TIM For Satellite & Aerospace Electronics: Qualification And Outgassing Standards

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Evolution and Aerospace Application Objectives

Thermal Interface Materials (TIMs) have evolved significantly since their inception in the electronics industry during the 1970s. Initially, simple thermal greases composed of silicone oils filled with metal oxides were the standard solution for thermal management. These early materials offered modest thermal conductivity values of 0.5-1.0 W/mK, which proved sufficient for the computing and electronics applications of that era.

The aerospace industry's adoption of TIMs began in earnest during the 1980s, as satellite systems became more sophisticated and power-dense. This period marked the transition from rudimentary thermal solutions to more specialized materials designed specifically for the unique challenges of space environments. The evolution accelerated in the 1990s with the development of phase change materials (PCMs) that could maintain consistent performance through thermal cycling.

By the early 2000s, the emergence of carbon-based fillers, particularly carbon nanotubes and graphene, revolutionized TIM technology, pushing thermal conductivity values beyond 5 W/mK while maintaining the compliance necessary for effective interfacing. This advancement coincided with increasing power densities in satellite electronics, making these enhanced TIMs critical for mission success.

The primary objective for aerospace TIM applications centers on achieving reliable thermal management under extreme environmental conditions. Unlike consumer electronics, aerospace TIMs must maintain performance integrity through launch vibrations, vacuum exposure, radiation bombardment, and extreme temperature cycling from -150°C to +150°C. Additionally, these materials must demonstrate minimal outgassing to prevent contamination of sensitive optical equipment and solar arrays.

Another critical objective is long-term reliability without maintenance. While consumer electronics typically have design lifespans of 3-5 years, satellite missions often extend beyond 15 years, requiring TIMs that maintain consistent performance throughout this extended period without degradation or pump-out effects.

Weight optimization represents another key objective, as each gram launched into orbit incurs substantial costs. Modern aerospace TIMs must balance thermal performance with mass efficiency, often requiring innovative formulations that maximize conductivity while minimizing density.

The qualification standards for aerospace TIMs have evolved alongside the materials themselves, with ASTM E595 emerging as the industry benchmark for outgassing properties, requiring materials to demonstrate Total Mass Loss (TML) below 1.0% and Collected Volatile Condensable Materials (CVCM) below 0.1%. These stringent requirements drive continuous innovation in TIM chemistry and application methodologies.

The aerospace industry's adoption of TIMs began in earnest during the 1980s, as satellite systems became more sophisticated and power-dense. This period marked the transition from rudimentary thermal solutions to more specialized materials designed specifically for the unique challenges of space environments. The evolution accelerated in the 1990s with the development of phase change materials (PCMs) that could maintain consistent performance through thermal cycling.

By the early 2000s, the emergence of carbon-based fillers, particularly carbon nanotubes and graphene, revolutionized TIM technology, pushing thermal conductivity values beyond 5 W/mK while maintaining the compliance necessary for effective interfacing. This advancement coincided with increasing power densities in satellite electronics, making these enhanced TIMs critical for mission success.

The primary objective for aerospace TIM applications centers on achieving reliable thermal management under extreme environmental conditions. Unlike consumer electronics, aerospace TIMs must maintain performance integrity through launch vibrations, vacuum exposure, radiation bombardment, and extreme temperature cycling from -150°C to +150°C. Additionally, these materials must demonstrate minimal outgassing to prevent contamination of sensitive optical equipment and solar arrays.

Another critical objective is long-term reliability without maintenance. While consumer electronics typically have design lifespans of 3-5 years, satellite missions often extend beyond 15 years, requiring TIMs that maintain consistent performance throughout this extended period without degradation or pump-out effects.

Weight optimization represents another key objective, as each gram launched into orbit incurs substantial costs. Modern aerospace TIMs must balance thermal performance with mass efficiency, often requiring innovative formulations that maximize conductivity while minimizing density.

The qualification standards for aerospace TIMs have evolved alongside the materials themselves, with ASTM E595 emerging as the industry benchmark for outgassing properties, requiring materials to demonstrate Total Mass Loss (TML) below 1.0% and Collected Volatile Condensable Materials (CVCM) below 0.1%. These stringent requirements drive continuous innovation in TIM chemistry and application methodologies.

Market Analysis for Space-Grade Thermal Interface Materials

The global market for space-grade Thermal Interface Materials (TIMs) is experiencing robust growth, driven by increasing satellite deployments and the expansion of aerospace electronics applications. Current market valuations indicate the space-grade TIM sector represents approximately 5-7% of the overall aerospace materials market, with projections showing accelerated growth at a compound annual rate of 8-10% through 2030.

This growth trajectory is primarily fueled by the unprecedented expansion of satellite constellations for communications, Earth observation, and navigation purposes. SpaceX's Starlink alone plans to deploy over 42,000 satellites, while competitors like Amazon's Project Kuiper and OneWeb are developing their own extensive networks. Each satellite requires multiple thermal management solutions, creating substantial demand for specialized TIMs that can withstand the extreme conditions of space.

The market segmentation reveals distinct categories based on material composition, with silicone-based TIMs currently dominating with approximately 45% market share due to their reliability and outgassing characteristics. Phase change materials are gaining traction, showing the fastest growth rate among all TIM types, particularly in applications requiring cyclical thermal management. Graphene and carbon nanotube-enhanced TIMs represent the premium segment, commanding higher prices but offering superior thermal conductivity.

Geographically, North America leads the market with approximately 40% share, housing major aerospace manufacturers and space agencies. Europe follows at 30%, with significant contributions from ESA-affiliated projects. The Asia-Pacific region, particularly Japan, China, and India, represents the fastest-growing market segment as these nations expand their space programs and satellite manufacturing capabilities.

Customer segmentation shows government space agencies remain the largest purchasers, accounting for approximately 35% of total market value. However, private satellite manufacturers and commercial space companies are rapidly increasing their market share, growing at nearly twice the rate of traditional government procurement channels.

Price sensitivity varies significantly across market segments. While government agencies prioritize reliability over cost, commercial satellite manufacturers are increasingly seeking cost-effective solutions that maintain performance standards while enabling mass production economics. This has created a two-tier market where premium, ultra-high-reliability TIMs coexist with more affordable options designed for commercial satellite constellations.

The market forecast indicates particularly strong growth in TIMs specifically engineered to meet the stringent outgassing standards of ASTM E595 and NASA SP-R-0022A, as these qualifications become mandatory requirements for most space applications.

This growth trajectory is primarily fueled by the unprecedented expansion of satellite constellations for communications, Earth observation, and navigation purposes. SpaceX's Starlink alone plans to deploy over 42,000 satellites, while competitors like Amazon's Project Kuiper and OneWeb are developing their own extensive networks. Each satellite requires multiple thermal management solutions, creating substantial demand for specialized TIMs that can withstand the extreme conditions of space.

The market segmentation reveals distinct categories based on material composition, with silicone-based TIMs currently dominating with approximately 45% market share due to their reliability and outgassing characteristics. Phase change materials are gaining traction, showing the fastest growth rate among all TIM types, particularly in applications requiring cyclical thermal management. Graphene and carbon nanotube-enhanced TIMs represent the premium segment, commanding higher prices but offering superior thermal conductivity.

Geographically, North America leads the market with approximately 40% share, housing major aerospace manufacturers and space agencies. Europe follows at 30%, with significant contributions from ESA-affiliated projects. The Asia-Pacific region, particularly Japan, China, and India, represents the fastest-growing market segment as these nations expand their space programs and satellite manufacturing capabilities.

Customer segmentation shows government space agencies remain the largest purchasers, accounting for approximately 35% of total market value. However, private satellite manufacturers and commercial space companies are rapidly increasing their market share, growing at nearly twice the rate of traditional government procurement channels.

Price sensitivity varies significantly across market segments. While government agencies prioritize reliability over cost, commercial satellite manufacturers are increasingly seeking cost-effective solutions that maintain performance standards while enabling mass production economics. This has created a two-tier market where premium, ultra-high-reliability TIMs coexist with more affordable options designed for commercial satellite constellations.

The market forecast indicates particularly strong growth in TIMs specifically engineered to meet the stringent outgassing standards of ASTM E595 and NASA SP-R-0022A, as these qualifications become mandatory requirements for most space applications.

Current TIM Technologies and Space Environment Challenges

Thermal Interface Materials (TIMs) in aerospace applications face unique challenges due to the extreme conditions of space environments. Current TIM technologies include traditional thermal greases, phase change materials (PCMs), thermal gap pads, and advanced carbon-based solutions such as graphene and carbon nanotubes. Thermal greases offer excellent thermal conductivity (1-10 W/mK) but suffer from pump-out and dry-out effects during thermal cycling in space. PCMs provide consistent performance through phase transitions but have limited temperature ranges that may be problematic for spacecraft experiencing extreme temperature variations.

Gap pads and thermal putties offer advantages in managing uneven surfaces and gaps between components, crucial for maintaining thermal connections during launch vibrations and in-orbit thermal expansion/contraction cycles. However, their thermal conductivity (typically 1-5 W/mK) remains lower than optimal for high-power density electronics increasingly common in satellite systems.

The space environment presents several critical challenges for TIM performance. Vacuum conditions accelerate outgassing of volatile components, potentially contaminating sensitive optical equipment and electronics. NASA's ASTM E595 standard specifies maximum Total Mass Loss (TML) of 1.0% and Collected Volatile Condensable Materials (CVCM) of 0.1%, severely limiting material selection for space-grade TIMs.

Radiation exposure represents another significant challenge, with materials experiencing degradation from both ionizing radiation and ultraviolet exposure. This can lead to crosslinking or chain scission in polymer-based TIMs, altering their mechanical and thermal properties over the mission lifetime. Typical satellites in LEO may experience 10-100 krad total dose over a 5-year mission, while GEO missions face even higher radiation levels.

Temperature extremes in space (-150°C to +150°C in direct sunlight/shadow transitions) create thermal cycling stresses that can cause interface delamination, material fatigue, and performance degradation. Most commercial TIMs are qualified for -40°C to +125°C, highlighting the gap between commercial and space-grade requirements.

Recent innovations include metal-matrix composites incorporating gallium and indium alloys that maintain performance in vacuum while meeting outgassing standards. Ceramic-filled silicones with specialized cross-linking agents have also shown promise in radiation resistance testing. However, the qualification process for space-grade TIMs remains lengthy and costly, typically requiring 12-18 months of testing before flight approval.

The trade-off between thermal performance and space-environment compatibility continues to drive research in this field, with particular emphasis on developing materials that maintain stable performance throughout the mission lifetime while meeting stringent outgassing requirements.

Gap pads and thermal putties offer advantages in managing uneven surfaces and gaps between components, crucial for maintaining thermal connections during launch vibrations and in-orbit thermal expansion/contraction cycles. However, their thermal conductivity (typically 1-5 W/mK) remains lower than optimal for high-power density electronics increasingly common in satellite systems.

The space environment presents several critical challenges for TIM performance. Vacuum conditions accelerate outgassing of volatile components, potentially contaminating sensitive optical equipment and electronics. NASA's ASTM E595 standard specifies maximum Total Mass Loss (TML) of 1.0% and Collected Volatile Condensable Materials (CVCM) of 0.1%, severely limiting material selection for space-grade TIMs.

Radiation exposure represents another significant challenge, with materials experiencing degradation from both ionizing radiation and ultraviolet exposure. This can lead to crosslinking or chain scission in polymer-based TIMs, altering their mechanical and thermal properties over the mission lifetime. Typical satellites in LEO may experience 10-100 krad total dose over a 5-year mission, while GEO missions face even higher radiation levels.

Temperature extremes in space (-150°C to +150°C in direct sunlight/shadow transitions) create thermal cycling stresses that can cause interface delamination, material fatigue, and performance degradation. Most commercial TIMs are qualified for -40°C to +125°C, highlighting the gap between commercial and space-grade requirements.

Recent innovations include metal-matrix composites incorporating gallium and indium alloys that maintain performance in vacuum while meeting outgassing standards. Ceramic-filled silicones with specialized cross-linking agents have also shown promise in radiation resistance testing. However, the qualification process for space-grade TIMs remains lengthy and costly, typically requiring 12-18 months of testing before flight approval.

The trade-off between thermal performance and space-environment compatibility continues to drive research in this field, with particular emphasis on developing materials that maintain stable performance throughout the mission lifetime while meeting stringent outgassing requirements.

Existing Qualification Methodologies for Space-Grade TIMs

01 Thermal Interface Material Testing and Qualification Methods

Various testing methodologies are employed to qualify thermal interface materials, including thermal conductivity measurements, thermal resistance testing, and reliability assessments under different environmental conditions. These qualification procedures ensure that TIMs meet specific performance requirements for heat transfer efficiency and long-term stability in electronic applications. Standard test methods evaluate parameters such as thermal impedance, bulk thermal conductivity, and interface resistance under simulated operating conditions.- Testing and qualification standards for thermal interface materials: Various testing methodologies and qualification standards are employed to evaluate the performance and reliability of thermal interface materials (TIMs). These standards include thermal conductivity measurements, thermal resistance testing, and reliability assessments under different environmental conditions. Standardized testing procedures ensure consistent evaluation of TIM properties across different applications and help in selecting appropriate materials for specific thermal management requirements.

- Outgassing characteristics and control methods for TIMs: Outgassing is a critical concern for thermal interface materials, particularly in sensitive electronic applications and aerospace environments. Standards and methods for measuring and controlling outgassing include vacuum testing, mass loss determination, and condensable volatile materials analysis. Low outgassing TIMs are formulated with specific materials and processing techniques to minimize volatile organic compound (VOC) emissions that could potentially contaminate surrounding components or degrade thermal performance over time.

- Thermal interface material composition and performance characteristics: The composition of thermal interface materials significantly affects their performance characteristics. Various formulations incorporate fillers such as metal particles, ceramic powders, or carbon-based materials in polymer matrices to enhance thermal conductivity. The balance between thermal conductivity, conformability, and long-term reliability is crucial for effective heat transfer. Advanced TIMs may include phase change materials, liquid metal alloys, or specialized compounds designed to maintain performance under thermal cycling and aging conditions.

- Application-specific TIM qualification requirements: Different applications impose varying qualification requirements for thermal interface materials. High-reliability electronics, aerospace components, automotive systems, and consumer electronics each have specific standards for TIM performance. These application-specific requirements may include temperature range tolerance, pressure sensitivity, electrical insulation properties, and compatibility with adjacent materials. Qualification protocols often involve accelerated aging tests, thermal cycling, and environmental stress testing to ensure long-term reliability in the intended operating environment.

- Manufacturing process controls and quality assurance for TIMs: Manufacturing process controls and quality assurance measures are essential for producing consistent and reliable thermal interface materials. These include raw material qualification, process parameter monitoring, and finished product testing. Statistical process control methods help maintain consistency in TIM properties such as thickness, density, and thermal performance. Quality assurance protocols may involve lot sampling, accelerated reliability testing, and certification to industry standards to ensure that manufactured TIMs meet specified performance and outgassing requirements.

02 Outgassing Standards and Evaluation for Space Applications

Thermal interface materials used in aerospace and satellite applications must meet strict outgassing standards to prevent contamination of sensitive components in vacuum environments. These materials undergo specialized testing according to established standards such as ASTM E595, which measures Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM). Low outgassing TIMs are formulated with specific polymers and fillers that maintain stability under vacuum conditions while providing effective thermal management for space-grade electronics.Expand Specific Solutions03 Reliability Testing for Semiconductor Package Applications

Thermal interface materials used in semiconductor packaging undergo comprehensive reliability testing to ensure performance over the device lifetime. These tests include thermal cycling, high temperature storage, temperature-humidity-bias testing, and power cycling. The qualification standards evaluate TIM degradation mechanisms such as pump-out, dry-out, and delamination that can compromise thermal performance. Advanced testing protocols simulate accelerated aging conditions to predict long-term reliability in various electronic applications.Expand Specific Solutions04 Material Composition and Performance Characterization

The composition of thermal interface materials significantly impacts their qualification requirements and outgassing characteristics. Materials containing silicone, phase change compounds, metal alloys, or carbon-based fillers each have distinct performance profiles and testing needs. Characterization techniques include differential scanning calorimetry, thermogravimetric analysis, and mechanical property testing to evaluate phase transition behavior, thermal stability, and compliance. These analyses help determine the suitability of specific TIM formulations for different electronic cooling applications.Expand Specific Solutions05 Industry-Specific Standards and Compliance Requirements

Different industries have established specific qualification standards for thermal interface materials based on application requirements. Automotive electronics demand testing under extreme temperature ranges and vibration conditions according to AEC-Q standards. Medical devices require biocompatibility testing alongside thermal performance. Consumer electronics focus on cost-effective reliability testing, while military and aerospace applications emphasize extended reliability under harsh environmental conditions. Compliance with these industry-specific standards ensures that TIMs meet the unique thermal management needs of each application sector.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Aerospace TIMs

The thermal interface materials (TIM) market for satellite and aerospace electronics is in a growth phase, driven by increasing satellite deployments and aerospace advancements. The market is characterized by stringent qualification requirements and outgassing standards that ensure reliability in extreme space environments. Key players include SolAero Technologies, specializing in space-grade solar cells with proven reliability across 160 missions, and established aerospace suppliers like Parker-Hannifin and 3M Innovative Properties offering specialized thermal management solutions. Research institutions such as Beihang University and satellite manufacturers like DFH Satellite Co. are advancing TIM technologies to meet evolving requirements. The competitive landscape features both specialized aerospace material providers and diversified electronics companies like Samsung and Mitsubishi Electric that leverage their thermal management expertise for space applications.

SolAero Technologies Corp.

Technical Solution: SolAero Technologies has developed advanced Thermal Interface Materials (TIMs) specifically engineered for satellite and aerospace electronics that meet rigorous outgassing standards including ASTM E595 and NASA SP-R-0022A. Their proprietary TIM solutions incorporate space-grade silicone matrices with high thermal conductivity fillers (>5 W/m·K) while maintaining outgassing levels below 1.0% Total Mass Loss (TML) and 0.1% Collected Volatile Condensable Materials (CVCM). SolAero's qualification process includes thermal cycling from -180°C to +150°C to simulate the extreme temperature variations in space environments, with their materials demonstrating less than 5% performance degradation after 2,000 cycles. Their TIMs are currently deployed in multiple satellite constellations and deep space missions, providing reliable thermal management for critical components including high-power amplifiers, processors, and solar cell assemblies.

Strengths: Exceptional thermal stability in extreme temperature environments, ultra-low outgassing properties meeting NASA standards, and proven flight heritage on multiple space missions. Weaknesses: Higher cost compared to commercial-grade alternatives, longer lead times due to rigorous qualification processes, and limited flexibility in customization for specific mission requirements.

Parker-Hannifin Corp.

Technical Solution: Parker-Hannifin has developed the Chomerics THERM-A-GAP series specifically qualified for aerospace and satellite applications. These TIMs utilize a silicone elastomer base with thermally conductive ceramic fillers achieving conductivity values of 3-6 W/m·K while meeting NASA outgassing standards (TML <1.0%, CVCM <0.1%). Their materials undergo extensive qualification testing including thermal cycling (-65°C to +125°C), vacuum stability testing, and radiation resistance evaluation up to 100 kGy. Parker's aerospace-grade TIMs feature reinforced structures that maintain performance under launch vibration conditions and incorporate proprietary additives that prevent silicone migration—a critical concern for optical instruments in spacecraft. Their THERM-A-GAP T63X series has been specifically formulated to maintain gap-filling capabilities and compliance over 15+ year mission lifespans, with documented performance in geostationary satellites where thermal cycling occurs approximately 1,500 times annually.

Strengths: Extensive aerospace qualification heritage, excellent compression set resistance maintaining thermal performance over extended missions, and specialized formulations for different satellite subsystems. Weaknesses: Higher compression forces required for optimal thermal performance compared to some competitors, limited electrical insulation properties in certain formulations, and potential for increased hardening in extended radiation environments.

Critical Patents and Innovations in Low-Outgassing TIM Technology

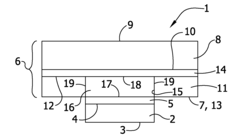

Thermal interface material and solder preforms

PatentInactiveUS20070145546A1

Innovation

- A high-performance TIM comprising a solder component with a thermal conductivity enhancement component and a CTE modifying component, along with an intrinsic oxygen getter, which allows for bonding without extrinsic fluxing and enhances heat transfer while minimizing thermal stress.

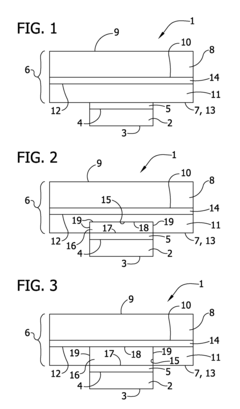

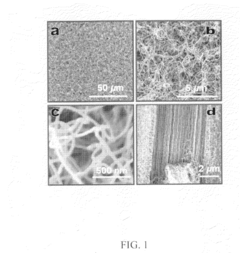

Carbon Nanotube Arrays as Thermal Interface Materials

PatentInactiveUS20110189500A1

Innovation

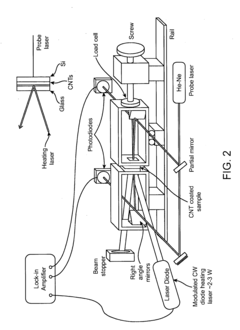

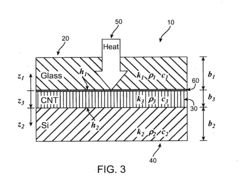

- A thermal interface material comprising a base layer with an array of vertically aligned carbon nanostructures and an indium layer, which enhances thermal conductance by minimizing interfacial resistances through direct and improved contact, as demonstrated by the use of a phase-sensitive transient thermo-reflectance technique.

Space Agency Standards and Certification Requirements

Space agencies worldwide have established rigorous standards and certification requirements for Thermal Interface Materials (TIMs) used in satellite and aerospace electronics. NASA's standards, particularly NASA-STD-8739.1 for workmanship and NASA-STD-6016 for materials, provide comprehensive guidelines for TIM selection and implementation. These standards emphasize thermal performance under vacuum conditions, long-term reliability, and compatibility with spacecraft systems.

The European Space Agency (ESA) has developed the European Cooperation for Space Standardization (ECSS) framework, which includes ECSS-Q-ST-70-02C for thermal vacuum outgassing qualification and ECSS-Q-ST-70-71C for materials and hardware compatibility. ESA's standards are particularly stringent regarding outgassing properties, requiring TIMs to demonstrate Total Mass Loss (TML) below 1.0% and Collected Volatile Condensable Material (CVCM) below 0.1%.

JAXA, Japan's space agency, follows JERG-0-039 for outgassing and contamination control, while Roscosmos adheres to OST 92-1380-83 for space materials qualification. The Chinese space program implements GB/T 14159 standards, focusing on material stability in space environments.

Certification processes typically involve multi-stage testing protocols. Initial screening includes thermal conductivity verification under both ambient and vacuum conditions. Materials must then undergo thermal cycling tests (typically -55°C to +125°C for 500-1000 cycles) to demonstrate stability and performance retention. Vacuum outgassing tests following ASTM E595 or equivalent standards are mandatory, with results documented in NASA and ESA outgassing databases.

Radiation hardness certification requires TIMs to withstand Total Ionizing Dose (TID) levels of 100 krad to 1 Mrad, depending on mission parameters. Long-term aging tests, sometimes accelerated through elevated temperatures, verify performance stability over projected mission lifetimes of 15+ years.

Certification documentation must include detailed material composition, manufacturing process controls, lot-specific test results, and traceability information. Many space agencies maintain Qualified Products Lists (QPLs) for pre-approved TIMs, though mission-specific requirements may necessitate additional qualification testing even for listed materials.

Cross-recognition of certifications between agencies remains limited, requiring manufacturers to pursue multiple certification paths for global market access. Recent initiatives like the International Space Components Coordination Group (ISCCG) aim to harmonize standards and reduce redundant testing requirements.

The European Space Agency (ESA) has developed the European Cooperation for Space Standardization (ECSS) framework, which includes ECSS-Q-ST-70-02C for thermal vacuum outgassing qualification and ECSS-Q-ST-70-71C for materials and hardware compatibility. ESA's standards are particularly stringent regarding outgassing properties, requiring TIMs to demonstrate Total Mass Loss (TML) below 1.0% and Collected Volatile Condensable Material (CVCM) below 0.1%.

JAXA, Japan's space agency, follows JERG-0-039 for outgassing and contamination control, while Roscosmos adheres to OST 92-1380-83 for space materials qualification. The Chinese space program implements GB/T 14159 standards, focusing on material stability in space environments.

Certification processes typically involve multi-stage testing protocols. Initial screening includes thermal conductivity verification under both ambient and vacuum conditions. Materials must then undergo thermal cycling tests (typically -55°C to +125°C for 500-1000 cycles) to demonstrate stability and performance retention. Vacuum outgassing tests following ASTM E595 or equivalent standards are mandatory, with results documented in NASA and ESA outgassing databases.

Radiation hardness certification requires TIMs to withstand Total Ionizing Dose (TID) levels of 100 krad to 1 Mrad, depending on mission parameters. Long-term aging tests, sometimes accelerated through elevated temperatures, verify performance stability over projected mission lifetimes of 15+ years.

Certification documentation must include detailed material composition, manufacturing process controls, lot-specific test results, and traceability information. Many space agencies maintain Qualified Products Lists (QPLs) for pre-approved TIMs, though mission-specific requirements may necessitate additional qualification testing even for listed materials.

Cross-recognition of certifications between agencies remains limited, requiring manufacturers to pursue multiple certification paths for global market access. Recent initiatives like the International Space Components Coordination Group (ISCCG) aim to harmonize standards and reduce redundant testing requirements.

Reliability Testing Protocols for Extreme Temperature Cycling

Reliability testing protocols for thermal interface materials (TIMs) in aerospace applications must address the extreme temperature cycling conditions encountered in space environments. These protocols typically involve subjecting TIM samples to temperature ranges from -65°C to +150°C, simulating the harsh thermal conditions experienced by satellite electronics during orbit transitions between sunlight and shadow. Standard test methods include JEDEC JESD22-A104 and MIL-STD-883, Method 1010, which specify precise temperature extremes, dwell times, and transition rates.

The testing methodology must incorporate sufficient cycle counts—typically 500 to 1000 cycles—to validate long-term performance degradation patterns. During these cycles, critical parameters such as thermal conductivity, bond line thickness, and interfacial contact resistance are monitored to detect performance deterioration. Advanced testing protocols also measure changes in mechanical properties, including compression set, elastic modulus, and adhesion strength, as these directly impact the TIM's ability to maintain thermal contact under repeated thermal stress.

Accelerated life testing represents a crucial component of qualification protocols, employing statistical models like Arrhenius equations to extrapolate long-term reliability from accelerated test data. This approach enables manufacturers to predict TIM performance over the 10-15 year operational lifespan of satellite systems without conducting decade-long tests. The acceleration factor calculations must account for the specific failure mechanisms of different TIM types, whether they are gap fillers, putties, or phase change materials.

Vacuum thermal cycling tests are particularly significant for aerospace applications, as they combine thermal stress with the outgassing conditions of space. These tests are conducted in specialized chambers that maintain vacuum levels of 10^-6 torr while executing temperature cycles. This dual-stress environment reveals potential interactions between thermal cycling and outgassing behaviors that might not be apparent in standard atmospheric testing.

Failure analysis methodologies form an essential element of these protocols, employing techniques such as scanning acoustic microscopy, cross-sectional analysis, and thermomechanical analysis to characterize degradation mechanisms. Common failure modes identified include pump-out (material migration), dry-out (volatile component loss), delamination, and cracking. The correlation between these physical changes and thermal performance degradation provides valuable insights for material optimization.

Industry standards require that reliability data be reported with statistical confidence levels, typically requiring multiple test samples and standardized reporting formats. NASA GSFC, ESA ECSS-Q-ST-70, and ASTM E595 standards provide specific guidelines for data collection, analysis, and qualification thresholds that TIMs must meet for space flight certification.

The testing methodology must incorporate sufficient cycle counts—typically 500 to 1000 cycles—to validate long-term performance degradation patterns. During these cycles, critical parameters such as thermal conductivity, bond line thickness, and interfacial contact resistance are monitored to detect performance deterioration. Advanced testing protocols also measure changes in mechanical properties, including compression set, elastic modulus, and adhesion strength, as these directly impact the TIM's ability to maintain thermal contact under repeated thermal stress.

Accelerated life testing represents a crucial component of qualification protocols, employing statistical models like Arrhenius equations to extrapolate long-term reliability from accelerated test data. This approach enables manufacturers to predict TIM performance over the 10-15 year operational lifespan of satellite systems without conducting decade-long tests. The acceleration factor calculations must account for the specific failure mechanisms of different TIM types, whether they are gap fillers, putties, or phase change materials.

Vacuum thermal cycling tests are particularly significant for aerospace applications, as they combine thermal stress with the outgassing conditions of space. These tests are conducted in specialized chambers that maintain vacuum levels of 10^-6 torr while executing temperature cycles. This dual-stress environment reveals potential interactions between thermal cycling and outgassing behaviors that might not be apparent in standard atmospheric testing.

Failure analysis methodologies form an essential element of these protocols, employing techniques such as scanning acoustic microscopy, cross-sectional analysis, and thermomechanical analysis to characterize degradation mechanisms. Common failure modes identified include pump-out (material migration), dry-out (volatile component loss), delamination, and cracking. The correlation between these physical changes and thermal performance degradation provides valuable insights for material optimization.

Industry standards require that reliability data be reported with statistical confidence levels, typically requiring multiple test samples and standardized reporting formats. NASA GSFC, ESA ECSS-Q-ST-70, and ASTM E595 standards provide specific guidelines for data collection, analysis, and qualification thresholds that TIMs must meet for space flight certification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!