TIM Failure Analysis: Cross-Section, SEM, And Elemental Testing Protocols

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Failure Analysis Background and Objectives

Thermal Interface Materials (TIMs) have become increasingly critical components in modern electronic systems, serving as essential thermal management solutions that facilitate heat transfer between heat-generating components and heat dissipation devices. The evolution of TIMs has been closely tied to the advancement of semiconductor technology, with each generation of smaller, more powerful chips demanding more efficient thermal management solutions. From simple thermal greases used in early computing systems to advanced phase-change materials, thermal gels, and graphene-based solutions employed today, TIMs have undergone significant transformation to meet escalating thermal challenges.

The primary objective of TIM failure analysis is to develop comprehensive understanding of the degradation mechanisms and failure modes that affect thermal interface materials in various operating environments. This understanding is crucial as TIM failures can lead to catastrophic system failures, reduced product lifespans, and significant reliability issues in critical applications ranging from consumer electronics to aerospace systems. By establishing standardized cross-sectional analysis, Scanning Electron Microscopy (SEM), and elemental testing protocols, we aim to create a systematic approach to identify, characterize, and mitigate TIM failures.

Current TIM failure analysis faces several challenges, including the lack of standardized testing methodologies, difficulties in replicating real-world operating conditions in laboratory settings, and the complex interplay between thermal, mechanical, and chemical degradation mechanisms. The industry has recognized the need for more sophisticated analytical techniques that can provide insights into failure mechanisms at micro and nano scales, where traditional testing methods fall short.

The technological trajectory in this field points toward integration of advanced imaging techniques with computational modeling to predict TIM behavior under various stress conditions. Recent developments in high-resolution SEM, Energy-Dispersive X-ray Spectroscopy (EDS), and Focused Ion Beam (FIB) techniques have significantly enhanced our ability to examine TIM failures at unprecedented detail levels, revealing previously undetectable failure mechanisms.

This technical research aims to establish a comprehensive framework for TIM failure analysis that combines cross-sectional preparation techniques, advanced SEM imaging protocols, and elemental analysis methods. The goal is to develop reproducible, industry-standard testing protocols that can accurately identify failure mechanisms, predict TIM performance degradation, and inform the development of next-generation thermal interface materials with enhanced reliability and performance characteristics.

The primary objective of TIM failure analysis is to develop comprehensive understanding of the degradation mechanisms and failure modes that affect thermal interface materials in various operating environments. This understanding is crucial as TIM failures can lead to catastrophic system failures, reduced product lifespans, and significant reliability issues in critical applications ranging from consumer electronics to aerospace systems. By establishing standardized cross-sectional analysis, Scanning Electron Microscopy (SEM), and elemental testing protocols, we aim to create a systematic approach to identify, characterize, and mitigate TIM failures.

Current TIM failure analysis faces several challenges, including the lack of standardized testing methodologies, difficulties in replicating real-world operating conditions in laboratory settings, and the complex interplay between thermal, mechanical, and chemical degradation mechanisms. The industry has recognized the need for more sophisticated analytical techniques that can provide insights into failure mechanisms at micro and nano scales, where traditional testing methods fall short.

The technological trajectory in this field points toward integration of advanced imaging techniques with computational modeling to predict TIM behavior under various stress conditions. Recent developments in high-resolution SEM, Energy-Dispersive X-ray Spectroscopy (EDS), and Focused Ion Beam (FIB) techniques have significantly enhanced our ability to examine TIM failures at unprecedented detail levels, revealing previously undetectable failure mechanisms.

This technical research aims to establish a comprehensive framework for TIM failure analysis that combines cross-sectional preparation techniques, advanced SEM imaging protocols, and elemental analysis methods. The goal is to develop reproducible, industry-standard testing protocols that can accurately identify failure mechanisms, predict TIM performance degradation, and inform the development of next-generation thermal interface materials with enhanced reliability and performance characteristics.

Market Demand for Advanced Thermal Interface Materials

The global market for Thermal Interface Materials (TIMs) has been experiencing robust growth, driven primarily by the increasing thermal management requirements across multiple industries. The electronics sector, particularly semiconductor manufacturing, represents the largest market segment with an estimated annual growth rate of 8-12%. This growth is directly correlated with the miniaturization trend in electronic devices, which has resulted in higher power densities and consequently greater heat generation in smaller spaces.

Consumer electronics, including smartphones, tablets, and laptops, constitute a significant portion of TIM demand. As these devices become thinner while incorporating more powerful processors, the need for efficient thermal management solutions has intensified. The automotive industry represents another rapidly expanding market for advanced TIMs, particularly with the rise of electric vehicles (EVs) and hybrid electric vehicles (HEVs), where battery thermal management is critical for performance, safety, and longevity.

Data centers and telecommunications infrastructure have emerged as major consumers of high-performance TIMs. The exponential growth in cloud computing and data processing capabilities has led to increased heat generation in server farms, necessitating more effective thermal management solutions. Industry analysts project that this segment will continue to expand at above-average rates as global data consumption increases.

The renewable energy sector, particularly solar power and wind energy systems, has also contributed to the growing demand for specialized TIMs. These applications often involve exposure to harsh environmental conditions, requiring TIMs with enhanced reliability and longevity characteristics.

Market research indicates a shift in customer preferences toward TIMs with improved reliability, longer service life, and reduced thermal resistance. End-users are increasingly willing to invest in premium TIM solutions that offer demonstrable improvements in device performance and longevity. This trend has created opportunities for manufacturers to develop and market advanced TIM formulations with enhanced thermal conductivity and reliability.

Geographically, Asia-Pacific dominates the global TIM market, accounting for approximately 45% of global consumption. This regional dominance is attributed to the high concentration of electronics manufacturing facilities in countries like China, Taiwan, South Korea, and Japan. North America and Europe follow as significant markets, with growing demand from automotive, aerospace, and medical device sectors.

Consumer electronics, including smartphones, tablets, and laptops, constitute a significant portion of TIM demand. As these devices become thinner while incorporating more powerful processors, the need for efficient thermal management solutions has intensified. The automotive industry represents another rapidly expanding market for advanced TIMs, particularly with the rise of electric vehicles (EVs) and hybrid electric vehicles (HEVs), where battery thermal management is critical for performance, safety, and longevity.

Data centers and telecommunications infrastructure have emerged as major consumers of high-performance TIMs. The exponential growth in cloud computing and data processing capabilities has led to increased heat generation in server farms, necessitating more effective thermal management solutions. Industry analysts project that this segment will continue to expand at above-average rates as global data consumption increases.

The renewable energy sector, particularly solar power and wind energy systems, has also contributed to the growing demand for specialized TIMs. These applications often involve exposure to harsh environmental conditions, requiring TIMs with enhanced reliability and longevity characteristics.

Market research indicates a shift in customer preferences toward TIMs with improved reliability, longer service life, and reduced thermal resistance. End-users are increasingly willing to invest in premium TIM solutions that offer demonstrable improvements in device performance and longevity. This trend has created opportunities for manufacturers to develop and market advanced TIM formulations with enhanced thermal conductivity and reliability.

Geographically, Asia-Pacific dominates the global TIM market, accounting for approximately 45% of global consumption. This regional dominance is attributed to the high concentration of electronics manufacturing facilities in countries like China, Taiwan, South Korea, and Japan. North America and Europe follow as significant markets, with growing demand from automotive, aerospace, and medical device sectors.

Current Challenges in TIM Failure Analysis Techniques

Despite significant advancements in Thermal Interface Materials (TIMs) failure analysis techniques, researchers and engineers continue to face substantial challenges that limit comprehensive understanding of failure mechanisms. Cross-sectional analysis, while valuable for revealing internal structures, presents difficulties in sample preparation as TIMs are often composite materials with vastly different mechanical properties between their constituent phases. This disparity causes uneven cutting, smearing, and material pull-out during sectioning, potentially introducing artifacts that can be misinterpreted as actual failure modes.

SEM analysis of TIMs encounters resolution limitations when examining nanoscale features critical to understanding thermal performance degradation. The non-conductive nature of many polymer-based TIMs necessitates conductive coating application, which can obscure fine surface details and alter the very interfaces being studied. Additionally, charging effects remain problematic even with coating, particularly when analyzing degraded materials with varying conductivity across the sample.

Elemental testing protocols face significant challenges in detecting and quantifying low atomic number elements that are common in TIM formulations. Light elements such as carbon, oxygen, and silicon—fundamental to many TIM compositions—are difficult to accurately measure using standard EDS (Energy Dispersive X-ray Spectroscopy) techniques due to their low X-ray yield and energy. This creates blind spots in compositional analysis precisely where critical information about degradation mechanisms may exist.

Environmental control during analysis represents another major hurdle. TIMs often undergo testing in conditions that poorly simulate actual operational environments, particularly regarding temperature cycling, humidity exposure, and mechanical stress. The disconnect between laboratory testing conditions and real-world application environments leads to incomplete understanding of failure progression and mechanisms.

Sample preservation throughout the analytical workflow presents ongoing difficulties. Many TIMs are thermally sensitive, and the heat generated during sample preparation or electron beam exposure can alter their microstructure or chemical composition. This creates uncertainty about whether observed features represent actual failure modes or preparation-induced artifacts.

Standardization across the industry remains inadequate, with various manufacturers and research institutions employing different testing protocols, making direct comparisons between studies challenging. The lack of universally accepted methodologies for sample preparation, imaging parameters, and elemental analysis thresholds hampers collective progress in understanding TIM failure mechanisms.

Correlative analysis between different techniques presents technical and interpretive challenges. Integrating data from cross-sectional imaging, surface topography, and elemental mapping requires sophisticated registration techniques and interpretive frameworks that are not yet fully developed for TIM analysis.

SEM analysis of TIMs encounters resolution limitations when examining nanoscale features critical to understanding thermal performance degradation. The non-conductive nature of many polymer-based TIMs necessitates conductive coating application, which can obscure fine surface details and alter the very interfaces being studied. Additionally, charging effects remain problematic even with coating, particularly when analyzing degraded materials with varying conductivity across the sample.

Elemental testing protocols face significant challenges in detecting and quantifying low atomic number elements that are common in TIM formulations. Light elements such as carbon, oxygen, and silicon—fundamental to many TIM compositions—are difficult to accurately measure using standard EDS (Energy Dispersive X-ray Spectroscopy) techniques due to their low X-ray yield and energy. This creates blind spots in compositional analysis precisely where critical information about degradation mechanisms may exist.

Environmental control during analysis represents another major hurdle. TIMs often undergo testing in conditions that poorly simulate actual operational environments, particularly regarding temperature cycling, humidity exposure, and mechanical stress. The disconnect between laboratory testing conditions and real-world application environments leads to incomplete understanding of failure progression and mechanisms.

Sample preservation throughout the analytical workflow presents ongoing difficulties. Many TIMs are thermally sensitive, and the heat generated during sample preparation or electron beam exposure can alter their microstructure or chemical composition. This creates uncertainty about whether observed features represent actual failure modes or preparation-induced artifacts.

Standardization across the industry remains inadequate, with various manufacturers and research institutions employing different testing protocols, making direct comparisons between studies challenging. The lack of universally accepted methodologies for sample preparation, imaging parameters, and elemental analysis thresholds hampers collective progress in understanding TIM failure mechanisms.

Correlative analysis between different techniques presents technical and interpretive challenges. Integrating data from cross-sectional imaging, surface topography, and elemental mapping requires sophisticated registration techniques and interpretive frameworks that are not yet fully developed for TIM analysis.

Standard Protocols for Cross-Section, SEM and Elemental Testing

01 Thermal degradation and material failure mechanisms

Thermal interface materials can degrade over time due to exposure to high temperatures, thermal cycling, and mechanical stress. This degradation can lead to decreased thermal conductivity, delamination, and eventual failure. Analysis of these failure mechanisms involves examining changes in material properties, such as thermal resistance increase, physical cracking, or chemical decomposition of the TIM components. Understanding these mechanisms is crucial for improving TIM reliability in electronic devices.- Thermal degradation and material failure mechanisms: Thermal interface materials can degrade over time due to exposure to high temperatures, thermal cycling, and mechanical stress. This degradation can lead to decreased thermal conductivity, increased thermal resistance, and eventual failure. Analysis of these failure mechanisms involves examining changes in material properties, such as thermal conductivity, adhesion strength, and physical integrity. Understanding these mechanisms is crucial for improving TIM reliability and performance in electronic devices.

- Delamination and interface separation analysis: One common failure mode in thermal interface materials is delamination or separation at the interface between the TIM and adjacent surfaces. This can occur due to coefficient of thermal expansion mismatches, inadequate surface preparation, or mechanical stresses. Failure analysis techniques for delamination include acoustic microscopy, cross-sectional analysis, and adhesion testing. These methods help identify the root causes of interface separation and inform improvements in TIM formulation and application processes.

- Void formation and material distribution analysis: Voids or non-uniform distribution of thermal interface materials can significantly impact thermal performance. These defects can form during application, curing, or over time during operation. Analysis techniques include X-ray imaging, acoustic microscopy, and thermal imaging to detect and characterize voids. Understanding the causes of void formation helps improve application methods, material formulations, and processing conditions to ensure optimal thermal contact and heat transfer efficiency.

- Chemical composition changes and contamination analysis: Chemical changes in thermal interface materials, including oxidation, cross-linking, and polymer degradation, can lead to performance deterioration. Additionally, contamination from external sources or migration of components within the TIM can affect thermal conductivity and reliability. Analytical techniques such as FTIR spectroscopy, thermogravimetric analysis, and elemental mapping are used to identify chemical changes and contaminants. This analysis helps in developing more stable TIM formulations and appropriate handling procedures.

- Thermal performance degradation measurement and analysis: Quantifying the degradation in thermal performance of TIMs over time is essential for reliability assessment. This involves measuring changes in thermal conductivity, thermal resistance, and heat dissipation efficiency. Testing methods include thermal transient testing, laser flash analysis, and in-situ temperature monitoring during accelerated aging tests. These measurements help establish correlations between material changes and thermal performance, enabling the development of predictive models for TIM lifetime and reliability in various operating conditions.

02 Void formation and interfacial delamination analysis

Voids and delamination at the interface between TIM and adjacent surfaces are common failure modes that significantly impact thermal performance. These defects can form during initial application, curing processes, or develop over time due to thermal cycling. Advanced imaging techniques and cross-sectional analysis are used to detect and characterize these defects. The presence of voids increases thermal resistance and creates hotspots that accelerate device failure, making void analysis critical for TIM reliability assessment.Expand Specific Solutions03 Pump-out and bleed-out failure detection

Pump-out and bleed-out are failure mechanisms where TIM components migrate or separate under thermal and mechanical stress. This material displacement reduces the effective contact area and thermal transfer efficiency. Detection methods include weight loss measurements, surface analysis for residue, and thermal performance monitoring over time. These phenomena are particularly problematic in applications with significant thermal cycling or vibration, leading to gradual performance degradation of the thermal interface.Expand Specific Solutions04 Environmental stress and reliability testing

Environmental factors such as humidity, temperature cycling, and mechanical vibration can accelerate TIM failure. Reliability testing protocols simulate these conditions to predict long-term performance and identify potential failure modes. Accelerated aging tests, thermal shock testing, and high-temperature storage tests are commonly employed to evaluate TIM durability. These tests help in understanding how environmental stressors affect the chemical stability, adhesion properties, and thermal conductivity of interface materials over time.Expand Specific Solutions05 Advanced analytical techniques for TIM failure characterization

Sophisticated analytical methods are employed to characterize TIM failures at micro and nano scales. These include scanning electron microscopy (SEM), infrared thermography, X-ray tomography, and thermal impedance spectroscopy. These techniques provide insights into failure mechanisms by visualizing material structure changes, measuring thermal property variations, and detecting chemical composition alterations. The data obtained helps in root cause analysis of failures and guides the development of more reliable thermal interface materials with enhanced performance under various operating conditions.Expand Specific Solutions

Leading Organizations in TIM Analysis and Testing

The TIM Failure Analysis market is currently in a growth phase, with increasing demand driven by semiconductor manufacturing complexity. The market size is expanding as more companies invest in advanced failure analysis techniques to improve yield and reliability. Technologically, cross-section analysis, SEM imaging, and elemental testing protocols are maturing rapidly, with key players demonstrating varying levels of expertise. Leading companies like Applied Materials, Intel, and Samsung Electronics have established comprehensive failure analysis capabilities, while specialized equipment providers such as JEOL and FEI offer advanced analytical tools. Chinese manufacturers including SMIC and Huali Microelectronics are rapidly developing their capabilities to support domestic semiconductor production. The competitive landscape shows a mix of established global players and emerging regional competitors, with technological differentiation becoming increasingly important as manufacturing nodes continue to shrink.

Hitachi High-Tech America, Inc.

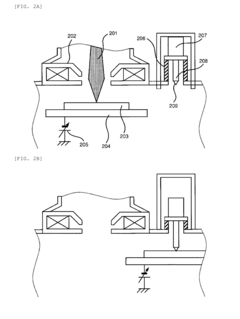

Technical Solution: Hitachi High-Tech has developed comprehensive TIM failure analysis protocols utilizing their advanced electron microscopy systems. Their approach combines high-resolution SEM imaging with specialized cross-sectioning techniques to evaluate thermal interface material degradation at the microscopic level. The company's protocol includes precision sample preparation using their FIB (Focused Ion Beam) systems to create nanometer-scale cross-sections without damaging the TIM structure. Their dual-beam FIB-SEM systems allow for site-specific cross-sectioning and immediate high-resolution imaging. For elemental analysis, Hitachi employs integrated EDS (Energy Dispersive X-ray Spectroscopy) and EELS (Electron Energy Loss Spectroscopy) to map elemental distribution across the TIM and identify contamination or diffusion issues. Their automated workflow enables statistical analysis across multiple sample points to identify failure patterns.

Strengths: Superior resolution imaging capabilities with nanometer precision; integrated multi-modal analysis combining structural and elemental data; automated workflow reduces human error. Weaknesses: High equipment costs limit accessibility; requires specialized operator training; sample preparation can be time-consuming for complex semiconductor packages.

FEI Co.

Technical Solution: FEI (now part of Thermo Fisher Scientific) has pioneered advanced TIM failure analysis protocols centered around their DualBeam FIB-SEM technology. Their methodology employs a three-stage approach for comprehensive TIM evaluation: First, non-destructive X-ray tomography to identify regions of interest; second, precision cross-sectioning using their Helios plasma FIB systems capable of removing material at rates up to 100x faster than conventional gallium FIBs while maintaining nanometer precision; and finally, high-resolution SEM imaging combined with elemental mapping. Their protocol specifically addresses TIM failure challenges by incorporating specialized sample holders that maintain the thermal interface integrity during preparation. FEI's systems include automated TIM void detection algorithms that quantify delamination, cracking, and material migration. Their ChemiSTEM technology enables atomic-resolution elemental mapping to identify diffusion and contamination issues at TIM interfaces.

Strengths: Industry-leading plasma FIB technology enables larger cross-sections while maintaining precision; integrated workflow from non-destructive to high-resolution analysis; advanced automation reduces analysis time. Weaknesses: Premium pricing positions systems beyond reach of smaller labs; complex systems require extensive training; sample preparation protocols can be material-specific requiring customization.

Critical Technical Insights from TIM Failure Case Studies

Thermal interface material, interface thermal coupling method, and production method for thermal interface material

PatentWO2018143190A1

Innovation

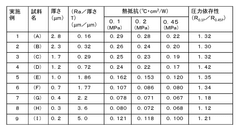

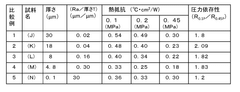

- A graphite TIM with a thickness of 200 nm to 3 μm, featuring optimal wrinkles and high thermal conductivity, is developed to minimize interfacial resistance and pressure dependence, allowing for efficient heat transfer without the need for strong mechanical tightening.

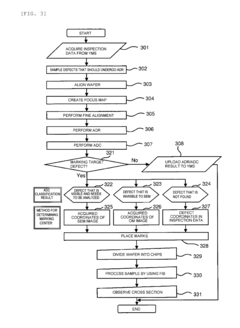

Scanning electron microscope and method for preparing specimen

PatentInactiveUS20140084159A1

Innovation

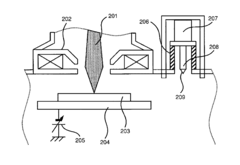

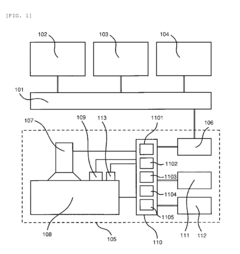

- An automatic defect classification function in a defect review apparatus classifies defects for failure analysis, using either beam-based or mechanical marking to identify and mark critical defects, allowing for efficient wafer division and analysis, even for defects not observable with SEM or optical microscopes.

Quality Control Standards for Thermal Interface Materials

Quality control standards for thermal interface materials (TIMs) are essential to ensure consistent performance and reliability in electronic devices. These standards encompass comprehensive testing protocols that evaluate thermal conductivity, thermal resistance, viscosity, bond strength, and long-term stability under various operating conditions. Industry organizations such as ASTM International, JEDEC, and IPC have established standardized test methods specifically for TIMs, providing manufacturers and end-users with reliable benchmarks for material evaluation.

The quality control process for TIMs typically begins with incoming material inspection, where raw materials are tested against supplier specifications. During production, in-process testing monitors key parameters such as viscosity, filler distribution, and cure characteristics. Finished product testing then verifies thermal performance, mechanical properties, and reliability metrics against predetermined acceptance criteria.

Statistical process control (SPC) methodologies are increasingly implemented in TIM manufacturing to monitor process variations and identify potential quality issues before they affect product performance. These approaches utilize control charts, capability indices, and other statistical tools to maintain process stability and reduce variability in critical material properties.

Environmental testing forms another crucial component of TIM quality standards, subjecting materials to temperature cycling, humidity exposure, and thermal aging to simulate real-world operating conditions. These accelerated stress tests help predict long-term reliability and identify potential failure mechanisms before field deployment.

Specialized testing protocols for different TIM types have been developed to address their unique characteristics. For gap fillers and thermal pads, compression-set testing and stress relaxation measurements are critical. For thermal greases, pump-out and dry-out testing under thermal cycling conditions helps evaluate long-term stability. Phase-change materials require precise melting point verification and flow behavior characterization.

Documentation and traceability requirements complete the quality control framework, with batch records, test reports, and material certifications providing a comprehensive audit trail. Many industries, particularly automotive and aerospace, require additional qualification testing and documentation to meet sector-specific reliability standards such as AEC-Q200 for automotive applications or NASA outgassing specifications for space applications.

The quality control process for TIMs typically begins with incoming material inspection, where raw materials are tested against supplier specifications. During production, in-process testing monitors key parameters such as viscosity, filler distribution, and cure characteristics. Finished product testing then verifies thermal performance, mechanical properties, and reliability metrics against predetermined acceptance criteria.

Statistical process control (SPC) methodologies are increasingly implemented in TIM manufacturing to monitor process variations and identify potential quality issues before they affect product performance. These approaches utilize control charts, capability indices, and other statistical tools to maintain process stability and reduce variability in critical material properties.

Environmental testing forms another crucial component of TIM quality standards, subjecting materials to temperature cycling, humidity exposure, and thermal aging to simulate real-world operating conditions. These accelerated stress tests help predict long-term reliability and identify potential failure mechanisms before field deployment.

Specialized testing protocols for different TIM types have been developed to address their unique characteristics. For gap fillers and thermal pads, compression-set testing and stress relaxation measurements are critical. For thermal greases, pump-out and dry-out testing under thermal cycling conditions helps evaluate long-term stability. Phase-change materials require precise melting point verification and flow behavior characterization.

Documentation and traceability requirements complete the quality control framework, with batch records, test reports, and material certifications providing a comprehensive audit trail. Many industries, particularly automotive and aerospace, require additional qualification testing and documentation to meet sector-specific reliability standards such as AEC-Q200 for automotive applications or NASA outgassing specifications for space applications.

Environmental Impact of TIM Testing Procedures

The environmental impact of Thermal Interface Material (TIM) testing procedures represents a growing concern in the electronics manufacturing industry. Traditional TIM failure analysis methods, including cross-sectioning, Scanning Electron Microscopy (SEM), and elemental testing, utilize various chemicals and energy-intensive processes that can have significant environmental consequences.

Cross-sectioning procedures typically employ epoxy resins and hardeners containing volatile organic compounds (VOCs) that contribute to air pollution and pose potential health risks to laboratory personnel. Additionally, the grinding and polishing processes generate particulate waste containing heavy metals and other contaminants that require specialized disposal protocols to prevent environmental contamination.

SEM analysis, while crucial for high-resolution imaging of TIM failures, demands substantial energy consumption. Modern SEM equipment operates at high voltages and requires continuous cooling systems, resulting in considerable electricity usage. The vacuum systems essential for SEM operation also contribute to the overall energy footprint of these testing procedures.

Elemental testing protocols, particularly Energy-Dispersive X-ray Spectroscopy (EDS) and X-ray Fluorescence (XRF), involve radiation sources that necessitate strict safety measures and proper disposal of radioactive components at end-of-life. These testing methods also generate electronic waste from sophisticated detection equipment that contains rare earth elements and precious metals.

Chemical etching processes used in sample preparation release acidic solutions and heavy metal compounds that require neutralization and treatment before disposal. Improper handling of these waste streams can lead to soil and water contamination, affecting local ecosystems and potentially entering the food chain.

Recent industry initiatives have focused on developing more environmentally sustainable TIM testing methodologies. These include non-destructive testing approaches that minimize waste generation, water-based alternatives to solvent-intensive processes, and energy-efficient equipment designs that reduce power consumption during analysis.

Life cycle assessment studies of TIM testing procedures indicate that the environmental impact extends beyond the immediate laboratory environment to include resource extraction for equipment manufacturing and end-of-life disposal considerations. The carbon footprint of comprehensive TIM failure analysis can be substantial when accounting for all these factors.

Regulatory frameworks governing laboratory waste management continue to evolve, with increasingly stringent requirements for the handling and disposal of hazardous materials used in TIM testing. Compliance with these regulations represents both a challenge and an opportunity for developing more sustainable testing protocols that minimize environmental harm while maintaining analytical precision and reliability.

Cross-sectioning procedures typically employ epoxy resins and hardeners containing volatile organic compounds (VOCs) that contribute to air pollution and pose potential health risks to laboratory personnel. Additionally, the grinding and polishing processes generate particulate waste containing heavy metals and other contaminants that require specialized disposal protocols to prevent environmental contamination.

SEM analysis, while crucial for high-resolution imaging of TIM failures, demands substantial energy consumption. Modern SEM equipment operates at high voltages and requires continuous cooling systems, resulting in considerable electricity usage. The vacuum systems essential for SEM operation also contribute to the overall energy footprint of these testing procedures.

Elemental testing protocols, particularly Energy-Dispersive X-ray Spectroscopy (EDS) and X-ray Fluorescence (XRF), involve radiation sources that necessitate strict safety measures and proper disposal of radioactive components at end-of-life. These testing methods also generate electronic waste from sophisticated detection equipment that contains rare earth elements and precious metals.

Chemical etching processes used in sample preparation release acidic solutions and heavy metal compounds that require neutralization and treatment before disposal. Improper handling of these waste streams can lead to soil and water contamination, affecting local ecosystems and potentially entering the food chain.

Recent industry initiatives have focused on developing more environmentally sustainable TIM testing methodologies. These include non-destructive testing approaches that minimize waste generation, water-based alternatives to solvent-intensive processes, and energy-efficient equipment designs that reduce power consumption during analysis.

Life cycle assessment studies of TIM testing procedures indicate that the environmental impact extends beyond the immediate laboratory environment to include resource extraction for equipment manufacturing and end-of-life disposal considerations. The carbon footprint of comprehensive TIM failure analysis can be substantial when accounting for all these factors.

Regulatory frameworks governing laboratory waste management continue to evolve, with increasingly stringent requirements for the handling and disposal of hazardous materials used in TIM testing. Compliance with these regulations represents both a challenge and an opportunity for developing more sustainable testing protocols that minimize environmental harm while maintaining analytical precision and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!