power density, the need for accurate and reliable TIM performance data becomes increasingly critical. The development of comprehensive standards for measurement uncertainty reporting and calibration requirements will support innovation in thermal management solutions and enable more efficient thermal design processes across the electronics industry.

The measurement of TIM thermal performance has become increasingly important as electronic devices continue to miniaturize while generating more heat. Historically, thermal conductivity was the primary metric of interest, but industry understanding has evolved to recognize that thermal interface resistance (or thermal impedance) provides a more comprehensive and application-relevant performance indicator.

Current measurement methodologies for TIMs include steady-state techniques such as ASTM D5470, transient methods like laser flash analysis, and modified hot wire methods. Each approach offers distinct advantages but also presents unique challenges regarding accuracy, repeatability, and correlation to real-world performance. The diversity of measurement techniques has led to significant variability in reported thermal performance values across the industry.

The primary objective of TIM measurement standardization is to establish consistent protocols for quantifying measurement uncertainty, ensuring that thermal performance data can be meaningfully compared across different materials, manufacturers, and application scenarios. This standardization effort aims to address the current challenges in the industry where performance claims often lack proper uncertainty quantification, making it difficult for engineers to make informed material selection decisions.

Calibration requirements represent a critical component of this standardization effort. Current practices vary widely, with inconsistent reference materials, calibration intervals, and verification procedures. The establishment of traceable calibration standards and procedures is essential for ensuring measurement reliability and facilitating meaningful cross-laboratory comparisons.

The reporting format for TIM measurement data presents another significant challenge. Current industry practices lack uniformity in how thermal performance data is presented, particularly regarding the disclosure of test conditions, sample preparation methods, and uncertainty quantification. A standardized reporting format would enable more transparent communication of material performance and support more effective material selection processes.

As electronic devices continue to advance in complexity and power density, the need for accurate and reliable TIM performance data becomes increasingly critical. The development of comprehensive standards for measurement uncertainty reporting and calibration requirements will support innovation in thermal management solutions and enable more efficient thermal design processes across the electronics industry.

Market Requirements for TIM Measurement Accuracy

The thermal interface materials (TIM) market is experiencing a significant shift towards higher precision measurement requirements, driven primarily by the increasing thermal management demands in advanced electronics. Industry stakeholders, including semiconductor manufacturers, electronic device producers, and thermal solution providers, are collectively pushing for more stringent accuracy standards in TIM thermal performance measurements.

Current market requirements indicate that measurement accuracy within ±5% has become the baseline expectation for high-performance applications, while leading-edge applications in aerospace, medical devices, and high-performance computing are demanding accuracies approaching ±2-3%. This trend is particularly evident in the data center sector, where even marginal improvements in thermal conductivity measurement accuracy can translate to significant operational cost savings through optimized cooling solutions.

The automotive electronics industry, especially with the rise of electric vehicles, has established requirements for measurement repeatability within ±3% across different testing facilities to ensure consistent thermal management in safety-critical systems. This cross-facility consistency has emerged as a key market requirement, as global supply chains necessitate comparable measurement results regardless of geographic location or testing equipment variations.

Market feedback from TIM manufacturers reveals a growing demand for standardized reporting formats that clearly communicate measurement uncertainty. End users increasingly require comprehensive uncertainty budgets that account for all variables affecting measurement accuracy, including sample preparation variations, temperature control precision, and pressure application consistency.

The consumer electronics segment has been particularly vocal about the need for realistic testing conditions that mirror actual device operation, rather than idealized laboratory environments. This has led to requirements for dynamic testing protocols that can assess TIM performance under varying thermal loads and operating conditions, with clearly quantified accuracy metrics for each testing scenario.

Financial implications are also driving accuracy requirements, as warranty claims and product reliability concerns directly correlate with the precision of thermal performance specifications. Industry analysts estimate that measurement inaccuracies currently contribute to approximately 8-12% of thermal management failures in electronic devices, creating a strong economic incentive for improved measurement standards.

Regulatory bodies and industry consortia are responding to these market demands by developing more rigorous certification requirements for testing facilities, with particular emphasis on calibration traceability and uncertainty reporting. The market increasingly values third-party verification of measurement capabilities, with documented calibration procedures becoming a competitive differentiator for testing service providers.

Current market requirements indicate that measurement accuracy within ±5% has become the baseline expectation for high-performance applications, while leading-edge applications in aerospace, medical devices, and high-performance computing are demanding accuracies approaching ±2-3%. This trend is particularly evident in the data center sector, where even marginal improvements in thermal conductivity measurement accuracy can translate to significant operational cost savings through optimized cooling solutions.

The automotive electronics industry, especially with the rise of electric vehicles, has established requirements for measurement repeatability within ±3% across different testing facilities to ensure consistent thermal management in safety-critical systems. This cross-facility consistency has emerged as a key market requirement, as global supply chains necessitate comparable measurement results regardless of geographic location or testing equipment variations.

Market feedback from TIM manufacturers reveals a growing demand for standardized reporting formats that clearly communicate measurement uncertainty. End users increasingly require comprehensive uncertainty budgets that account for all variables affecting measurement accuracy, including sample preparation variations, temperature control precision, and pressure application consistency.

The consumer electronics segment has been particularly vocal about the need for realistic testing conditions that mirror actual device operation, rather than idealized laboratory environments. This has led to requirements for dynamic testing protocols that can assess TIM performance under varying thermal loads and operating conditions, with clearly quantified accuracy metrics for each testing scenario.

Financial implications are also driving accuracy requirements, as warranty claims and product reliability concerns directly correlate with the precision of thermal performance specifications. Industry analysts estimate that measurement inaccuracies currently contribute to approximately 8-12% of thermal management failures in electronic devices, creating a strong economic incentive for improved measurement standards.

Regulatory bodies and industry consortia are responding to these market demands by developing more rigorous certification requirements for testing facilities, with particular emphasis on calibration traceability and uncertainty reporting. The market increasingly values third-party verification of measurement capabilities, with documented calibration procedures becoming a competitive differentiator for testing service providers.

Current Challenges in TIM Measurement Uncertainty

Despite significant advancements in thermal interface material (TIM) measurement technologies, the field continues to face substantial challenges regarding measurement uncertainty. One of the primary obstacles is the lack of standardized reporting formats across different testing laboratories and manufacturers. This inconsistency creates difficulties when comparing TIM performance data from various sources, as each entity may report uncertainty using different statistical methods, confidence intervals, or presentation formats.

The absence of universally accepted calibration protocols further complicates the reliability of TIM thermal performance measurements. Current calibration procedures often vary significantly between testing facilities, leading to systematic errors that remain unaccounted for in final uncertainty calculations. This variability is particularly problematic when measuring high-performance TIMs with thermal conductivities exceeding 10 W/mK, where even small calibration discrepancies can lead to significant performance mischaracterizations.

Temperature and pressure dependencies represent another major challenge in TIM measurement uncertainty. Many current measurement systems fail to adequately account for how measurement uncertainty changes across different operating temperatures and applied pressures. This limitation is especially critical for applications in extreme environments where TIMs must perform reliably under varying conditions.

Sample-to-sample variation presents a persistent challenge that is often underreported in uncertainty analyses. The inherent heterogeneity of many TIM formulations, particularly those containing particulate fillers or phase-change materials, contributes to measurement inconsistencies that are difficult to quantify systematically. Current practices frequently fail to distinguish between measurement uncertainty and actual material variability.

Contact resistance effects continue to plague accurate TIM thermal characterization. The uncertainty introduced at material interfaces often dominates the overall measurement uncertainty, yet quantifying this component remains elusive. Current methods struggle to separate bulk material properties from interface effects, leading to potentially misleading performance metrics.

Time-dependent behavior of TIMs introduces additional complexity to uncertainty quantification. Many materials exhibit changing thermal properties during testing due to curing, aging, or thermal cycling, yet current uncertainty reporting rarely accounts for these temporal variations. This oversight can result in significant discrepancies between laboratory measurements and real-world performance.

Finally, there exists a critical gap between laboratory measurement uncertainty and application-relevant performance metrics. The translation of controlled laboratory measurements to predictions of in-situ performance involves additional uncertainty factors that are rarely quantified or reported, limiting the practical utility of thermal performance data for design engineers.

The absence of universally accepted calibration protocols further complicates the reliability of TIM thermal performance measurements. Current calibration procedures often vary significantly between testing facilities, leading to systematic errors that remain unaccounted for in final uncertainty calculations. This variability is particularly problematic when measuring high-performance TIMs with thermal conductivities exceeding 10 W/mK, where even small calibration discrepancies can lead to significant performance mischaracterizations.

Temperature and pressure dependencies represent another major challenge in TIM measurement uncertainty. Many current measurement systems fail to adequately account for how measurement uncertainty changes across different operating temperatures and applied pressures. This limitation is especially critical for applications in extreme environments where TIMs must perform reliably under varying conditions.

Sample-to-sample variation presents a persistent challenge that is often underreported in uncertainty analyses. The inherent heterogeneity of many TIM formulations, particularly those containing particulate fillers or phase-change materials, contributes to measurement inconsistencies that are difficult to quantify systematically. Current practices frequently fail to distinguish between measurement uncertainty and actual material variability.

Contact resistance effects continue to plague accurate TIM thermal characterization. The uncertainty introduced at material interfaces often dominates the overall measurement uncertainty, yet quantifying this component remains elusive. Current methods struggle to separate bulk material properties from interface effects, leading to potentially misleading performance metrics.

Time-dependent behavior of TIMs introduces additional complexity to uncertainty quantification. Many materials exhibit changing thermal properties during testing due to curing, aging, or thermal cycling, yet current uncertainty reporting rarely accounts for these temporal variations. This oversight can result in significant discrepancies between laboratory measurements and real-world performance.

Finally, there exists a critical gap between laboratory measurement uncertainty and application-relevant performance metrics. The translation of controlled laboratory measurements to predictions of in-situ performance involves additional uncertainty factors that are rarely quantified or reported, limiting the practical utility of thermal performance data for design engineers.

Current Reporting Format Solutions for TIM Measurements

01 Measurement methods for thermal interface materials

Various methods are employed to measure the thermal properties of TIMs, including thermal conductivity, thermal resistance, and heat transfer capabilities. These measurement techniques often involve specialized equipment and procedures to accurately characterize the performance of thermal interface materials under different conditions. The methods may include steady-state and transient techniques, each with their own advantages for specific applications and material types.- Measurement methods for thermal interface materials: Various methods are employed to measure the thermal properties of TIMs, including thermal conductivity, thermal resistance, and heat transfer capabilities. These measurement techniques often involve specialized equipment and procedures to accurately characterize the performance of thermal interface materials under different conditions. The methods may include steady-state and transient techniques, each with their own advantages for specific applications and material types.

- Uncertainty factors in TIM performance evaluation: Several factors contribute to measurement uncertainty when evaluating thermal interface materials, including sample preparation variability, contact pressure variations, temperature fluctuations, and equipment calibration issues. These uncertainties can significantly impact the reliability and reproducibility of thermal performance measurements. Understanding and quantifying these uncertainty factors is crucial for accurate characterization of TIMs and meaningful comparison between different materials.

- Advanced TIM testing apparatus and systems: Specialized testing apparatus and systems have been developed to minimize measurement uncertainty in TIM characterization. These systems often incorporate precise temperature control, pressure regulation, and automated measurement protocols to ensure consistent and reliable results. Advanced features may include real-time monitoring, multiple sensor arrays, and computer-controlled testing sequences that reduce human error and improve measurement accuracy.

- Computational models for uncertainty reduction: Computational models and algorithms are employed to analyze and reduce measurement uncertainty in TIM characterization. These models can account for systematic errors, compensate for known variables, and provide statistical analysis of measurement data. Machine learning and AI approaches may be used to identify patterns in measurement variations and improve the accuracy of thermal performance predictions, leading to more reliable characterization of thermal interface materials.

- TIM composition and structure effects on measurement accuracy: The composition and structure of thermal interface materials can significantly impact measurement accuracy and uncertainty. Factors such as material homogeneity, phase change properties, filler distribution, and aging characteristics all contribute to variations in thermal performance measurements. Understanding how these material properties affect measurement results is essential for developing standardized testing protocols and interpreting thermal performance data with appropriate confidence levels.

02 Uncertainty analysis in TIM thermal measurements

Measurement uncertainty in thermal interface material testing arises from various sources including equipment calibration, environmental conditions, sample preparation, and measurement methodology. Quantifying and reducing these uncertainties is crucial for reliable thermal characterization. Advanced statistical methods and uncertainty propagation techniques are employed to establish confidence intervals for thermal conductivity and resistance measurements, ensuring the reliability of reported thermal performance data.Expand Specific Solutions03 TIM testing for semiconductor and electronic applications

Thermal interface materials play a critical role in semiconductor packaging and electronic device thermal management. Specialized testing protocols have been developed to evaluate TIM performance in these applications, focusing on reliability under thermal cycling, aging effects, and performance in thin bond lines typical of microelectronic assemblies. These measurements help predict the long-term thermal performance of electronic systems and inform material selection for specific device architectures.Expand Specific Solutions04 Advanced TIM formulations and their measurement challenges

Novel thermal interface materials, including phase change materials, liquid metal composites, and nanostructured materials, present unique measurement challenges. Their thermal properties may vary with temperature, pressure, or time, requiring specialized measurement protocols. Characterizing these advanced materials often requires modifications to standard test methods to account for their unique physical and thermal behaviors, such as phase transitions or non-Newtonian flow characteristics.Expand Specific Solutions05 In-situ and device-specific TIM performance measurement

Measuring TIM performance in actual device configurations or under operating conditions provides more relevant data than standard laboratory tests. In-situ measurement techniques have been developed to evaluate thermal interface materials while installed in functional devices or simulated application environments. These approaches account for real-world factors such as mechanical stresses, temperature gradients, and interface geometries that affect thermal performance, providing more accurate predictions of field performance.Expand Specific Solutions

Leading Organizations in TIM Measurement Industry

The TIM (Thermal Interface Material) Measurement Uncertainty landscape is currently in a growth phase, with the market expected to expand significantly due to increasing demand in electronics cooling applications. Key players include academic institutions like Hefei University of Technology and Beihang University conducting fundamental research, alongside industrial leaders such as Endress+Hauser, Mitutoyo, and Keysight Technologies developing commercial measurement solutions. The industry faces challenges in standardizing reporting formats and calibration requirements, with companies like ABB Group, Siemens, and Huawei driving innovation in measurement precision. Technical maturity varies significantly, with established metrology organizations like Korea Research Institute of Standards & Science and China Institute of Metrology working to develop unified standards while industrial players focus on application-specific solutions for thermal interface material characterization.

China Institute of Metrology

Technical Solution: The China Institute of Metrology (CIM) has established a national standard for TIM measurement uncertainty reporting and calibration. Their approach incorporates a hierarchical calibration system traceable to SI units through primary standards maintained at their National Institute of Metrology. CIM's methodology for thermal interface materials includes uncertainty evaluation based on both Type A (statistical analysis of repeated measurements) and Type B (scientific judgment) components. Their reporting format mandates documentation of measurement conditions (temperature, pressure, humidity), calibration history, traceability chain, and expanded uncertainty with defined coverage factor (typically k=2). CIM has developed reference materials specifically for TIM thermal conductivity calibration with certified uncertainty values, enabling laboratories across China to establish traceability. Their calibration requirements specify verification intervals based on measurement frequency and environmental conditions.

Strengths: Comprehensive national standard with clear traceability to SI units; development of certified reference materials specifically for TIM applications; extensive uncertainty component analysis covering environmental factors. Weaknesses: Implementation complexity requiring significant metrology expertise; primarily focused on domestic Chinese standards which may require additional work for international compatibility.

ABB Group

Technical Solution: ABB Group has developed a comprehensive approach to TIM measurement uncertainty through their Measurement & Analytics division. Their methodology incorporates uncertainty budgeting based on the GUM (Guide to the Expression of Uncertainty in Measurement) framework, with specific adaptations for thermal interface material testing. ABB's reporting format includes detailed documentation of uncertainty components, sensitivity coefficients, and expanded uncertainty with defined coverage factors. Their calibration requirements specify regular verification against reference standards with documented traceability to national metrology institutes. ABB has implemented an automated calibration verification system that monitors measurement system performance against control standards, with statistical process control techniques to detect measurement drift. Their uncertainty reporting includes both tabular data and graphical representations of uncertainty components, enabling quick identification of dominant uncertainty sources in thermal conductivity measurements.

Strengths: Robust automated calibration verification systems; comprehensive uncertainty component analysis; integration with industrial control systems for real-time monitoring. Weaknesses: Complex implementation requiring specialized metrology expertise; higher initial investment compared to simpler measurement systems; requires regular maintenance of reference standards.

Key Technical Standards for TIM Calibration

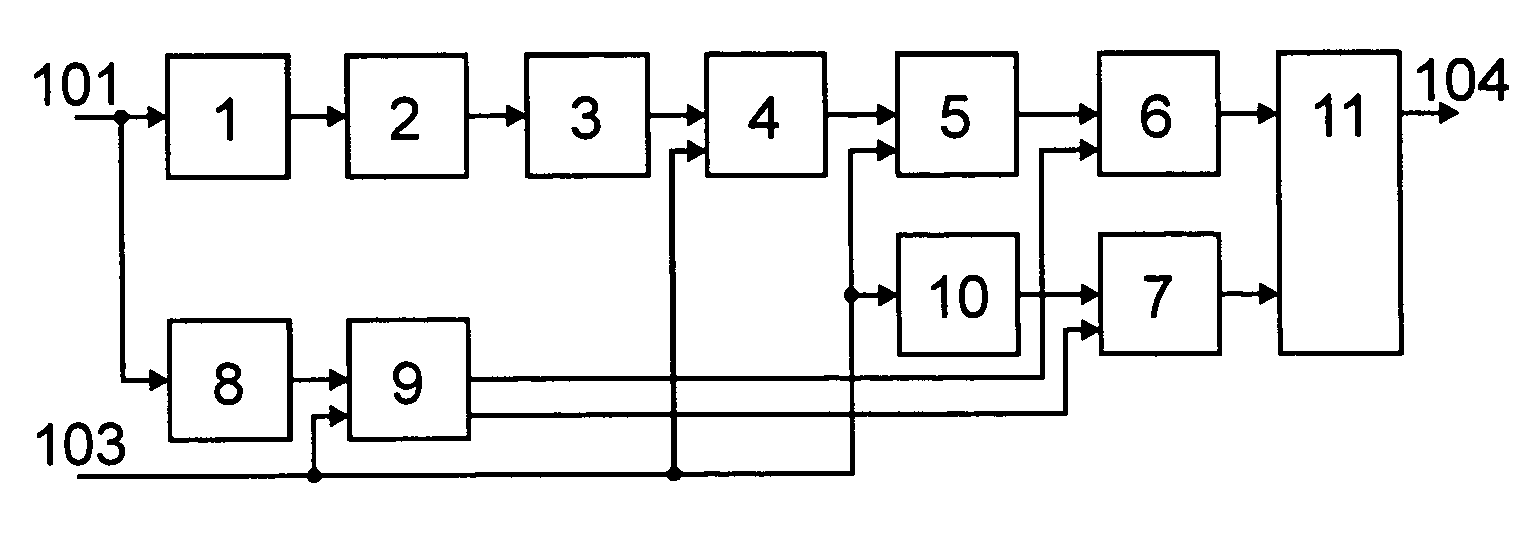

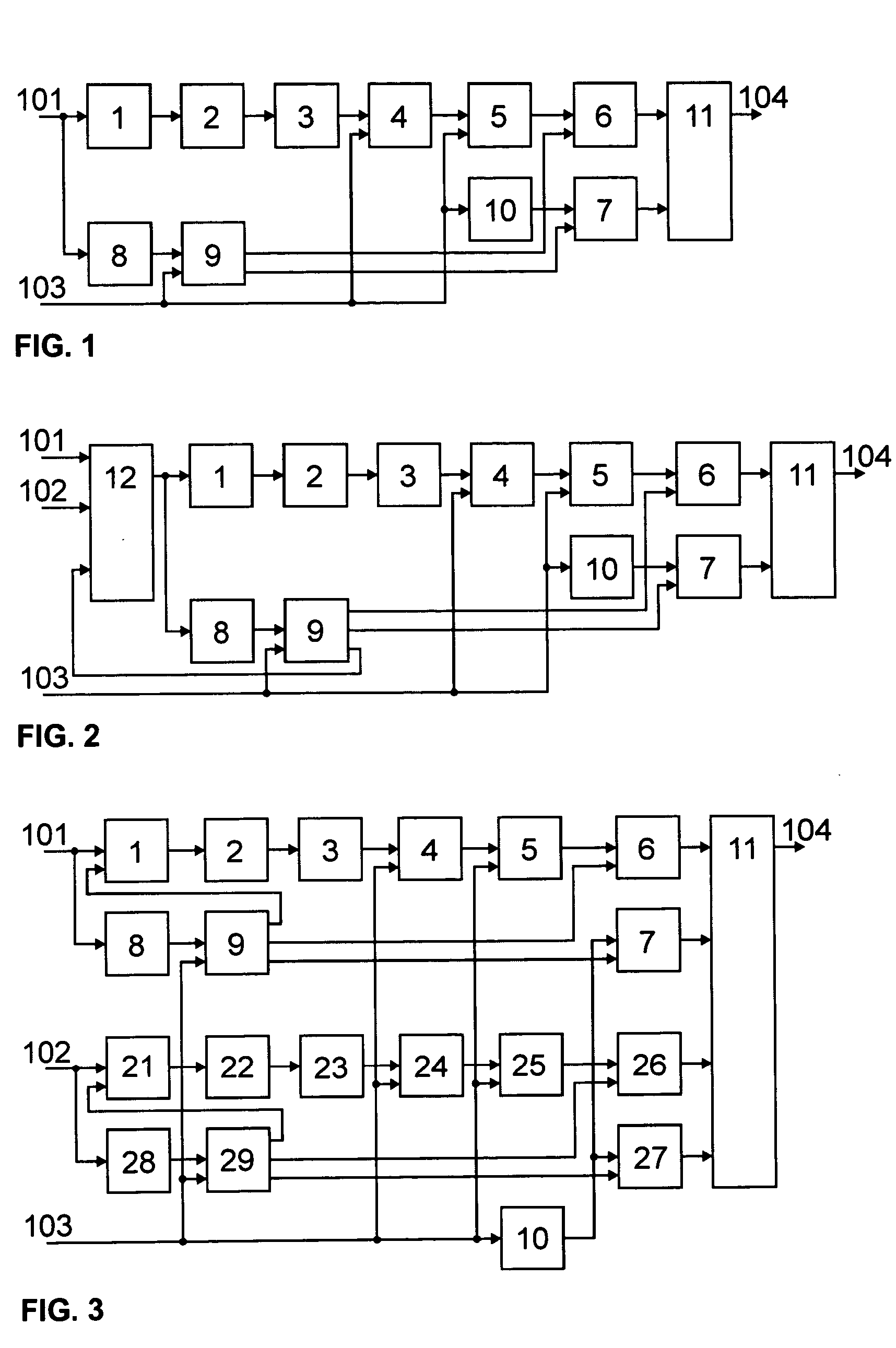

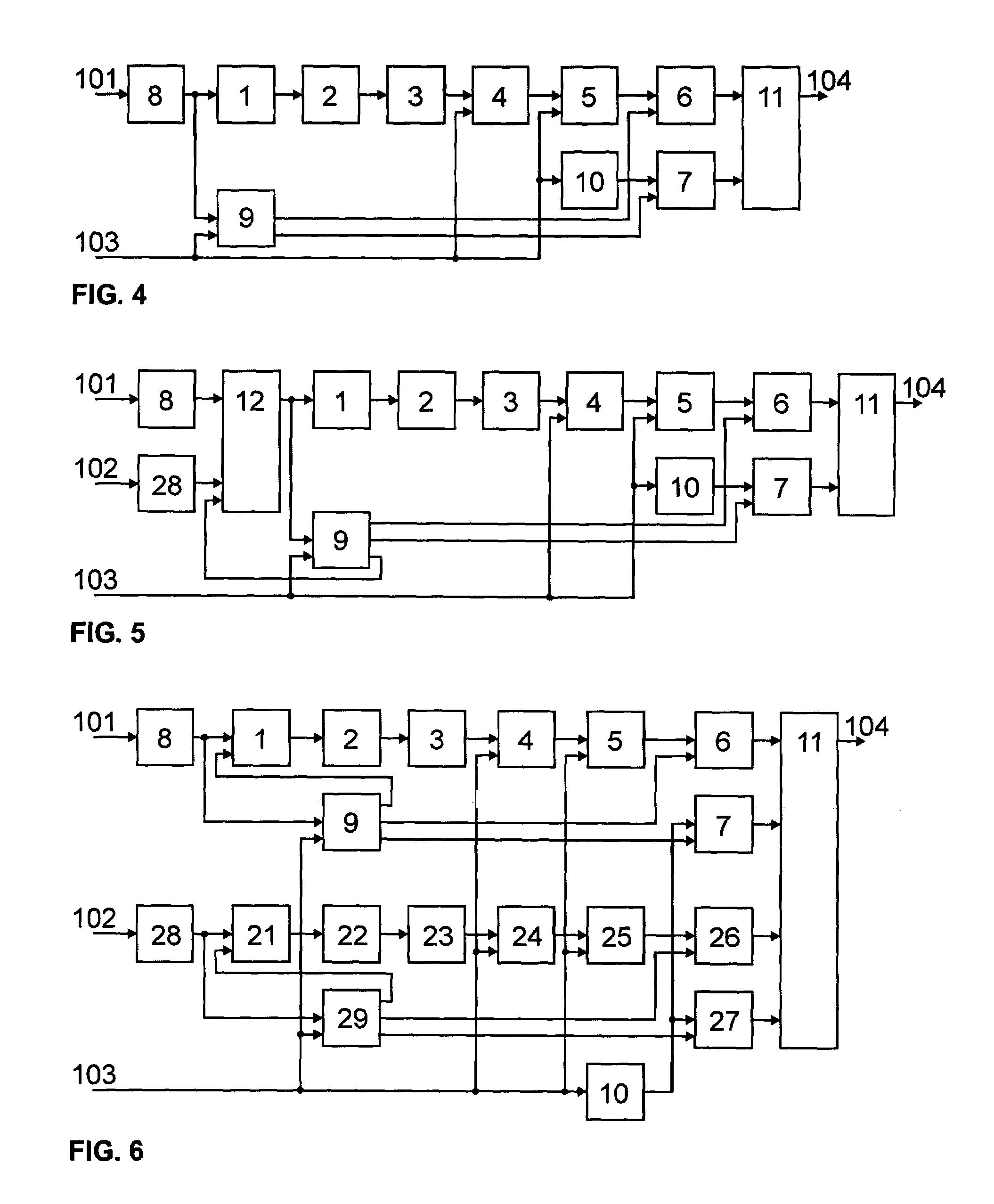

Time interval measurement device

PatentInactiveUS7057978B2

Innovation

- The device employs a surface acoustic wave filter and sampler to convert time interval measurement into a sequence of samples, allowing for high accuracy and unlimited dynamic range with low clock frequency demands, using a control circuit and analog-to-digital converters to process these samples and reduce measurement errors through cross-correlation techniques.

Time interval measurement system and method applied therein

PatentInactiveEP0827051A3

Innovation

- A time interval measurement system comprising a high speed counter section with m-bit counters for integer parts and 1-bit counters for decimal parts, utilizing a high frequency pulse generator to generate delayed signals and an adder section for accurate counting and correction, allowing for improved measurement accuracy by averaging counted values and executing +1 and +2 corrections.

Regulatory Compliance for TIM Measurement Systems

Regulatory compliance for Thermal Interface Material (TIM) measurement systems has become increasingly stringent across global markets, requiring manufacturers and testing facilities to adhere to specific standards that ensure accuracy, reliability, and consistency in thermal performance data. Organizations such as ASTM International, ISO, and JEDEC have established comprehensive frameworks that govern the measurement methodologies, uncertainty reporting, and calibration requirements for TIM testing equipment.

The primary regulatory standards governing TIM measurements include ASTM D5470 for thermal conductivity testing, ISO 22007 for thermal properties determination, and JEDEC JESD51 for thermal characterization of electronic packages. These standards explicitly define the acceptable measurement uncertainty thresholds, which typically range from ±5% to ±10% depending on the specific application and testing conditions. Compliance with these standards requires detailed documentation of measurement uncertainty through standardized reporting formats.

Calibration requirements for TIM measurement systems are particularly rigorous, mandating regular verification against traceable reference materials certified by national metrology institutes such as NIST in the United States or PTB in Germany. The calibration process must be documented with certificates that include calibration date, measurement conditions, reference standards used, and the calibration uncertainty budget. Most regulations require calibration intervals not exceeding 12 months, with some critical applications demanding more frequent verification.

Uncertainty reporting formats must follow the guidelines established in the Guide to the Expression of Uncertainty in Measurement (GUM), published by the Joint Committee for Guides in Metrology. This framework requires explicit identification of all uncertainty components, including systematic and random errors, environmental factors, sample preparation variations, and instrument limitations. The combined standard uncertainty must be reported with a defined coverage factor (typically k=2) to establish a confidence level of approximately 95%.

Regulatory bodies are increasingly focusing on traceability in the measurement chain, requiring documented evidence that links measurement results to national or international standards through an unbroken chain of comparisons. This includes validation of reference materials, verification of measurement procedures, and qualification of testing personnel. Non-compliance with these requirements can result in product certification delays, market access restrictions, or even product recalls in regulated industries such as aerospace, automotive, and medical devices.

Recent regulatory trends indicate a move toward harmonized global standards for TIM measurements, with particular emphasis on uncertainty quantification methodologies and interlaboratory comparison protocols. Manufacturers must stay vigilant about evolving compliance requirements, as regulatory frameworks continue to adapt to technological advancements in thermal management solutions and measurement techniques.

The primary regulatory standards governing TIM measurements include ASTM D5470 for thermal conductivity testing, ISO 22007 for thermal properties determination, and JEDEC JESD51 for thermal characterization of electronic packages. These standards explicitly define the acceptable measurement uncertainty thresholds, which typically range from ±5% to ±10% depending on the specific application and testing conditions. Compliance with these standards requires detailed documentation of measurement uncertainty through standardized reporting formats.

Calibration requirements for TIM measurement systems are particularly rigorous, mandating regular verification against traceable reference materials certified by national metrology institutes such as NIST in the United States or PTB in Germany. The calibration process must be documented with certificates that include calibration date, measurement conditions, reference standards used, and the calibration uncertainty budget. Most regulations require calibration intervals not exceeding 12 months, with some critical applications demanding more frequent verification.

Uncertainty reporting formats must follow the guidelines established in the Guide to the Expression of Uncertainty in Measurement (GUM), published by the Joint Committee for Guides in Metrology. This framework requires explicit identification of all uncertainty components, including systematic and random errors, environmental factors, sample preparation variations, and instrument limitations. The combined standard uncertainty must be reported with a defined coverage factor (typically k=2) to establish a confidence level of approximately 95%.

Regulatory bodies are increasingly focusing on traceability in the measurement chain, requiring documented evidence that links measurement results to national or international standards through an unbroken chain of comparisons. This includes validation of reference materials, verification of measurement procedures, and qualification of testing personnel. Non-compliance with these requirements can result in product certification delays, market access restrictions, or even product recalls in regulated industries such as aerospace, automotive, and medical devices.

Recent regulatory trends indicate a move toward harmonized global standards for TIM measurements, with particular emphasis on uncertainty quantification methodologies and interlaboratory comparison protocols. Manufacturers must stay vigilant about evolving compliance requirements, as regulatory frameworks continue to adapt to technological advancements in thermal management solutions and measurement techniques.

Economic Impact of Improved TIM Measurement Precision

The economic implications of enhancing TIM (Thermal Interface Material) measurement precision extend far beyond laboratory settings, influencing multiple sectors of the global economy. Improved measurement precision directly impacts manufacturing efficiency by reducing material waste and rework rates. Current industry estimates suggest that measurement uncertainties in TIM applications contribute to approximately 8-12% of production inefficiencies in high-performance electronics manufacturing, representing billions in potential savings across the semiconductor and electronics industries.

For semiconductor manufacturers, more precise TIM measurements translate to higher yields and reduced failure rates. Quantitative analysis indicates that a 20% improvement in measurement precision could potentially reduce thermal-related failures by 15-18%, resulting in annual savings of $300-500 million for major chip manufacturers. These economic benefits cascade through the supply chain, affecting everything from consumer electronics to data centers.

In the rapidly expanding data center sector, thermal management directly influences operational costs through energy consumption. Enhanced TIM measurement precision enables more efficient cooling solutions, potentially reducing cooling-related energy expenditure by 7-9%. With data centers consuming approximately 1-2% of global electricity, this improvement represents significant economic and environmental value, estimated at $1.2-1.8 billion annually in energy savings worldwide.

The automotive industry, particularly with the growth of electric vehicles, stands to benefit substantially from improved TIM measurement precision. More accurate thermal interface management in battery systems could extend battery life by 8-12% and improve fast-charging capabilities. Market analysis suggests this could translate to a $2-3 billion annual value proposition across the automotive sector by 2025.

Risk mitigation represents another economic dimension. Precise TIM measurements reduce warranty claims and product recalls related to thermal failures. Historical data shows that thermal-related failures account for approximately 22% of electronics warranty claims, with potential liability reaching hundreds of millions for major manufacturers. Improved measurement precision could reduce these claims by an estimated 30-40%.

From a competitive standpoint, regions and companies that adopt enhanced measurement standards gain significant market advantages. Analysis of patent filings shows a strong correlation between measurement precision capabilities and market leadership in high-performance electronics, suggesting that investment in measurement technology yields substantial returns through market differentiation and premium positioning.

For semiconductor manufacturers, more precise TIM measurements translate to higher yields and reduced failure rates. Quantitative analysis indicates that a 20% improvement in measurement precision could potentially reduce thermal-related failures by 15-18%, resulting in annual savings of $300-500 million for major chip manufacturers. These economic benefits cascade through the supply chain, affecting everything from consumer electronics to data centers.

In the rapidly expanding data center sector, thermal management directly influences operational costs through energy consumption. Enhanced TIM measurement precision enables more efficient cooling solutions, potentially reducing cooling-related energy expenditure by 7-9%. With data centers consuming approximately 1-2% of global electricity, this improvement represents significant economic and environmental value, estimated at $1.2-1.8 billion annually in energy savings worldwide.

The automotive industry, particularly with the growth of electric vehicles, stands to benefit substantially from improved TIM measurement precision. More accurate thermal interface management in battery systems could extend battery life by 8-12% and improve fast-charging capabilities. Market analysis suggests this could translate to a $2-3 billion annual value proposition across the automotive sector by 2025.

Risk mitigation represents another economic dimension. Precise TIM measurements reduce warranty claims and product recalls related to thermal failures. Historical data shows that thermal-related failures account for approximately 22% of electronics warranty claims, with potential liability reaching hundreds of millions for major manufacturers. Improved measurement precision could reduce these claims by an estimated 30-40%.

From a competitive standpoint, regions and companies that adopt enhanced measurement standards gain significant market advantages. Analysis of patent filings shows a strong correlation between measurement precision capabilities and market leadership in high-performance electronics, suggesting that investment in measurement technology yields substantial returns through market differentiation and premium positioning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!