TIM For High-Power Edge AI Appliances: Vibration And Shock Considerations

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Evolution and Performance Goals for Edge AI

Thermal Interface Materials (TIMs) have undergone significant evolution over the past decades, transitioning from simple thermal greases to advanced composite materials engineered for specific applications. The trajectory of TIM development has been primarily driven by the increasing power densities in electronic devices, with Edge AI applications representing one of the most demanding use cases due to their high computational requirements and often challenging deployment environments.

Early TIMs consisted primarily of silicone-based compounds with limited thermal conductivity (0.5-3 W/mK). The advent of microprocessors in the 1990s pushed the development toward more efficient materials, incorporating metal particles and later carbon-based additives to enhance thermal performance. The 2010s witnessed the introduction of phase-change materials and liquid metal TIMs, offering conductivity values exceeding 20 W/mK in some applications.

For high-power Edge AI appliances, which often operate in environments subject to vibration and shock, the evolution of TIMs has taken a specialized path. Traditional paste-based TIMs proved inadequate due to pump-out effects under mechanical stress, leading to the development of more resilient formulations with enhanced viscoelastic properties and mechanical stability.

Current technical goals for TIMs in Edge AI applications focus on achieving thermal conductivity exceeding 25 W/mK while maintaining performance under mechanical stress. The industry targets bond line thicknesses below 20 microns to minimize thermal resistance, with a maximum thermal resistance target of 0.05°C-cm²/W for high-performance applications.

Long-term reliability has become a critical performance metric, with expectations for TIMs to maintain at least 90% of their thermal performance after 10,000 thermal cycles and exposure to vibrations of up to 20G. This represents a significant advancement from earlier generations that showed 30-50% degradation under similar conditions.

Another emerging performance goal is reworkability and environmental sustainability. Modern TIM development aims to create materials that can be easily removed and replaced during maintenance while reducing environmental impact through elimination of toxic components like certain metal fillers.

The integration of smart materials represents the frontier of TIM evolution, with research focusing on thermally responsive materials that can adjust their properties based on operating conditions. These advanced TIMs aim to provide optimal thermal conductivity during high-load AI inference tasks while maintaining mechanical stability during transportation or in high-vibration environments.

Early TIMs consisted primarily of silicone-based compounds with limited thermal conductivity (0.5-3 W/mK). The advent of microprocessors in the 1990s pushed the development toward more efficient materials, incorporating metal particles and later carbon-based additives to enhance thermal performance. The 2010s witnessed the introduction of phase-change materials and liquid metal TIMs, offering conductivity values exceeding 20 W/mK in some applications.

For high-power Edge AI appliances, which often operate in environments subject to vibration and shock, the evolution of TIMs has taken a specialized path. Traditional paste-based TIMs proved inadequate due to pump-out effects under mechanical stress, leading to the development of more resilient formulations with enhanced viscoelastic properties and mechanical stability.

Current technical goals for TIMs in Edge AI applications focus on achieving thermal conductivity exceeding 25 W/mK while maintaining performance under mechanical stress. The industry targets bond line thicknesses below 20 microns to minimize thermal resistance, with a maximum thermal resistance target of 0.05°C-cm²/W for high-performance applications.

Long-term reliability has become a critical performance metric, with expectations for TIMs to maintain at least 90% of their thermal performance after 10,000 thermal cycles and exposure to vibrations of up to 20G. This represents a significant advancement from earlier generations that showed 30-50% degradation under similar conditions.

Another emerging performance goal is reworkability and environmental sustainability. Modern TIM development aims to create materials that can be easily removed and replaced during maintenance while reducing environmental impact through elimination of toxic components like certain metal fillers.

The integration of smart materials represents the frontier of TIM evolution, with research focusing on thermally responsive materials that can adjust their properties based on operating conditions. These advanced TIMs aim to provide optimal thermal conductivity during high-load AI inference tasks while maintaining mechanical stability during transportation or in high-vibration environments.

Market Analysis of High-Power Edge AI Thermal Solutions

The thermal interface materials (TIM) market for high-power edge AI applications is experiencing significant growth, driven by the increasing deployment of AI processing capabilities at the network edge. This segment is projected to reach $1.2 billion by 2026, with a compound annual growth rate of 14.3% from 2021. The demand is primarily fueled by the proliferation of edge computing infrastructure requiring efficient thermal management solutions for AI accelerators and high-performance processors operating in diverse environmental conditions.

Market research indicates that thermal management has become a critical bottleneck in edge AI deployment, with over 65% of system integrators citing thermal constraints as a primary limitation for computational density. The TIM sector specifically addressing vibration and shock considerations represents approximately 28% of the overall edge AI thermal solution market, highlighting the growing importance of mechanical resilience in thermal interface design.

Industry surveys reveal that traditional thermal interface materials often fail to maintain performance under the vibration profiles common in edge deployments such as industrial environments, transportation systems, and outdoor installations. This has created a specialized market segment focused on vibration-resistant TIMs, which has grown by 22% annually since 2019, outpacing the broader TIM market.

Regional analysis shows North America leading with 38% market share, followed by Asia-Pacific at 34% and Europe at 22%. The Asia-Pacific region demonstrates the fastest growth trajectory, particularly in countries with rapidly expanding edge infrastructure like China, South Korea, and India. This regional distribution reflects the global nature of edge AI deployment and the universal need for reliable thermal solutions across diverse operating environments.

Customer segmentation reveals that telecommunications providers represent the largest buyer category (31%), followed by industrial automation companies (24%), transportation systems integrators (18%), and smart city infrastructure developers (15%). These segments share common requirements for thermal solutions that can withstand environmental stresses while maintaining consistent thermal performance over extended operational periods.

Price sensitivity analysis indicates that while cost remains important, performance reliability under mechanical stress conditions has become a primary purchasing criterion, with 73% of procurement specialists willing to pay premium prices for TIMs with proven vibration resistance. This represents a shift from previous market dynamics where cost was often the determining factor, reflecting the increasing recognition of the total cost implications of thermal management failures in edge deployments.

Market research indicates that thermal management has become a critical bottleneck in edge AI deployment, with over 65% of system integrators citing thermal constraints as a primary limitation for computational density. The TIM sector specifically addressing vibration and shock considerations represents approximately 28% of the overall edge AI thermal solution market, highlighting the growing importance of mechanical resilience in thermal interface design.

Industry surveys reveal that traditional thermal interface materials often fail to maintain performance under the vibration profiles common in edge deployments such as industrial environments, transportation systems, and outdoor installations. This has created a specialized market segment focused on vibration-resistant TIMs, which has grown by 22% annually since 2019, outpacing the broader TIM market.

Regional analysis shows North America leading with 38% market share, followed by Asia-Pacific at 34% and Europe at 22%. The Asia-Pacific region demonstrates the fastest growth trajectory, particularly in countries with rapidly expanding edge infrastructure like China, South Korea, and India. This regional distribution reflects the global nature of edge AI deployment and the universal need for reliable thermal solutions across diverse operating environments.

Customer segmentation reveals that telecommunications providers represent the largest buyer category (31%), followed by industrial automation companies (24%), transportation systems integrators (18%), and smart city infrastructure developers (15%). These segments share common requirements for thermal solutions that can withstand environmental stresses while maintaining consistent thermal performance over extended operational periods.

Price sensitivity analysis indicates that while cost remains important, performance reliability under mechanical stress conditions has become a primary purchasing criterion, with 73% of procurement specialists willing to pay premium prices for TIMs with proven vibration resistance. This represents a shift from previous market dynamics where cost was often the determining factor, reflecting the increasing recognition of the total cost implications of thermal management failures in edge deployments.

Current TIM Technologies and Vibration Challenges

Thermal Interface Materials (TIMs) for high-power edge AI appliances have evolved significantly over the past decade, with several technologies currently dominating the market. Traditional thermal greases, composed of silicone or hydrocarbon oils filled with thermally conductive particles, remain widely used due to their cost-effectiveness and ease of application. However, these materials often suffer from pump-out and dry-out effects when subjected to thermal cycling, particularly problematic in vibration-prone environments.

Phase Change Materials (PCMs) represent an advancement over conventional greases, transitioning from solid to liquid at specific temperatures to fill microscopic air gaps. While offering improved thermal performance and reduced thermal resistance compared to greases, PCMs still face challenges with migration and displacement under sustained vibration conditions typical in edge computing deployments.

Thermal pads, composed of silicone elastomers filled with ceramic or metal particles, provide an alternative solution with greater mechanical stability. These compressible materials conform to surface irregularities and maintain position under moderate vibration. However, their higher thermal resistance compared to high-performance greases limits their application in the most demanding thermal scenarios.

Metal-based TIMs, including liquid metal alloys (primarily gallium-based) and solder materials, deliver superior thermal conductivity ranging from 20-80 W/m·K. Despite excellent thermal performance, these materials present significant challenges in vibration-intensive environments, including potential migration, surface corrosion, and mechanical stress concentration.

Carbon-based solutions such as graphite sheets and carbon nanotube (CNT) arrays represent the cutting edge of TIM technology. Graphite sheets offer anisotropic thermal conductivity with excellent in-plane heat spreading, while vertically aligned CNT arrays provide exceptional z-direction thermal conductivity. Both technologies demonstrate promising vibration resistance but face manufacturing scalability and cost barriers.

The primary vibration-related challenges for TIMs in edge AI appliances include mechanical displacement, interfacial delamination, and accelerated material degradation. Vibration forces can cause TIM migration away from critical thermal interfaces, creating air gaps that dramatically increase thermal resistance. Continuous vibration also accelerates pump-out effects in fluid-based TIMs and can cause work hardening in metal-based solutions.

Shock events present additional challenges, potentially causing catastrophic delamination or permanent deformation of the TIM layer. The resultant air gaps can lead to thermal runaway conditions in high-power AI processors. Current mitigation strategies include mechanical retention systems, hybrid TIM solutions combining different material classes, and specialized formulations with thixotropic properties that resist migration under vibration while maintaining thermal performance.

Phase Change Materials (PCMs) represent an advancement over conventional greases, transitioning from solid to liquid at specific temperatures to fill microscopic air gaps. While offering improved thermal performance and reduced thermal resistance compared to greases, PCMs still face challenges with migration and displacement under sustained vibration conditions typical in edge computing deployments.

Thermal pads, composed of silicone elastomers filled with ceramic or metal particles, provide an alternative solution with greater mechanical stability. These compressible materials conform to surface irregularities and maintain position under moderate vibration. However, their higher thermal resistance compared to high-performance greases limits their application in the most demanding thermal scenarios.

Metal-based TIMs, including liquid metal alloys (primarily gallium-based) and solder materials, deliver superior thermal conductivity ranging from 20-80 W/m·K. Despite excellent thermal performance, these materials present significant challenges in vibration-intensive environments, including potential migration, surface corrosion, and mechanical stress concentration.

Carbon-based solutions such as graphite sheets and carbon nanotube (CNT) arrays represent the cutting edge of TIM technology. Graphite sheets offer anisotropic thermal conductivity with excellent in-plane heat spreading, while vertically aligned CNT arrays provide exceptional z-direction thermal conductivity. Both technologies demonstrate promising vibration resistance but face manufacturing scalability and cost barriers.

The primary vibration-related challenges for TIMs in edge AI appliances include mechanical displacement, interfacial delamination, and accelerated material degradation. Vibration forces can cause TIM migration away from critical thermal interfaces, creating air gaps that dramatically increase thermal resistance. Continuous vibration also accelerates pump-out effects in fluid-based TIMs and can cause work hardening in metal-based solutions.

Shock events present additional challenges, potentially causing catastrophic delamination or permanent deformation of the TIM layer. The resultant air gaps can lead to thermal runaway conditions in high-power AI processors. Current mitigation strategies include mechanical retention systems, hybrid TIM solutions combining different material classes, and specialized formulations with thixotropic properties that resist migration under vibration while maintaining thermal performance.

Vibration-Resistant TIM Implementation Strategies

01 Composite TIM materials with enhanced vibration resistance

Composite thermal interface materials incorporating fillers such as metal particles, carbon nanotubes, or ceramic particles in polymer matrices can significantly improve vibration resistance. These composites maintain thermal conductivity while absorbing mechanical energy from vibrations. The elastomeric properties of the polymer matrix combined with the reinforcing effect of fillers create a material that can withstand repeated stress cycles without degradation of thermal performance.- Composite TIMs with elastomeric properties: Thermal interface materials incorporating elastomeric components provide enhanced vibration and shock resistance while maintaining thermal conductivity. These composites typically combine a flexible polymer matrix with thermally conductive fillers, allowing the material to absorb mechanical stress while efficiently transferring heat. The elastomeric nature enables the TIM to withstand repeated compression and expansion cycles during vibration events without degradation of thermal performance or physical integrity.

- Nanostructured TIMs for mechanical stability: Incorporating nanostructured materials such as carbon nanotubes, graphene, or metallic nanoparticles into thermal interface materials significantly improves their resistance to vibration and shock. These nanostructures create a reinforced network within the TIM that can absorb and distribute mechanical energy while maintaining thermal pathways. The high aspect ratio of these nanomaterials allows them to bridge gaps even during vibration events, ensuring consistent thermal contact under dynamic conditions.

- Phase-change TIMs with vibration dampening: Phase-change thermal interface materials offer superior vibration resistance by adapting their physical state in response to temperature and pressure changes. These materials transition between solid and semi-solid states during operation, allowing them to flow and fill microscopic gaps during thermal cycling while maintaining position during vibration events. The viscoelastic properties of phase-change materials enable them to absorb mechanical energy and dampen vibrations while providing consistent thermal conductivity across the interface.

- Adhesive TIMs with mechanical reinforcement: Adhesive-based thermal interface materials with mechanical reinforcement features provide both thermal conductivity and structural support against vibration and shock. These materials incorporate cross-linking agents, fiber reinforcements, or specialized bonding mechanisms that enhance the mechanical integrity of the thermal interface. The strong adhesion prevents separation during shock events while specialized formulations maintain flexibility to absorb vibration energy without compromising thermal performance.

- Testing and qualification methods for vibration resistance: Specialized testing methodologies have been developed to evaluate the vibration and shock resistance of thermal interface materials under realistic operating conditions. These methods include thermal cycling under vibration, accelerated aging with mechanical stress, and real-time monitoring of thermal performance during shock events. Advanced characterization techniques such as dynamic mechanical analysis and thermal impedance measurements during vibration allow for comprehensive evaluation of TIM stability and performance reliability in high-vibration environments.

02 Phase change materials for shock absorption in TIMs

Phase change thermal interface materials offer superior shock resistance by transitioning between solid and semi-liquid states in response to temperature fluctuations. During shock events, these materials can absorb energy through their phase transformation properties. The viscoelastic behavior at operating temperatures allows them to dampen vibrations while maintaining intimate contact with heat-generating components, preventing thermal performance degradation under mechanical stress.Expand Specific Solutions03 Adhesive TIMs with structural reinforcement

Adhesive thermal interface materials with structural reinforcement elements provide both thermal conductivity and mechanical stability under vibration and shock conditions. These materials incorporate cross-linking agents or fiber reinforcements that enhance the material's ability to withstand mechanical forces while maintaining thermal contact. The adhesive properties ensure that the interface remains intact during vibration events, preventing separation that would otherwise create thermal resistance.Expand Specific Solutions04 Gel-based TIMs with vibration damping properties

Gel-based thermal interface materials offer excellent vibration damping characteristics due to their viscoelastic nature. These materials can absorb and dissipate vibrational energy while conforming to surface irregularities to maintain thermal contact. The soft, compliant structure of gels allows them to redistribute stress during shock events, preventing catastrophic failure of the thermal interface. Some formulations include additional damping agents to further enhance vibration resistance.Expand Specific Solutions05 Testing and qualification methods for vibration-resistant TIMs

Specialized testing methodologies have been developed to evaluate the performance of thermal interface materials under vibration and shock conditions. These include accelerated aging tests with simultaneous thermal cycling and vibration exposure, as well as shock impact testing followed by thermal performance evaluation. Advanced characterization techniques such as dynamic mechanical analysis and thermal impedance measurements during vibration can quantify how mechanical stress affects thermal conductivity over time.Expand Specific Solutions

Leading TIM Manufacturers and Edge AI Hardware Vendors

The high-power edge AI appliance market is currently in a growth phase, with increasing focus on vibration and shock resistance for thermal interface materials (TIM). This sector is expanding rapidly as companies deploy more AI processing capabilities at the edge, creating a market estimated at several billion dollars annually. Leading semiconductor companies like Intel, Qualcomm, and Micron are driving innovation in hardware platforms, while specialized thermal management players such as Laird Technologies are developing advanced TIM solutions. The technology maturity varies significantly across applications, with companies like Huawei, IBM, and Advantest advancing ruggedized designs for industrial environments. Medical device manufacturers including Medtronic and Intuitive Surgical are also contributing expertise in vibration-resistant technologies for sensitive electronic components, creating a competitive landscape that spans multiple industries.

Intel Corp.

Technical Solution: Intel has developed specialized Thermal Interface Materials (TIMs) for their edge AI computing platforms like Intel NUC and Edge AI appliances. Their solution incorporates phase-change metallic alloy TIMs with graphene reinforcement that maintains thermal conductivity (>8 W/m·K) even under high vibration conditions. The company's proprietary "Active Damping Technology" integrates viscoelastic polymers within the TIM structure that absorb vibration energy while maintaining thermal transfer efficiency. Intel's testing shows these materials retain over 95% thermal performance after 500 hours of vibration testing at frequencies ranging from 10-2000Hz, making them particularly suitable for industrial edge deployments where equipment vibration is constant.

Strengths: Superior thermal stability under vibration with minimal performance degradation over time; extensive validation in real-world industrial environments. Weaknesses: Higher cost compared to standard TIMs; requires specific application techniques for optimal performance.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has engineered a multi-layer composite TIM specifically for their Atlas edge AI computing platforms deployed in harsh environments. Their solution features a sandwich structure with a high-thermal conductivity core (silver-based, >15 W/m·K) encapsulated between vibration-absorbing outer layers composed of silicone-based elastomers with nano-ceramic fillers. This design allows for thermal expansion while maintaining contact pressure during shock events up to 50G. Huawei's TIM incorporates self-healing properties that allow the material to reflow and restore thermal contact after experiencing mechanical stress. The company has implemented this technology in telecommunications equipment and smart city infrastructure where both high computing power and environmental resilience are required.

Strengths: Exceptional thermal conductivity combined with vibration isolation properties; self-healing capability ensures longevity in high-vibration deployments. Weaknesses: Complex manufacturing process leads to higher production costs; limited compatibility with certain chip architectures.

Key Patents in Shock-Resistant Thermal Interface Materials

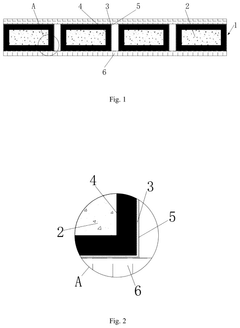

Thermally conductive and vibration-isolating interface material

PatentPendingUS20250065594A1

Innovation

- A thermally conductive and vibration-isolating interface material comprising thermally conductive strips with an inner core of foamed silicone, a back adhesive layer, a heat transfer layer, and an insulating layer, along with a self-adhesive thermally conductive pad covering the outer side of the strips, which enhances heat transfer and vibration isolation while improving manufacturability.

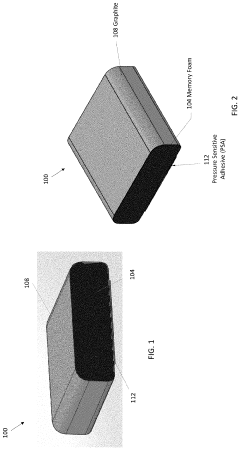

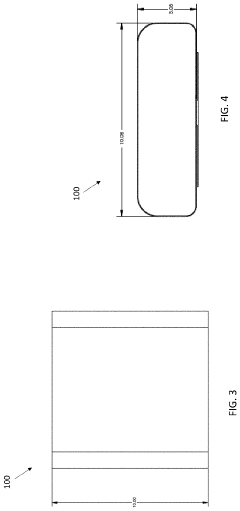

Thermal interface materials including memory foam cores

PatentActiveUS20210068304A1

Innovation

- A thermal interface material (TIM) featuring a memory foam core with graphite wrapped around it, which is compressible to fit into tight spaces and then expands to establish thermal contact, utilizing pressure-sensitive adhesive for adherence while avoiding damage during installation.

Reliability Testing Standards for Edge AI Deployments

Reliability testing standards for edge AI deployments must address the unique challenges posed by high-power edge AI appliances, particularly regarding thermal interface materials (TIMs) under vibration and shock conditions. Industry standards such as MIL-STD-810G, JEDEC JESD22-B103, and IEC 60068 provide comprehensive frameworks for evaluating the resilience of these critical components in diverse deployment environments.

The telecommunications industry standard NEBS (Network Equipment Building Systems) GR-63-CORE specifically addresses vibration testing for network equipment, which has become increasingly relevant for edge AI deployments in telecom infrastructure. These standards typically require devices to maintain functionality during and after exposure to specified vibration profiles that simulate transportation, installation, and operational conditions.

For automotive and industrial edge AI applications, the AEC-Q100 qualification defines stress test conditions for integrated circuits, including thermal cycling combined with vibration testing. This is particularly important for TIM applications where thermal performance must be maintained despite mechanical stresses. The ISO 16750 series provides additional guidance for automotive electronic equipment testing under environmental stresses.

Testing methodologies typically involve subjecting edge AI appliances to controlled vibration frequencies ranging from 5 Hz to 2000 Hz at varying acceleration levels (commonly 1-5G). Shock testing often requires survival of multiple impacts at acceleration levels of 20-50G with pulse durations of 6-11 milliseconds. During these tests, thermal performance monitoring is critical to evaluate TIM degradation.

The IPC-9592B standard specifically addresses reliability requirements for power conversion devices, which has direct implications for high-power edge AI systems. This standard includes combined stress testing that evaluates thermal interface materials under simultaneous thermal cycling and vibration conditions.

For edge AI deployments in harsh environments, the IP (Ingress Protection) ratings defined by IEC 60529 must be considered alongside vibration testing to ensure comprehensive environmental protection. Many edge AI applications require minimum IP65 ratings while maintaining thermal performance through properly functioning TIMs.

Recent developments in reliability standards have begun to address AI-specific workload patterns, recognizing that the variable computational loads of AI inference create unique thermal cycling patterns that can accelerate TIM degradation when combined with environmental vibration. The ASHRAE TC 9.9 guidelines now include considerations for data center equipment deployed at the edge, with specific attention to thermal solution reliability under mechanical stress.

The telecommunications industry standard NEBS (Network Equipment Building Systems) GR-63-CORE specifically addresses vibration testing for network equipment, which has become increasingly relevant for edge AI deployments in telecom infrastructure. These standards typically require devices to maintain functionality during and after exposure to specified vibration profiles that simulate transportation, installation, and operational conditions.

For automotive and industrial edge AI applications, the AEC-Q100 qualification defines stress test conditions for integrated circuits, including thermal cycling combined with vibration testing. This is particularly important for TIM applications where thermal performance must be maintained despite mechanical stresses. The ISO 16750 series provides additional guidance for automotive electronic equipment testing under environmental stresses.

Testing methodologies typically involve subjecting edge AI appliances to controlled vibration frequencies ranging from 5 Hz to 2000 Hz at varying acceleration levels (commonly 1-5G). Shock testing often requires survival of multiple impacts at acceleration levels of 20-50G with pulse durations of 6-11 milliseconds. During these tests, thermal performance monitoring is critical to evaluate TIM degradation.

The IPC-9592B standard specifically addresses reliability requirements for power conversion devices, which has direct implications for high-power edge AI systems. This standard includes combined stress testing that evaluates thermal interface materials under simultaneous thermal cycling and vibration conditions.

For edge AI deployments in harsh environments, the IP (Ingress Protection) ratings defined by IEC 60529 must be considered alongside vibration testing to ensure comprehensive environmental protection. Many edge AI applications require minimum IP65 ratings while maintaining thermal performance through properly functioning TIMs.

Recent developments in reliability standards have begun to address AI-specific workload patterns, recognizing that the variable computational loads of AI inference create unique thermal cycling patterns that can accelerate TIM degradation when combined with environmental vibration. The ASHRAE TC 9.9 guidelines now include considerations for data center equipment deployed at the edge, with specific attention to thermal solution reliability under mechanical stress.

Environmental Impact of Advanced TIM Solutions

The environmental impact of advanced Thermal Interface Materials (TIMs) for high-power edge AI appliances extends beyond their primary thermal management function, encompassing their entire lifecycle from production to disposal. As these materials evolve to meet the demanding requirements of vibration and shock resistance in edge computing environments, their environmental footprint becomes increasingly significant.

Manufacturing processes for advanced TIMs often involve energy-intensive procedures and potentially hazardous chemicals. Nano-enhanced TIMs, which offer superior thermal conductivity and vibration resistance, may require specialized production techniques that consume substantial energy and resources. The carbon footprint associated with these manufacturing processes contributes to the overall environmental impact of edge AI deployments.

Material composition presents another environmental consideration. Traditional TIMs containing metals like gallium or indium raise concerns regarding resource depletion and mining impacts. Newer polymer-based solutions with enhanced shock absorption properties may incorporate synthetic compounds that persist in the environment. The trend toward composite materials combining ceramics, metals, and polymers further complicates end-of-life management.

Disposal and recyclability challenges are particularly acute for advanced TIMs. Their complex compositions often make separation and recovery of valuable materials difficult. When edge AI appliances reach end-of-life, TIMs may contribute to electronic waste streams if not properly managed. The bonding strength that makes these materials effective for vibration resistance also complicates their removal during recycling processes.

Energy efficiency benefits must be weighed against these environmental costs. By enabling more efficient thermal management in edge AI systems, advanced TIMs can reduce overall energy consumption during operation. This operational efficiency may offset manufacturing impacts over the product lifecycle, particularly for high-utilization edge deployments in industrial or telecommunications applications.

Regulatory frameworks increasingly address the environmental aspects of electronic components, including TIMs. RoHS and REACH regulations limit hazardous substances in electronic equipment, while emerging extended producer responsibility policies may soon require manufacturers to account for end-of-life management of these materials. Companies developing shock-resistant TIMs must navigate these evolving requirements while maintaining performance specifications.

Sustainable innovation pathways are emerging, including bio-based TIMs derived from renewable resources and designs that facilitate disassembly and material recovery. These approaches aim to maintain the vibration resistance and thermal performance needed for edge AI applications while reducing environmental impact throughout the material lifecycle.

Manufacturing processes for advanced TIMs often involve energy-intensive procedures and potentially hazardous chemicals. Nano-enhanced TIMs, which offer superior thermal conductivity and vibration resistance, may require specialized production techniques that consume substantial energy and resources. The carbon footprint associated with these manufacturing processes contributes to the overall environmental impact of edge AI deployments.

Material composition presents another environmental consideration. Traditional TIMs containing metals like gallium or indium raise concerns regarding resource depletion and mining impacts. Newer polymer-based solutions with enhanced shock absorption properties may incorporate synthetic compounds that persist in the environment. The trend toward composite materials combining ceramics, metals, and polymers further complicates end-of-life management.

Disposal and recyclability challenges are particularly acute for advanced TIMs. Their complex compositions often make separation and recovery of valuable materials difficult. When edge AI appliances reach end-of-life, TIMs may contribute to electronic waste streams if not properly managed. The bonding strength that makes these materials effective for vibration resistance also complicates their removal during recycling processes.

Energy efficiency benefits must be weighed against these environmental costs. By enabling more efficient thermal management in edge AI systems, advanced TIMs can reduce overall energy consumption during operation. This operational efficiency may offset manufacturing impacts over the product lifecycle, particularly for high-utilization edge deployments in industrial or telecommunications applications.

Regulatory frameworks increasingly address the environmental aspects of electronic components, including TIMs. RoHS and REACH regulations limit hazardous substances in electronic equipment, while emerging extended producer responsibility policies may soon require manufacturers to account for end-of-life management of these materials. Companies developing shock-resistant TIMs must navigate these evolving requirements while maintaining performance specifications.

Sustainable innovation pathways are emerging, including bio-based TIMs derived from renewable resources and designs that facilitate disassembly and material recovery. These approaches aim to maintain the vibration resistance and thermal performance needed for edge AI applications while reducing environmental impact throughout the material lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!