TIM Cost-Per-Unit-Of-Heat-Removed: A Practical ROI Calculator (Excel)

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Thermal Management Background and Objectives

Thermal Interface Materials (TIMs) have evolved significantly over the past decades as electronic devices have become more powerful and compact, creating unprecedented thermal management challenges. The fundamental purpose of TIMs is to fill microscopic air gaps between heat-generating components and heat dissipation systems, thereby enhancing thermal conductivity and improving overall heat transfer efficiency. This technology has progressed from basic thermal greases to advanced materials including phase change materials, thermal pads, liquid metal compounds, and carbon-based solutions such as graphene and carbon nanotubes.

The evolution of TIMs has been primarily driven by the exponential increase in power density within modern electronic devices, particularly in high-performance computing, telecommunications, automotive electronics, and consumer electronics sectors. As transistor density continues to increase according to Moore's Law, the heat generated per unit area has risen dramatically, making efficient thermal management a critical factor in system reliability and performance.

Current industry trends indicate a growing demand for TIMs with higher thermal conductivity, lower thermal resistance, improved long-term reliability, and enhanced environmental sustainability. The market is witnessing a shift toward materials that can maintain performance under extreme operating conditions while meeting increasingly stringent regulatory requirements regarding hazardous substances and end-of-life recyclability.

The primary objective of the "TIM Cost-Per-Unit-Of-Heat-Removed" calculator is to provide a standardized, quantitative approach to evaluating the return on investment (ROI) of various thermal interface materials. This tool aims to bridge the gap between technical performance metrics and financial decision-making by translating thermal efficiency into tangible cost implications.

By analyzing parameters such as thermal conductivity, bond line thickness, application area, material cost, application cost, and expected lifetime, the calculator enables engineers and procurement specialists to make data-driven decisions that optimize both thermal performance and cost-effectiveness. This approach moves beyond the traditional focus on material cost alone to consider the total cost of ownership throughout the product lifecycle.

The calculator also addresses the industry's need for comparative analysis tools that can account for the increasingly complex trade-offs between different TIM solutions. As the market diversifies with specialized materials for specific applications, decision-makers require sophisticated methods to evaluate options based on their unique requirements and constraints.

Looking forward, the technology roadmap for TIMs indicates continued research into novel materials and composites that can achieve thermal conductivity values approaching those of bulk metals while maintaining the conformability and ease of application characteristic of traditional interface materials. The development of this ROI calculator represents an important step in quantifying the value proposition of these emerging technologies.

The evolution of TIMs has been primarily driven by the exponential increase in power density within modern electronic devices, particularly in high-performance computing, telecommunications, automotive electronics, and consumer electronics sectors. As transistor density continues to increase according to Moore's Law, the heat generated per unit area has risen dramatically, making efficient thermal management a critical factor in system reliability and performance.

Current industry trends indicate a growing demand for TIMs with higher thermal conductivity, lower thermal resistance, improved long-term reliability, and enhanced environmental sustainability. The market is witnessing a shift toward materials that can maintain performance under extreme operating conditions while meeting increasingly stringent regulatory requirements regarding hazardous substances and end-of-life recyclability.

The primary objective of the "TIM Cost-Per-Unit-Of-Heat-Removed" calculator is to provide a standardized, quantitative approach to evaluating the return on investment (ROI) of various thermal interface materials. This tool aims to bridge the gap between technical performance metrics and financial decision-making by translating thermal efficiency into tangible cost implications.

By analyzing parameters such as thermal conductivity, bond line thickness, application area, material cost, application cost, and expected lifetime, the calculator enables engineers and procurement specialists to make data-driven decisions that optimize both thermal performance and cost-effectiveness. This approach moves beyond the traditional focus on material cost alone to consider the total cost of ownership throughout the product lifecycle.

The calculator also addresses the industry's need for comparative analysis tools that can account for the increasingly complex trade-offs between different TIM solutions. As the market diversifies with specialized materials for specific applications, decision-makers require sophisticated methods to evaluate options based on their unique requirements and constraints.

Looking forward, the technology roadmap for TIMs indicates continued research into novel materials and composites that can achieve thermal conductivity values approaching those of bulk metals while maintaining the conformability and ease of application characteristic of traditional interface materials. The development of this ROI calculator represents an important step in quantifying the value proposition of these emerging technologies.

Market Analysis for Thermal Interface Materials

The thermal interface materials (TIM) market has experienced significant growth in recent years, driven primarily by increasing demand for efficient heat management solutions across various industries. The global TIM market was valued at approximately $2.5 billion in 2021 and is projected to reach $4.8 billion by 2027, growing at a CAGR of around 11.4% during the forecast period.

Electronics and semiconductor industries represent the largest application segments, accounting for over 60% of the total market share. This dominance is attributed to the continuous miniaturization of electronic components and increasing power densities, which necessitate more effective thermal management solutions. The automotive sector follows as the second-largest consumer of TIMs, particularly with the rapid expansion of electric vehicles that require sophisticated battery thermal management systems.

Regionally, Asia-Pacific dominates the TIM market, holding approximately 45% of the global share, primarily due to the concentration of electronics manufacturing facilities in countries like China, Taiwan, South Korea, and Japan. North America and Europe follow with market shares of approximately 25% and 20% respectively, driven by advanced technological applications and research activities.

The market segmentation by material type reveals that thermal greases and adhesives currently lead with about 35% market share, followed by thermal pads and gap fillers at 28%, phase change materials at 20%, and metal-based TIMs at 17%. However, the fastest growth is observed in phase change materials and graphene-based solutions due to their superior thermal conductivity properties.

End-user analysis indicates that consumer electronics manufacturers constitute the largest customer segment (38%), followed by telecommunications equipment producers (22%), automotive manufacturers (18%), industrial equipment makers (12%), and others (10%). The increasing adoption of 5G technology, IoT devices, and high-performance computing systems is expected to further accelerate demand across these sectors.

Price sensitivity varies significantly across different market segments. While consumer electronics manufacturers often prioritize cost-effectiveness, high-performance computing and aerospace applications typically focus on thermal efficiency regardless of cost. This market dynamic underscores the importance of tools like the "TIM Cost-Per-Unit-Of-Heat-Removed Calculator," which enables customers to make informed decisions based on both performance and economic considerations, ultimately optimizing their return on investment in thermal management solutions.

Electronics and semiconductor industries represent the largest application segments, accounting for over 60% of the total market share. This dominance is attributed to the continuous miniaturization of electronic components and increasing power densities, which necessitate more effective thermal management solutions. The automotive sector follows as the second-largest consumer of TIMs, particularly with the rapid expansion of electric vehicles that require sophisticated battery thermal management systems.

Regionally, Asia-Pacific dominates the TIM market, holding approximately 45% of the global share, primarily due to the concentration of electronics manufacturing facilities in countries like China, Taiwan, South Korea, and Japan. North America and Europe follow with market shares of approximately 25% and 20% respectively, driven by advanced technological applications and research activities.

The market segmentation by material type reveals that thermal greases and adhesives currently lead with about 35% market share, followed by thermal pads and gap fillers at 28%, phase change materials at 20%, and metal-based TIMs at 17%. However, the fastest growth is observed in phase change materials and graphene-based solutions due to their superior thermal conductivity properties.

End-user analysis indicates that consumer electronics manufacturers constitute the largest customer segment (38%), followed by telecommunications equipment producers (22%), automotive manufacturers (18%), industrial equipment makers (12%), and others (10%). The increasing adoption of 5G technology, IoT devices, and high-performance computing systems is expected to further accelerate demand across these sectors.

Price sensitivity varies significantly across different market segments. While consumer electronics manufacturers often prioritize cost-effectiveness, high-performance computing and aerospace applications typically focus on thermal efficiency regardless of cost. This market dynamic underscores the importance of tools like the "TIM Cost-Per-Unit-Of-Heat-Removed Calculator," which enables customers to make informed decisions based on both performance and economic considerations, ultimately optimizing their return on investment in thermal management solutions.

Current TIM Technology Limitations and Challenges

Despite the promising advancements in Thermal Interface Materials (TIMs), several significant limitations and challenges persist in current technologies that impact their cost-effectiveness and thermal performance. The primary challenge remains the thermal resistance at material interfaces, where even the most advanced TIMs struggle to achieve perfect contact due to microscopic surface irregularities. This imperfect contact creates air gaps that significantly reduce heat transfer efficiency, resulting in higher operational temperatures and increased cooling costs.

Material degradation presents another critical challenge, as many TIMs experience performance deterioration over time due to thermal cycling, mechanical stress, and environmental factors. This degradation necessitates more frequent replacement cycles, increasing the total cost of ownership and reducing the return on investment for cooling solutions. The pump-out effect, where TIM material migrates away from the thermal interface during thermal cycling, further exacerbates this issue.

Application consistency poses a significant practical challenge in manufacturing environments. Variations in application thickness, coverage, and pressure can lead to inconsistent thermal performance across identical systems. This inconsistency makes it difficult to accurately predict cooling performance and calculate precise cost-per-unit-of-heat-removed metrics, complicating ROI calculations for cooling investments.

The trade-off between thermal conductivity and other desirable properties represents another fundamental limitation. Materials with excellent thermal conductivity often exhibit poor mechanical properties, electrical insulation characteristics, or long-term stability. This forces engineers to compromise between optimal thermal performance and other essential requirements, potentially increasing costs or reducing efficiency.

Environmental and regulatory concerns are increasingly constraining TIM selection. Many traditional high-performance TIMs contain environmentally harmful substances facing regulatory restrictions. The transition to more environmentally friendly alternatives often comes with performance penalties or higher costs, further complicating the ROI equation.

Cost scalability remains problematic, particularly for high-volume applications. Premium TIMs with superior thermal performance typically come with significantly higher costs that don't scale linearly with performance improvements. This non-linear cost-to-performance ratio makes it challenging to justify investments in premium materials, especially when calculating cost-per-unit-of-heat-removed metrics.

Finally, the lack of standardized testing methodologies for real-world performance creates uncertainty in ROI calculations. Laboratory measurements often fail to accurately predict field performance under variable conditions, leading to discrepancies between expected and actual thermal management costs. This uncertainty complicates investment decisions and highlights the need for practical ROI calculators that account for these real-world variables.

Material degradation presents another critical challenge, as many TIMs experience performance deterioration over time due to thermal cycling, mechanical stress, and environmental factors. This degradation necessitates more frequent replacement cycles, increasing the total cost of ownership and reducing the return on investment for cooling solutions. The pump-out effect, where TIM material migrates away from the thermal interface during thermal cycling, further exacerbates this issue.

Application consistency poses a significant practical challenge in manufacturing environments. Variations in application thickness, coverage, and pressure can lead to inconsistent thermal performance across identical systems. This inconsistency makes it difficult to accurately predict cooling performance and calculate precise cost-per-unit-of-heat-removed metrics, complicating ROI calculations for cooling investments.

The trade-off between thermal conductivity and other desirable properties represents another fundamental limitation. Materials with excellent thermal conductivity often exhibit poor mechanical properties, electrical insulation characteristics, or long-term stability. This forces engineers to compromise between optimal thermal performance and other essential requirements, potentially increasing costs or reducing efficiency.

Environmental and regulatory concerns are increasingly constraining TIM selection. Many traditional high-performance TIMs contain environmentally harmful substances facing regulatory restrictions. The transition to more environmentally friendly alternatives often comes with performance penalties or higher costs, further complicating the ROI equation.

Cost scalability remains problematic, particularly for high-volume applications. Premium TIMs with superior thermal performance typically come with significantly higher costs that don't scale linearly with performance improvements. This non-linear cost-to-performance ratio makes it challenging to justify investments in premium materials, especially when calculating cost-per-unit-of-heat-removed metrics.

Finally, the lack of standardized testing methodologies for real-world performance creates uncertainty in ROI calculations. Laboratory measurements often fail to accurately predict field performance under variable conditions, leading to discrepancies between expected and actual thermal management costs. This uncertainty complicates investment decisions and highlights the need for practical ROI calculators that account for these real-world variables.

ROI Calculator Methodology and Implementation

01 Cost-effective thermal interface material formulations

Various formulations of thermal interface materials (TIMs) can be developed to optimize the cost-per-unit-of-heat-removed. These formulations may include composite materials with enhanced thermal conductivity properties while maintaining cost efficiency. By carefully selecting materials and their proportions, manufacturers can create TIMs that provide optimal heat transfer capabilities at competitive price points, improving the return on investment for cooling solutions in electronic devices.- Cost-effective thermal interface materials for heat management: Various thermal interface materials (TIMs) can be formulated to optimize cost-effectiveness in heat removal applications. These materials are designed to maximize thermal conductivity while minimizing production costs, resulting in better return on investment (ROI). The cost-per-unit-of-heat-removed calculation helps in selecting the most economical TIM solution for specific thermal management requirements in electronic devices and systems.

- ROI calculation methods for thermal interface materials: Methods for calculating return on investment (ROI) for thermal interface materials involve analyzing the cost-per-unit-of-heat-removed. These calculation methods consider factors such as material costs, application costs, thermal performance, and lifespan of the TIM. By quantifying the thermal efficiency in relation to cost, these methods help engineers and manufacturers make data-driven decisions when selecting thermal management solutions for electronic components.

- Advanced TIM formulations for improved thermal performance: Advanced formulations of thermal interface materials incorporate novel components such as nanoparticles, phase change materials, and specialized polymers to enhance thermal conductivity. These formulations are designed to improve heat transfer efficiency, resulting in better cost-per-unit-of-heat-removed metrics. The enhanced thermal performance leads to better ROI by extending the lifespan of electronic components and reducing cooling system requirements.

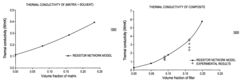

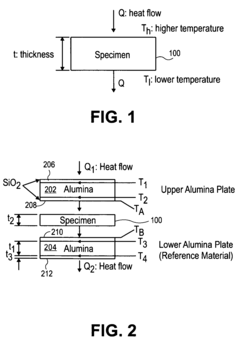

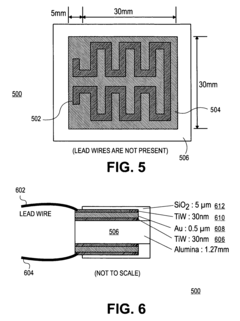

- Testing and measurement systems for TIM performance evaluation: Specialized testing and measurement systems are developed to accurately evaluate the thermal performance of interface materials. These systems quantify heat transfer efficiency, thermal resistance, and long-term reliability of TIMs under various operating conditions. The data obtained from these measurements enables precise calculation of cost-per-unit-of-heat-removed metrics, supporting ROI analysis for different thermal management solutions.

- Application-specific TIM solutions for optimized ROI: Thermal interface materials can be customized for specific applications to optimize return on investment. These application-specific solutions consider factors such as operating temperature range, power density, space constraints, and environmental conditions. By tailoring TIM properties to match specific requirements, manufacturers can achieve optimal cost-per-unit-of-heat-removed metrics for diverse applications ranging from consumer electronics to industrial equipment and automotive systems.

02 ROI calculation methods for thermal management systems

Methods for calculating return on investment (ROI) for thermal interface materials focus on measuring the cost-per-unit-of-heat-removed. These calculation methods consider factors such as material costs, application costs, lifespan of the TIM, thermal performance metrics, and energy savings achieved through improved heat dissipation. By quantifying these factors, engineers can make data-driven decisions about which thermal management solutions provide the best economic value while meeting technical requirements.Expand Specific Solutions03 Testing and performance evaluation of TIMs

Standardized testing methods are essential for accurately evaluating the performance and cost-effectiveness of thermal interface materials. These testing protocols measure thermal resistance, conductivity, and long-term reliability under various operating conditions. Advanced testing equipment and methodologies enable precise measurement of heat transfer capabilities, allowing for accurate calculation of cost-per-unit-of-heat-removed metrics and facilitating meaningful comparisons between different TIM solutions.Expand Specific Solutions04 Application-specific TIM optimization

Thermal interface materials can be optimized for specific applications to maximize ROI and heat removal efficiency. Different electronic components and systems have varying thermal management requirements based on power density, operating temperatures, and space constraints. By tailoring TIM formulations and application methods to specific use cases such as CPUs, GPUs, power electronics, or LED lighting, manufacturers can achieve optimal cost-per-unit-of-heat-removed for each application scenario.Expand Specific Solutions05 Manufacturing processes affecting TIM cost-efficiency

Manufacturing processes significantly impact the cost-efficiency of thermal interface materials. Innovations in production techniques, such as automated dispensing, screen printing, or novel curing methods, can reduce manufacturing costs while maintaining or improving thermal performance. Additionally, scalable manufacturing processes enable economies of scale, further reducing the cost-per-unit-of-heat-removed. Process optimization also contributes to consistent quality and performance, ensuring reliable thermal management solutions.Expand Specific Solutions

Leading TIM Manufacturers and Market Competition

The thermal interface material (TIM) cost-per-unit-of-heat-removed market is currently in a growth phase, driven by increasing demand for efficient thermal management solutions in electronics and power systems. The global market size is estimated to exceed $3 billion, expanding at a CAGR of 8-10% due to rising thermal challenges in miniaturized electronics. Technology maturity varies across players, with industry leaders like Huawei Technologies, IBM, and Lam Research demonstrating advanced capabilities through patented solutions and comprehensive ROI calculators. Companies including Resonac Corp, Hon Hai Precision, and Yokogawa Electric are developing specialized TIM applications for industrial electronics, while academic institutions such as Zhejiang University and Southeast University contribute significant research advancements in novel thermal interface materials and cost-optimization methodologies.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a sophisticated TIM cost-effectiveness calculator specifically optimized for data center and telecommunications equipment applications. Their Excel-based tool incorporates detailed thermal modeling that accounts for the unique cooling challenges in high-density server environments. The calculator features a comprehensive database of TIM materials with their thermal conductivity values, application characteristics, and cost structures. Huawei's approach emphasizes total cost of ownership, factoring in not only material costs but also energy consumption, maintenance requirements, and system reliability impacts. The tool includes scenario modeling capabilities that allow users to evaluate different cooling strategies under varying workload conditions and ambient temperatures. Particularly notable is the calculator's ability to model the impact of TIM selection on server lifespan and reliability, translating thermal performance into tangible business metrics like downtime risk and hardware replacement costs.

Strengths: Specifically optimized for data center and telecommunications applications; strong focus on reliability and system longevity; integration with broader data center management strategies. Weaknesses: May be less applicable to non-IT cooling applications; potentially optimized primarily for Huawei hardware; requires detailed input parameters for maximum accuracy.

International Business Machines Corp.

Technical Solution: IBM has developed a comprehensive Thermal Interface Material (TIM) cost-effectiveness calculator that evaluates the return on investment for different cooling solutions. Their approach incorporates a holistic view of data center thermal management, considering not just the immediate cost of TIMs but the total cost of ownership. IBM's calculator factors in parameters such as thermal conductivity, bond line thickness, contact resistance, application method, and material degradation over time. The system uses advanced algorithms to predict heat dissipation efficiency and calculates cost-per-unit-of-heat-removed metrics that help data center operators make informed decisions. IBM's solution also incorporates machine learning capabilities that analyze historical performance data to optimize TIM selection based on specific server configurations and workload patterns.

Strengths: Comprehensive approach that considers total cost of ownership rather than just material costs; integration with IBM's broader data center management solutions; sophisticated predictive modeling capabilities. Weaknesses: May be optimized primarily for IBM hardware; potentially complex implementation requiring specialized knowledge; higher initial investment compared to simpler calculation methods.

Key Thermal Performance Metrics and Calculations

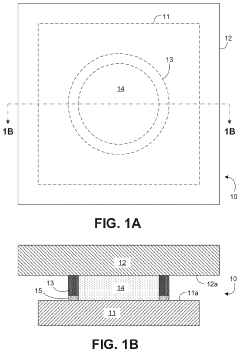

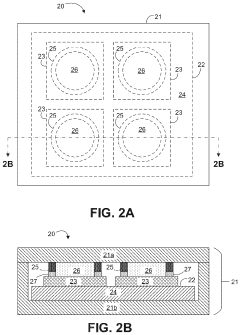

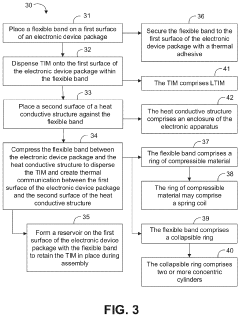

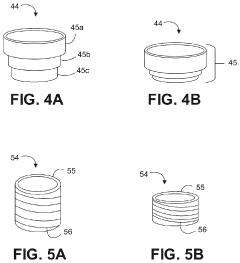

Flexible retention ring for thermal interface material

PatentActiveUS11844197B2

Innovation

- A flexible retention ring, made of compressible or collapsible materials like concentric cylinders or spring coils, is placed on top of electronic components to contain LTIM, adjusting to the gap between the component and the SSD enclosure, ensuring proper thermal contact and minimizing application issues.

Method of making thermal interface material (TIM) with carbon nanotubes (CNT)

PatentInactiveUS7387747B2

Innovation

- The use of carbon nanotubes as thermally conductive fillers in a silicone thermal grease matrix, with chloroform as a solvent, to create a thermal interface material that enhances thermal conductivity and reduces thickness, combined with a resistor network model for accurate thermal property measurement.

Economic Impact Analysis of TIM Selection

The economic implications of thermal interface material (TIM) selection extend far beyond the initial purchase price. When evaluating TIMs, organizations must consider the total cost of ownership, which encompasses installation costs, maintenance requirements, replacement frequency, and most critically, thermal performance efficiency.

The "Cost-Per-Unit-Of-Heat-Removed" calculator provides a standardized methodology for comparing the true economic value of different TIM solutions. This metric divides the total lifecycle cost of a TIM by its thermal performance capability, yielding a figure that represents the investment required to achieve a specific level of heat dissipation.

For enterprise applications, particularly in data centers and high-performance computing environments, the economic impact of TIM selection manifests in several critical areas. Power consumption for cooling systems represents a significant operational expense, often accounting for 30-40% of data center energy costs. A high-performance TIM that reduces thermal resistance by even 10% can translate to measurable reductions in cooling requirements and associated energy expenditures.

Equipment lifespan extension represents another substantial economic benefit. Electronic components operating at lower temperatures typically experience fewer failures and longer operational lives. Research indicates that every 10°C reduction in operating temperature can potentially double the lifespan of semiconductor devices, creating significant deferred replacement costs and reduced downtime.

Maintenance cost reduction must also factor into the economic analysis. TIMs with longer service lives and stable performance characteristics require less frequent replacement, reducing both material costs and labor expenses associated with maintenance operations. The calculator quantifies these savings by incorporating replacement frequency into the total cost model.

Performance optimization yields perhaps the most significant economic impact. In applications where thermal constraints limit computational performance, superior TIMs can enable higher clock speeds, greater processing density, or more consistent performance under load. This translates directly to improved productivity, enhanced service delivery, or increased computational capacity without additional hardware investments.

The ROI calculator enables decision-makers to input organization-specific variables including energy costs, maintenance labor rates, equipment value, and performance requirements to generate customized economic impact projections. This allows for data-driven selection processes that align with specific organizational priorities and constraints rather than defaulting to the lowest initial purchase price option.

The "Cost-Per-Unit-Of-Heat-Removed" calculator provides a standardized methodology for comparing the true economic value of different TIM solutions. This metric divides the total lifecycle cost of a TIM by its thermal performance capability, yielding a figure that represents the investment required to achieve a specific level of heat dissipation.

For enterprise applications, particularly in data centers and high-performance computing environments, the economic impact of TIM selection manifests in several critical areas. Power consumption for cooling systems represents a significant operational expense, often accounting for 30-40% of data center energy costs. A high-performance TIM that reduces thermal resistance by even 10% can translate to measurable reductions in cooling requirements and associated energy expenditures.

Equipment lifespan extension represents another substantial economic benefit. Electronic components operating at lower temperatures typically experience fewer failures and longer operational lives. Research indicates that every 10°C reduction in operating temperature can potentially double the lifespan of semiconductor devices, creating significant deferred replacement costs and reduced downtime.

Maintenance cost reduction must also factor into the economic analysis. TIMs with longer service lives and stable performance characteristics require less frequent replacement, reducing both material costs and labor expenses associated with maintenance operations. The calculator quantifies these savings by incorporating replacement frequency into the total cost model.

Performance optimization yields perhaps the most significant economic impact. In applications where thermal constraints limit computational performance, superior TIMs can enable higher clock speeds, greater processing density, or more consistent performance under load. This translates directly to improved productivity, enhanced service delivery, or increased computational capacity without additional hardware investments.

The ROI calculator enables decision-makers to input organization-specific variables including energy costs, maintenance labor rates, equipment value, and performance requirements to generate customized economic impact projections. This allows for data-driven selection processes that align with specific organizational priorities and constraints rather than defaulting to the lowest initial purchase price option.

Sustainability Considerations in Thermal Solutions

The environmental impact of thermal management solutions has become increasingly significant as organizations worldwide commit to sustainability goals. When evaluating thermal interface materials (TIMs) through cost-per-unit-of-heat-removed calculations, sustainability considerations must be integrated into the decision-making process to ensure a comprehensive assessment of long-term value.

Energy efficiency represents a primary sustainability factor in thermal solutions. TIMs that enable more efficient heat transfer directly contribute to reduced energy consumption in cooling systems. The Excel calculator can be enhanced to quantify these energy savings over the product lifecycle, translating thermal performance into carbon footprint reduction metrics and potential energy cost savings.

Material composition and environmental impact of TIMs warrant careful examination. Some thermal materials contain environmentally harmful substances or require energy-intensive manufacturing processes. The calculator should incorporate fields for evaluating the environmental footprint of different TIM options, including recyclability, biodegradability, and compliance with regulations such as RoHS and REACH.

Longevity and durability of thermal solutions significantly impact sustainability. TIMs that maintain performance over extended periods reduce replacement frequency and associated waste. The ROI calculator can be modified to account for the environmental costs of manufacturing, transportation, installation, and disposal across multiple replacement cycles, providing a more accurate total environmental cost assessment.

Circular economy principles should be reflected in thermal solution evaluations. The calculator could include metrics for end-of-life considerations, such as ease of disassembly, potential for material recovery, and reuse capabilities. These factors become increasingly important as regulations around electronic waste management become more stringent globally.

Water usage in manufacturing and operational phases represents another critical sustainability dimension. Certain cooling solutions may require significant water resources, particularly in data center applications. The calculator could incorporate water footprint analysis to provide a more comprehensive view of resource utilization.

Carbon pricing mechanisms and environmental regulations are evolving rapidly across different markets. The ROI calculator should include functionality to model potential carbon tax implications and regulatory compliance costs, allowing organizations to future-proof their thermal management strategies against evolving environmental policies.

By integrating these sustainability considerations into the TIM Cost-Per-Unit-Of-Heat-Removed calculator, organizations can make more holistic decisions that align financial objectives with environmental responsibility, ultimately driving innovation toward more sustainable thermal management solutions.

Energy efficiency represents a primary sustainability factor in thermal solutions. TIMs that enable more efficient heat transfer directly contribute to reduced energy consumption in cooling systems. The Excel calculator can be enhanced to quantify these energy savings over the product lifecycle, translating thermal performance into carbon footprint reduction metrics and potential energy cost savings.

Material composition and environmental impact of TIMs warrant careful examination. Some thermal materials contain environmentally harmful substances or require energy-intensive manufacturing processes. The calculator should incorporate fields for evaluating the environmental footprint of different TIM options, including recyclability, biodegradability, and compliance with regulations such as RoHS and REACH.

Longevity and durability of thermal solutions significantly impact sustainability. TIMs that maintain performance over extended periods reduce replacement frequency and associated waste. The ROI calculator can be modified to account for the environmental costs of manufacturing, transportation, installation, and disposal across multiple replacement cycles, providing a more accurate total environmental cost assessment.

Circular economy principles should be reflected in thermal solution evaluations. The calculator could include metrics for end-of-life considerations, such as ease of disassembly, potential for material recovery, and reuse capabilities. These factors become increasingly important as regulations around electronic waste management become more stringent globally.

Water usage in manufacturing and operational phases represents another critical sustainability dimension. Certain cooling solutions may require significant water resources, particularly in data center applications. The calculator could incorporate water footprint analysis to provide a more comprehensive view of resource utilization.

Carbon pricing mechanisms and environmental regulations are evolving rapidly across different markets. The ROI calculator should include functionality to model potential carbon tax implications and regulatory compliance costs, allowing organizations to future-proof their thermal management strategies against evolving environmental policies.

By integrating these sustainability considerations into the TIM Cost-Per-Unit-Of-Heat-Removed calculator, organizations can make more holistic decisions that align financial objectives with environmental responsibility, ultimately driving innovation toward more sustainable thermal management solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!