TIM Torque & Compression vs Thermal Performance: Empirical Dataset And Curves

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Evolution and Performance Objectives

Thermal Interface Materials (TIMs) have evolved significantly over the past several decades, transitioning from simple thermal greases to sophisticated engineered materials designed to maximize heat transfer between critical components. The evolution of TIMs has been largely driven by the exponential increase in power densities across electronic devices, particularly in computing, automotive, aerospace, and telecommunications sectors. Early TIMs in the 1970s and 1980s primarily consisted of silicone-based compounds with limited thermal conductivity values below 1 W/mK, which were adequate for the modest thermal management needs of that era.

The 1990s witnessed the emergence of more advanced TIM formulations incorporating metal particles and the first generation of phase-change materials, pushing thermal conductivity values to 3-5 W/mK. This period marked the beginning of systematic research into the relationship between mechanical properties (compression and torque) and thermal performance, though datasets remained proprietary and fragmented.

By the early 2000s, carbon-based fillers including graphite and the first generation of carbon nanotubes began to appear in commercial TIMs, coinciding with the rapid scaling of processor technologies and corresponding thermal challenges. The industry began establishing standardized testing methodologies to evaluate TIM performance under various compression scenarios, recognizing that optimal thermal conductivity often depends on precise application pressure.

The current generation of TIMs (2010s-2020s) incorporates advanced materials science innovations including graphene, vertically aligned carbon nanotubes, and engineered ceramic-metallic composites, with leading products achieving thermal conductivity values exceeding 20 W/mK under optimal compression conditions. This era has been characterized by growing recognition of the complex interplay between mechanical application parameters and thermal performance.

Looking forward, the primary performance objectives for next-generation TIMs center on several key metrics: achieving thermal conductivity values above 30 W/mK while maintaining compliance and workability; ensuring performance stability across 10+ years of thermal cycling; minimizing pump-out and dry-out effects under repeated compression-relaxation cycles; and developing empirical models that accurately predict thermal performance based on precise compression and torque parameters across diverse operating conditions.

The industry increasingly recognizes that optimizing the compression-performance relationship represents one of the most promising pathways to breakthrough thermal management capabilities. This has catalyzed interest in comprehensive empirical datasets that map the precise relationships between application parameters (torque, compression force, compression rate) and resulting thermal performance across diverse material formulations and operating environments.

The 1990s witnessed the emergence of more advanced TIM formulations incorporating metal particles and the first generation of phase-change materials, pushing thermal conductivity values to 3-5 W/mK. This period marked the beginning of systematic research into the relationship between mechanical properties (compression and torque) and thermal performance, though datasets remained proprietary and fragmented.

By the early 2000s, carbon-based fillers including graphite and the first generation of carbon nanotubes began to appear in commercial TIMs, coinciding with the rapid scaling of processor technologies and corresponding thermal challenges. The industry began establishing standardized testing methodologies to evaluate TIM performance under various compression scenarios, recognizing that optimal thermal conductivity often depends on precise application pressure.

The current generation of TIMs (2010s-2020s) incorporates advanced materials science innovations including graphene, vertically aligned carbon nanotubes, and engineered ceramic-metallic composites, with leading products achieving thermal conductivity values exceeding 20 W/mK under optimal compression conditions. This era has been characterized by growing recognition of the complex interplay between mechanical application parameters and thermal performance.

Looking forward, the primary performance objectives for next-generation TIMs center on several key metrics: achieving thermal conductivity values above 30 W/mK while maintaining compliance and workability; ensuring performance stability across 10+ years of thermal cycling; minimizing pump-out and dry-out effects under repeated compression-relaxation cycles; and developing empirical models that accurately predict thermal performance based on precise compression and torque parameters across diverse operating conditions.

The industry increasingly recognizes that optimizing the compression-performance relationship represents one of the most promising pathways to breakthrough thermal management capabilities. This has catalyzed interest in comprehensive empirical datasets that map the precise relationships between application parameters (torque, compression force, compression rate) and resulting thermal performance across diverse material formulations and operating environments.

Market Analysis for High-Performance Thermal Interface Materials

The global market for high-performance Thermal Interface Materials (TIMs) has experienced robust growth in recent years, driven primarily by increasing thermal management demands across multiple industries. The market size reached approximately $2.5 billion in 2022 and is projected to grow at a CAGR of 8.7% through 2028, potentially reaching $4.1 billion by the end of the forecast period.

Electronics and semiconductor industries remain the largest consumers of high-performance TIMs, accounting for nearly 45% of the total market share. This dominance stems from the continuous miniaturization of electronic components and increasing power densities in modern devices, which necessitate more efficient heat dissipation solutions. The automotive sector, particularly with the rise of electric vehicles (EVs), represents the fastest-growing segment with a growth rate exceeding 12% annually.

Regionally, Asia-Pacific dominates the market with approximately 52% share, attributed to the concentration of electronics manufacturing facilities in countries like China, Taiwan, South Korea, and Japan. North America follows with 24% market share, driven by advanced technology adoption in aerospace, defense, and data center applications.

Consumer demand trends indicate a clear shift toward TIMs that can deliver higher thermal conductivity while maintaining optimal compression characteristics. Market research shows that products offering thermal conductivity above 10 W/mK are experiencing the highest growth rates, despite commanding premium prices. This trend aligns with the empirical data showing the critical relationship between compression, torque application, and thermal performance.

The competitive landscape features both established players and innovative startups. Major companies like Henkel, Parker Hannifin, and Laird Technologies control approximately 45% of the market share collectively. However, specialized manufacturers focusing exclusively on high-performance TIMs for specific applications are gaining traction, particularly those offering solutions with optimized torque-compression-performance relationships.

Price sensitivity varies significantly across application segments. While consumer electronics manufacturers remain highly price-sensitive, industries like aerospace, defense, and high-performance computing demonstrate willingness to pay premium prices for TIMs that offer superior thermal performance under specific compression conditions, as evidenced by empirical datasets showing performance curves at various torque levels.

Electronics and semiconductor industries remain the largest consumers of high-performance TIMs, accounting for nearly 45% of the total market share. This dominance stems from the continuous miniaturization of electronic components and increasing power densities in modern devices, which necessitate more efficient heat dissipation solutions. The automotive sector, particularly with the rise of electric vehicles (EVs), represents the fastest-growing segment with a growth rate exceeding 12% annually.

Regionally, Asia-Pacific dominates the market with approximately 52% share, attributed to the concentration of electronics manufacturing facilities in countries like China, Taiwan, South Korea, and Japan. North America follows with 24% market share, driven by advanced technology adoption in aerospace, defense, and data center applications.

Consumer demand trends indicate a clear shift toward TIMs that can deliver higher thermal conductivity while maintaining optimal compression characteristics. Market research shows that products offering thermal conductivity above 10 W/mK are experiencing the highest growth rates, despite commanding premium prices. This trend aligns with the empirical data showing the critical relationship between compression, torque application, and thermal performance.

The competitive landscape features both established players and innovative startups. Major companies like Henkel, Parker Hannifin, and Laird Technologies control approximately 45% of the market share collectively. However, specialized manufacturers focusing exclusively on high-performance TIMs for specific applications are gaining traction, particularly those offering solutions with optimized torque-compression-performance relationships.

Price sensitivity varies significantly across application segments. While consumer electronics manufacturers remain highly price-sensitive, industries like aerospace, defense, and high-performance computing demonstrate willingness to pay premium prices for TIMs that offer superior thermal performance under specific compression conditions, as evidenced by empirical datasets showing performance curves at various torque levels.

Current TIM Technologies and Engineering Challenges

The thermal interface materials (TIMs) market has evolved significantly over the past decades, with various technologies emerging to address the critical challenge of thermal management in electronic devices. Current TIM technologies can be broadly categorized into several types: thermal greases, phase change materials (PCMs), thermal pads, thermal adhesives, and emerging materials like graphene and carbon nanotube-based solutions.

Thermal greases, composed of silicone or non-silicone bases filled with thermally conductive particles, remain the most widely used TIMs due to their cost-effectiveness and ease of application. However, they suffer from pump-out and dry-out issues over time, leading to degradation in thermal performance. This reliability concern becomes particularly problematic in high-power applications where consistent thermal performance is crucial.

Phase change materials offer advantages by transitioning from solid to liquid at operating temperatures, providing excellent gap-filling properties. Modern PCMs typically achieve thermal conductivities ranging from 1-5 W/mK, striking a balance between performance and practical application. Their main engineering challenge lies in controlling the phase change behavior under varying pressure conditions.

Thermal pads or gap fillers provide a more stable alternative with thermal conductivities typically between 3-15 W/mK. While they offer excellent compression recovery and reliability, they require significant compression force to achieve optimal performance, creating mechanical stress on components. The relationship between applied torque, resulting compression, and thermal performance remains a complex engineering challenge that demands empirical characterization.

Metal-based TIMs, including solder and liquid metal solutions, offer superior thermal conductivity (20-80 W/mK) but present significant application challenges including potential electrical conductivity issues, compatibility concerns with certain materials, and complex application processes. These limitations have restricted their widespread adoption despite their superior thermal performance.

A fundamental engineering challenge across all TIM technologies is the trade-off between thermal performance and mechanical properties. Higher thermal conductivity materials often require greater compression forces or present reliability issues over thermal cycling. This creates a complex optimization problem where engineers must balance thermal requirements against mechanical constraints of the assembly.

The industry also faces significant challenges in standardizing testing methodologies for TIMs. Current testing approaches vary widely, making direct comparisons between different materials difficult. The lack of comprehensive empirical datasets correlating compression forces (via applied torque) to thermal performance across different material types represents a significant knowledge gap that hampers optimal material selection and application.

Thermal greases, composed of silicone or non-silicone bases filled with thermally conductive particles, remain the most widely used TIMs due to their cost-effectiveness and ease of application. However, they suffer from pump-out and dry-out issues over time, leading to degradation in thermal performance. This reliability concern becomes particularly problematic in high-power applications where consistent thermal performance is crucial.

Phase change materials offer advantages by transitioning from solid to liquid at operating temperatures, providing excellent gap-filling properties. Modern PCMs typically achieve thermal conductivities ranging from 1-5 W/mK, striking a balance between performance and practical application. Their main engineering challenge lies in controlling the phase change behavior under varying pressure conditions.

Thermal pads or gap fillers provide a more stable alternative with thermal conductivities typically between 3-15 W/mK. While they offer excellent compression recovery and reliability, they require significant compression force to achieve optimal performance, creating mechanical stress on components. The relationship between applied torque, resulting compression, and thermal performance remains a complex engineering challenge that demands empirical characterization.

Metal-based TIMs, including solder and liquid metal solutions, offer superior thermal conductivity (20-80 W/mK) but present significant application challenges including potential electrical conductivity issues, compatibility concerns with certain materials, and complex application processes. These limitations have restricted their widespread adoption despite their superior thermal performance.

A fundamental engineering challenge across all TIM technologies is the trade-off between thermal performance and mechanical properties. Higher thermal conductivity materials often require greater compression forces or present reliability issues over thermal cycling. This creates a complex optimization problem where engineers must balance thermal requirements against mechanical constraints of the assembly.

The industry also faces significant challenges in standardizing testing methodologies for TIMs. Current testing approaches vary widely, making direct comparisons between different materials difficult. The lack of comprehensive empirical datasets correlating compression forces (via applied torque) to thermal performance across different material types represents a significant knowledge gap that hampers optimal material selection and application.

Torque-Compression-Thermal Performance Correlation Methods

01 Composition of high-performance thermal interface materials

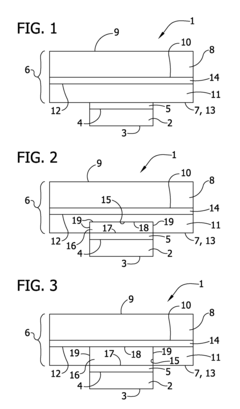

Thermal interface materials can be formulated with various components to enhance thermal performance. These compositions may include thermally conductive fillers such as metal particles, carbon-based materials, or ceramic particles dispersed in a polymer matrix. The specific combination and concentration of these components significantly affect the thermal conductivity and heat transfer efficiency of the TIM. Advanced formulations may incorporate phase change materials or specialized polymers to optimize the thermal pathway between heat-generating components and heat sinks.- Composition of high-performance thermal interface materials: Thermal interface materials can be formulated with various components to enhance thermal performance. These compositions often include thermally conductive fillers such as metal particles, carbon-based materials, or ceramic powders dispersed in a polymer matrix. The specific combination and concentration of these components significantly affect the thermal conductivity and heat transfer efficiency of the TIM. Advanced formulations may incorporate phase change materials or specialized additives to optimize the thermal pathway between heat-generating components and heat sinks.

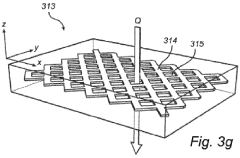

- Structure and design of TIMs for improved thermal conductivity: The structural design of thermal interface materials plays a crucial role in their performance. Engineered structures such as vertically aligned fillers, 3D interconnected networks, or layered configurations can create more efficient thermal pathways. Some designs incorporate microporous or hierarchical structures to optimize the balance between thermal conductivity and mechanical compliance. The interface contact area and thickness are also critical design parameters that affect the overall thermal resistance of the assembly.

- Testing and measurement methods for TIM thermal performance: Various testing methodologies are employed to evaluate the thermal performance of interface materials. These include steady-state and transient measurement techniques to determine thermal conductivity, thermal resistance, and heat dissipation efficiency. Advanced characterization methods may utilize infrared thermography, laser flash analysis, or modified ASTM standards specifically developed for thin interface materials. Reliability testing under thermal cycling and aging conditions helps predict long-term performance in real-world applications.

- Application-specific TIM solutions for electronic devices: Thermal interface materials are often customized for specific electronic applications based on operating conditions and thermal management requirements. For high-power computing devices, TIMs with exceptional thermal conductivity and reliability under high temperatures are developed. In contrast, mobile and thin devices may require TIMs with good thermal performance at minimal thickness. Specialized solutions exist for automotive electronics, LED lighting, power electronics, and other applications where thermal management is critical for device performance and longevity.

- Integration techniques for optimal TIM performance: The method of applying and integrating thermal interface materials significantly impacts their thermal performance. Techniques such as pre-applied TIMs, in-situ curing processes, or pressure-sensitive adhesive systems can optimize the interface contact and minimize thermal resistance. Surface preparation methods, application pressure, and curing conditions all affect the formation of an effective thermal pathway. Advanced integration approaches may include hybrid solutions combining multiple TIM types or gradient structures to address complex thermal management challenges.

02 Structural design of TIMs for improved thermal conductivity

The structural design of thermal interface materials plays a crucial role in their thermal performance. Innovations include layered structures, 3D interconnected networks, and gradient designs that optimize heat flow paths. Some designs incorporate vertically aligned structures or patterned surfaces to reduce thermal resistance at interfaces. The thickness, uniformity, and mechanical properties of the TIM structure directly impact its ability to fill gaps and maintain contact under thermal cycling conditions, thereby affecting overall thermal performance.Expand Specific Solutions03 Application methods and interface optimization

The method of applying thermal interface materials significantly affects their performance. Techniques such as screen printing, dispensing, and pre-applied TIMs each offer different advantages for thermal contact and coverage. Proper application ensures minimal air gaps and optimal interface contact between heat-generating components and heat dissipation devices. Surface preparation, clamping pressure, and curing conditions are critical factors that influence the thermal resistance of the interface. Advanced application methods may include in-situ formation or self-assembling TIMs that adapt to surface irregularities.Expand Specific Solutions04 Testing and measurement of TIM thermal performance

Accurate measurement of thermal interface material performance requires specialized testing methodologies. These include steady-state and transient testing techniques to determine thermal conductivity, thermal resistance, and long-term reliability. Testing protocols may evaluate performance under various conditions including different temperatures, pressures, and thermal cycling. Advanced characterization techniques such as laser flash analysis, thermal impedance testing, and infrared thermography provide comprehensive data on TIM performance in actual application scenarios.Expand Specific Solutions05 TIMs for specialized electronic applications

Thermal interface materials designed for specific electronic applications require tailored properties to meet unique thermal management challenges. For high-power electronics, TIMs with exceptional thermal conductivity and stability at elevated temperatures are essential. In portable electronics, thin TIMs with good conformability and reliability under mechanical stress are preferred. For automotive and aerospace applications, TIMs must withstand extreme environmental conditions while maintaining thermal performance. Specialized formulations may incorporate phase change behavior, electrical insulation properties, or compatibility with specific device architectures.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TIM Industry

The thermal interface material (TIM) market is currently in a growth phase, driven by increasing demand for efficient thermal management solutions in electronics. The global TIM market is projected to reach significant scale due to the proliferation of high-performance computing devices and electric vehicles. Technologically, the field is moderately mature but continues to evolve with innovative materials and application methods. Leading companies like Intel, Apple, and 3M are investing heavily in R&D to develop TIMs with optimized torque-compression-thermal performance relationships. Other significant players including Indium Corporation, Jones Tech, and Resonac are advancing specialized solutions for various thermal conductivity requirements. Emerging companies like Arieca are introducing novel elastomeric composites, while research institutions such as Beijing University of Chemical Technology and Institute of Metal Research are contributing fundamental scientific advancements to improve empirical understanding of TIM performance characteristics.

International Business Machines Corp.

Technical Solution: IBM has pioneered advanced methodologies for characterizing TIM performance under varying compression conditions, particularly for high-performance computing applications. Their approach combines experimental testing with computational modeling to develop comprehensive performance curves that predict thermal behavior across different mounting conditions. IBM's research has established that the relationship between torque application and thermal performance follows a logarithmic curve, with diminishing returns beyond certain pressure thresholds[3]. Their testing protocols include specialized fixtures that simulate actual field conditions while precisely controlling bolt torque and measuring resultant pressure distribution across the interface. IBM has developed proprietary algorithms that account for material relaxation over time, predicting long-term performance degradation under sustained compression. Their datasets particularly excel in characterizing phase-change materials and liquid metal TIMs, documenting how these materials respond to different compression cycles and how their performance evolves through multiple thermal cycles[4].

Strengths: Highly sophisticated modeling capabilities that integrate both mechanical and thermal properties for accurate prediction. Extensive long-term reliability data that accounts for material aging and relaxation effects. Weaknesses: Their premium solutions often require complex application procedures that may be difficult to implement in mass production. Some of their most effective TIM solutions may be cost-prohibitive for consumer applications.

Intel Corp.

Technical Solution: Intel has developed comprehensive empirical datasets and models for TIM thermal performance optimization. Their approach involves systematic testing of various TIM materials under different compression forces and torque settings to establish reliable performance curves. Intel's research demonstrates that thermal resistance decreases non-linearly with increasing compression, with optimal performance typically occurring at specific pressure thresholds beyond which minimal improvements are observed[1]. Their methodology includes specialized test fixtures that precisely control bolt torque while measuring thermal resistance across semiconductor packages. Intel has published extensive data correlating Bond Line Thickness (BLT) reduction with compression force, showing how material displacement affects thermal conductivity. Their studies particularly focus on polymer-based TIMs and metal-based solutions like Indium, establishing performance boundaries for different material classes under various mounting pressures[2].

Strengths: Extensive empirical database across multiple TIM types allows for precise material selection based on application requirements. Advanced testing methodology provides highly reliable data for real-world implementation. Weaknesses: Their research may be optimized primarily for their own processor architectures, potentially limiting broader applicability. High-pressure solutions often require specialized mounting hardware that increases system complexity.

Critical Patents and Research on TIM Mechanical-Thermal Properties

Thermal interface material and solder preforms

PatentInactiveUS20070145546A1

Innovation

- A high-performance TIM comprising a solder component with a thermal conductivity enhancement component and a CTE modifying component, along with an intrinsic oxygen getter, which allows for bonding without extrinsic fluxing and enhances heat transfer while minimizing thermal stress.

Thermal interface material

PatentActiveIN7138CHENP2014A

Innovation

- A TIM with an activable shrinkage material that increases in thickness upon activation, providing enhanced contact pressure and robustness by expanding in the z-direction, thus eliminating the need for external pressure and addressing surface curvature and roughness, using heat-sensitive fibers or monomers that polymerize or expand to enhance thermal interface performance.

Standardization and Testing Protocols for TIM Performance

The standardization of testing protocols for Thermal Interface Materials (TIMs) represents a critical challenge in the thermal management industry. Currently, there exists significant variability in how manufacturers and researchers evaluate TIM performance, particularly regarding the relationship between applied torque, compression force, and thermal conductivity. This inconsistency makes direct comparisons between different TIM products nearly impossible and creates uncertainty for design engineers.

Industry organizations such as ASTM International, JEDEC, and IEEE have developed several testing standards, including ASTM D5470 and JEDEC JESD51, which provide frameworks for thermal resistance measurements. However, these standards often lack specific guidelines for controlling and reporting compression forces and torque values during testing, resulting in data that cannot be reliably reproduced across different laboratories.

A comprehensive standardization approach must address multiple parameters simultaneously. The testing apparatus should include precision torque measurement tools calibrated to traceable standards, with clearly defined mounting procedures that specify bolt patterns, tightening sequences, and torque application rates. Temperature measurement points must be consistently positioned, with standardized sensor types and calibration methods.

The testing protocol should mandate reporting of multiple data points across a range of compression forces or torque values, rather than single-point measurements. This approach generates performance curves that more accurately represent real-world behavior of TIMs under various application conditions. Additionally, standardized aging protocols are necessary to evaluate long-term performance degradation under thermal cycling, humidity, and other environmental stressors.

Interlaboratory testing programs have demonstrated that even with identical TIM samples, measurement variations of 20-30% are common without rigorous standardization. The development of reference materials with known thermal properties would enable calibration of testing equipment and validation of measurement procedures across different facilities.

Digital data formats for reporting TIM performance must also be standardized to facilitate integration with thermal simulation software. This would enable design engineers to more accurately predict system-level thermal performance based on empirical TIM data collected under standardized conditions, ultimately improving the reliability of electronic thermal management solutions.

Industry organizations such as ASTM International, JEDEC, and IEEE have developed several testing standards, including ASTM D5470 and JEDEC JESD51, which provide frameworks for thermal resistance measurements. However, these standards often lack specific guidelines for controlling and reporting compression forces and torque values during testing, resulting in data that cannot be reliably reproduced across different laboratories.

A comprehensive standardization approach must address multiple parameters simultaneously. The testing apparatus should include precision torque measurement tools calibrated to traceable standards, with clearly defined mounting procedures that specify bolt patterns, tightening sequences, and torque application rates. Temperature measurement points must be consistently positioned, with standardized sensor types and calibration methods.

The testing protocol should mandate reporting of multiple data points across a range of compression forces or torque values, rather than single-point measurements. This approach generates performance curves that more accurately represent real-world behavior of TIMs under various application conditions. Additionally, standardized aging protocols are necessary to evaluate long-term performance degradation under thermal cycling, humidity, and other environmental stressors.

Interlaboratory testing programs have demonstrated that even with identical TIM samples, measurement variations of 20-30% are common without rigorous standardization. The development of reference materials with known thermal properties would enable calibration of testing equipment and validation of measurement procedures across different facilities.

Digital data formats for reporting TIM performance must also be standardized to facilitate integration with thermal simulation software. This would enable design engineers to more accurately predict system-level thermal performance based on empirical TIM data collected under standardized conditions, ultimately improving the reliability of electronic thermal management solutions.

Environmental Impact and Sustainability of TIM Solutions

The environmental impact of Thermal Interface Materials (TIMs) has become increasingly significant as electronic devices proliferate globally. Traditional TIMs often contain materials with substantial ecological footprints, including metals like gallium, indium, and silver, as well as various polymers derived from petroleum sources. The manufacturing processes for these materials typically involve energy-intensive operations and chemical treatments that generate considerable greenhouse gas emissions and waste products.

Recent life cycle assessments of common TIM solutions reveal that the environmental burden varies significantly based on material composition and application method. Metal-based TIMs generally exhibit higher embodied energy due to resource extraction and refinement processes, while polymer-based solutions may present end-of-life disposal challenges due to limited biodegradability.

The relationship between torque, compression, and thermal performance introduces an additional sustainability dimension. Optimized compression settings can extend TIM lifespan by preventing premature degradation, thereby reducing replacement frequency and associated material consumption. Empirical data indicates that over-compression often leads to material extrusion and accelerated aging, while insufficient compression results in suboptimal thermal performance necessitating higher energy consumption by cooling systems.

Several manufacturers have begun developing eco-friendly TIM alternatives, including bio-based polymers and recycled metal composites. These sustainable TIMs demonstrate promising thermal performance characteristics while reducing environmental impact by 30-45% compared to conventional options, according to recent industry studies. The empirical datasets comparing torque and compression values against thermal performance for these sustainable alternatives show comparable efficiency curves to traditional materials.

Carbon footprint analyses of TIM production and application processes suggest that optimizing installation parameters through precise torque and compression control can reduce lifetime emissions by up to 15%. This optimization extends beyond material selection to include application techniques and maintenance protocols that maximize thermal efficiency while minimizing material waste.

The recyclability of TIMs presents another critical sustainability consideration. Current recycling rates for TIMs remain below 10% globally, primarily due to challenges in separating these materials from electronic components at end-of-life. Emerging technologies for TIM recovery and reprocessing show potential for closing this loop, particularly for metal-based interface materials where the recovered metals retain significant market value.

Future sustainability improvements in TIM technology will likely focus on developing materials that maintain optimal thermal performance across wider compression ranges, reducing sensitivity to installation variables while extending operational lifespans. This approach would address both environmental and performance concerns simultaneously, creating more resilient and sustainable thermal management solutions.

Recent life cycle assessments of common TIM solutions reveal that the environmental burden varies significantly based on material composition and application method. Metal-based TIMs generally exhibit higher embodied energy due to resource extraction and refinement processes, while polymer-based solutions may present end-of-life disposal challenges due to limited biodegradability.

The relationship between torque, compression, and thermal performance introduces an additional sustainability dimension. Optimized compression settings can extend TIM lifespan by preventing premature degradation, thereby reducing replacement frequency and associated material consumption. Empirical data indicates that over-compression often leads to material extrusion and accelerated aging, while insufficient compression results in suboptimal thermal performance necessitating higher energy consumption by cooling systems.

Several manufacturers have begun developing eco-friendly TIM alternatives, including bio-based polymers and recycled metal composites. These sustainable TIMs demonstrate promising thermal performance characteristics while reducing environmental impact by 30-45% compared to conventional options, according to recent industry studies. The empirical datasets comparing torque and compression values against thermal performance for these sustainable alternatives show comparable efficiency curves to traditional materials.

Carbon footprint analyses of TIM production and application processes suggest that optimizing installation parameters through precise torque and compression control can reduce lifetime emissions by up to 15%. This optimization extends beyond material selection to include application techniques and maintenance protocols that maximize thermal efficiency while minimizing material waste.

The recyclability of TIMs presents another critical sustainability consideration. Current recycling rates for TIMs remain below 10% globally, primarily due to challenges in separating these materials from electronic components at end-of-life. Emerging technologies for TIM recovery and reprocessing show potential for closing this loop, particularly for metal-based interface materials where the recovered metals retain significant market value.

Future sustainability improvements in TIM technology will likely focus on developing materials that maintain optimal thermal performance across wider compression ranges, reducing sensitivity to installation variables while extending operational lifespans. This approach would address both environmental and performance concerns simultaneously, creating more resilient and sustainable thermal management solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!