TIM For Co-Packaged Optics: Planarization, Adhesion, And Optical Clearance Considerations

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CPO Thermal Interface Materials Background and Objectives

Co-Packaged Optics (CPO) represents a transformative approach in data center interconnect technology, integrating optical components directly with electronic devices to overcome bandwidth and power limitations of traditional electrical interconnects. The evolution of CPO technology has been driven by exponential growth in data center traffic, which demands higher bandwidth, lower latency, and improved energy efficiency. This technological progression has moved from discrete components to more integrated solutions, with CPO emerging as a promising next step in this continuum.

Thermal Interface Materials (TIMs) play a critical role in CPO implementations, serving as the crucial thermal bridge between heat-generating components and cooling solutions. The historical development of TIMs has evolved from simple thermal greases to advanced composite materials with tailored properties. In CPO applications, TIMs face unique challenges due to the proximity of optical and electronic components, requiring specialized characteristics beyond traditional thermal management solutions.

The primary objective of TIM development for CPO is to address three interconnected challenges: planarization, adhesion, and optical clearance. Planarization concerns the ability of TIMs to fill irregular surfaces and gaps between components, ensuring maximum thermal contact area. Adhesion requirements focus on maintaining reliable mechanical connections between disparate materials with different thermal expansion coefficients. Optical clearance considerations are unique to CPO, requiring TIMs that do not interfere with optical pathways while maintaining thermal performance.

Current technological trajectories indicate growing interest in developing specialized TIMs that can meet these multifaceted requirements. Research is increasingly focused on materials that offer excellent thermal conductivity while providing the mechanical compliance needed for planarization, strong adhesion properties for reliability, and optical transparency or strategic placement options to maintain signal integrity.

The development of effective TIM solutions for CPO represents a critical enabling technology for the broader adoption of co-packaged optics in high-performance computing and data center applications. As data rates continue to increase and power constraints become more stringent, the importance of optimized thermal management through advanced TIMs becomes increasingly central to system performance and reliability.

This technical exploration aims to comprehensively analyze the current state of TIM technology for CPO applications, identify key challenges, and outline potential development pathways to address the unique requirements of planarization, adhesion, and optical clearance in next-generation integrated photonic systems.

Thermal Interface Materials (TIMs) play a critical role in CPO implementations, serving as the crucial thermal bridge between heat-generating components and cooling solutions. The historical development of TIMs has evolved from simple thermal greases to advanced composite materials with tailored properties. In CPO applications, TIMs face unique challenges due to the proximity of optical and electronic components, requiring specialized characteristics beyond traditional thermal management solutions.

The primary objective of TIM development for CPO is to address three interconnected challenges: planarization, adhesion, and optical clearance. Planarization concerns the ability of TIMs to fill irregular surfaces and gaps between components, ensuring maximum thermal contact area. Adhesion requirements focus on maintaining reliable mechanical connections between disparate materials with different thermal expansion coefficients. Optical clearance considerations are unique to CPO, requiring TIMs that do not interfere with optical pathways while maintaining thermal performance.

Current technological trajectories indicate growing interest in developing specialized TIMs that can meet these multifaceted requirements. Research is increasingly focused on materials that offer excellent thermal conductivity while providing the mechanical compliance needed for planarization, strong adhesion properties for reliability, and optical transparency or strategic placement options to maintain signal integrity.

The development of effective TIM solutions for CPO represents a critical enabling technology for the broader adoption of co-packaged optics in high-performance computing and data center applications. As data rates continue to increase and power constraints become more stringent, the importance of optimized thermal management through advanced TIMs becomes increasingly central to system performance and reliability.

This technical exploration aims to comprehensively analyze the current state of TIM technology for CPO applications, identify key challenges, and outline potential development pathways to address the unique requirements of planarization, adhesion, and optical clearance in next-generation integrated photonic systems.

Market Analysis for Co-Packaged Optics TIM Solutions

The co-packaged optics (CPO) thermal interface material (TIM) market is experiencing robust growth, driven by increasing data center bandwidth demands and the limitations of traditional electrical interconnects. Current market estimates value the CPO TIM segment at approximately $120 million in 2023, with projections indicating a compound annual growth rate of 34% through 2028, potentially reaching $530 million by the end of the forecast period.

This growth is primarily fueled by hyperscale data center operators seeking to overcome the power and density limitations of traditional switch architectures. As data rates exceed 51.2 Tbps and approach 102.4 Tbps, the energy efficiency advantages of optical interconnects become increasingly compelling, creating substantial demand for specialized TIM solutions that can address the unique thermal management challenges of CPO implementations.

Market segmentation reveals distinct categories within the CPO TIM space. High-performance thermal greases currently dominate with roughly 45% market share due to their established manufacturing processes and reworkability advantages. Phase-change materials represent approximately 30% of the market, offering a balance between performance and ease of application. Emerging solutions including thermally conductive adhesives and specialized optical-grade gap fillers account for the remaining 25%, with the latter showing the fastest growth trajectory.

From a regional perspective, North America leads CPO TIM adoption with 48% market share, driven by concentrated hyperscale data center development and the presence of major networking equipment manufacturers. Asia-Pacific follows at 32%, with particularly strong growth in China, Japan, and South Korea where government initiatives supporting next-generation data center technologies are accelerating deployment. Europe represents 18% of the market, with the remaining 2% distributed across other regions.

Key customer segments include networking equipment manufacturers (52%), optical transceiver suppliers (28%), and data center operators pursuing custom hardware solutions (20%). This distribution highlights the evolving supply chain dynamics as system integrators increasingly influence TIM selection based on overall thermal solution performance rather than component-level specifications.

Market analysis indicates that TIM solutions addressing all three critical requirements – planarization, adhesion, and optical clearance – command premium pricing, with average selling prices 2.5-3.5 times higher than standard data center TIMs. This premium reflects the specialized formulations required to maintain optical alignment while providing effective thermal transfer across irregular surfaces with minimal bond line thickness.

Industry forecasts suggest that as CPO architectures mature and production volumes increase, the market will gradually shift toward more specialized TIM solutions optimized specifically for optical interfaces, potentially creating new market segments focused on photonic-specific thermal management solutions.

This growth is primarily fueled by hyperscale data center operators seeking to overcome the power and density limitations of traditional switch architectures. As data rates exceed 51.2 Tbps and approach 102.4 Tbps, the energy efficiency advantages of optical interconnects become increasingly compelling, creating substantial demand for specialized TIM solutions that can address the unique thermal management challenges of CPO implementations.

Market segmentation reveals distinct categories within the CPO TIM space. High-performance thermal greases currently dominate with roughly 45% market share due to their established manufacturing processes and reworkability advantages. Phase-change materials represent approximately 30% of the market, offering a balance between performance and ease of application. Emerging solutions including thermally conductive adhesives and specialized optical-grade gap fillers account for the remaining 25%, with the latter showing the fastest growth trajectory.

From a regional perspective, North America leads CPO TIM adoption with 48% market share, driven by concentrated hyperscale data center development and the presence of major networking equipment manufacturers. Asia-Pacific follows at 32%, with particularly strong growth in China, Japan, and South Korea where government initiatives supporting next-generation data center technologies are accelerating deployment. Europe represents 18% of the market, with the remaining 2% distributed across other regions.

Key customer segments include networking equipment manufacturers (52%), optical transceiver suppliers (28%), and data center operators pursuing custom hardware solutions (20%). This distribution highlights the evolving supply chain dynamics as system integrators increasingly influence TIM selection based on overall thermal solution performance rather than component-level specifications.

Market analysis indicates that TIM solutions addressing all three critical requirements – planarization, adhesion, and optical clearance – command premium pricing, with average selling prices 2.5-3.5 times higher than standard data center TIMs. This premium reflects the specialized formulations required to maintain optical alignment while providing effective thermal transfer across irregular surfaces with minimal bond line thickness.

Industry forecasts suggest that as CPO architectures mature and production volumes increase, the market will gradually shift toward more specialized TIM solutions optimized specifically for optical interfaces, potentially creating new market segments focused on photonic-specific thermal management solutions.

Current TIM Challenges in Co-Packaged Optics Integration

The integration of Thermal Interface Materials (TIMs) in Co-Packaged Optics (CPO) systems presents several significant challenges that must be addressed to ensure optimal performance and reliability. One primary challenge is achieving uniform planarization across the interface between optical components and electronic substrates. The inherent topographical variations in CPO assemblies, which combine silicon photonics with ASICs and other electronic components, create gaps of varying dimensions that TIMs must effectively bridge. These non-uniform gaps can range from microns to hundreds of microns, requiring TIMs with exceptional gap-filling capabilities while maintaining thermal conductivity.

Adhesion represents another critical challenge, as TIMs must form reliable bonds with multiple material types simultaneously. CPO packages typically incorporate silicon, glass, polymers, and various metals, each with different surface energies and chemical properties. TIMs must adhere effectively to all these surfaces under thermal cycling conditions, where coefficient of thermal expansion (CTE) mismatches between materials can induce significant stress at interfaces. This stress often leads to delamination or adhesion failure, compromising the thermal pathway and potentially causing catastrophic system failure.

Optical clearance considerations add another layer of complexity unique to CPO applications. Unlike traditional electronic packages, CPO systems require TIMs that do not interfere with optical pathways. This necessitates careful material selection and precise application techniques to prevent contamination of optical surfaces or obstruction of light transmission paths. Any material migration or outgassing during thermal cycling can deposit residues on optical interfaces, severely degrading signal integrity.

The refractive index matching requirements further complicate TIM selection for CPO applications. In areas where TIMs might contact or come near optical pathways, their refractive properties must be carefully controlled to minimize light scattering or reflection. This optical consideration must be balanced with thermal performance, creating a complex multi-parameter optimization problem.

Long-term reliability presents perhaps the most significant challenge. CPO systems are expected to maintain performance over 5-10 year operational lifetimes in varying environmental conditions. TIMs must resist degradation mechanisms including pump-out (material migration under pressure cycles), dry-out (loss of volatile components), and phase separation, all while maintaining consistent thermal and mechanical properties. The accelerated testing methodologies for predicting such long-term behavior remain underdeveloped for CPO-specific applications.

Manufacturing scalability adds a final dimension to these challenges, as TIM application processes must be compatible with high-volume production while maintaining the precision required for optical components. Current dispensing and application technologies struggle to meet the combined requirements of speed, precision, and consistency needed for cost-effective CPO manufacturing.

Adhesion represents another critical challenge, as TIMs must form reliable bonds with multiple material types simultaneously. CPO packages typically incorporate silicon, glass, polymers, and various metals, each with different surface energies and chemical properties. TIMs must adhere effectively to all these surfaces under thermal cycling conditions, where coefficient of thermal expansion (CTE) mismatches between materials can induce significant stress at interfaces. This stress often leads to delamination or adhesion failure, compromising the thermal pathway and potentially causing catastrophic system failure.

Optical clearance considerations add another layer of complexity unique to CPO applications. Unlike traditional electronic packages, CPO systems require TIMs that do not interfere with optical pathways. This necessitates careful material selection and precise application techniques to prevent contamination of optical surfaces or obstruction of light transmission paths. Any material migration or outgassing during thermal cycling can deposit residues on optical interfaces, severely degrading signal integrity.

The refractive index matching requirements further complicate TIM selection for CPO applications. In areas where TIMs might contact or come near optical pathways, their refractive properties must be carefully controlled to minimize light scattering or reflection. This optical consideration must be balanced with thermal performance, creating a complex multi-parameter optimization problem.

Long-term reliability presents perhaps the most significant challenge. CPO systems are expected to maintain performance over 5-10 year operational lifetimes in varying environmental conditions. TIMs must resist degradation mechanisms including pump-out (material migration under pressure cycles), dry-out (loss of volatile components), and phase separation, all while maintaining consistent thermal and mechanical properties. The accelerated testing methodologies for predicting such long-term behavior remain underdeveloped for CPO-specific applications.

Manufacturing scalability adds a final dimension to these challenges, as TIM application processes must be compatible with high-volume production while maintaining the precision required for optical components. Current dispensing and application technologies struggle to meet the combined requirements of speed, precision, and consistency needed for cost-effective CPO manufacturing.

Current Planarization and Adhesion Technical Solutions

01 Thermal interface materials for optical clarity in co-packaged optics

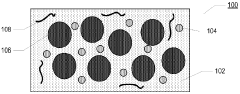

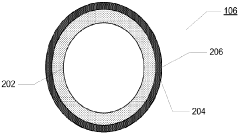

Specialized thermal interface materials are designed to provide both heat dissipation and optical clarity for co-packaged optics applications. These materials maintain transparency while efficiently transferring heat from optical components to heat sinks. The formulations typically include optically clear adhesives with high thermal conductivity fillers that don't compromise light transmission. These materials enable proper functioning of optical interconnects while managing thermal loads in densely packed optoelectronic assemblies.- Polymer-based TIMs for optical coupling and planarization: Polymer-based thermal interface materials provide effective optical coupling between co-packaged optics components while simultaneously offering planarization capabilities. These materials typically include silicones, epoxies, and acrylics that can conform to surface irregularities, reducing air gaps and enhancing thermal conductivity. The polymer matrices are often filled with thermally conductive particles to improve heat transfer while maintaining optical clarity. These materials can be applied in liquid form and then cured to create a stable interface that accommodates coefficient of thermal expansion mismatches between components.

- Optically clear adhesives with thermal management properties: Specialized adhesives that combine optical clarity with thermal conductivity are essential for co-packaged optics applications. These materials provide strong bonding between optical components while facilitating heat dissipation. The adhesives are formulated to maintain transparency in the relevant wavelength ranges while incorporating thermally conductive fillers at concentrations that don't compromise optical performance. Some formulations include phase-change materials that improve thermal contact at operating temperatures. These adhesives can be engineered with specific refractive indices to minimize light loss at interfaces.

- Nanoparticle-enhanced TIMs for improved optical and thermal performance: Incorporating nanoparticles into thermal interface materials can significantly enhance both thermal conductivity and optical properties for co-packaged optics. These nanocomposites utilize particles such as aluminum oxide, boron nitride, or diamond at the nanoscale, which allows them to fill microscopic gaps without scattering light. The small particle size maintains optical clarity while creating efficient thermal pathways. Some formulations use surface-modified nanoparticles to improve dispersion and prevent agglomeration, ensuring uniform properties throughout the material and maintaining consistent optical performance.

- Liquid metal and metallic TIMs for high thermal conductivity applications: Liquid metal and metallic-based thermal interface materials offer exceptionally high thermal conductivity for demanding co-packaged optics applications. These materials, including gallium-based alloys and silver-filled composites, can be formulated to maintain optical clearance in specific regions while providing superior heat dissipation. Advanced manufacturing techniques allow for selective application of these materials in non-optical paths. Some formulations incorporate encapsulation technologies to prevent metal migration and corrosion while maintaining the thermal benefits. These materials are particularly valuable in high-power optical systems where heat management is critical.

- Multi-functional TIMs with integrated optical and electrical properties: Advanced thermal interface materials for co-packaged optics can integrate multiple functionalities beyond thermal management. These materials combine thermal conductivity with specific optical properties like controlled refractive indices or wavelength-specific transparency. Some formulations also incorporate electrical conductivity or insulation properties as needed for the application. These multi-functional materials often use layered structures or gradient compositions to optimize different properties in specific regions. By combining multiple functions in a single material, these TIMs simplify manufacturing processes and improve overall system reliability while maintaining the necessary optical clearance and planarization.

02 Planarization techniques for TIM in photonic integrated circuits

Planarization techniques for thermal interface materials are crucial in co-packaged optics to create uniform surfaces between optical components and substrates. These methods ensure consistent optical coupling and thermal contact across the entire interface. Advanced planarization approaches include chemical-mechanical polishing, self-leveling formulations, and precision dispensing technologies. These techniques minimize air gaps and optical distortion while maintaining thermal performance in complex photonic integrated circuits.Expand Specific Solutions03 Adhesive properties of TIMs for optical component bonding

Thermal interface materials with enhanced adhesive properties are developed specifically for bonding optical components in co-packaged systems. These materials provide strong mechanical attachment while maintaining precise optical alignment between components. The adhesives are formulated to withstand thermal cycling, vibration, and environmental stresses without degrading optical performance. Key characteristics include controlled cure shrinkage, stress relaxation properties, and long-term reliability for optical interconnect applications.Expand Specific Solutions04 Novel TIM compositions for optical and thermal performance

Novel thermal interface material compositions are engineered to simultaneously optimize optical clarity, thermal conductivity, and mechanical stability. These materials incorporate specialized fillers such as optically transparent ceramic particles, functionalized nanomaterials, or phase-change compounds. The compositions are designed to minimize light scattering and absorption while maximizing heat transfer efficiency. These advanced formulations enable higher optical power handling and improved signal integrity in co-packaged optoelectronic systems.Expand Specific Solutions05 Integration methods for TIMs in co-packaged optics manufacturing

Specialized integration methods for applying thermal interface materials in co-packaged optics manufacturing processes ensure optimal performance. These techniques include precision dispensing, vacuum-assisted deposition, and controlled pressure application to eliminate voids and air bubbles. Advanced manufacturing approaches incorporate in-situ curing, real-time optical alignment monitoring, and automated placement systems. These methods enable high-volume production of co-packaged optics with consistent thermal management and optical performance.Expand Specific Solutions

Leading Manufacturers and Suppliers in CPO TIM Industry

The co-packaged optics (CPO) market is in its early growth phase, characterized by increasing demand for high-bandwidth, energy-efficient data center solutions. The market is projected to expand significantly as data centers evolve to meet escalating computational demands. Key players like Intel, Cisco, and Coherent are driving technological advancements in thermal interface materials (TIMs) for CPO applications, focusing on planarization, adhesion, and optical clearance challenges. Companies including 3M, Dow Silicones, and Nitto Denko are leveraging their materials expertise to develop specialized TIM solutions. The technology remains in development stage with varying maturity levels across different players, with semiconductor and optical communications companies forming strategic partnerships to accelerate commercialization and address integration challenges in next-generation photonic interconnects.

Intel Corp.

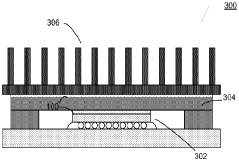

Technical Solution: Intel has developed advanced TIM solutions specifically for co-packaged optics (CPO) that address the critical challenges of planarization, adhesion, and optical clearance. Their approach utilizes a multi-layer TIM architecture with specialized silicone-based polymers that maintain consistent performance across temperature fluctuations. The company's proprietary formulation includes nano-particle fillers that enhance thermal conductivity (>3 W/mK) while maintaining the optical transparency required for CPO applications. Intel's solution incorporates a controlled bond line thickness (BLT) mechanism that ensures uniform planarization across the optical interface, critical for maintaining signal integrity in high-bandwidth applications. Their TIM materials undergo specialized curing processes that optimize adhesion to both silicon and optical materials while minimizing stress during thermal cycling. Intel has integrated these TIM solutions into their Silicon Photonics platform, demonstrating reliable performance in data center applications with operational temperatures ranging from -40°C to 125°C.

Strengths: Superior thermal conductivity while maintaining optical transparency; excellent planarization control for complex geometries; proven reliability in high-performance computing environments. Weaknesses: Higher cost compared to conventional TIMs; requires specialized application equipment; longer curing times that may impact manufacturing throughput.

Cisco Technology, Inc.

Technical Solution: Cisco has engineered specialized TIM solutions for co-packaged optics that focus on maintaining optical signal integrity while providing effective thermal management. Their approach utilizes optically clear adhesives (OCAs) modified with thermally conductive additives that achieve conductivity values of 1.8-2.5 W/mK while maintaining >95% optical transmittance in the relevant wavelength ranges. Cisco's TIM formulations incorporate proprietary coupling agents that enhance adhesion between dissimilar materials (silicon, glass, polymers) commonly found in CPO packages. Their solution addresses planarization challenges through controlled dispensing techniques and self-leveling formulations that accommodate height variations across optical interfaces. Cisco has implemented these materials in their 400G and 800G optical transceiver modules, where they've demonstrated the ability to maintain consistent optical coupling efficiency while managing the thermal loads from both electrical and optical components. Their TIM solutions feature customized viscosity profiles that facilitate precise application in the narrow gaps typical of co-packaged optical interfaces while minimizing the risk of contaminating optical surfaces.

Strengths: Excellent optical clarity combined with good thermal performance; superior adhesion to multiple substrate types; proven reliability in commercial networking equipment. Weaknesses: Moderate thermal conductivity compared to metal-based TIMs; potential for yellowing with extended UV exposure; limited effectiveness in very high-power applications.

Key Innovations in Optically Clear TIM Technologies

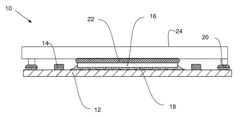

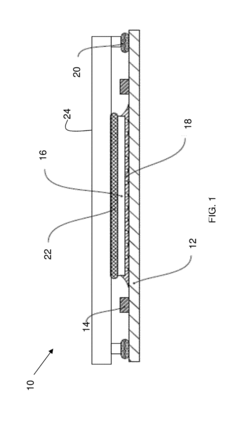

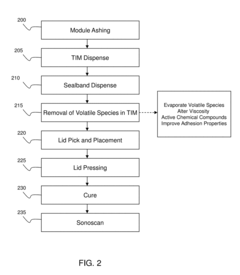

Thermal interface material on package

PatentInactiveUS20180190565A1

Innovation

- A method involving the removal of volatile species from TIM, such as cyclic siloxanes and decyl trimethoxysilane, through processes like extended delay, low-temperature heating, or vacuum outgassing, followed by lid placement and pressing, to enhance adhesion and minimize voiding, thereby improving thermal performance.

Polymer thermal interface material

PatentActiveGB2508320A

Innovation

- A polymer thermal interface material comprising a silicone-based gel or flexible epoxy polymer matrix, spherical filler material with varying diameters, and fibrous material, such as carbon fibers, to enhance adhesion, flexibility, and thermal conductivity, along with additives like fluxing agents and antioxidants to improve interface properties and thermal stability.

Reliability and Performance Testing Methodologies

Reliability and performance testing methodologies for Thermal Interface Materials (TIMs) in Co-Packaged Optics (CPO) applications require comprehensive evaluation protocols that address the unique challenges of optical-electronic integration. These methodologies must verify that TIMs maintain their thermal, mechanical, and optical properties throughout the product lifecycle under various environmental conditions.

Temperature cycling tests represent a critical evaluation method, typically subjecting TIM samples to cycles between -40°C and 125°C for 1,000 to 3,000 cycles. This assessment reveals the material's ability to maintain adhesion and thermal conductivity despite repeated thermal expansion and contraction, which is particularly important for CPO applications where optical alignment must be preserved.

High-temperature storage tests expose TIMs to elevated temperatures (typically 125°C to 150°C) for extended periods (1,000 to 2,000 hours) to accelerate aging effects. These tests help predict long-term performance degradation, particularly focusing on changes in thermal conductivity and potential material outgassing that could compromise optical clarity.

Humidity resistance testing, conducted in environments with 85% relative humidity at 85°C for 1,000 hours, evaluates moisture absorption characteristics of TIMs. This is crucial for CPO applications as moisture ingress can significantly impact both thermal performance and optical transmission properties.

Mechanical stress testing examines the TIM's response to vibration and shock conditions, typically following standards like JEDEC JESD22-B103 or MIL-STD-883. These tests ensure that the TIM maintains proper contact and adhesion between optical and electronic components during transportation and operation.

Optical performance verification methodologies include measurements of light transmission, refractive index stability, and optical clarity over time. These tests typically employ spectrophotometric analysis across relevant wavelength ranges (often 1310nm and 1550nm for telecommunications applications) before and after environmental stress testing.

Thermal resistance measurement techniques, such as ASTM D5470, are adapted specifically for CPO applications to verify that the TIM maintains its thermal conductivity performance. These measurements are conducted at various stages of reliability testing to track performance degradation over time.

Integration testing evaluates the TIM's compatibility with the entire CPO assembly process, including its interaction with solder reflow profiles, underfill materials, and cleaning agents. This ensures that the TIM's properties remain stable throughout the manufacturing process and subsequent operation.

Temperature cycling tests represent a critical evaluation method, typically subjecting TIM samples to cycles between -40°C and 125°C for 1,000 to 3,000 cycles. This assessment reveals the material's ability to maintain adhesion and thermal conductivity despite repeated thermal expansion and contraction, which is particularly important for CPO applications where optical alignment must be preserved.

High-temperature storage tests expose TIMs to elevated temperatures (typically 125°C to 150°C) for extended periods (1,000 to 2,000 hours) to accelerate aging effects. These tests help predict long-term performance degradation, particularly focusing on changes in thermal conductivity and potential material outgassing that could compromise optical clarity.

Humidity resistance testing, conducted in environments with 85% relative humidity at 85°C for 1,000 hours, evaluates moisture absorption characteristics of TIMs. This is crucial for CPO applications as moisture ingress can significantly impact both thermal performance and optical transmission properties.

Mechanical stress testing examines the TIM's response to vibration and shock conditions, typically following standards like JEDEC JESD22-B103 or MIL-STD-883. These tests ensure that the TIM maintains proper contact and adhesion between optical and electronic components during transportation and operation.

Optical performance verification methodologies include measurements of light transmission, refractive index stability, and optical clarity over time. These tests typically employ spectrophotometric analysis across relevant wavelength ranges (often 1310nm and 1550nm for telecommunications applications) before and after environmental stress testing.

Thermal resistance measurement techniques, such as ASTM D5470, are adapted specifically for CPO applications to verify that the TIM maintains its thermal conductivity performance. These measurements are conducted at various stages of reliability testing to track performance degradation over time.

Integration testing evaluates the TIM's compatibility with the entire CPO assembly process, including its interaction with solder reflow profiles, underfill materials, and cleaning agents. This ensures that the TIM's properties remain stable throughout the manufacturing process and subsequent operation.

Manufacturing Process Integration Considerations

The integration of Thermal Interface Materials (TIMs) into Co-Packaged Optics (CPO) manufacturing workflows presents unique challenges that require careful consideration of process compatibility and sequence optimization. When implementing TIMs in CPO assemblies, manufacturers must first evaluate the thermal material's compatibility with existing semiconductor and optical assembly processes, particularly regarding temperature sensitivity and chemical interactions.

Process sequence optimization becomes critical, as TIM application must occur at the appropriate manufacturing stage to prevent contamination of optical surfaces while ensuring proper thermal contact. This often necessitates specialized dispensing equipment capable of precise material placement with controlled thickness and coverage area, avoiding interference with optical pathways.

Environmental control during TIM integration represents another significant consideration. Clean room conditions must be maintained to prevent particulate contamination, while temperature and humidity must be tightly regulated to ensure proper TIM curing and performance characteristics. These environmental parameters directly impact the planarization quality and adhesion strength of the thermal interface.

Testing and quality control protocols require adaptation to accommodate the unique requirements of CPO assemblies. In-line inspection techniques must verify proper TIM coverage without disturbing the optical alignment, while thermal performance validation must occur without risking damage to sensitive optical components. This often necessitates the development of specialized non-destructive testing methodologies.

Scalability considerations present additional challenges as manufacturers transition from prototype to volume production. TIM application processes that work effectively in low-volume laboratory settings may prove impractical at production scale, requiring significant process engineering to maintain consistency across high-volume manufacturing lines. Automated dispensing systems with advanced vision guidance often become necessary to achieve the required precision at scale.

Rework and repair strategies must also be developed specifically for CPO assemblies with TIMs. The ability to remove and replace thermal materials without damaging optical components becomes essential for yield management, particularly given the high value of these integrated assemblies. This may require specialized tooling and techniques that preserve the integrity of optical surfaces during rework operations.

Finally, end-of-life and sustainability considerations are increasingly important in manufacturing process integration. TIM selection must account for eventual recycling or disposal requirements, with preference given to materials that enable component recovery without hazardous waste generation. This forward-thinking approach aligns with broader industry sustainability initiatives while potentially reducing long-term manufacturing costs.

Process sequence optimization becomes critical, as TIM application must occur at the appropriate manufacturing stage to prevent contamination of optical surfaces while ensuring proper thermal contact. This often necessitates specialized dispensing equipment capable of precise material placement with controlled thickness and coverage area, avoiding interference with optical pathways.

Environmental control during TIM integration represents another significant consideration. Clean room conditions must be maintained to prevent particulate contamination, while temperature and humidity must be tightly regulated to ensure proper TIM curing and performance characteristics. These environmental parameters directly impact the planarization quality and adhesion strength of the thermal interface.

Testing and quality control protocols require adaptation to accommodate the unique requirements of CPO assemblies. In-line inspection techniques must verify proper TIM coverage without disturbing the optical alignment, while thermal performance validation must occur without risking damage to sensitive optical components. This often necessitates the development of specialized non-destructive testing methodologies.

Scalability considerations present additional challenges as manufacturers transition from prototype to volume production. TIM application processes that work effectively in low-volume laboratory settings may prove impractical at production scale, requiring significant process engineering to maintain consistency across high-volume manufacturing lines. Automated dispensing systems with advanced vision guidance often become necessary to achieve the required precision at scale.

Rework and repair strategies must also be developed specifically for CPO assemblies with TIMs. The ability to remove and replace thermal materials without damaging optical components becomes essential for yield management, particularly given the high value of these integrated assemblies. This may require specialized tooling and techniques that preserve the integrity of optical surfaces during rework operations.

Finally, end-of-life and sustainability considerations are increasingly important in manufacturing process integration. TIM selection must account for eventual recycling or disposal requirements, with preference given to materials that enable component recovery without hazardous waste generation. This forward-thinking approach aligns with broader industry sustainability initiatives while potentially reducing long-term manufacturing costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!