TIM For Battery Packs: High-Voltage Isolation And Thermal Performance Tradeoffs

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Battery Pack Evolution and Objectives

Thermal Interface Materials (TIMs) for battery packs have undergone significant evolution over the past decade, driven primarily by the rapid advancement of electric vehicle technology and energy storage systems. Initially, battery thermal management relied on basic gap fillers and thermal pads with modest thermal conductivity values of 1-3 W/mK. These early solutions prioritized cost-effectiveness over thermal performance, as battery energy densities were relatively low and thermal challenges were less pronounced.

As battery energy densities increased and fast-charging capabilities became standard requirements, the thermal management demands escalated dramatically. The industry witnessed a shift toward more sophisticated TIM solutions around 2015-2018, when manufacturers began implementing phase-change materials and advanced thermal gap fillers with conductivity values reaching 5-8 W/mK. This transition marked a critical point in recognizing thermal management as a key factor in battery performance and longevity.

The current generation of battery packs, particularly those in premium electric vehicles and grid-scale energy storage systems, employ highly engineered TIM solutions that must balance multiple competing requirements. Modern TIMs now achieve thermal conductivity values of 10-15 W/mK while maintaining essential electrical isolation properties. This dual functionality has become increasingly challenging as battery pack voltages have risen from 400V to 800V and beyond in newer architectures.

The primary objective of contemporary TIM development for battery applications centers on resolving the fundamental tradeoff between thermal conductivity and electrical isolation. Higher thermal conductivity typically requires increased metal content or conductive fillers, which inherently compromises dielectric strength and electrical isolation properties. This technical contradiction represents the central challenge in the field, particularly as battery systems operate at increasingly higher voltages.

Additional objectives include developing TIMs with enhanced long-term reliability under thermal cycling conditions, as battery packs routinely experience temperature fluctuations between -40°C and 85°C throughout their operational lifetime. Material stability, compression set resistance, and consistent performance over thousands of thermal cycles have become critical parameters in TIM selection and development.

Looking forward, the industry aims to develop next-generation TIMs capable of achieving thermal conductivity values exceeding 20 W/mK while maintaining dielectric strength above 20 kV/mm. These materials must also demonstrate enhanced aging resistance, with minimal performance degradation over a 15+ year service life, aligning with the extended warranty periods now offered by premium electric vehicle manufacturers. Simultaneously, there is growing emphasis on developing environmentally sustainable TIM solutions that eliminate halogenated compounds and facilitate end-of-life recycling processes.

As battery energy densities increased and fast-charging capabilities became standard requirements, the thermal management demands escalated dramatically. The industry witnessed a shift toward more sophisticated TIM solutions around 2015-2018, when manufacturers began implementing phase-change materials and advanced thermal gap fillers with conductivity values reaching 5-8 W/mK. This transition marked a critical point in recognizing thermal management as a key factor in battery performance and longevity.

The current generation of battery packs, particularly those in premium electric vehicles and grid-scale energy storage systems, employ highly engineered TIM solutions that must balance multiple competing requirements. Modern TIMs now achieve thermal conductivity values of 10-15 W/mK while maintaining essential electrical isolation properties. This dual functionality has become increasingly challenging as battery pack voltages have risen from 400V to 800V and beyond in newer architectures.

The primary objective of contemporary TIM development for battery applications centers on resolving the fundamental tradeoff between thermal conductivity and electrical isolation. Higher thermal conductivity typically requires increased metal content or conductive fillers, which inherently compromises dielectric strength and electrical isolation properties. This technical contradiction represents the central challenge in the field, particularly as battery systems operate at increasingly higher voltages.

Additional objectives include developing TIMs with enhanced long-term reliability under thermal cycling conditions, as battery packs routinely experience temperature fluctuations between -40°C and 85°C throughout their operational lifetime. Material stability, compression set resistance, and consistent performance over thousands of thermal cycles have become critical parameters in TIM selection and development.

Looking forward, the industry aims to develop next-generation TIMs capable of achieving thermal conductivity values exceeding 20 W/mK while maintaining dielectric strength above 20 kV/mm. These materials must also demonstrate enhanced aging resistance, with minimal performance degradation over a 15+ year service life, aligning with the extended warranty periods now offered by premium electric vehicle manufacturers. Simultaneously, there is growing emphasis on developing environmentally sustainable TIM solutions that eliminate halogenated compounds and facilitate end-of-life recycling processes.

Market Demand Analysis for High-Performance Battery TIMs

The global market for thermal interface materials (TIMs) in battery applications is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production. Market research indicates that the battery TIM segment is projected to grow at a CAGR of 14.2% through 2030, significantly outpacing the broader TIM market growth rate of 8.5%. This acceleration is directly linked to the increasing energy density requirements of modern battery packs, which generate more heat and require more sophisticated thermal management solutions.

Consumer demand for faster charging capabilities has emerged as a critical market driver. Fast-charging technologies generate substantial heat that must be efficiently dissipated to prevent battery degradation and safety issues. Market surveys reveal that 78% of potential EV buyers consider charging speed a decisive factor in their purchasing decisions, creating downstream pressure for advanced TIM solutions that can maintain optimal battery temperatures during high-current charging cycles.

Safety concerns represent another significant market force. Following several high-profile thermal runaway incidents in consumer electronics and EVs, regulatory bodies worldwide have implemented stricter thermal management requirements. The automotive industry has responded by prioritizing battery thermal management systems, with major manufacturers increasing their R&D budgets for TIM solutions by an average of 22% annually since 2020.

The market shows distinct segmentation between consumer electronics and automotive applications. While consumer electronics manufacturers typically prioritize thin, lightweight TIM solutions with moderate thermal performance, automotive applications demand materials that combine excellent thermal conductivity with high-voltage isolation properties and long-term reliability under extreme conditions. This divergence has created specialized market niches for TIM manufacturers.

Geographic market analysis reveals regional differences in demand patterns. Asian markets, particularly China, Japan, and South Korea, show the highest volume demand, corresponding to their dominant positions in battery manufacturing. However, European and North American markets exhibit stronger demand for premium, high-performance TIMs that meet stringent safety and environmental standards, often commanding price premiums of 30-45% over standard solutions.

The sustainability aspect is increasingly influencing market dynamics. Approximately 65% of major automotive manufacturers have committed to environmentally friendly supply chains, creating growing demand for TIMs with reduced environmental impact, recyclability, and compliance with emerging green manufacturing standards. This trend is expected to intensify as circular economy principles become more embedded in regulatory frameworks globally.

Consumer demand for faster charging capabilities has emerged as a critical market driver. Fast-charging technologies generate substantial heat that must be efficiently dissipated to prevent battery degradation and safety issues. Market surveys reveal that 78% of potential EV buyers consider charging speed a decisive factor in their purchasing decisions, creating downstream pressure for advanced TIM solutions that can maintain optimal battery temperatures during high-current charging cycles.

Safety concerns represent another significant market force. Following several high-profile thermal runaway incidents in consumer electronics and EVs, regulatory bodies worldwide have implemented stricter thermal management requirements. The automotive industry has responded by prioritizing battery thermal management systems, with major manufacturers increasing their R&D budgets for TIM solutions by an average of 22% annually since 2020.

The market shows distinct segmentation between consumer electronics and automotive applications. While consumer electronics manufacturers typically prioritize thin, lightweight TIM solutions with moderate thermal performance, automotive applications demand materials that combine excellent thermal conductivity with high-voltage isolation properties and long-term reliability under extreme conditions. This divergence has created specialized market niches for TIM manufacturers.

Geographic market analysis reveals regional differences in demand patterns. Asian markets, particularly China, Japan, and South Korea, show the highest volume demand, corresponding to their dominant positions in battery manufacturing. However, European and North American markets exhibit stronger demand for premium, high-performance TIMs that meet stringent safety and environmental standards, often commanding price premiums of 30-45% over standard solutions.

The sustainability aspect is increasingly influencing market dynamics. Approximately 65% of major automotive manufacturers have committed to environmentally friendly supply chains, creating growing demand for TIMs with reduced environmental impact, recyclability, and compliance with emerging green manufacturing standards. This trend is expected to intensify as circular economy principles become more embedded in regulatory frameworks globally.

Technical Challenges in Battery TIM Development

The development of Thermal Interface Materials (TIMs) for battery packs presents significant technical challenges due to the conflicting requirements of thermal conductivity and electrical isolation. Modern electric vehicle battery packs operate at voltages exceeding 800V, necessitating materials that can simultaneously transfer heat efficiently while preventing electrical current flow between components.

One primary challenge is achieving the optimal balance between thermal conductivity and dielectric strength. Materials with excellent thermal properties often contain metal particles or carbon-based fillers that increase electrical conductivity—a potentially catastrophic property in high-voltage battery environments. Conversely, materials with superior electrical isolation typically contain ceramic fillers or polymeric matrices that limit thermal performance.

The operating temperature range presents another significant hurdle. Battery TIMs must maintain consistent performance across extreme temperature variations, from sub-zero winter conditions to potential thermal runaway scenarios exceeding 150°C. Material degradation at these temperature extremes can compromise both thermal management and electrical safety, creating reliability concerns over the battery pack's lifetime.

Mechanical stress resistance poses additional complications. Battery cells expand and contract during charge-discharge cycles, subjecting TIMs to continuous mechanical strain. This cyclic stress can create gaps or cracks in the interface material, reducing thermal conductivity and potentially compromising electrical isolation over time. Developing materials that maintain both properties while accommodating these dimensional changes remains technically challenging.

Manufacturing integration presents practical obstacles as well. TIMs must be compatible with automated assembly processes while ensuring complete coverage and consistent thickness across large battery modules. Gaps or inconsistencies can create hotspots that accelerate battery degradation or create potential electrical failure points.

Long-term stability under combined thermal, electrical, and chemical stresses represents perhaps the most demanding challenge. Battery packs contain electrolytes and other chemicals that may interact with TIMs over time. Materials must resist chemical degradation while maintaining their thermal and electrical properties for the vehicle's operational lifetime—typically 8-15 years under diverse environmental conditions.

Cost-effectiveness adds another dimension to these technical challenges. While specialized aerospace or military-grade materials might offer superior performance, they remain prohibitively expensive for mass-market electric vehicles. Developing materials that meet all technical requirements while remaining economically viable for production vehicles requires significant innovation in material science and manufacturing processes.

One primary challenge is achieving the optimal balance between thermal conductivity and dielectric strength. Materials with excellent thermal properties often contain metal particles or carbon-based fillers that increase electrical conductivity—a potentially catastrophic property in high-voltage battery environments. Conversely, materials with superior electrical isolation typically contain ceramic fillers or polymeric matrices that limit thermal performance.

The operating temperature range presents another significant hurdle. Battery TIMs must maintain consistent performance across extreme temperature variations, from sub-zero winter conditions to potential thermal runaway scenarios exceeding 150°C. Material degradation at these temperature extremes can compromise both thermal management and electrical safety, creating reliability concerns over the battery pack's lifetime.

Mechanical stress resistance poses additional complications. Battery cells expand and contract during charge-discharge cycles, subjecting TIMs to continuous mechanical strain. This cyclic stress can create gaps or cracks in the interface material, reducing thermal conductivity and potentially compromising electrical isolation over time. Developing materials that maintain both properties while accommodating these dimensional changes remains technically challenging.

Manufacturing integration presents practical obstacles as well. TIMs must be compatible with automated assembly processes while ensuring complete coverage and consistent thickness across large battery modules. Gaps or inconsistencies can create hotspots that accelerate battery degradation or create potential electrical failure points.

Long-term stability under combined thermal, electrical, and chemical stresses represents perhaps the most demanding challenge. Battery packs contain electrolytes and other chemicals that may interact with TIMs over time. Materials must resist chemical degradation while maintaining their thermal and electrical properties for the vehicle's operational lifetime—typically 8-15 years under diverse environmental conditions.

Cost-effectiveness adds another dimension to these technical challenges. While specialized aerospace or military-grade materials might offer superior performance, they remain prohibitively expensive for mass-market electric vehicles. Developing materials that meet all technical requirements while remaining economically viable for production vehicles requires significant innovation in material science and manufacturing processes.

Current TIM Solutions for High-Voltage Battery Systems

01 Ceramic-based TIMs for high-voltage isolation

Ceramic-based thermal interface materials provide excellent electrical isolation properties while maintaining good thermal conductivity. These materials typically incorporate aluminum oxide, aluminum nitride, or boron nitride ceramics that offer high dielectric strength necessary for high-voltage applications. The ceramic particles are often embedded in polymer matrices to create composites that can withstand high electrical potentials while efficiently transferring heat from electronic components to heat sinks.- Ceramic-based TIMs for high-voltage isolation: Ceramic-based thermal interface materials provide excellent electrical isolation properties while maintaining good thermal conductivity. These materials typically incorporate aluminum oxide, boron nitride, or aluminum nitride particles in a polymer matrix. The ceramic fillers create an electrically insulating barrier that can withstand high voltages while efficiently transferring heat from electronic components to heat sinks. These materials are particularly useful in high-power electronics where electrical isolation and thermal management are both critical requirements.

- Composite TIMs with phase change properties: Phase change thermal interface materials combine the benefits of solid fillers with phase-changing compounds that melt at operating temperatures. These materials provide excellent thermal contact by conforming to surface irregularities when heated, eliminating air gaps that impede heat transfer. The composite structure maintains electrical isolation while improving thermal performance through better surface wetting and contact. These materials typically contain high thermal conductivity fillers suspended in a phase change matrix that softens during operation, creating an optimal thermal path while maintaining dielectric strength.

- Nano-enhanced TIMs for improved thermal conductivity: Incorporating nanomaterials such as carbon nanotubes, graphene, or metallic nanoparticles into thermal interface materials significantly enhances thermal conductivity while maintaining electrical isolation properties. These nanomaterials create efficient thermal pathways through the material while the polymer matrix maintains electrical isolation. The nano-scale fillers can achieve higher thermal conductivity at lower loading levels compared to conventional fillers, resulting in materials that remain compliant and easy to apply while offering superior thermal performance in high-voltage applications.

- Silicone-based TIMs with high dielectric strength: Silicone-based thermal interface materials offer excellent electrical isolation properties combined with good thermal performance and flexibility. These materials typically incorporate thermally conductive fillers within a silicone elastomer matrix that provides high dielectric strength and voltage isolation. The inherent flexibility of silicone allows these materials to conform to irregular surfaces, reducing thermal contact resistance while maintaining electrical isolation. These materials are particularly suitable for applications requiring vibration dampening, stress relief, and long-term reliability under thermal cycling conditions.

- Testing and characterization methods for TIM performance: Various testing methodologies have been developed to accurately characterize the thermal performance and electrical isolation properties of thermal interface materials. These include thermal impedance testing, dielectric breakdown voltage measurement, thermal conductivity analysis, and accelerated aging tests. Advanced techniques such as laser flash analysis, thermal transient testing, and high-voltage isolation testing help evaluate the performance of TIMs under actual operating conditions. These testing methods ensure that materials meet both the thermal management requirements and electrical isolation specifications for high-voltage applications.

02 Phase change materials with enhanced thermal performance

Phase change thermal interface materials undergo a solid-to-liquid transition at operating temperatures, allowing them to fill microscopic surface irregularities and reduce thermal resistance. These materials combine the handling benefits of solid materials with the thermal performance advantages of liquids. Advanced formulations incorporate high thermal conductivity fillers such as metal particles or carbon-based materials to further enhance heat transfer efficiency while maintaining the necessary electrical isolation properties for high-voltage applications.Expand Specific Solutions03 Nano-enhanced TIMs for superior thermal conductivity

Thermal interface materials incorporating nanomaterials such as carbon nanotubes, graphene, or metallic nanoparticles demonstrate significantly improved thermal conductivity. These nano-enhanced TIMs create efficient thermal pathways through the interface while maintaining electrical isolation properties. The nanomaterials can be functionalized or surface-treated to improve dispersion within the base material and enhance compatibility with the polymer matrix, resulting in more uniform thermal performance and reliable high-voltage isolation.Expand Specific Solutions04 Silicone-based TIMs with high dielectric strength

Silicone-based thermal interface materials offer excellent electrical isolation properties combined with good thermal performance and flexibility. These materials typically contain silicone polymers filled with thermally conductive but electrically insulating particles. The formulations are engineered to maintain high dielectric strength even at elevated temperatures, making them suitable for high-voltage applications. Their conformability allows them to establish intimate contact with mating surfaces, reducing thermal resistance while maintaining the required electrical isolation.Expand Specific Solutions05 Hybrid TIMs with layered structures for optimized performance

Hybrid thermal interface materials utilize layered or composite structures that combine different materials to optimize both thermal performance and electrical isolation. These TIMs may feature a thermally conductive core layer sandwiched between electrically insulating outer layers, or gradient structures with varying compositions throughout the material. This approach allows for customization of thermal and electrical properties to meet specific application requirements, providing enhanced performance in high-voltage environments while efficiently managing heat dissipation.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal interface materials (TIM) market for battery packs is currently in a growth phase, driven by the expanding electric vehicle sector. The market faces critical challenges in balancing high-voltage isolation requirements with thermal performance needs. Major players like Samsung SDI, LG Energy Solution, and CATL are advancing proprietary TIM solutions that address these trade-offs, while companies such as 3M and Aspen Aerogels focus on specialized insulation materials. TSMC and Intel contribute semiconductor expertise for integrated thermal management systems. The technology remains in mid-maturity, with significant R&D investment from automotive manufacturers including Ford and battery specialists like Panasonic and NEC Energy Devices, who are developing next-generation solutions that optimize both safety and thermal efficiency.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced thermal interface materials specifically designed for high-voltage battery packs that utilize a composite structure combining silicone-based polymers with ceramic fillers. Their proprietary TIM solution employs a gradient structure where the material composition changes across its thickness, providing optimal electrical isolation near the battery cells while maximizing thermal conductivity near the cooling system. This approach achieves thermal conductivity values of 3-5 W/m·K while maintaining dielectric strength exceeding 20 kV/mm. Samsung's TIM technology incorporates nano-scale boron nitride particles dispersed in a flexible silicone matrix, allowing for compression under assembly pressure to minimize thermal contact resistance while maintaining shape recovery properties to accommodate battery expansion during cycling.

Strengths: Excellent balance between thermal conductivity and electrical isolation; Maintains performance over wide temperature ranges (-40°C to 85°C); Compensates for manufacturing tolerances through compressibility. Weaknesses: Higher cost compared to conventional TIMs; Requires precise application processes; Performance degradation possible under extreme thermal cycling conditions.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a multi-layer TIM approach for high-voltage battery packs that strategically separates thermal management and electrical isolation functions. Their system utilizes a thin (50-100μm) high-dielectric strength layer made from modified polyimide directly contacting battery cells, followed by a thicker (0.5-2mm) highly thermally conductive layer composed of aluminum nitride particles in a silicone base. This dual-layer design achieves effective thermal conductivity of approximately 4.2 W/m·K while maintaining isolation ratings suitable for 800V battery architectures. The company has further enhanced this technology with a proprietary surface treatment process that improves long-term adhesion between the TIM and both battery and cooling surfaces, reducing thermal resistance degradation over time. Their latest iterations incorporate phase-change characteristics that optimize performance across varying operating temperatures.

Strengths: Superior electrical isolation properties suitable for next-generation 800V+ battery systems; Excellent aging characteristics with minimal performance degradation; Automated application process increases manufacturing efficiency. Weaknesses: More complex manufacturing process than single-layer solutions; Higher initial cost; Requires precise thickness control during application.

Key Patents in Electrically Insulating Thermal Materials

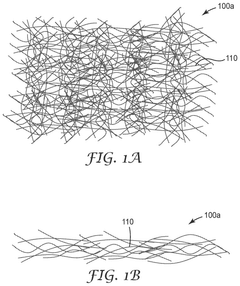

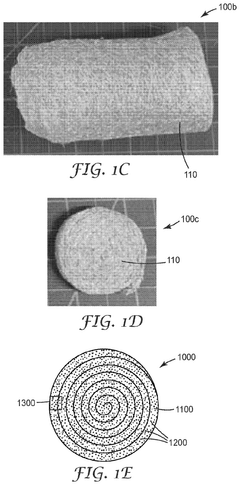

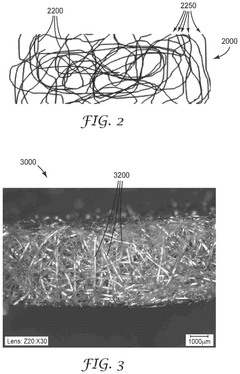

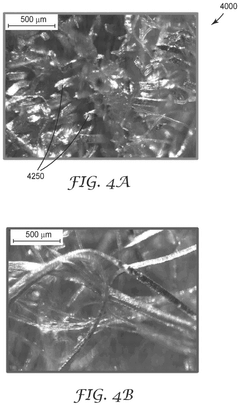

Thermally conductive articles including entangled or aligned fibers, methods of making same, and battery modules

PatentActiveUS12115737B2

Innovation

- The development of thermally conductive articles featuring entangled fibers with terminal ends on major surfaces and void spaces, which are impregnated with a polymer, allowing for continuous thermal pathways and low density through the use of less conductive material, thereby achieving high thermal conductivity and compressibility.

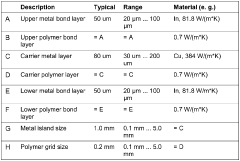

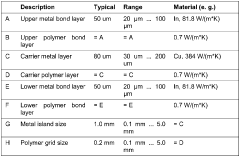

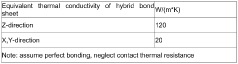

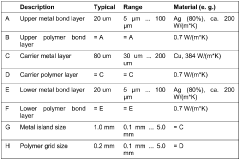

Hybrid bond sheet and cooled semiconductor power module

PatentWO2023179090A1

Innovation

- Development of a hybrid bond sheet technology that homogenizes junction temperature across power modules while maintaining high-voltage isolation properties.

- Implementation of a thermally optimized power module design that addresses the limitations of traditional substrate-level thermal management approaches.

- Solution for reducing stress and warpage in TIM materials caused by thermal mismatch and unbalanced vertical package structures.

Safety Standards and Compliance Requirements

The regulatory landscape for thermal interface materials (TIMs) in battery pack applications is governed by stringent safety standards that address both electrical isolation and thermal management requirements. IEC 60664-1 establishes the fundamental principles for electrical insulation coordination, specifying minimum clearance and creepage distances based on voltage levels, pollution degree, and material group. For electric vehicle battery systems operating at 400-800V, these standards typically require insulation materials to maintain dielectric strength exceeding 10-20 kV/mm.

UL 94 flame retardancy standards are particularly critical for TIMs in battery applications, with most automotive specifications requiring a minimum V-0 rating. This ensures that materials self-extinguish within 10 seconds after flame removal and produce minimal flaming particles. Additionally, ISO 26262 functional safety standards classify battery thermal management as an ASIL-C or ASIL-D system, necessitating rigorous validation of TIM reliability under various operating conditions.

Automotive-specific standards such as LV 123 and LV 124 define environmental testing protocols for high-voltage components, including temperature cycling (-40°C to +125°C), humidity resistance, and vibration testing. TIMs must maintain their electrical isolation properties throughout these test regimes without degradation. The SAE J2380 standard specifically addresses battery pack thermal cycling durability, requiring materials to withstand 1,000+ thermal cycles without significant performance deterioration.

Regional regulations introduce additional compliance requirements. European ECE R100 regulations mandate isolation resistance of at least 100 Ω/V for DC voltage components, while China's GB/T 31467 standard requires battery packs to maintain isolation resistance above 500 Ω/V after mechanical shock testing. These standards directly impact TIM selection and implementation strategies.

The UL 746A standard provides test methods for evaluating the long-term electrical properties of insulating materials, including comparative tracking index (CTI) measurements that are crucial for high-voltage applications. For battery systems, materials with CTI values exceeding 600V are typically preferred to prevent surface tracking under humid conditions.

Emerging standards are beginning to address the unique challenges of solid-state batteries, which may operate at higher temperatures and voltage potentials. These developments suggest that future TIMs will need to maintain electrical isolation properties at temperatures exceeding 100°C while providing thermal conductivity above 5 W/m·K to meet both safety and performance requirements in next-generation battery systems.

UL 94 flame retardancy standards are particularly critical for TIMs in battery applications, with most automotive specifications requiring a minimum V-0 rating. This ensures that materials self-extinguish within 10 seconds after flame removal and produce minimal flaming particles. Additionally, ISO 26262 functional safety standards classify battery thermal management as an ASIL-C or ASIL-D system, necessitating rigorous validation of TIM reliability under various operating conditions.

Automotive-specific standards such as LV 123 and LV 124 define environmental testing protocols for high-voltage components, including temperature cycling (-40°C to +125°C), humidity resistance, and vibration testing. TIMs must maintain their electrical isolation properties throughout these test regimes without degradation. The SAE J2380 standard specifically addresses battery pack thermal cycling durability, requiring materials to withstand 1,000+ thermal cycles without significant performance deterioration.

Regional regulations introduce additional compliance requirements. European ECE R100 regulations mandate isolation resistance of at least 100 Ω/V for DC voltage components, while China's GB/T 31467 standard requires battery packs to maintain isolation resistance above 500 Ω/V after mechanical shock testing. These standards directly impact TIM selection and implementation strategies.

The UL 746A standard provides test methods for evaluating the long-term electrical properties of insulating materials, including comparative tracking index (CTI) measurements that are crucial for high-voltage applications. For battery systems, materials with CTI values exceeding 600V are typically preferred to prevent surface tracking under humid conditions.

Emerging standards are beginning to address the unique challenges of solid-state batteries, which may operate at higher temperatures and voltage potentials. These developments suggest that future TIMs will need to maintain electrical isolation properties at temperatures exceeding 100°C while providing thermal conductivity above 5 W/m·K to meet both safety and performance requirements in next-generation battery systems.

Lifecycle Assessment of Battery TIM Materials

The lifecycle assessment of battery thermal interface materials (TIMs) reveals critical environmental and economic considerations throughout their production, use, and disposal phases. Battery TIMs present unique sustainability challenges due to their specialized formulations designed to balance thermal conductivity with electrical isolation properties.

During the raw material extraction phase, many high-performance TIMs rely on rare earth elements, metal oxides, and specialized polymers that involve energy-intensive mining and refining processes. Particularly, ceramic-filled silicones and boron nitride compounds, commonly used for their electrical isolation properties, have significant upstream environmental footprints compared to conventional thermal greases.

Manufacturing processes for battery-specific TIMs typically require precision mixing, controlled curing environments, and stringent quality control measures to ensure consistent electrical isolation properties. These manufacturing steps consume substantial energy and often involve volatile organic compounds (VOCs) that require careful management to minimize environmental impact.

The use phase demonstrates the environmental trade-offs inherent in TIM selection. Materials with superior thermal conductivity may reduce battery cooling energy requirements throughout the battery pack's operational life, potentially offsetting their higher production impacts. However, materials optimized primarily for electrical isolation might require thicker application, reducing thermal efficiency and increasing overall material usage.

End-of-life considerations present significant challenges. Many high-performance TIMs used in EV battery packs are difficult to separate from battery components during recycling processes. Ceramic-filled polymers and phase change materials with electrical isolation properties often cannot be effectively recovered or reused, contributing to electronic waste streams.

Recent lifecycle analyses indicate that TIMs represent approximately 2-5% of a battery pack's total environmental impact, with the proportion increasing for advanced formulations designed to handle high-voltage isolation requirements. The environmental payback period for premium TIMs varies significantly based on application, ranging from 1-3 years in high-performance EV applications to 5+ years in stationary storage systems.

Emerging sustainable alternatives include bio-based polymers with ceramic fillers that maintain electrical isolation properties while reducing fossil fuel dependency. Additionally, design approaches that facilitate TIM recovery during battery recycling are gaining attention, including reversible adhesion mechanisms and material identification systems to improve sortability in recycling streams.

During the raw material extraction phase, many high-performance TIMs rely on rare earth elements, metal oxides, and specialized polymers that involve energy-intensive mining and refining processes. Particularly, ceramic-filled silicones and boron nitride compounds, commonly used for their electrical isolation properties, have significant upstream environmental footprints compared to conventional thermal greases.

Manufacturing processes for battery-specific TIMs typically require precision mixing, controlled curing environments, and stringent quality control measures to ensure consistent electrical isolation properties. These manufacturing steps consume substantial energy and often involve volatile organic compounds (VOCs) that require careful management to minimize environmental impact.

The use phase demonstrates the environmental trade-offs inherent in TIM selection. Materials with superior thermal conductivity may reduce battery cooling energy requirements throughout the battery pack's operational life, potentially offsetting their higher production impacts. However, materials optimized primarily for electrical isolation might require thicker application, reducing thermal efficiency and increasing overall material usage.

End-of-life considerations present significant challenges. Many high-performance TIMs used in EV battery packs are difficult to separate from battery components during recycling processes. Ceramic-filled polymers and phase change materials with electrical isolation properties often cannot be effectively recovered or reused, contributing to electronic waste streams.

Recent lifecycle analyses indicate that TIMs represent approximately 2-5% of a battery pack's total environmental impact, with the proportion increasing for advanced formulations designed to handle high-voltage isolation requirements. The environmental payback period for premium TIMs varies significantly based on application, ranging from 1-3 years in high-performance EV applications to 5+ years in stationary storage systems.

Emerging sustainable alternatives include bio-based polymers with ceramic fillers that maintain electrical isolation properties while reducing fossil fuel dependency. Additionally, design approaches that facilitate TIM recovery during battery recycling are gaining attention, including reversible adhesion mechanisms and material identification systems to improve sortability in recycling streams.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!