TIM For Power Modules: Thermal Path Design And Busbar Interactions

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Module TIM Background and Objectives

Thermal Interface Materials (TIMs) have emerged as critical components in power electronics, particularly in power modules where efficient heat dissipation directly impacts performance, reliability, and lifespan. The evolution of TIMs has been closely tied to the advancement of power semiconductor technology, with significant developments occurring since the 1990s when silicon-based power devices began to reach their thermal management limits.

The power electronics industry has witnessed a paradigm shift with the introduction of wide bandgap semiconductors such as Silicon Carbide (SiC) and Gallium Nitride (GaN), which operate at higher temperatures and power densities. This transition has intensified the demands on thermal management systems, pushing TIM technology to evolve from simple thermal greases to sophisticated engineered materials with enhanced thermal conductivity and reliability characteristics.

Current technological trends indicate a growing focus on nano-enhanced TIMs, phase change materials, and graphene-based solutions that promise thermal conductivities exceeding 10 W/m·K while maintaining the mechanical compliance necessary for power module applications. The integration of these advanced TIMs into power modules represents a complex engineering challenge that extends beyond simple material selection to encompass the entire thermal path design.

The primary objective of TIM research and development in power modules is to minimize thermal resistance across the entire assembly while ensuring long-term reliability under cyclic thermal and mechanical stresses. This includes addressing the critical interface between semiconductor devices and heat spreaders, as well as optimizing the interaction between TIMs and busbars, which serve dual electrical and thermal functions in modern power modules.

Another significant goal is to develop TIMs that can accommodate the increasing power densities and switching frequencies of next-generation power modules without compromising on thermal performance or electrical isolation properties. This requires a multidisciplinary approach combining materials science, thermal engineering, and electrical design considerations.

The industry also aims to standardize TIM testing and characterization methodologies specifically for power module applications, as current standards often fail to capture the unique operating conditions and failure modes relevant to power electronics. This standardization would facilitate more accurate comparisons between different TIM solutions and enable more informed design decisions.

Looking forward, the development of TIMs for power modules is expected to focus on environmentally sustainable formulations that maintain or exceed current performance metrics while eliminating hazardous components such as certain metal fillers or silicone oils that pose end-of-life disposal challenges.

The power electronics industry has witnessed a paradigm shift with the introduction of wide bandgap semiconductors such as Silicon Carbide (SiC) and Gallium Nitride (GaN), which operate at higher temperatures and power densities. This transition has intensified the demands on thermal management systems, pushing TIM technology to evolve from simple thermal greases to sophisticated engineered materials with enhanced thermal conductivity and reliability characteristics.

Current technological trends indicate a growing focus on nano-enhanced TIMs, phase change materials, and graphene-based solutions that promise thermal conductivities exceeding 10 W/m·K while maintaining the mechanical compliance necessary for power module applications. The integration of these advanced TIMs into power modules represents a complex engineering challenge that extends beyond simple material selection to encompass the entire thermal path design.

The primary objective of TIM research and development in power modules is to minimize thermal resistance across the entire assembly while ensuring long-term reliability under cyclic thermal and mechanical stresses. This includes addressing the critical interface between semiconductor devices and heat spreaders, as well as optimizing the interaction between TIMs and busbars, which serve dual electrical and thermal functions in modern power modules.

Another significant goal is to develop TIMs that can accommodate the increasing power densities and switching frequencies of next-generation power modules without compromising on thermal performance or electrical isolation properties. This requires a multidisciplinary approach combining materials science, thermal engineering, and electrical design considerations.

The industry also aims to standardize TIM testing and characterization methodologies specifically for power module applications, as current standards often fail to capture the unique operating conditions and failure modes relevant to power electronics. This standardization would facilitate more accurate comparisons between different TIM solutions and enable more informed design decisions.

Looking forward, the development of TIMs for power modules is expected to focus on environmentally sustainable formulations that maintain or exceed current performance metrics while eliminating hazardous components such as certain metal fillers or silicone oils that pose end-of-life disposal challenges.

Market Analysis for TIM in Power Electronics

The global market for Thermal Interface Materials (TIMs) in power electronics is experiencing robust growth, driven primarily by the increasing power density and miniaturization trends across multiple industries. The market value reached approximately $1.2 billion in 2022 and is projected to grow at a CAGR of 8.5% through 2028, potentially reaching $2 billion by the end of the forecast period.

Electric vehicle applications represent the fastest-growing segment for TIMs in power modules, with a market expansion rate exceeding 12% annually. This growth is directly correlated with the rapid electrification of transportation systems worldwide and stringent thermal management requirements for high-performance EV power electronics.

Industrial power conversion systems constitute the largest current market segment, accounting for roughly 35% of TIM consumption in power electronics. This dominance stems from the widespread deployment of variable frequency drives, industrial inverters, and power supply units across manufacturing sectors.

Renewable energy applications, particularly solar inverters and wind power converters, represent another significant growth vector, with market demand increasing at approximately 9% annually. The push toward higher efficiency power conversion in these applications has intensified the need for advanced thermal management solutions.

Regional analysis reveals Asia-Pacific as the dominant market, controlling nearly 45% of global TIM consumption for power electronics. This regional leadership is attributed to the concentration of semiconductor packaging and power module manufacturing facilities in countries like China, Japan, South Korea, and Taiwan.

Material segmentation shows silicone-based TIMs maintaining market leadership with approximately 40% share, though metal-based TIMs and phase change materials are gaining traction in high-performance applications due to their superior thermal conductivity properties.

Price sensitivity varies significantly across application segments, with automotive and aerospace applications demonstrating willingness to adopt premium solutions that offer reliability advantages, while consumer electronics and lower-tier industrial applications remain highly cost-conscious.

The competitive landscape features both specialized TIM manufacturers and diversified materials companies. Key market participants include Henkel, Parker Chomerics, Dow, 3M, Laird Technologies, and Momentive Performance Materials, collectively accounting for over 60% of the market share.

Electric vehicle applications represent the fastest-growing segment for TIMs in power modules, with a market expansion rate exceeding 12% annually. This growth is directly correlated with the rapid electrification of transportation systems worldwide and stringent thermal management requirements for high-performance EV power electronics.

Industrial power conversion systems constitute the largest current market segment, accounting for roughly 35% of TIM consumption in power electronics. This dominance stems from the widespread deployment of variable frequency drives, industrial inverters, and power supply units across manufacturing sectors.

Renewable energy applications, particularly solar inverters and wind power converters, represent another significant growth vector, with market demand increasing at approximately 9% annually. The push toward higher efficiency power conversion in these applications has intensified the need for advanced thermal management solutions.

Regional analysis reveals Asia-Pacific as the dominant market, controlling nearly 45% of global TIM consumption for power electronics. This regional leadership is attributed to the concentration of semiconductor packaging and power module manufacturing facilities in countries like China, Japan, South Korea, and Taiwan.

Material segmentation shows silicone-based TIMs maintaining market leadership with approximately 40% share, though metal-based TIMs and phase change materials are gaining traction in high-performance applications due to their superior thermal conductivity properties.

Price sensitivity varies significantly across application segments, with automotive and aerospace applications demonstrating willingness to adopt premium solutions that offer reliability advantages, while consumer electronics and lower-tier industrial applications remain highly cost-conscious.

The competitive landscape features both specialized TIM manufacturers and diversified materials companies. Key market participants include Henkel, Parker Chomerics, Dow, 3M, Laird Technologies, and Momentive Performance Materials, collectively accounting for over 60% of the market share.

Current Challenges in Thermal Interface Materials

Despite significant advancements in thermal interface materials (TIMs) for power modules, several critical challenges persist that impede optimal thermal management performance. The primary challenge remains the thermal resistance optimization across the entire thermal path, particularly at material interfaces. Current TIMs struggle to maintain consistent performance under the extreme thermal cycling conditions typical in power electronics applications, where temperature fluctuations can range from -40°C to over 150°C.

Material degradation presents another significant hurdle, as many TIMs experience pump-out effects, dry-out phenomena, or delamination after prolonged thermal cycling. This degradation substantially reduces thermal conductivity over time, compromising the long-term reliability of power modules. The industry still lacks TIMs that can simultaneously provide excellent thermal conductivity, mechanical compliance, and long-term stability under harsh operating conditions.

The interaction between TIMs and busbars introduces additional complexities. Electrical current flowing through busbars generates localized heating that can create thermal gradients across the interface material. These gradients often lead to uneven thermal expansion and mechanical stress, accelerating TIM degradation at critical junction points. Furthermore, the electromagnetic fields generated by high-current busbars can potentially affect the performance of certain TIMs containing metallic particles.

Manufacturing consistency represents another persistent challenge. The application process for TIMs remains highly sensitive to thickness variations, air entrapment, and coverage uniformity. Even minor inconsistencies during application can create hotspots that significantly reduce overall thermal performance and reliability. This issue becomes particularly pronounced in automated high-volume production environments.

Environmental and regulatory concerns further complicate TIM selection and development. Traditional high-performance TIMs often contain environmentally problematic substances such as silicones, certain metal compounds, or halogenated flame retardants. The industry faces increasing pressure to develop eco-friendly alternatives without compromising thermal performance.

Cost-effectiveness remains a significant barrier to widespread adoption of advanced TIM solutions. High-performance materials like metal-based TIMs or phase-change materials with enhanced thermal conductivity typically come with substantially higher costs compared to conventional thermal greases or pads. This cost premium creates adoption challenges, particularly in price-sensitive market segments.

Finally, there exists a fundamental gap between theoretical thermal performance and real-world application results. Laboratory measurements often fail to accurately predict field performance due to the complex interplay of thermal, mechanical, and electrical factors in actual power module operations. This discrepancy complicates material selection and system design processes for engineers seeking reliable thermal management solutions.

Material degradation presents another significant hurdle, as many TIMs experience pump-out effects, dry-out phenomena, or delamination after prolonged thermal cycling. This degradation substantially reduces thermal conductivity over time, compromising the long-term reliability of power modules. The industry still lacks TIMs that can simultaneously provide excellent thermal conductivity, mechanical compliance, and long-term stability under harsh operating conditions.

The interaction between TIMs and busbars introduces additional complexities. Electrical current flowing through busbars generates localized heating that can create thermal gradients across the interface material. These gradients often lead to uneven thermal expansion and mechanical stress, accelerating TIM degradation at critical junction points. Furthermore, the electromagnetic fields generated by high-current busbars can potentially affect the performance of certain TIMs containing metallic particles.

Manufacturing consistency represents another persistent challenge. The application process for TIMs remains highly sensitive to thickness variations, air entrapment, and coverage uniformity. Even minor inconsistencies during application can create hotspots that significantly reduce overall thermal performance and reliability. This issue becomes particularly pronounced in automated high-volume production environments.

Environmental and regulatory concerns further complicate TIM selection and development. Traditional high-performance TIMs often contain environmentally problematic substances such as silicones, certain metal compounds, or halogenated flame retardants. The industry faces increasing pressure to develop eco-friendly alternatives without compromising thermal performance.

Cost-effectiveness remains a significant barrier to widespread adoption of advanced TIM solutions. High-performance materials like metal-based TIMs or phase-change materials with enhanced thermal conductivity typically come with substantially higher costs compared to conventional thermal greases or pads. This cost premium creates adoption challenges, particularly in price-sensitive market segments.

Finally, there exists a fundamental gap between theoretical thermal performance and real-world application results. Laboratory measurements often fail to accurately predict field performance due to the complex interplay of thermal, mechanical, and electrical factors in actual power module operations. This discrepancy complicates material selection and system design processes for engineers seeking reliable thermal management solutions.

Current Thermal Path Design Solutions

01 Advanced TIM compositions for power modules

Various advanced thermal interface materials have been developed specifically for power modules to enhance heat dissipation. These include composite materials with high thermal conductivity fillers, phase change materials that optimize contact at operating temperatures, and novel polymer matrices designed to maintain performance over the lifetime of power electronics. These advanced compositions provide improved thermal conductivity while maintaining necessary mechanical properties such as compliance and reliability under thermal cycling.- Advanced TIM compositions for power modules: Various advanced thermal interface materials have been developed specifically for power modules to enhance heat dissipation. These include composite materials with high thermal conductivity fillers, phase change materials that optimize contact at operating temperatures, and novel polymer matrices designed to maintain performance over thermal cycling. These advanced compositions provide improved thermal conductivity while maintaining necessary mechanical properties such as compliance and reliability under thermal stress.

- Thermal path optimization in semiconductor packages: Optimizing the thermal path design in semiconductor packages involves strategic placement of thermal vias, heat spreaders, and thermal interface materials. This approach focuses on minimizing thermal resistance between heat-generating components and heat sinks by creating efficient thermal pathways. Designs may incorporate multiple layers of different TIMs, each serving specific functions in the thermal management system, resulting in more effective heat dissipation and improved device reliability.

- Integration of cooling systems with TIMs: Effective thermal management in power modules often requires the integration of cooling systems with appropriate thermal interface materials. This approach combines active or passive cooling technologies with specially formulated TIMs to create comprehensive thermal solutions. The integration may include liquid cooling channels, vapor chambers, or advanced heat sink designs that work in conjunction with TIMs to maximize heat transfer efficiency and maintain optimal operating temperatures for power electronics.

- Testing and characterization methods for TIM performance: Specialized testing and characterization methods have been developed to evaluate the performance of thermal interface materials in power module applications. These methods include thermal resistance measurements, reliability testing under thermal cycling, aging studies, and in-situ monitoring techniques. Advanced analytical approaches help quantify key parameters such as thermal conductivity, contact resistance, and long-term stability, enabling more informed selection of appropriate TIMs for specific power module designs.

- Novel application techniques for TIMs in power modules: Innovative application techniques for thermal interface materials significantly impact their performance in power modules. These techniques include precision dispensing methods, pre-applied TIM solutions, sintering processes for metal-based TIMs, and pressure-controlled application systems. The application methodology affects critical parameters such as bond line thickness, void formation, and material distribution, which directly influence the thermal performance and reliability of the power module assembly.

02 Thermal path optimization in semiconductor packages

Effective thermal path design in semiconductor packages involves strategic placement of thermal vias, heat spreaders, and optimized substrate materials. By creating direct thermal pathways from heat-generating components to heat sinks, these designs minimize thermal resistance across the package. Advanced thermal path designs incorporate multiple heat dissipation routes and consider the entire thermal network to prevent hotspots and ensure uniform cooling across power modules.Expand Specific Solutions03 Integration of cooling systems with TIM

Integrated cooling systems work in conjunction with thermal interface materials to create comprehensive thermal management solutions for power modules. These systems may include liquid cooling channels, vapor chambers, or advanced air cooling designs that complement the TIM's function. The integration approach considers the interaction between the cooling system and the TIM to optimize overall thermal performance, addressing both conductive and convective heat transfer mechanisms in power electronics.Expand Specific Solutions04 Testing and characterization methods for TIM performance

Specialized testing methodologies have been developed to accurately characterize thermal interface materials in power module applications. These include thermal resistance measurements under various operating conditions, accelerated aging tests to predict long-term performance, and in-situ monitoring techniques. Advanced characterization methods help quantify the actual performance of TIMs in real-world applications, enabling better selection and optimization of materials for specific power module designs.Expand Specific Solutions05 TIM application techniques for power modules

Precise application techniques for thermal interface materials significantly impact their performance in power modules. These techniques include controlled dispensing methods, pre-applied TIM solutions, and automated application processes that ensure optimal thickness and coverage. Proper application minimizes air gaps and ensures complete interfacial contact between the power components and heat sinks, maximizing the effectiveness of the thermal path design and enhancing overall thermal management.Expand Specific Solutions

Leading Manufacturers and Competitors in TIM Industry

The thermal interface materials (TIM) market for power modules is currently in a growth phase, driven by increasing demand for efficient thermal management in power electronics. The market is expanding rapidly due to the electrification trend in automotive and renewable energy sectors, with an estimated global value exceeding $2 billion. Technologically, the field is evolving from traditional thermal greases toward advanced solutions like phase change materials and sintered silver. Leading players demonstrate varying levels of technical maturity: Mitsubishi Electric, Infineon, and ABB have established comprehensive thermal design expertise for power modules, while companies like Huawei Digital Power and Delta Electronics are rapidly advancing their capabilities. Intel and IBM contribute significant innovations in thermal interface materials, particularly for high-performance computing applications where thermal path optimization is critical.

Mitsubishi Electric Corp.

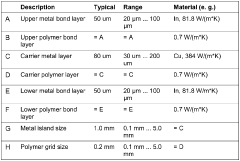

Technical Solution: Mitsubishi Electric has developed advanced thermal interface materials (TIMs) specifically designed for power modules with optimized thermal path design. Their solution incorporates a hybrid TIM approach using phase-change materials combined with high thermal conductivity fillers (>8 W/m·K) that maintain performance under thermal cycling conditions. The company's power modules feature a direct bonded copper (DBC) substrate design with carefully engineered thermal interfaces between semiconductor chips, substrates, and heatsinks to minimize thermal resistance. Mitsubishi's thermal management system includes integrated busbar designs that consider electromagnetic interference (EMI) effects while optimizing thermal paths. Their latest generation modules incorporate pre-applied TIM materials that achieve thermal resistance values below 0.1 K/W·cm² while maintaining electrical isolation properties required for high-voltage applications. The company has also developed specialized TIM application processes that ensure uniform coverage and optimal thickness (typically 50-100μm) to maximize heat transfer efficiency while accommodating coefficient of thermal expansion (CTE) mismatches between different materials in the power module assembly.

Strengths: Superior thermal conductivity with minimal contact resistance; excellent reliability under thermal cycling conditions; integrated approach considering both thermal and electrical performance. Weaknesses: Higher cost compared to conventional solutions; requires precise application processes; potential for degradation in extreme environmental conditions over extended periods.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei Digital Power has pioneered an innovative thermal management solution for power modules that integrates advanced TIM materials with optimized busbar designs. Their approach utilizes a multi-layer TIM structure with nano-enhanced thermal interface materials achieving thermal conductivity exceeding 10 W/m·K while maintaining electrical isolation properties. The company's power modules feature a patented thermal path design that minimizes thermal resistance through strategic material selection and interface engineering. Huawei's solution incorporates phase-change TIMs that optimize contact at operating temperatures, reducing thermal resistance by up to 30% compared to conventional greases. Their busbar design integrates cooling channels and optimizes current distribution to reduce hotspots, with electromagnetic simulations ensuring minimal interference between thermal and electrical paths. The company has developed automated TIM application processes that ensure consistent thickness (typically 40-80μm) and coverage, critical for maintaining thermal performance in high-power density applications such as data center power supplies and electric vehicle charging infrastructure.

Strengths: Exceptional thermal performance in high-power density applications; automated manufacturing processes ensuring consistency; comprehensive approach integrating electrical and thermal considerations. Weaknesses: Proprietary solutions may limit compatibility with third-party components; higher initial implementation costs; requires specialized equipment for optimal application and maintenance.

Critical TIM-Busbar Interface Technologies

Thermal Interface Material System

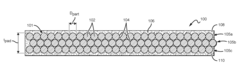

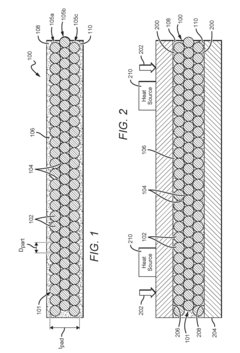

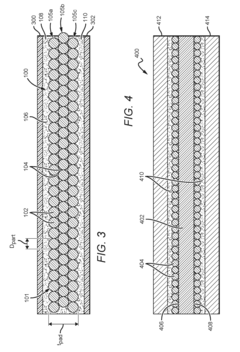

PatentActiveUS20160169598A1

Innovation

- A thermally conductive porous matrix with interstitial voids and a high-temperature resistant colloidal suspension applied on both sides, forming a porous thermal pad that inhibits thermal migration and maintains low thermal resistance.

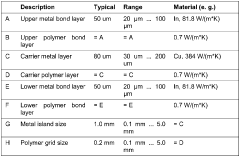

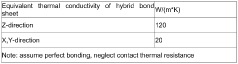

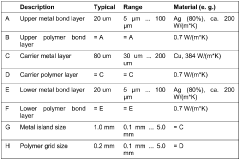

Hybrid bond sheet and cooled semiconductor power module

PatentWO2023179090A1

Innovation

- Homogenization of junction temperature across the power module to reduce overall junction temperature and increase performance and reliability.

- Thermally optimized power module design that addresses the limitations of traditional substrate-level design constraints while maintaining electrical isolation requirements.

- Novel approach to balance vertical package structures to reduce stress in the TIM layer, minimizing warpage during thermal cycling.

Reliability Testing Standards for Power Module TIMs

Reliability testing standards for power module Thermal Interface Materials (TIMs) are critical frameworks that ensure these materials can withstand the demanding operational conditions of power electronic systems. The primary standards governing TIM reliability include JEDEC JESD22-A104 for temperature cycling, JEDEC JESD22-B106 for thermal shock, and IEC 60068-2-78 for steady-state humidity testing. These standards establish methodologies for evaluating TIM performance under various environmental stressors.

Temperature cycling tests typically subject power module TIMs to repeated temperature excursions between -40°C and 150°C, with dwell times at extreme temperatures ranging from 10 to 30 minutes. These tests simulate the thermal expansion and contraction stresses that occur during normal operation and are conducted for 500 to 3000 cycles depending on application requirements.

Thermal shock testing exposes TIMs to rapid temperature changes, often transitioning between temperature extremes in less than 10 seconds. This evaluates the material's resistance to cracking, delamination, and other failure modes induced by sudden thermal gradients. Standard protocols typically require 100 to 1000 shock cycles.

Power cycling tests represent another critical reliability standard, where the power module is electrically cycled on and off while monitoring thermal resistance changes. The industry standard typically requires TIMs to maintain less than 20% increase in thermal resistance after 10,000 power cycles.

Humidity testing standards evaluate TIM performance under high moisture conditions, typically 85% relative humidity at 85°C for 1000 hours. This test identifies potential issues related to moisture absorption, corrosion, and interfacial degradation that could compromise thermal performance.

Mechanical stress testing standards assess TIM resilience under vibration and mechanical shock conditions according to MIL-STD-810 or IEC 60068-2-6. These tests are particularly important for automotive and industrial applications where significant mechanical forces may be present.

Long-term reliability standards include high-temperature storage tests (typically at 125°C for 1000 hours) and thermal aging protocols that accelerate the degradation mechanisms to predict service life. The ASTM D5470 standard provides methodologies for measuring thermal performance before and after reliability testing to quantify degradation.

Emerging standards are beginning to address specific challenges related to busbar interactions, where electromagnetic fields and current-induced heating can affect TIM performance. These standards incorporate combined electrical-thermal-mechanical testing protocols to evaluate TIM reliability under realistic operating conditions.

Temperature cycling tests typically subject power module TIMs to repeated temperature excursions between -40°C and 150°C, with dwell times at extreme temperatures ranging from 10 to 30 minutes. These tests simulate the thermal expansion and contraction stresses that occur during normal operation and are conducted for 500 to 3000 cycles depending on application requirements.

Thermal shock testing exposes TIMs to rapid temperature changes, often transitioning between temperature extremes in less than 10 seconds. This evaluates the material's resistance to cracking, delamination, and other failure modes induced by sudden thermal gradients. Standard protocols typically require 100 to 1000 shock cycles.

Power cycling tests represent another critical reliability standard, where the power module is electrically cycled on and off while monitoring thermal resistance changes. The industry standard typically requires TIMs to maintain less than 20% increase in thermal resistance after 10,000 power cycles.

Humidity testing standards evaluate TIM performance under high moisture conditions, typically 85% relative humidity at 85°C for 1000 hours. This test identifies potential issues related to moisture absorption, corrosion, and interfacial degradation that could compromise thermal performance.

Mechanical stress testing standards assess TIM resilience under vibration and mechanical shock conditions according to MIL-STD-810 or IEC 60068-2-6. These tests are particularly important for automotive and industrial applications where significant mechanical forces may be present.

Long-term reliability standards include high-temperature storage tests (typically at 125°C for 1000 hours) and thermal aging protocols that accelerate the degradation mechanisms to predict service life. The ASTM D5470 standard provides methodologies for measuring thermal performance before and after reliability testing to quantify degradation.

Emerging standards are beginning to address specific challenges related to busbar interactions, where electromagnetic fields and current-induced heating can affect TIM performance. These standards incorporate combined electrical-thermal-mechanical testing protocols to evaluate TIM reliability under realistic operating conditions.

Environmental Impact of TIM Materials in Power Electronics

The environmental impact of Thermal Interface Materials (TIMs) in power electronics represents a growing concern as the industry expands. Traditional TIMs often contain environmentally problematic substances such as silicones, metal particles, and various synthetic compounds that pose significant end-of-life disposal challenges. These materials typically have poor biodegradability profiles and can release harmful substances when improperly disposed of or incinerated.

Manufacturing processes for conventional TIMs frequently involve energy-intensive production methods and the use of volatile organic compounds (VOCs) that contribute to air pollution and climate change. The carbon footprint associated with TIM production, particularly for high-performance materials used in power modules, can be substantial when considering the entire supply chain from raw material extraction to final processing.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), have begun to address these concerns by limiting the use of certain harmful substances in electronic components. This regulatory pressure has accelerated research into environmentally friendly alternatives for thermal management in power electronics.

Emerging eco-friendly TIM solutions include bio-based thermal greases derived from vegetable oils, biodegradable polymer matrices, and recyclable metal-based TIMs designed for easier recovery at end-of-life. These materials aim to maintain thermal performance while reducing environmental impact. For instance, graphene-based TIMs offer excellent thermal conductivity with potentially lower environmental footprints compared to traditional metal-loaded compounds.

Life Cycle Assessment (LCA) studies indicate that the environmental impact of TIMs extends beyond their composition to include their effect on the overall energy efficiency of power modules. More effective TIMs can improve thermal management, potentially extending device lifespan and reducing electronic waste. This relationship creates an important balance between immediate environmental concerns of TIM materials and their long-term contribution to system sustainability.

The power electronics industry is increasingly adopting design-for-environment approaches that consider the entire lifecycle of thermal management solutions. This includes designing power modules with TIM reworkability in mind, facilitating easier separation of components for recycling, and selecting materials with lower environmental impacts. The integration of these considerations with busbar design and overall thermal path optimization represents a holistic approach to sustainable power electronics development.

Manufacturing processes for conventional TIMs frequently involve energy-intensive production methods and the use of volatile organic compounds (VOCs) that contribute to air pollution and climate change. The carbon footprint associated with TIM production, particularly for high-performance materials used in power modules, can be substantial when considering the entire supply chain from raw material extraction to final processing.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), have begun to address these concerns by limiting the use of certain harmful substances in electronic components. This regulatory pressure has accelerated research into environmentally friendly alternatives for thermal management in power electronics.

Emerging eco-friendly TIM solutions include bio-based thermal greases derived from vegetable oils, biodegradable polymer matrices, and recyclable metal-based TIMs designed for easier recovery at end-of-life. These materials aim to maintain thermal performance while reducing environmental impact. For instance, graphene-based TIMs offer excellent thermal conductivity with potentially lower environmental footprints compared to traditional metal-loaded compounds.

Life Cycle Assessment (LCA) studies indicate that the environmental impact of TIMs extends beyond their composition to include their effect on the overall energy efficiency of power modules. More effective TIMs can improve thermal management, potentially extending device lifespan and reducing electronic waste. This relationship creates an important balance between immediate environmental concerns of TIM materials and their long-term contribution to system sustainability.

The power electronics industry is increasingly adopting design-for-environment approaches that consider the entire lifecycle of thermal management solutions. This includes designing power modules with TIM reworkability in mind, facilitating easier separation of components for recycling, and selecting materials with lower environmental impacts. The integration of these considerations with busbar design and overall thermal path optimization represents a holistic approach to sustainable power electronics development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!