TIM Conductive Pathways: Measuring Contact Resistance Under Compression

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Conductive Pathways Background and Objectives

Thermal Interface Materials (TIMs) have evolved significantly over the past several decades, transitioning from simple thermal greases to sophisticated engineered materials designed to maximize heat transfer between contacting surfaces. The development of TIMs has been driven primarily by the electronics industry's continuous pursuit of higher performance computing systems that generate increasing amounts of heat in smaller form factors. Understanding the conductive pathways within these materials, particularly under compression, represents a critical frontier in thermal management technology.

The evolution of TIM technology can be traced through several key phases: from basic silicone-based compounds in the 1970s and 1980s, to the introduction of particle-filled polymers in the 1990s, and more recently to advanced materials incorporating carbon nanotubes, graphene, and other novel fillers with exceptional thermal conductivity properties. Each advancement has aimed to reduce thermal resistance at the interface between heat-generating components and heat dissipation systems.

Contact resistance measurement under compression presents unique challenges that have not been fully addressed by conventional thermal characterization methods. When a TIM is compressed between two surfaces, complex microstructural changes occur that significantly affect thermal conductivity pathways. These changes include particle reorientation, filler network formation, and interface deformation that collectively determine the material's thermal performance in real-world applications.

The primary objective of this technical investigation is to develop robust methodologies for measuring and characterizing the contact resistance of TIMs under various compression conditions that accurately reflect operational environments. This includes understanding how conductive pathways form, evolve, and potentially degrade under sustained or cyclic compression, as well as identifying the fundamental physical mechanisms that govern these processes.

Additionally, this research aims to establish correlations between material composition, microstructure, and thermal performance under compression. By identifying these relationships, we can create predictive models that will accelerate the development of next-generation TIMs with optimized performance characteristics for specific applications, from consumer electronics to high-performance computing and automotive systems.

The technological significance of this research extends beyond immediate applications in electronics cooling. As industries increasingly adopt electrification strategies and high-power density designs, effective thermal management becomes a limiting factor in system performance and reliability. Advances in understanding TIM conductive pathways under compression will enable more efficient thermal designs, longer product lifespans, and ultimately more sustainable electronic systems with reduced energy consumption for cooling.

The evolution of TIM technology can be traced through several key phases: from basic silicone-based compounds in the 1970s and 1980s, to the introduction of particle-filled polymers in the 1990s, and more recently to advanced materials incorporating carbon nanotubes, graphene, and other novel fillers with exceptional thermal conductivity properties. Each advancement has aimed to reduce thermal resistance at the interface between heat-generating components and heat dissipation systems.

Contact resistance measurement under compression presents unique challenges that have not been fully addressed by conventional thermal characterization methods. When a TIM is compressed between two surfaces, complex microstructural changes occur that significantly affect thermal conductivity pathways. These changes include particle reorientation, filler network formation, and interface deformation that collectively determine the material's thermal performance in real-world applications.

The primary objective of this technical investigation is to develop robust methodologies for measuring and characterizing the contact resistance of TIMs under various compression conditions that accurately reflect operational environments. This includes understanding how conductive pathways form, evolve, and potentially degrade under sustained or cyclic compression, as well as identifying the fundamental physical mechanisms that govern these processes.

Additionally, this research aims to establish correlations between material composition, microstructure, and thermal performance under compression. By identifying these relationships, we can create predictive models that will accelerate the development of next-generation TIMs with optimized performance characteristics for specific applications, from consumer electronics to high-performance computing and automotive systems.

The technological significance of this research extends beyond immediate applications in electronics cooling. As industries increasingly adopt electrification strategies and high-power density designs, effective thermal management becomes a limiting factor in system performance and reliability. Advances in understanding TIM conductive pathways under compression will enable more efficient thermal designs, longer product lifespans, and ultimately more sustainable electronic systems with reduced energy consumption for cooling.

Market Analysis for Thermal Interface Materials

The Thermal Interface Materials (TIM) market has been experiencing robust growth, driven primarily by the increasing demand for efficient thermal management solutions across various industries. The global TIM market was valued at approximately 2.5 billion USD in 2021 and is projected to reach 4.8 billion USD by 2027, representing a compound annual growth rate (CAGR) of 11.3% during the forecast period.

Electronics and semiconductor industries remain the dominant end-users of TIMs, accounting for nearly 60% of the total market share. This dominance is attributed to the continuous miniaturization of electronic components and the increasing power densities in modern devices, which necessitate more effective thermal management solutions. The automotive sector follows as the second-largest consumer, particularly with the rapid expansion of electric vehicles (EVs) that require sophisticated thermal management systems for battery packs and power electronics.

Geographically, Asia-Pacific leads the TIM market, holding approximately 45% of the global share, with China, Japan, South Korea, and Taiwan being the major contributors. This regional dominance is closely tied to the concentration of electronics manufacturing facilities in these countries. North America and Europe follow with market shares of 25% and 20% respectively, driven by advancements in automotive, aerospace, and telecommunications sectors.

The market segmentation by material type reveals that silicone-based TIMs currently dominate with a 35% market share, followed by phase change materials (22%), thermal greases (18%), gap fillers (15%), and others including graphite sheets and metal TIMs (10%). However, emerging materials such as graphene-enhanced TIMs and carbon nanotube-based solutions are showing promising growth trajectories due to their superior thermal conductivity properties.

Key market drivers include the growing adoption of 5G technology, increasing data center infrastructure, expansion of EV markets, and the trend toward more powerful computing devices. Additionally, the push for more energy-efficient systems across industries is creating sustained demand for high-performance TIMs that can effectively manage heat dissipation.

Market challenges primarily revolve around the high cost of advanced TIMs, technical limitations in achieving optimal thermal conductivity while maintaining other desirable properties, and environmental concerns regarding certain materials used in traditional TIMs. The industry is responding with increased R&D investments, with major players allocating 8-12% of their revenue to develop more sustainable and efficient thermal interface solutions.

The competitive landscape features established players like Henkel, 3M, Dow Corning, and Parker Chomerics, alongside emerging specialized manufacturers focusing on novel materials and application-specific solutions. Strategic partnerships between material suppliers and device manufacturers are becoming increasingly common to develop customized thermal management solutions.

Electronics and semiconductor industries remain the dominant end-users of TIMs, accounting for nearly 60% of the total market share. This dominance is attributed to the continuous miniaturization of electronic components and the increasing power densities in modern devices, which necessitate more effective thermal management solutions. The automotive sector follows as the second-largest consumer, particularly with the rapid expansion of electric vehicles (EVs) that require sophisticated thermal management systems for battery packs and power electronics.

Geographically, Asia-Pacific leads the TIM market, holding approximately 45% of the global share, with China, Japan, South Korea, and Taiwan being the major contributors. This regional dominance is closely tied to the concentration of electronics manufacturing facilities in these countries. North America and Europe follow with market shares of 25% and 20% respectively, driven by advancements in automotive, aerospace, and telecommunications sectors.

The market segmentation by material type reveals that silicone-based TIMs currently dominate with a 35% market share, followed by phase change materials (22%), thermal greases (18%), gap fillers (15%), and others including graphite sheets and metal TIMs (10%). However, emerging materials such as graphene-enhanced TIMs and carbon nanotube-based solutions are showing promising growth trajectories due to their superior thermal conductivity properties.

Key market drivers include the growing adoption of 5G technology, increasing data center infrastructure, expansion of EV markets, and the trend toward more powerful computing devices. Additionally, the push for more energy-efficient systems across industries is creating sustained demand for high-performance TIMs that can effectively manage heat dissipation.

Market challenges primarily revolve around the high cost of advanced TIMs, technical limitations in achieving optimal thermal conductivity while maintaining other desirable properties, and environmental concerns regarding certain materials used in traditional TIMs. The industry is responding with increased R&D investments, with major players allocating 8-12% of their revenue to develop more sustainable and efficient thermal interface solutions.

The competitive landscape features established players like Henkel, 3M, Dow Corning, and Parker Chomerics, alongside emerging specialized manufacturers focusing on novel materials and application-specific solutions. Strategic partnerships between material suppliers and device manufacturers are becoming increasingly common to develop customized thermal management solutions.

Current Challenges in Contact Resistance Measurement

Despite significant advancements in thermal interface materials (TIMs), accurately measuring contact resistance under compression remains one of the most challenging aspects in this field. Current measurement methodologies suffer from several fundamental limitations that impede precise characterization of conductive pathways. The primary challenge lies in isolating the contact resistance from the bulk material resistance, as these components are inherently coupled in most experimental setups. This distinction becomes particularly critical when evaluating TIMs under varying compression loads, where material deformation continuously alters the contact geometry.

Traditional steady-state methods, while widely adopted, introduce significant measurement uncertainties due to heat spreading effects and thermal boundary resistances at multiple interfaces. These uncertainties can account for deviations of 15-30% in reported values across different laboratories using ostensibly identical materials and methods. The lack of standardization in measurement protocols further exacerbates this issue, making cross-study comparisons problematic.

Transient measurement techniques offer improved temporal resolution but struggle with spatial resolution limitations. Current technologies cannot adequately capture the microscale variations in contact resistance that occur across the interface plane, particularly in heterogeneous TIMs where conductive fillers create complex pathways. This microscale characterization gap represents a significant blind spot in understanding compression-dependent behavior.

Environmental factors introduce additional complications, as humidity, oxidation, and surface contamination can dramatically alter contact resistance measurements. Most current testing platforms inadequately control or account for these variables, leading to poor reproducibility. Temperature-dependent effects further complicate measurements, as many TIMs exhibit non-linear thermal behavior across their operating temperature range.

In-situ measurement capabilities remain severely limited, with most techniques requiring specialized sample preparation that may alter the very properties being measured. The inability to observe real-time changes in contact resistance during compression cycles prevents accurate characterization of hysteresis effects and long-term reliability under thermal cycling conditions.

Computational models attempting to predict contact resistance often rely on oversimplified assumptions about surface roughness and material deformation. The disconnect between theoretical models and experimental validation creates significant uncertainty in design optimization. Current finite element approaches struggle to incorporate multi-scale phenomena ranging from nanoscale thermal transport to macroscale mechanical deformation.

These measurement challenges collectively hinder the development of next-generation TIMs, as designers lack reliable data for material selection and performance prediction under actual operating conditions. Addressing these limitations requires interdisciplinary approaches combining advanced metrology, materials science, and computational modeling to develop more robust measurement methodologies.

Traditional steady-state methods, while widely adopted, introduce significant measurement uncertainties due to heat spreading effects and thermal boundary resistances at multiple interfaces. These uncertainties can account for deviations of 15-30% in reported values across different laboratories using ostensibly identical materials and methods. The lack of standardization in measurement protocols further exacerbates this issue, making cross-study comparisons problematic.

Transient measurement techniques offer improved temporal resolution but struggle with spatial resolution limitations. Current technologies cannot adequately capture the microscale variations in contact resistance that occur across the interface plane, particularly in heterogeneous TIMs where conductive fillers create complex pathways. This microscale characterization gap represents a significant blind spot in understanding compression-dependent behavior.

Environmental factors introduce additional complications, as humidity, oxidation, and surface contamination can dramatically alter contact resistance measurements. Most current testing platforms inadequately control or account for these variables, leading to poor reproducibility. Temperature-dependent effects further complicate measurements, as many TIMs exhibit non-linear thermal behavior across their operating temperature range.

In-situ measurement capabilities remain severely limited, with most techniques requiring specialized sample preparation that may alter the very properties being measured. The inability to observe real-time changes in contact resistance during compression cycles prevents accurate characterization of hysteresis effects and long-term reliability under thermal cycling conditions.

Computational models attempting to predict contact resistance often rely on oversimplified assumptions about surface roughness and material deformation. The disconnect between theoretical models and experimental validation creates significant uncertainty in design optimization. Current finite element approaches struggle to incorporate multi-scale phenomena ranging from nanoscale thermal transport to macroscale mechanical deformation.

These measurement challenges collectively hinder the development of next-generation TIMs, as designers lack reliable data for material selection and performance prediction under actual operating conditions. Addressing these limitations requires interdisciplinary approaches combining advanced metrology, materials science, and computational modeling to develop more robust measurement methodologies.

Existing Methodologies for Compression Resistance Testing

01 Composition of thermal interface materials for reducing contact resistance

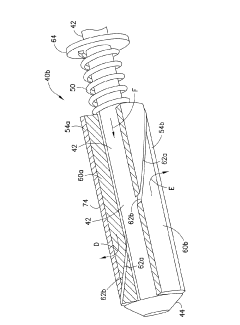

Various compositions of thermal interface materials can be designed to reduce contact resistance in conductive pathways. These compositions often include conductive fillers such as metal particles, carbon nanotubes, or graphene dispersed in a polymer matrix. The specific combination and concentration of these materials can significantly affect the thermal conductivity and contact resistance at interfaces. Advanced formulations may incorporate phase change materials that melt at operating temperatures to fill microscopic air gaps and improve thermal contact.- Composition of thermal interface materials for reducing contact resistance: Thermal interface materials can be formulated with specific compositions to reduce contact resistance between surfaces. These compositions often include conductive fillers such as metal particles, carbon nanotubes, or graphene dispersed in a polymer matrix. The selection and concentration of these fillers significantly impact the thermal conductivity and contact resistance of the TIM. Advanced formulations may incorporate phase change materials that melt at operating temperatures to fill microscopic air gaps and improve thermal contact.

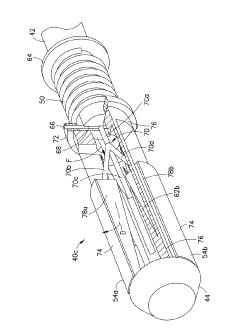

- Surface preparation and treatment techniques for TIM applications: Surface preparation and treatment methods can significantly reduce contact resistance in thermal interface materials. Techniques include surface planarization, chemical treatments to remove oxides or contaminants, and application of adhesion promoters. Some approaches involve plasma treatment or chemical functionalization of surfaces to improve wetting and adhesion of the TIM. These methods help minimize air gaps and ensure maximum contact area between the TIM and the mating surfaces, thereby reducing thermal contact resistance.

- Pressure-sensitive and phase-change TIM designs: Pressure-sensitive and phase-change thermal interface materials are designed to reduce contact resistance under application conditions. These materials deform under applied pressure to conform to surface irregularities or undergo phase transformation at specific temperatures to fill gaps between contact surfaces. Some designs incorporate microstructured surfaces or gradient material properties that optimize both mechanical compliance and thermal conductivity. These approaches help maximize the effective contact area and minimize thermal resistance at interfaces.

- Testing and measurement methods for TIM contact resistance: Various testing and measurement methods have been developed to accurately evaluate contact resistance in thermal interface materials. These include steady-state and transient thermal testing techniques, laser flash analysis, and specialized test fixtures that simulate actual application conditions. Advanced methods may employ infrared thermography or micro-scale temperature sensors to map thermal gradients across interfaces. These measurement approaches help quantify the effectiveness of different TIM formulations and application methods in reducing contact resistance.

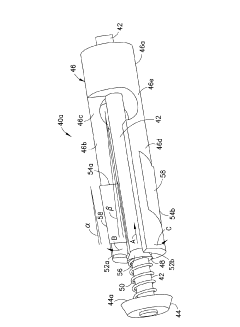

- Novel TIM structures and application methods: Innovative thermal interface material structures and application methods have been developed to minimize contact resistance. These include vertically aligned carbon nanotube arrays, graphene-based films, liquid metal composites, and 3D-printed thermal interface structures. Some approaches use pre-applied TIMs with protective release liners or in-situ formation of the interface material. Novel application methods may involve spray coating, vapor deposition, or selective patterning of the TIM to optimize thermal pathways and reduce contact resistance at critical junctions.

02 Surface modification techniques for TIM contact resistance reduction

Surface modification techniques can be employed to reduce contact resistance in thermal interface materials. These techniques include chemical treatments, plasma processing, or physical texturing of surfaces to improve wetting and adhesion of the TIM. By modifying the surface characteristics, the effective contact area between the TIM and the mating surfaces increases, reducing thermal resistance. Some approaches involve creating microstructures or nanostructures on contact surfaces to enhance thermal transfer across interfaces.Expand Specific Solutions03 Testing and measurement methods for TIM contact resistance

Various testing and measurement methodologies have been developed to accurately quantify contact resistance in thermal interface materials. These methods include laser flash analysis, steady-state heat flow measurements, and transient thermal testing. Advanced techniques may utilize infrared thermography or micro-sensors embedded at interfaces to map temperature distributions and calculate thermal resistance. Standardized testing protocols ensure consistent evaluation of TIM performance across different applications and operating conditions.Expand Specific Solutions04 Semiconductor package TIM applications for reducing thermal resistance

Thermal interface materials play a critical role in semiconductor packaging by reducing contact resistance between chips and heat spreaders or heat sinks. Specialized TIM formulations for semiconductor applications focus on long-term reliability, minimal pump-out under thermal cycling, and compatibility with semiconductor manufacturing processes. Advanced semiconductor packages may incorporate pre-applied TIMs, embedded heat spreaders with optimized TIM layers, or direct bonded interfaces to minimize thermal resistance in high-power density applications.Expand Specific Solutions05 Novel TIM structures and manufacturing methods for enhanced thermal conductivity

Innovative thermal interface material structures and manufacturing methods have been developed to enhance thermal conductivity and reduce contact resistance. These include vertically aligned carbon nanotube arrays, sintered metal networks, and 3D-printed thermal structures with optimized geometries. Some approaches utilize liquid metal composites that maintain fluidity at interfaces while providing high thermal conductivity. Manufacturing innovations such as in-situ polymerization, controlled particle alignment, or gradient material structures can create TIMs with directionally optimized thermal properties.Expand Specific Solutions

Leading Companies in TIM Development and Testing

The TIM Conductive Pathways market is currently in a growth phase, with increasing demand for reliable contact resistance measurement under compression across multiple industries. The global market size is expanding as applications in electronics, automotive, and energy sectors proliferate. Technologically, the field shows varying maturity levels, with companies like Infineon Technologies and IBM leading innovation in semiconductor applications, while OMICRON electronics and Hexcel Composites focus on specialized testing solutions. Chinese players including Guangdong Power Grid and ChangXin Memory are rapidly advancing in this space, particularly for power transmission and memory applications. Companies like TDK and Corning are developing advanced materials to enhance conductivity performance, while aerospace leaders Boeing and Airbus are implementing these technologies in critical systems requiring high reliability under mechanical stress.

Infineon Technologies AG

Technical Solution: Infineon has developed advanced TIM (Thermal Interface Material) conductive pathways measurement systems that utilize precision micro-ohm meters to evaluate contact resistance under various compression loads. Their approach incorporates automated pressure application mechanisms that can simulate real-world operating conditions while simultaneously measuring electrical resistance changes. The system employs four-point probe measurement techniques to eliminate lead resistance errors, achieving measurement accuracy in the micro-ohm range. Infineon's solution includes temperature-controlled test environments (from -40°C to 150°C) to characterize how thermal cycling affects contact resistance, critical for automotive and industrial applications where thermal reliability is paramount. Their data acquisition system captures real-time resistance variations during compression/decompression cycles, enabling analysis of hysteresis effects and long-term reliability predictions.

Strengths: Superior measurement precision in micro-ohm range with excellent repeatability; comprehensive temperature range testing capability; automated test sequences reduce human error. Weaknesses: System complexity requires specialized training; high initial equipment investment; testing protocols may be time-consuming for high-volume production environments.

The Boeing Co.

Technical Solution: Boeing has engineered a specialized TIM conductive pathways measurement system designed specifically for aerospace applications where reliability under extreme conditions is critical. Their approach features a hermetically sealed test chamber capable of simulating altitude conditions (vacuum to 100,000 feet) while simultaneously applying precise compression forces and measuring electrical contact resistance. The system incorporates custom-designed electrodes with ultra-low thermal expansion coefficients to maintain measurement stability across extreme temperature ranges (-65°C to +200°C). Boeing's technology utilizes a combination of DC resistance measurements and high-frequency impedance analysis to characterize both static and dynamic electrical performance of TIM materials under compression. Their measurement protocol includes accelerated life testing capabilities that can simulate years of thermal cycling and vibration exposure in compressed timeframes, providing critical reliability data for aerospace certification requirements. The system features automated data logging with secure cloud storage for maintaining complete material qualification records throughout the aircraft lifecycle.

Strengths: Unmatched environmental simulation capabilities for aerospace conditions; comprehensive reliability testing protocols; exceptional measurement stability under extreme temperatures. Weaknesses: Extremely high system cost limits accessibility; specialized for aerospace applications rather than general-purpose testing; requires extensive operator training and certification.

Key Technical Innovations in Contact Resistance Measurement

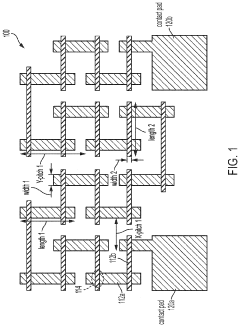

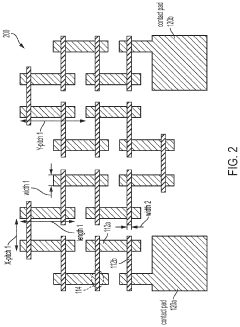

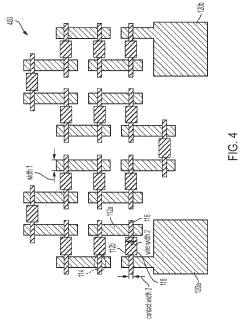

System and method for measuring electric contact resistance in interface

PatentActiveJP2019197042A

Innovation

- A method and system for measuring electrical contact resistance at the interface between a conductive coating and a cross-ply surface of CFRP using a dielectric sensing pad, capacitive coupling, and a resistance measurement circuit to determine the thickness of the conductive coating by monitoring the effective resistance.

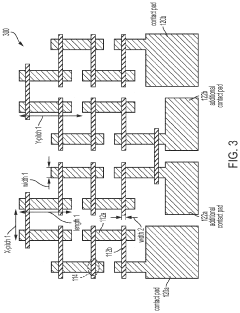

Methods and structure to probe the metal-metal interface for superconducting circuits

PatentActiveUS20220034833A1

Innovation

- A method involving a chain structure of superconducting elements arranged in series, where the chain is operated below the superconducting transition temperature to eliminate ohmic resistance, allowing for precise measurement of contact resistance by measuring the serial resistance of the chain.

Thermal Management Standards and Compliance

Thermal management standards play a crucial role in ensuring the reliability and performance of electronic systems utilizing Thermal Interface Materials (TIMs). For measuring contact resistance under compression in TIM conductive pathways, several international standards provide methodologies and compliance requirements that manufacturers and engineers must adhere to.

ASTM D5470 stands as the primary standard for thermal resistance measurements of TIMs, offering detailed procedures for measuring thermal impedance under various compression loads. This standard specifically addresses the challenges in quantifying contact resistance at material interfaces, which is essential when evaluating TIM performance in real-world applications.

The JEDEC JESD51 series of standards focuses on thermal measurements for semiconductor devices and includes specific protocols for measuring thermal resistance in electronic packages where TIMs are employed. These standards are particularly relevant when evaluating how contact resistance changes under different compression scenarios in semiconductor cooling applications.

ISO 22007 provides methods for determining thermal conductivity and thermal diffusivity of plastics and composite materials, including those used in TIM applications. The standard includes provisions for measuring these properties under varying pressure conditions, directly applicable to compression-dependent contact resistance studies.

Military standards such as MIL-STD-810G incorporate thermal management requirements that include specifications for TIM performance under extreme conditions. These standards often require rigorous testing of contact resistance stability under compression cycling, which is critical for military and aerospace applications.

Industry-specific guidelines from organizations like SEMI (Semiconductor Equipment and Materials International) provide additional compliance frameworks for TIM applications in semiconductor manufacturing. Their standards often include specific requirements for measuring and reporting contact resistance under operational compression conditions.

UL (Underwriters Laboratories) standards address safety aspects related to thermal management, including maximum operating temperatures and thermal runaway prevention. Compliance with these standards requires thorough understanding of how contact resistance in TIM pathways responds to compression over time and under various environmental conditions.

The IPC-4101 standard for printed circuit board materials includes specifications for thermal management materials used in electronic assemblies, with requirements for testing thermal performance under assembly pressures that directly impact contact resistance measurements.

AI and data center industry consortiums like Open Compute Project (OCP) have also developed thermal specifications that address the unique cooling challenges in high-density computing environments, including standardized methods for evaluating TIM compression performance.

ASTM D5470 stands as the primary standard for thermal resistance measurements of TIMs, offering detailed procedures for measuring thermal impedance under various compression loads. This standard specifically addresses the challenges in quantifying contact resistance at material interfaces, which is essential when evaluating TIM performance in real-world applications.

The JEDEC JESD51 series of standards focuses on thermal measurements for semiconductor devices and includes specific protocols for measuring thermal resistance in electronic packages where TIMs are employed. These standards are particularly relevant when evaluating how contact resistance changes under different compression scenarios in semiconductor cooling applications.

ISO 22007 provides methods for determining thermal conductivity and thermal diffusivity of plastics and composite materials, including those used in TIM applications. The standard includes provisions for measuring these properties under varying pressure conditions, directly applicable to compression-dependent contact resistance studies.

Military standards such as MIL-STD-810G incorporate thermal management requirements that include specifications for TIM performance under extreme conditions. These standards often require rigorous testing of contact resistance stability under compression cycling, which is critical for military and aerospace applications.

Industry-specific guidelines from organizations like SEMI (Semiconductor Equipment and Materials International) provide additional compliance frameworks for TIM applications in semiconductor manufacturing. Their standards often include specific requirements for measuring and reporting contact resistance under operational compression conditions.

UL (Underwriters Laboratories) standards address safety aspects related to thermal management, including maximum operating temperatures and thermal runaway prevention. Compliance with these standards requires thorough understanding of how contact resistance in TIM pathways responds to compression over time and under various environmental conditions.

The IPC-4101 standard for printed circuit board materials includes specifications for thermal management materials used in electronic assemblies, with requirements for testing thermal performance under assembly pressures that directly impact contact resistance measurements.

AI and data center industry consortiums like Open Compute Project (OCP) have also developed thermal specifications that address the unique cooling challenges in high-density computing environments, including standardized methods for evaluating TIM compression performance.

Environmental Impact of TIM Materials

The environmental impact of Thermal Interface Materials (TIMs) represents a critical consideration in the sustainable development of electronic systems. As the electronics industry continues to expand, the volume of TIMs utilized in thermal management solutions grows proportionally, raising significant environmental concerns throughout their lifecycle.

Manufacturing processes for TIMs often involve energy-intensive operations and potentially hazardous chemicals. Particularly concerning are traditional TIMs containing heavy metals, such as lead-based solders, which pose serious environmental risks during production and disposal phases. The extraction of raw materials for TIMs, including rare earth elements and metals, contributes to habitat destruction, soil degradation, and water pollution in mining regions.

The compression behavior of TIMs directly influences their environmental footprint. Materials requiring higher compression forces typically demand more robust mechanical systems, increasing the overall material usage and energy consumption during operation. Conversely, TIMs that maintain effective thermal conductivity under lower compression pressures can contribute to more resource-efficient designs with extended operational lifespans.

Carbon-based TIMs, including graphene and carbon nanotubes, present a mixed environmental profile. While offering superior thermal performance under compression, their production processes currently generate substantial carbon emissions. However, their extended durability and efficiency may offset initial environmental costs through reduced replacement frequency and improved energy efficiency in electronic systems.

End-of-life considerations for TIMs present particular challenges. Many composite TIMs are difficult to recycle due to their heterogeneous composition and intimate integration with electronic components. The leaching of potentially toxic substances from improperly disposed TIMs threatens soil and groundwater quality, particularly in regions with inadequate electronic waste management infrastructure.

Recent innovations in bio-based and biodegradable TIMs offer promising alternatives with reduced environmental impact. Materials derived from renewable resources, such as cellulose-based composites and plant oils, demonstrate competitive thermal performance while significantly reducing ecological footprint. These sustainable alternatives typically exhibit favorable compression characteristics while minimizing toxic components.

Regulatory frameworks increasingly address the environmental aspects of TIMs, with legislation like the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) imposing strict limitations on environmentally harmful substances. These regulations drive industry innovation toward greener TIM solutions that maintain effective thermal conductivity under compression while minimizing environmental harm.

Manufacturing processes for TIMs often involve energy-intensive operations and potentially hazardous chemicals. Particularly concerning are traditional TIMs containing heavy metals, such as lead-based solders, which pose serious environmental risks during production and disposal phases. The extraction of raw materials for TIMs, including rare earth elements and metals, contributes to habitat destruction, soil degradation, and water pollution in mining regions.

The compression behavior of TIMs directly influences their environmental footprint. Materials requiring higher compression forces typically demand more robust mechanical systems, increasing the overall material usage and energy consumption during operation. Conversely, TIMs that maintain effective thermal conductivity under lower compression pressures can contribute to more resource-efficient designs with extended operational lifespans.

Carbon-based TIMs, including graphene and carbon nanotubes, present a mixed environmental profile. While offering superior thermal performance under compression, their production processes currently generate substantial carbon emissions. However, their extended durability and efficiency may offset initial environmental costs through reduced replacement frequency and improved energy efficiency in electronic systems.

End-of-life considerations for TIMs present particular challenges. Many composite TIMs are difficult to recycle due to their heterogeneous composition and intimate integration with electronic components. The leaching of potentially toxic substances from improperly disposed TIMs threatens soil and groundwater quality, particularly in regions with inadequate electronic waste management infrastructure.

Recent innovations in bio-based and biodegradable TIMs offer promising alternatives with reduced environmental impact. Materials derived from renewable resources, such as cellulose-based composites and plant oils, demonstrate competitive thermal performance while significantly reducing ecological footprint. These sustainable alternatives typically exhibit favorable compression characteristics while minimizing toxic components.

Regulatory frameworks increasingly address the environmental aspects of TIMs, with legislation like the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) imposing strict limitations on environmentally harmful substances. These regulations drive industry innovation toward greener TIM solutions that maintain effective thermal conductivity under compression while minimizing environmental harm.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!