TIM For Server OEMs: Standardized Test Program For Supplier Qualification

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Testing Background and Objectives

Thermal Interface Materials (TIMs) have become increasingly critical components in server thermal management as computing power densities continue to rise. The evolution of TIMs has been closely tied to the advancement of semiconductor technology, with each generation of processors demanding more efficient heat dissipation solutions. From simple thermal greases to advanced phase-change materials and liquid metal compounds, TIM technology has undergone significant transformation over the past decades to meet the escalating thermal challenges in server environments.

The primary objective of establishing a standardized test program for TIM supplier qualification is to create a consistent, reliable framework for evaluating thermal interface materials across the server industry. This standardization addresses the current fragmentation in testing methodologies, where different OEMs employ varying protocols, leading to inconsistent performance data and qualification results. By implementing uniform testing standards, server manufacturers can make more informed decisions based on comparable performance metrics.

Current TIM evaluation practices often vary significantly between organizations, creating challenges for suppliers who must adapt their testing protocols for each customer. This inconsistency increases development costs, extends qualification timelines, and introduces potential reliability risks when materials are deployed in production environments. The lack of standardization also complicates the comparison of different TIM solutions, hindering innovation and optimization efforts across the industry.

The standardized test program aims to evaluate several critical performance parameters, including thermal conductivity, thermal resistance, long-term reliability, pump-out resistance, and compatibility with various server components. These parameters directly impact the thermal efficiency of server systems and their long-term operational stability in data center environments, where equipment is expected to function reliably for years under varying workloads and environmental conditions.

Beyond technical performance, the standardization initiative seeks to address economic and environmental considerations. By streamlining the qualification process, both suppliers and OEMs can reduce development cycles and testing costs. Additionally, standardized testing enables more accurate lifecycle assessment of TIMs, supporting sustainability goals by ensuring optimal material selection and application.

The development of this standardized program represents a collaborative effort involving server OEMs, TIM suppliers, industry consortia, and testing laboratories. This multi-stakeholder approach ensures that the resulting standards reflect diverse industry perspectives and requirements, making them broadly applicable across the server ecosystem. The ultimate goal is to establish a universally accepted qualification framework that accelerates innovation while maintaining the highest standards of reliability and performance in server thermal management solutions.

The primary objective of establishing a standardized test program for TIM supplier qualification is to create a consistent, reliable framework for evaluating thermal interface materials across the server industry. This standardization addresses the current fragmentation in testing methodologies, where different OEMs employ varying protocols, leading to inconsistent performance data and qualification results. By implementing uniform testing standards, server manufacturers can make more informed decisions based on comparable performance metrics.

Current TIM evaluation practices often vary significantly between organizations, creating challenges for suppliers who must adapt their testing protocols for each customer. This inconsistency increases development costs, extends qualification timelines, and introduces potential reliability risks when materials are deployed in production environments. The lack of standardization also complicates the comparison of different TIM solutions, hindering innovation and optimization efforts across the industry.

The standardized test program aims to evaluate several critical performance parameters, including thermal conductivity, thermal resistance, long-term reliability, pump-out resistance, and compatibility with various server components. These parameters directly impact the thermal efficiency of server systems and their long-term operational stability in data center environments, where equipment is expected to function reliably for years under varying workloads and environmental conditions.

Beyond technical performance, the standardization initiative seeks to address economic and environmental considerations. By streamlining the qualification process, both suppliers and OEMs can reduce development cycles and testing costs. Additionally, standardized testing enables more accurate lifecycle assessment of TIMs, supporting sustainability goals by ensuring optimal material selection and application.

The development of this standardized program represents a collaborative effort involving server OEMs, TIM suppliers, industry consortia, and testing laboratories. This multi-stakeholder approach ensures that the resulting standards reflect diverse industry perspectives and requirements, making them broadly applicable across the server ecosystem. The ultimate goal is to establish a universally accepted qualification framework that accelerates innovation while maintaining the highest standards of reliability and performance in server thermal management solutions.

Market Requirements for Server Thermal Interface Materials

The server market demands increasingly efficient thermal interface materials (TIMs) as data centers face growing thermal management challenges. With server power densities rising by approximately 15-20% annually, traditional TIMs are struggling to meet performance requirements. Current market expectations center on thermal conductivity values exceeding 5 W/m·K, with premium solutions reaching 8-12 W/m·K, while maintaining bond line thicknesses below 100 microns.

Reliability has become paramount as server uptime requirements approach 99.999%, translating to less than 5.3 minutes of downtime annually. TIMs must maintain performance across 5-7 year server lifecycles while enduring thousands of thermal cycles. This has driven demand for materials with minimal pump-out and dry-out characteristics, particularly in edge computing deployments where environmental controls may be less stringent.

Cost sensitivity varies significantly by market segment. Hyperscale operators prioritize total cost of ownership, accepting premium TIM pricing if thermal performance reduces cooling costs. Enterprise customers typically seek balanced cost-performance solutions, while edge computing deployments often prioritize reliability over absolute thermal performance.

Environmental compliance has emerged as a critical requirement, with major OEMs establishing roadmaps to eliminate materials containing substances of very high concern (SVHCs). The market increasingly demands halogen-free formulations and solutions compliant with RoHS, REACH, and emerging regulations. Several major cloud service providers have announced carbon-neutral goals, creating demand for TIMs with reduced environmental footprints.

Application-specific requirements are becoming more diverse. High-performance computing applications require TIMs capable of managing extreme heat fluxes exceeding 150 W/cm², while edge servers need solutions resilient to variable environmental conditions. Liquid cooling adoption is creating demand for specialized TIMs compatible with cold plates and direct-to-chip cooling solutions.

Manufacturing considerations significantly impact TIM selection. Automated assembly lines require materials compatible with pick-and-place equipment and consistent dispensing characteristics. Reworkability has become essential for high-value components, with OEMs seeking TIMs that allow processor removal without damage for repair or upgrade scenarios.

Standardization of testing methodologies has become a market imperative as performance claims vary widely between suppliers, making direct comparisons challenging. OEMs increasingly demand standardized qualification programs that accurately predict in-field performance across diverse operating conditions and extended timeframes.

Reliability has become paramount as server uptime requirements approach 99.999%, translating to less than 5.3 minutes of downtime annually. TIMs must maintain performance across 5-7 year server lifecycles while enduring thousands of thermal cycles. This has driven demand for materials with minimal pump-out and dry-out characteristics, particularly in edge computing deployments where environmental controls may be less stringent.

Cost sensitivity varies significantly by market segment. Hyperscale operators prioritize total cost of ownership, accepting premium TIM pricing if thermal performance reduces cooling costs. Enterprise customers typically seek balanced cost-performance solutions, while edge computing deployments often prioritize reliability over absolute thermal performance.

Environmental compliance has emerged as a critical requirement, with major OEMs establishing roadmaps to eliminate materials containing substances of very high concern (SVHCs). The market increasingly demands halogen-free formulations and solutions compliant with RoHS, REACH, and emerging regulations. Several major cloud service providers have announced carbon-neutral goals, creating demand for TIMs with reduced environmental footprints.

Application-specific requirements are becoming more diverse. High-performance computing applications require TIMs capable of managing extreme heat fluxes exceeding 150 W/cm², while edge servers need solutions resilient to variable environmental conditions. Liquid cooling adoption is creating demand for specialized TIMs compatible with cold plates and direct-to-chip cooling solutions.

Manufacturing considerations significantly impact TIM selection. Automated assembly lines require materials compatible with pick-and-place equipment and consistent dispensing characteristics. Reworkability has become essential for high-value components, with OEMs seeking TIMs that allow processor removal without damage for repair or upgrade scenarios.

Standardization of testing methodologies has become a market imperative as performance claims vary widely between suppliers, making direct comparisons challenging. OEMs increasingly demand standardized qualification programs that accurately predict in-field performance across diverse operating conditions and extended timeframes.

Current TIM Testing Challenges and Limitations

The current landscape of Thermal Interface Material (TIM) testing for server OEMs faces significant challenges that impede standardization and reliable supplier qualification. Traditional testing methodologies often lack consistency across different testing environments, leading to discrepancies in performance evaluations. Temperature cycling tests, critical for assessing TIM reliability, frequently suffer from non-uniform heating and cooling rates, introducing variables that compromise result comparability between different testing facilities.

Material characterization presents another substantial hurdle, as existing testing protocols struggle to accurately simulate real-world server operating conditions. The dynamic thermal loads experienced in data centers—with rapid fluctuations between idle and peak processing—are particularly difficult to replicate in laboratory settings. This disconnect between testing environments and actual deployment conditions undermines the predictive value of qualification tests.

Measurement precision issues further complicate TIM evaluation. Contact resistance at material interfaces can vary significantly based on application pressure, surface roughness, and environmental factors. Current testing equipment often lacks the sensitivity to isolate these variables, resulting in performance data with wide error margins that complicate supplier comparisons and qualification decisions.

The absence of industry-wide standardized metrics represents perhaps the most fundamental limitation. Different OEMs prioritize different performance characteristics—thermal conductivity, long-term stability, pump-out resistance, or ease of application—without consensus on relative importance or standardized measurement protocols. This fragmentation forces suppliers to navigate multiple qualification frameworks, increasing costs and time-to-market.

Accelerated aging methodologies also present significant challenges. The correlation between accelerated testing results and actual field performance remains poorly established, with limited validation studies connecting laboratory predictions to real-world degradation patterns. This uncertainty undermines confidence in long-term reliability assessments critical for server deployments with expected lifespans of 5-7 years.

Cross-platform compatibility testing is increasingly important yet inadequately addressed in current protocols. As server architectures diversify—from traditional CPU-centric designs to heterogeneous systems incorporating GPUs, FPGAs, and specialized ASICs—TIM performance can vary significantly across different thermal interfaces. Current testing frameworks rarely account for these architectural variations, creating blind spots in qualification processes.

Finally, environmental sustainability considerations are becoming increasingly important but remain peripheral in most testing protocols. Assessments of TIM recyclability, environmental impact during manufacturing, and end-of-life disposal characteristics are inconsistently applied, despite growing regulatory pressure and corporate sustainability commitments.

Material characterization presents another substantial hurdle, as existing testing protocols struggle to accurately simulate real-world server operating conditions. The dynamic thermal loads experienced in data centers—with rapid fluctuations between idle and peak processing—are particularly difficult to replicate in laboratory settings. This disconnect between testing environments and actual deployment conditions undermines the predictive value of qualification tests.

Measurement precision issues further complicate TIM evaluation. Contact resistance at material interfaces can vary significantly based on application pressure, surface roughness, and environmental factors. Current testing equipment often lacks the sensitivity to isolate these variables, resulting in performance data with wide error margins that complicate supplier comparisons and qualification decisions.

The absence of industry-wide standardized metrics represents perhaps the most fundamental limitation. Different OEMs prioritize different performance characteristics—thermal conductivity, long-term stability, pump-out resistance, or ease of application—without consensus on relative importance or standardized measurement protocols. This fragmentation forces suppliers to navigate multiple qualification frameworks, increasing costs and time-to-market.

Accelerated aging methodologies also present significant challenges. The correlation between accelerated testing results and actual field performance remains poorly established, with limited validation studies connecting laboratory predictions to real-world degradation patterns. This uncertainty undermines confidence in long-term reliability assessments critical for server deployments with expected lifespans of 5-7 years.

Cross-platform compatibility testing is increasingly important yet inadequately addressed in current protocols. As server architectures diversify—from traditional CPU-centric designs to heterogeneous systems incorporating GPUs, FPGAs, and specialized ASICs—TIM performance can vary significantly across different thermal interfaces. Current testing frameworks rarely account for these architectural variations, creating blind spots in qualification processes.

Finally, environmental sustainability considerations are becoming increasingly important but remain peripheral in most testing protocols. Assessments of TIM recyclability, environmental impact during manufacturing, and end-of-life disposal characteristics are inconsistently applied, despite growing regulatory pressure and corporate sustainability commitments.

Standard TIM Qualification Test Protocols

01 Thermal conductivity testing methods for TIMs

Various methods are employed to measure the thermal conductivity of thermal interface materials, which is a critical parameter for evaluating their performance. These standardized testing approaches include steady-state and transient techniques that measure heat flow through the material under controlled conditions. The tests typically involve applying a known temperature differential across the TIM sample and measuring the resulting heat transfer, allowing for calculation of thermal conductivity values that can be used to compare different materials.- Thermal conductivity measurement methods for TIMs: Various methods are employed to measure the thermal conductivity of thermal interface materials, which is a critical parameter for evaluating their performance. These methods include steady-state techniques, transient techniques, and comparative approaches. Standardized test procedures ensure consistent and reliable measurements across different laboratories and testing conditions, allowing for accurate comparison of different TIM products.

- Reliability and aging tests for TIMs: Standardized reliability testing protocols are essential for evaluating the long-term performance of thermal interface materials under various environmental conditions. These tests include thermal cycling, humidity exposure, and accelerated aging tests to simulate real-world operating conditions. The results help predict the lifespan and performance degradation of TIMs over time, ensuring they maintain their thermal properties throughout the expected lifetime of electronic devices.

- Mechanical property testing of TIMs: Standardized tests for evaluating the mechanical properties of thermal interface materials include compression testing, adhesion strength, viscosity measurement, and phase change behavior. These tests are crucial for understanding how TIMs perform under mechanical stress and during assembly processes. The mechanical stability of TIMs directly impacts their thermal performance and reliability in electronic assemblies.

- TIM performance evaluation in semiconductor packaging: Specialized test methodologies have been developed to evaluate thermal interface materials specifically in semiconductor packaging applications. These tests assess the thermal resistance at interfaces, the ability to fill microscopic gaps, and compatibility with various substrate materials. Standardized testing in actual or simulated package environments provides more relevant performance data than generic material property tests.

- Advanced characterization techniques for TIM development: Novel analytical and characterization techniques are being incorporated into standardized test programs for thermal interface materials. These include microscopic imaging of interface contact, particle distribution analysis, and in-situ performance monitoring. Advanced characterization helps in understanding the fundamental mechanisms of heat transfer in TIMs and guides the development of next-generation materials with enhanced thermal properties.

02 Reliability and aging tests for TIMs

Standardized test programs for thermal interface materials include reliability and aging tests to evaluate long-term performance under various environmental conditions. These tests subject TIMs to thermal cycling, humidity exposure, and mechanical stress to simulate real-world operating conditions over extended periods. The tests help determine how the thermal and mechanical properties of the materials change over time, providing insights into their durability and expected service life in electronic applications.Expand Specific Solutions03 Mechanical property characterization of TIMs

Standardized testing programs for thermal interface materials include methods to characterize their mechanical properties such as compressibility, hardness, adhesion strength, and viscoelastic behavior. These tests evaluate how the material responds to applied forces and how it maintains contact between surfaces under various conditions. Mechanical property testing is crucial because TIMs must maintain good thermal contact between components while accommodating thermal expansion and mechanical stresses in electronic assemblies.Expand Specific Solutions04 Interface resistance measurement techniques

Specialized test methods are used to measure the thermal interface resistance between TIMs and adjoining surfaces, which is often a more significant factor than the bulk thermal conductivity of the material itself. These techniques evaluate how effectively the TIM fills microscopic air gaps and establishes thermal contact with mating surfaces. The tests typically involve measuring temperature differences across interfaces under controlled heat flow conditions, allowing for quantification of the contact resistance that impacts overall thermal performance in electronic assemblies.Expand Specific Solutions05 In-situ performance testing of TIMs in electronic assemblies

Standardized test programs include methods for evaluating TIM performance in actual electronic assemblies or simulated application environments. These tests measure thermal performance under realistic operating conditions, including power cycling, varying heat loads, and different mounting pressures. The testing may involve thermal imaging, embedded temperature sensors, or specialized test vehicles that replicate real-world electronic packages. This approach provides data on how TIMs perform in their intended applications rather than just in isolated laboratory conditions.Expand Specific Solutions

Leading Server OEMs and TIM Suppliers Landscape

The TIM for Server OEMs standardization program is emerging in a rapidly evolving market characterized by moderate technological maturity but significant growth potential. The server qualification testing landscape is transitioning from fragmented approaches to standardized methodologies, with the market expected to expand as data center infrastructure demands increase globally. Key players demonstrate varying levels of technological readiness: IBM and Inspur lead with comprehensive testing frameworks, while Hon Hai/Foxconn and Lenovo have established robust supplier qualification systems. Taiwan Semiconductor and Broadcom (via Avago) are advancing component-level testing protocols, with UL LLC providing third-party certification expertise. This standardization effort represents a critical development for improving server reliability and performance across the industry ecosystem.

Suzhou Inspur Intelligent Technology Co., Ltd.

Technical Solution: Inspur has developed a comprehensive TIM (Thermal Interface Material) qualification program specifically designed for server OEMs. Their standardized test methodology includes thermal resistance measurement under various pressure conditions, reliability testing through thermal cycling (-40°C to 125°C), and long-term performance evaluation. The program incorporates automated testing equipment that can simultaneously evaluate multiple TIM samples, ensuring consistent results across different manufacturing batches. Inspur's approach includes a detailed material characterization phase that analyzes viscosity, thermal conductivity, and phase change properties, followed by application-specific testing that simulates actual server operating conditions with controlled heat loads up to 350W.

Strengths: Extensive server manufacturing experience provides practical insights into real-world TIM requirements; comprehensive testing infrastructure allows for rapid qualification of multiple suppliers. Weaknesses: Testing standards may be optimized primarily for their own server designs, potentially limiting applicability to other OEM architectures.

International Business Machines Corp.

Technical Solution: IBM has implemented an advanced TIM qualification framework called "TIM-QT" (Thermal Interface Material Qualification Testing) specifically designed for enterprise server environments. This standardized program evaluates TIMs across multiple parameters including thermal performance, reliability, and manufacturing compatibility. IBM's approach incorporates accelerated aging tests that simulate 5-7 years of operational conditions within a compressed timeframe, utilizing environmental chambers that cycle between extreme temperatures while monitoring thermal performance degradation. Their methodology includes specialized testing for pump-out effects under power cycling, bond-line thickness optimization, and surface wetting characteristics. IBM has also developed proprietary testing fixtures that accurately replicate the mechanical constraints and pressure distributions found in actual server assemblies, ensuring that qualified materials perform consistently in production environments.

Strengths: Industry-leading research capabilities with decades of server thermal management expertise; qualification program incorporates both laboratory and production-line validation phases. Weaknesses: Testing protocols may be overly rigorous for some applications, potentially eliminating viable lower-cost TIM options that could be sufficient for less demanding server configurations.

Critical TIM Performance Parameters and Measurement Techniques

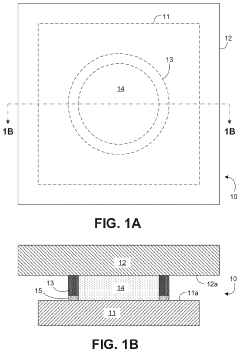

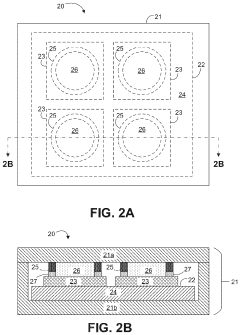

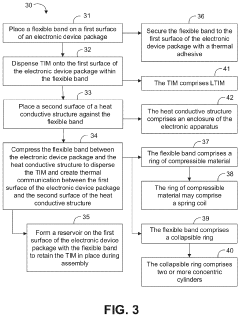

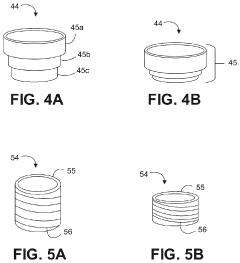

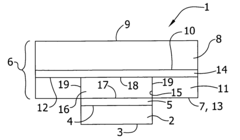

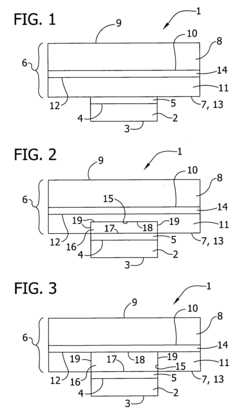

Flexible retention ring for thermal interface material

PatentActiveUS11844197B2

Innovation

- A flexible retention ring, made of compressible or collapsible materials like concentric cylinders or spring coils, is placed on top of electronic components to contain LTIM, adjusting to the gap between the component and the SSD enclosure, ensuring proper thermal contact and minimizing application issues.

Thermal interface material and solder preforms

PatentInactiveUS20040200879A1

Innovation

- A high-performance TIM comprising a solder component with a thermal conductivity enhancement component and a CTE modifying component, along with an intrinsic oxygen getter, which allows for effective heat transfer and reduced thermal stress without the need for extrinsic fluxing, enabling bonding to both metallic and non-metallic surfaces.

Compliance and Certification Framework for TIM Suppliers

The development of a robust compliance and certification framework is essential for ensuring that Thermal Interface Materials (TIMs) meet the stringent requirements of server environments. This framework establishes standardized protocols for supplier qualification, ensuring consistency and reliability across the industry.

A comprehensive TIM certification framework typically consists of multiple tiers, ranging from basic compliance verification to advanced performance validation. Tier 1 focuses on fundamental material properties and safety standards, including RoHS and REACH compliance, ensuring that TIMs do not contain restricted substances. Tier 2 addresses thermal performance metrics, with standardized testing procedures for thermal conductivity, thermal resistance, and long-term stability under various operating conditions.

Third-party certification plays a crucial role in maintaining objectivity and credibility within the framework. Independent laboratories accredited by organizations such as ISO/IEC 17025 provide unbiased verification of supplier claims and ensure adherence to testing protocols. This approach eliminates potential conflicts of interest and establishes a level playing field for all suppliers.

Documentation requirements form another critical component of the framework, with suppliers expected to provide comprehensive technical datasheets, material safety information, and detailed manufacturing process documentation. Traceability mechanisms must be implemented to track materials from raw components to finished products, facilitating quality control and issue resolution.

Regular audit schedules are established to verify ongoing compliance, with major recertification typically required every 12-24 months and spot checks conducted quarterly. These audits examine both documentation and physical samples to ensure continued adherence to standards.

The certification framework also incorporates performance-based categorization, classifying TIMs into distinct performance tiers based on thermal conductivity ranges, operating temperature limits, and reliability metrics. This classification system enables server OEMs to quickly identify materials suitable for specific applications, from standard enterprise servers to high-performance computing environments.

Continuous improvement mechanisms are embedded within the framework, with feedback loops between OEMs, suppliers, and certification bodies driving regular updates to testing methodologies and performance thresholds. This ensures that certification standards evolve alongside advancements in TIM technology and changing server thermal management requirements.

A comprehensive TIM certification framework typically consists of multiple tiers, ranging from basic compliance verification to advanced performance validation. Tier 1 focuses on fundamental material properties and safety standards, including RoHS and REACH compliance, ensuring that TIMs do not contain restricted substances. Tier 2 addresses thermal performance metrics, with standardized testing procedures for thermal conductivity, thermal resistance, and long-term stability under various operating conditions.

Third-party certification plays a crucial role in maintaining objectivity and credibility within the framework. Independent laboratories accredited by organizations such as ISO/IEC 17025 provide unbiased verification of supplier claims and ensure adherence to testing protocols. This approach eliminates potential conflicts of interest and establishes a level playing field for all suppliers.

Documentation requirements form another critical component of the framework, with suppliers expected to provide comprehensive technical datasheets, material safety information, and detailed manufacturing process documentation. Traceability mechanisms must be implemented to track materials from raw components to finished products, facilitating quality control and issue resolution.

Regular audit schedules are established to verify ongoing compliance, with major recertification typically required every 12-24 months and spot checks conducted quarterly. These audits examine both documentation and physical samples to ensure continued adherence to standards.

The certification framework also incorporates performance-based categorization, classifying TIMs into distinct performance tiers based on thermal conductivity ranges, operating temperature limits, and reliability metrics. This classification system enables server OEMs to quickly identify materials suitable for specific applications, from standard enterprise servers to high-performance computing environments.

Continuous improvement mechanisms are embedded within the framework, with feedback loops between OEMs, suppliers, and certification bodies driving regular updates to testing methodologies and performance thresholds. This ensures that certification standards evolve alongside advancements in TIM technology and changing server thermal management requirements.

Cost-Benefit Analysis of Standardized TIM Testing

Implementing a standardized TIM (Thermal Interface Material) testing program for server OEMs requires significant initial investment but offers substantial long-term financial benefits. The upfront costs include development of testing protocols, acquisition of specialized equipment, training of personnel, and establishment of laboratory facilities. For a mid-sized server OEM, these initial investments typically range from $250,000 to $500,000, with annual maintenance costs between $75,000 and $150,000.

However, these costs must be weighed against the considerable financial benefits. Standardized testing reduces supplier qualification time by approximately 40-60%, translating to faster time-to-market for new server products. This acceleration can provide competitive advantages worth millions in early market capture, particularly in the fast-evolving server industry.

Quality assurance improvements represent another significant benefit. Standardized TIM testing reduces thermal-related server failures by an estimated 15-25%, resulting in warranty cost savings of $300,000 to $700,000 annually for a typical server product line. Additionally, the enhanced reliability improves customer satisfaction and brand reputation, which, while difficult to quantify precisely, contributes to customer retention and premium pricing opportunities.

Operational efficiencies gained through standardization further enhance the cost-benefit equation. By eliminating redundant testing across different supplier qualification processes, companies typically realize labor savings of 20-30% in their thermal engineering departments. The standardized approach also enables more effective supplier negotiations, with documented cases showing 5-15% cost reductions in TIM procurement through improved specification clarity and competitive supplier selection.

Risk mitigation represents a critical but often undervalued benefit. Standardized testing significantly reduces the likelihood of large-scale thermal failures in deployed server fleets. Given that a major thermal design flaw can cost upwards of $10 million in recalls and remediation, the risk-adjusted value of this prevention is substantial, even when accounting for the low probability of such catastrophic events.

The return on investment timeline indicates that most server OEMs achieve break-even on their standardized TIM testing programs within 18-24 months, with accelerating returns thereafter as efficiency gains compound and risk avoidance benefits accumulate. This favorable ROI makes standardized TIM testing a financially sound strategic investment for server manufacturers operating in competitive markets where thermal performance is a critical differentiator.

However, these costs must be weighed against the considerable financial benefits. Standardized testing reduces supplier qualification time by approximately 40-60%, translating to faster time-to-market for new server products. This acceleration can provide competitive advantages worth millions in early market capture, particularly in the fast-evolving server industry.

Quality assurance improvements represent another significant benefit. Standardized TIM testing reduces thermal-related server failures by an estimated 15-25%, resulting in warranty cost savings of $300,000 to $700,000 annually for a typical server product line. Additionally, the enhanced reliability improves customer satisfaction and brand reputation, which, while difficult to quantify precisely, contributes to customer retention and premium pricing opportunities.

Operational efficiencies gained through standardization further enhance the cost-benefit equation. By eliminating redundant testing across different supplier qualification processes, companies typically realize labor savings of 20-30% in their thermal engineering departments. The standardized approach also enables more effective supplier negotiations, with documented cases showing 5-15% cost reductions in TIM procurement through improved specification clarity and competitive supplier selection.

Risk mitigation represents a critical but often undervalued benefit. Standardized testing significantly reduces the likelihood of large-scale thermal failures in deployed server fleets. Given that a major thermal design flaw can cost upwards of $10 million in recalls and remediation, the risk-adjusted value of this prevention is substantial, even when accounting for the low probability of such catastrophic events.

The return on investment timeline indicates that most server OEMs achieve break-even on their standardized TIM testing programs within 18-24 months, with accelerating returns thereafter as efficiency gains compound and risk avoidance benefits accumulate. This favorable ROI makes standardized TIM testing a financially sound strategic investment for server manufacturers operating in competitive markets where thermal performance is a critical differentiator.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!