TIM Thickness Optimization: Trade-Offs Between Thermal Resistance And Mechanical Stress

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Technology Background and Optimization Goals

Thermal Interface Materials (TIMs) have evolved significantly over the past four decades, transitioning from simple thermal greases to sophisticated engineered materials designed to address the increasing thermal management challenges in electronic devices. The fundamental purpose of TIMs remains consistent: to fill microscopic air gaps between mating surfaces, thereby enhancing thermal conductivity across interfaces. This function has become increasingly critical as power densities in electronic components continue to rise exponentially, particularly in applications such as high-performance computing, electric vehicles, and telecommunications infrastructure.

The evolution of TIM technology has progressed through several distinct phases. Early generations primarily consisted of silicone-based compounds with limited thermal conductivity (0.5-3 W/mK). The industry subsequently advanced to phase-change materials, thermal adhesives, and gap fillers. Current cutting-edge solutions include graphene-enhanced composites, liquid metal TIMs, and carbon nanotube arrays with thermal conductivities exceeding 20 W/mK.

A critical yet often overlooked aspect of TIM implementation is thickness optimization. This parameter represents a complex engineering trade-off between competing requirements. Thinner TIM layers generally provide lower thermal resistance, facilitating more efficient heat transfer. However, excessively thin layers may not adequately accommodate surface irregularities or manufacturing tolerances, potentially creating air gaps that severely compromise thermal performance.

Conversely, thicker TIM layers offer improved mechanical compliance and stress absorption capabilities, which are essential for maintaining interface integrity during thermal cycling and mechanical shock events. This mechanical resilience becomes particularly important in applications subject to significant thermal expansion differentials between mating components, such as in automotive or aerospace environments.

The optimization goal for TIM thickness therefore requires balancing these competing factors: minimizing thermal resistance while maintaining sufficient mechanical compliance to ensure long-term reliability. This balance must be achieved within the constraints of manufacturing capabilities, cost targets, and application-specific requirements such as operating temperature range, expected lifetime, and environmental exposure conditions.

Recent technological trends indicate a growing emphasis on developing TIM solutions with adaptive properties that can dynamically respond to changing thermal and mechanical conditions. These include phase-change materials with precisely engineered transition temperatures, nanostructured composites with directional thermal conductivity, and self-healing formulations that can recover from mechanical damage or material degradation over time.

The ultimate objective of TIM thickness optimization is to develop a systematic methodology that enables engineers to precisely determine the optimal thickness for specific application scenarios, taking into account the full spectrum of thermal, mechanical, and reliability considerations throughout the product lifecycle.

The evolution of TIM technology has progressed through several distinct phases. Early generations primarily consisted of silicone-based compounds with limited thermal conductivity (0.5-3 W/mK). The industry subsequently advanced to phase-change materials, thermal adhesives, and gap fillers. Current cutting-edge solutions include graphene-enhanced composites, liquid metal TIMs, and carbon nanotube arrays with thermal conductivities exceeding 20 W/mK.

A critical yet often overlooked aspect of TIM implementation is thickness optimization. This parameter represents a complex engineering trade-off between competing requirements. Thinner TIM layers generally provide lower thermal resistance, facilitating more efficient heat transfer. However, excessively thin layers may not adequately accommodate surface irregularities or manufacturing tolerances, potentially creating air gaps that severely compromise thermal performance.

Conversely, thicker TIM layers offer improved mechanical compliance and stress absorption capabilities, which are essential for maintaining interface integrity during thermal cycling and mechanical shock events. This mechanical resilience becomes particularly important in applications subject to significant thermal expansion differentials between mating components, such as in automotive or aerospace environments.

The optimization goal for TIM thickness therefore requires balancing these competing factors: minimizing thermal resistance while maintaining sufficient mechanical compliance to ensure long-term reliability. This balance must be achieved within the constraints of manufacturing capabilities, cost targets, and application-specific requirements such as operating temperature range, expected lifetime, and environmental exposure conditions.

Recent technological trends indicate a growing emphasis on developing TIM solutions with adaptive properties that can dynamically respond to changing thermal and mechanical conditions. These include phase-change materials with precisely engineered transition temperatures, nanostructured composites with directional thermal conductivity, and self-healing formulations that can recover from mechanical damage or material degradation over time.

The ultimate objective of TIM thickness optimization is to develop a systematic methodology that enables engineers to precisely determine the optimal thickness for specific application scenarios, taking into account the full spectrum of thermal, mechanical, and reliability considerations throughout the product lifecycle.

Market Demand Analysis for Advanced TIM Solutions

The global market for Thermal Interface Materials (TIMs) is experiencing robust growth driven by increasing thermal management demands across multiple industries. Current market valuations place the advanced TIM solutions sector at approximately $2.5 billion, with projections indicating a compound annual growth rate of 8-10% through 2028. This acceleration is primarily fueled by the semiconductor industry's continuous miniaturization efforts and the growing power densities in electronic components.

Consumer electronics represents the largest demand segment, with smartphone and laptop manufacturers seeking thinner yet more thermally efficient TIM solutions to manage heat in increasingly compact designs. The trade-off between thermal resistance and mechanical stress has become a critical consideration as device thickness continues to decrease while processing power increases. Industry surveys indicate that over 70% of electronics manufacturers cite thermal management as a primary design constraint in next-generation products.

The automotive sector presents another significant growth vector, particularly with the rapid expansion of electric vehicles (EVs). Battery thermal management systems require advanced TIMs that can maintain performance integrity under varying mechanical stresses while providing optimal thermal conductivity. Market research shows EV manufacturers are willing to pay premium prices for TIMs that can reduce battery thermal resistance by even marginal percentages, as this directly impacts vehicle range and battery longevity.

Data center infrastructure represents the fastest-growing segment for advanced TIM solutions. With the proliferation of high-performance computing and artificial intelligence applications, server density and heat generation have increased dramatically. Cooling efficiency has become a major operational cost factor, with data centers allocating 25-40% of their energy consumption to cooling systems. TIMs that can optimize the thickness-to-performance ratio are in high demand as they directly impact energy efficiency metrics.

The telecommunications industry, particularly with the ongoing 5G infrastructure deployment, has emerged as another significant market driver. Base stations and network equipment operating at higher frequencies generate more heat in smaller form factors, creating demand for TIMs that can balance mechanical reliability with superior thermal performance.

Regional analysis reveals that Asia-Pacific dominates the manufacturing landscape for TIMs, while North America leads in research and development investments. European markets show particular interest in environmentally sustainable TIM solutions that maintain optimal thickness-to-performance ratios while reducing environmental impact.

Customer requirements across these markets consistently emphasize the need for TIMs that can be applied in thinner layers without compromising thermal conductivity or introducing problematic mechanical stress. This balance represents the core market demand driving innovation in advanced TIM solutions.

Consumer electronics represents the largest demand segment, with smartphone and laptop manufacturers seeking thinner yet more thermally efficient TIM solutions to manage heat in increasingly compact designs. The trade-off between thermal resistance and mechanical stress has become a critical consideration as device thickness continues to decrease while processing power increases. Industry surveys indicate that over 70% of electronics manufacturers cite thermal management as a primary design constraint in next-generation products.

The automotive sector presents another significant growth vector, particularly with the rapid expansion of electric vehicles (EVs). Battery thermal management systems require advanced TIMs that can maintain performance integrity under varying mechanical stresses while providing optimal thermal conductivity. Market research shows EV manufacturers are willing to pay premium prices for TIMs that can reduce battery thermal resistance by even marginal percentages, as this directly impacts vehicle range and battery longevity.

Data center infrastructure represents the fastest-growing segment for advanced TIM solutions. With the proliferation of high-performance computing and artificial intelligence applications, server density and heat generation have increased dramatically. Cooling efficiency has become a major operational cost factor, with data centers allocating 25-40% of their energy consumption to cooling systems. TIMs that can optimize the thickness-to-performance ratio are in high demand as they directly impact energy efficiency metrics.

The telecommunications industry, particularly with the ongoing 5G infrastructure deployment, has emerged as another significant market driver. Base stations and network equipment operating at higher frequencies generate more heat in smaller form factors, creating demand for TIMs that can balance mechanical reliability with superior thermal performance.

Regional analysis reveals that Asia-Pacific dominates the manufacturing landscape for TIMs, while North America leads in research and development investments. European markets show particular interest in environmentally sustainable TIM solutions that maintain optimal thickness-to-performance ratios while reducing environmental impact.

Customer requirements across these markets consistently emphasize the need for TIMs that can be applied in thinner layers without compromising thermal conductivity or introducing problematic mechanical stress. This balance represents the core market demand driving innovation in advanced TIM solutions.

Current TIM Thickness Challenges and Limitations

The current landscape of Thermal Interface Material (TIM) thickness optimization presents several significant challenges that impede optimal thermal management in electronic devices. As semiconductor technologies advance toward higher power densities and smaller form factors, the traditional approaches to TIM application are increasingly inadequate, creating a complex engineering dilemma.

One of the primary limitations is the inherent trade-off between thermal resistance and mechanical stress. Thinner TIM layers generally provide better thermal conductivity and lower thermal resistance, which is crucial for efficient heat dissipation. However, when TIM thickness falls below certain thresholds (typically under 50 microns), manufacturing consistency becomes extremely difficult to maintain across large surfaces, resulting in potential air gaps and hotspots that paradoxically increase thermal resistance.

Conversely, thicker TIM layers accommodate manufacturing tolerances and surface irregularities more effectively, reducing mechanical stress on components. This is particularly important in applications subject to thermal cycling, where differential expansion rates between materials can lead to pump-out effects and reliability issues. However, thicker applications inherently increase the thermal resistance path, potentially compromising cooling efficiency by 15-30% compared to optimized thinner layers.

Material property limitations further complicate thickness optimization. Most commercially available TIMs exhibit non-linear behavior as thickness changes, with thermal conductivity values often decreasing at extremely thin applications due to interfacial thermal resistance effects becoming proportionally more significant. Current measurement techniques struggle to accurately characterize these behaviors at the micro-scale, leading to discrepancies between theoretical models and actual performance.

Manufacturing precision represents another significant challenge. Even state-of-the-art dispensing equipment typically achieves thickness variation of ±10-15% across large surfaces, which becomes increasingly problematic as absolute thickness decreases. This variation introduces unpredictability in thermal performance and mechanical stress distribution, particularly in high-reliability applications like automotive electronics and server infrastructure.

The industry also faces challenges in developing standardized testing methodologies that accurately reflect real-world conditions. Current testing protocols often fail to account for the dynamic nature of TIM performance under operational conditions, including the effects of thermal cycling, mechanical vibration, and long-term material degradation on optimal thickness requirements.

Finally, there exists a significant knowledge gap regarding the long-term reliability implications of different thickness strategies. While thinner TIMs may provide better initial thermal performance, their long-term reliability under repeated thermal cycling and mechanical stress remains inadequately characterized, particularly for newer material formulations designed specifically for ultra-thin applications.

One of the primary limitations is the inherent trade-off between thermal resistance and mechanical stress. Thinner TIM layers generally provide better thermal conductivity and lower thermal resistance, which is crucial for efficient heat dissipation. However, when TIM thickness falls below certain thresholds (typically under 50 microns), manufacturing consistency becomes extremely difficult to maintain across large surfaces, resulting in potential air gaps and hotspots that paradoxically increase thermal resistance.

Conversely, thicker TIM layers accommodate manufacturing tolerances and surface irregularities more effectively, reducing mechanical stress on components. This is particularly important in applications subject to thermal cycling, where differential expansion rates between materials can lead to pump-out effects and reliability issues. However, thicker applications inherently increase the thermal resistance path, potentially compromising cooling efficiency by 15-30% compared to optimized thinner layers.

Material property limitations further complicate thickness optimization. Most commercially available TIMs exhibit non-linear behavior as thickness changes, with thermal conductivity values often decreasing at extremely thin applications due to interfacial thermal resistance effects becoming proportionally more significant. Current measurement techniques struggle to accurately characterize these behaviors at the micro-scale, leading to discrepancies between theoretical models and actual performance.

Manufacturing precision represents another significant challenge. Even state-of-the-art dispensing equipment typically achieves thickness variation of ±10-15% across large surfaces, which becomes increasingly problematic as absolute thickness decreases. This variation introduces unpredictability in thermal performance and mechanical stress distribution, particularly in high-reliability applications like automotive electronics and server infrastructure.

The industry also faces challenges in developing standardized testing methodologies that accurately reflect real-world conditions. Current testing protocols often fail to account for the dynamic nature of TIM performance under operational conditions, including the effects of thermal cycling, mechanical vibration, and long-term material degradation on optimal thickness requirements.

Finally, there exists a significant knowledge gap regarding the long-term reliability implications of different thickness strategies. While thinner TIMs may provide better initial thermal performance, their long-term reliability under repeated thermal cycling and mechanical stress remains inadequately characterized, particularly for newer material formulations designed specifically for ultra-thin applications.

Current Approaches to TIM Thickness Optimization

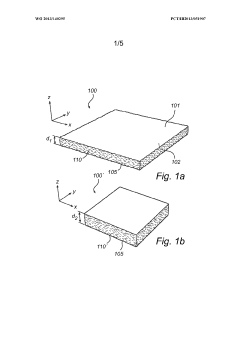

01 Relationship between TIM thickness and thermal resistance

The thickness of thermal interface materials significantly impacts thermal resistance in electronic assemblies. Thinner TIMs generally provide lower thermal resistance, improving heat transfer efficiency between components. However, the relationship is not always linear and depends on material properties such as thermal conductivity. Optimizing TIM thickness is crucial for balancing thermal performance with mechanical requirements in various electronic applications.- Relationship between TIM thickness and thermal resistance: The thickness of thermal interface materials significantly impacts thermal resistance in electronic assemblies. Thinner TIMs generally provide lower thermal resistance, improving heat transfer efficiency between components. However, the relationship is not always linear and depends on material properties such as thermal conductivity and contact resistance. Optimizing TIM thickness is crucial for balancing thermal performance with mechanical requirements in various electronic applications.

- Mechanical stress management in TIM applications: Mechanical stress in thermal interface materials can significantly affect device reliability and performance. TIMs must accommodate thermal expansion mismatches between joined components while maintaining thermal conductivity. Advanced TIM formulations incorporate stress-relieving properties to prevent warpage, delamination, and component damage during thermal cycling. Balancing mechanical compliance with thermal performance is essential for long-term reliability in high-power electronic devices.

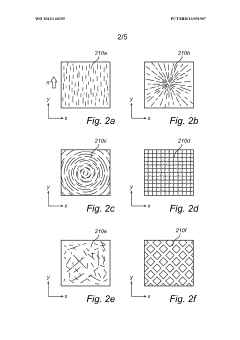

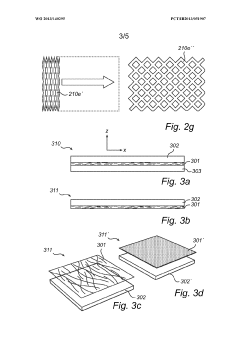

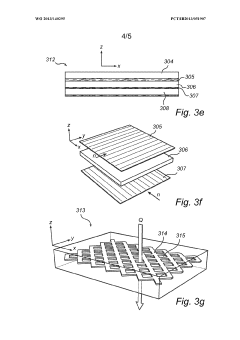

- Novel TIM compositions for enhanced thermal performance: Innovative thermal interface material compositions incorporate advanced fillers and matrix materials to achieve superior thermal conductivity while maintaining appropriate mechanical properties. These compositions may include metal particles, carbon nanotubes, graphene, ceramic particles, or phase change materials. The engineered structures allow for reduced thermal resistance while addressing challenges related to material thickness and mechanical stress, particularly in high-power density applications.

- Testing and measurement methods for TIM properties: Accurate measurement of thermal interface material properties is critical for proper material selection and application. Various testing methodologies have been developed to characterize thermal resistance across different thicknesses and under various mechanical stress conditions. These include laser flash analysis, thermal impedance testing, and in-situ performance monitoring. Advanced testing protocols help predict real-world performance and reliability of TIMs in electronic assemblies.

- TIM application techniques for optimized performance: The method of applying thermal interface materials significantly impacts their thermal and mechanical performance. Techniques such as precise dispensing, screen printing, and pre-applied TIMs help control thickness uniformity and minimize air gaps. Proper application procedures consider bond line thickness control, pressure distribution, and curing parameters to achieve optimal thermal resistance while managing mechanical stress. These techniques are particularly important in high-reliability applications such as automotive electronics and data centers.

02 Mechanical stress management in TIM applications

Mechanical stress in thermal interface materials can significantly affect device reliability and performance. TIMs must accommodate thermal expansion mismatches between connected components while maintaining thermal conductivity. Advanced formulations incorporate stress-relieving properties to prevent delamination, cracking, or pump-out effects during thermal cycling. Balancing mechanical compliance with thermal performance is essential for long-term reliability in high-power electronic devices.Expand Specific Solutions03 Testing and measurement methods for TIM performance

Various testing methodologies have been developed to accurately measure thermal interface material properties including thermal resistance, thickness consistency, and mechanical stress tolerance. These include laser flash analysis, thermal impedance testing, and mechanical compression testing. Advanced characterization techniques help in understanding the correlation between material composition, application methods, and thermal-mechanical performance, enabling more precise selection of TIMs for specific applications.Expand Specific Solutions04 Novel TIM compositions for improved thermal-mechanical properties

Innovative thermal interface material compositions incorporate fillers such as metal particles, carbon nanotubes, or ceramic materials to enhance thermal conductivity while maintaining mechanical flexibility. These advanced formulations aim to reduce thermal resistance while withstanding mechanical stresses from thermal cycling. Some compositions feature phase-change properties, allowing them to flow and fill microscopic gaps during operation while maintaining structural integrity under varying pressure and temperature conditions.Expand Specific Solutions05 TIM application techniques and thickness control

Precise application methods for thermal interface materials are critical for controlling thickness uniformity and minimizing thermal resistance. Techniques include screen printing, dispensing, pre-applied pads, and spray coating. Automated application systems can achieve consistent TIM thickness across components, reducing variability in thermal performance. Proper thickness control helps balance thermal resistance reduction with mechanical stress management, particularly in applications with high power density or where components experience significant thermal expansion.Expand Specific Solutions

Key Industry Players in TIM Development

The TIM (Thermal Interface Material) thickness optimization market is currently in a growth phase, with increasing demand driven by electronics miniaturization and thermal management challenges. The market is projected to reach approximately $4-5 billion by 2025, expanding at a CAGR of 8-10%. Leading technology companies like Intel, IBM, and Apple are advancing TIM solutions to balance thermal resistance reduction with mechanical stress mitigation. Specialized materials manufacturers including 3M, Dow Silicones, and Indium Corporation are developing next-generation composites with enhanced thermal conductivity while maintaining mechanical flexibility. TSMC and GlobalFoundries are implementing advanced TIM solutions in semiconductor manufacturing, while automotive players such as Toyota and Continental are adapting these technologies for electric vehicle thermal management applications.

Intel Corp.

Technical Solution: Intel has developed advanced TIM solutions focusing on the balance between thermal resistance and mechanical stress in semiconductor packaging. Their approach includes phase-change materials (PCMs) that optimize thermal conductivity while minimizing mechanical stress during thermal cycling. Intel's research has led to the development of indium-based TIMs that provide excellent wetting properties and thermal conductivity of approximately 86 W/mK. They've implemented a systematic optimization methodology that considers both the TIM thickness and composition, using finite element analysis to model the stress distribution across the chip-package interface. Intel's solutions incorporate polymer matrix composites with tailored filler concentrations to achieve the optimal balance between thermal performance and mechanical reliability in high-performance computing applications.

Strengths: Superior thermal management expertise in high-performance computing; extensive R&D capabilities; comprehensive testing infrastructure. Weaknesses: Solutions may be optimized primarily for their own semiconductor products; potentially higher cost compared to general-purpose TIMs.

Dow Global Technologies LLC

Technical Solution: Dow has developed sophisticated silicone-based TIM solutions that address the critical trade-off between thermal resistance and mechanical stress. Their approach focuses on engineered silicone elastomers with optimized filler loading and controlled thickness profiles. Dow's research has demonstrated that silicone-based TIMs with thickness ranges of 50-200 microns can be tailored to specific application requirements by adjusting the silicone chemistry and filler composition. Their technology includes gap-filling TIMs with thermal conductivity values ranging from 2 to 6 W/mK while maintaining compliance factors that accommodate coefficient of thermal expansion (CTE) mismatches between mating surfaces. Dow has pioneered the development of stress-relieving additives that allow their TIMs to maintain thermal performance even after thousands of thermal cycles. Their solutions incorporate advanced rheological control to ensure consistent thickness during application and compression, with specialized formulations that prevent pump-out effects under thermal cycling conditions.

Strengths: Industry-leading silicone chemistry expertise; formulations optimized for long-term reliability; solutions for diverse operating environments. Weaknesses: May have higher initial costs compared to conventional materials; some formulations require specific application techniques for optimal performance.

Critical Patents and Research in TIM Technology

Reliability enhancement of metal thermal interface

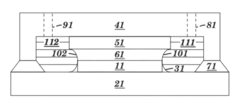

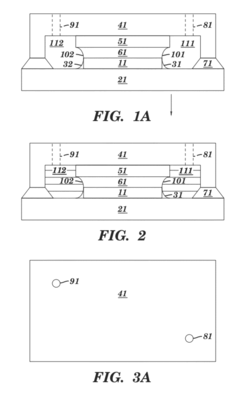

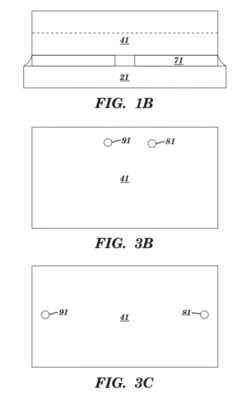

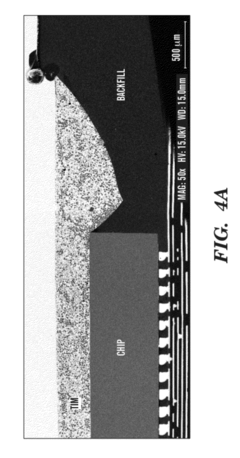

PatentInactiveUS8232636B2

Innovation

- A method involving a solder thermal interface material (TIM) bonded between a chip and a lid, with a polymeric seal and backfill material used to mitigate cracking, where the backfill material fills the space between the chip carrier and lid, abutting the sides of the TIM and curing simultaneously with the seal material to enhance bonding and stability.

Thermal interface material

PatentWO2013140295A2

Innovation

- A TIM with an activable shrinkage material that increases in thickness upon activation, providing controllable physical dimensions and enhancing contact pressure between heat generating and conducting components, thereby eliminating the need for external pressure and improving robustness against surface curvature and roughness.

Material Science Advancements for Next-Gen TIMs

Recent advancements in material science have opened new frontiers for thermal interface materials (TIMs), addressing the critical balance between thermal resistance and mechanical stress. The evolution of next-generation TIMs is being driven by innovative approaches in material composition, structure, and manufacturing techniques that specifically target this optimization challenge.

Nanocomposite TIMs represent one of the most promising developments, incorporating various nanoparticles such as graphene, carbon nanotubes, and metallic nanostructures into traditional polymer matrices. These materials demonstrate remarkable thermal conductivity improvements while maintaining compliance necessary for stress mitigation. For instance, graphene-enhanced TIMs have shown up to 500% increase in thermal conductivity compared to conventional materials while preserving mechanical flexibility.

Phase change materials (PCMs) with engineered transition temperatures are emerging as adaptive solutions that can dynamically respond to thermal conditions. These materials transform between solid and liquid states within operational temperature ranges, providing optimal contact during thermal expansion cycles and reducing mechanical stress at interfaces. Advanced PCMs incorporating metallic microparticles achieve thermal conductivities exceeding 5 W/m·K while maintaining stress-absorbing characteristics.

Liquid metal composites represent another breakthrough, utilizing gallium-based alloys encapsulated in elastic polymers. These materials combine the exceptional thermal conductivity of metals (typically 20-40 W/m·K) with the compliance of elastomers, creating TIMs that can be applied in ultra-thin layers without compromising thermal performance or increasing mechanical stress at interfaces.

Vertically aligned structures within TIMs are being developed to create anisotropic thermal pathways. These architectures, including aligned carbon fiber arrays and metallic micropillar forests, provide directional thermal conductivity while allowing lateral compliance. This approach enables TIM thickness reduction without proportionally increasing mechanical stress, addressing the fundamental trade-off challenge.

Self-healing TIMs incorporate microencapsulated healing agents that release upon mechanical damage, restoring both thermal and mechanical properties. This innovation extends TIM lifespan and maintains performance consistency under thermal cycling conditions, reducing the need for thicker applications to compensate for degradation over time.

Manufacturing innovations such as atomic layer deposition and controlled interface functionalization are enabling the production of ultra-thin TIMs with precisely engineered surface characteristics. These techniques allow for molecular-level control of interface properties, optimizing both thermal conductance and mechanical compliance simultaneously rather than treating them as competing factors.

Nanocomposite TIMs represent one of the most promising developments, incorporating various nanoparticles such as graphene, carbon nanotubes, and metallic nanostructures into traditional polymer matrices. These materials demonstrate remarkable thermal conductivity improvements while maintaining compliance necessary for stress mitigation. For instance, graphene-enhanced TIMs have shown up to 500% increase in thermal conductivity compared to conventional materials while preserving mechanical flexibility.

Phase change materials (PCMs) with engineered transition temperatures are emerging as adaptive solutions that can dynamically respond to thermal conditions. These materials transform between solid and liquid states within operational temperature ranges, providing optimal contact during thermal expansion cycles and reducing mechanical stress at interfaces. Advanced PCMs incorporating metallic microparticles achieve thermal conductivities exceeding 5 W/m·K while maintaining stress-absorbing characteristics.

Liquid metal composites represent another breakthrough, utilizing gallium-based alloys encapsulated in elastic polymers. These materials combine the exceptional thermal conductivity of metals (typically 20-40 W/m·K) with the compliance of elastomers, creating TIMs that can be applied in ultra-thin layers without compromising thermal performance or increasing mechanical stress at interfaces.

Vertically aligned structures within TIMs are being developed to create anisotropic thermal pathways. These architectures, including aligned carbon fiber arrays and metallic micropillar forests, provide directional thermal conductivity while allowing lateral compliance. This approach enables TIM thickness reduction without proportionally increasing mechanical stress, addressing the fundamental trade-off challenge.

Self-healing TIMs incorporate microencapsulated healing agents that release upon mechanical damage, restoring both thermal and mechanical properties. This innovation extends TIM lifespan and maintains performance consistency under thermal cycling conditions, reducing the need for thicker applications to compensate for degradation over time.

Manufacturing innovations such as atomic layer deposition and controlled interface functionalization are enabling the production of ultra-thin TIMs with precisely engineered surface characteristics. These techniques allow for molecular-level control of interface properties, optimizing both thermal conductance and mechanical compliance simultaneously rather than treating them as competing factors.

Reliability Testing Methods for TIM Performance Validation

Reliability testing methods for TIM (Thermal Interface Material) performance validation are essential to ensure that the optimized thickness balances thermal resistance and mechanical stress effectively over the product lifecycle. These methods must simulate real-world conditions while providing quantifiable data for engineering decisions.

Temperature cycling tests represent the cornerstone of TIM reliability validation, typically subjecting assemblies to extreme temperature variations ranging from -40°C to 125°C. These tests reveal how the TIM responds to thermal expansion and contraction cycles, which directly impacts both thermal performance and mechanical stress distribution. Standard protocols often require 500-1000 cycles to adequately predict long-term reliability.

Power cycling tests complement temperature cycling by introducing actual operational heat loads. This approach more accurately simulates real-world conditions where components generate variable heat during operation. The thermal resistance is measured before, during, and after cycling to detect any degradation in performance that might result from material pump-out, dry-out, or delamination.

High-temperature bake tests (typically at 125°C for 1000+ hours) evaluate TIM stability under sustained thermal stress. These tests are particularly valuable for identifying chemical degradation mechanisms that might not appear during shorter-duration testing but could significantly impact long-term performance.

Mechanical shock and vibration testing assesses the TIM's ability to maintain thermal contact under physical stress conditions. This is particularly critical for applications in transportation, industrial environments, or portable electronics where mechanical forces could compromise the thermal interface.

Humidity and environmental exposure tests evaluate how moisture and environmental contaminants affect TIM performance. Controlled humidity chambers (typically 85% relative humidity at 85°C) reveal potential issues with material degradation or changes in thermal conductivity due to moisture absorption.

Thermal resistance measurement techniques must be standardized across all testing phases. ASTM D5470 provides a common methodology, but laser flash analysis and transient thermal impedance measurements are increasingly utilized for more detailed characterization of thermal performance changes.

Statistical analysis of test results is essential for meaningful conclusions. Multiple samples must be tested under identical conditions to establish confidence intervals and identify outliers. Weibull analysis is commonly employed to predict failure rates and establish reliability metrics that can inform warranty periods and maintenance schedules.

Temperature cycling tests represent the cornerstone of TIM reliability validation, typically subjecting assemblies to extreme temperature variations ranging from -40°C to 125°C. These tests reveal how the TIM responds to thermal expansion and contraction cycles, which directly impacts both thermal performance and mechanical stress distribution. Standard protocols often require 500-1000 cycles to adequately predict long-term reliability.

Power cycling tests complement temperature cycling by introducing actual operational heat loads. This approach more accurately simulates real-world conditions where components generate variable heat during operation. The thermal resistance is measured before, during, and after cycling to detect any degradation in performance that might result from material pump-out, dry-out, or delamination.

High-temperature bake tests (typically at 125°C for 1000+ hours) evaluate TIM stability under sustained thermal stress. These tests are particularly valuable for identifying chemical degradation mechanisms that might not appear during shorter-duration testing but could significantly impact long-term performance.

Mechanical shock and vibration testing assesses the TIM's ability to maintain thermal contact under physical stress conditions. This is particularly critical for applications in transportation, industrial environments, or portable electronics where mechanical forces could compromise the thermal interface.

Humidity and environmental exposure tests evaluate how moisture and environmental contaminants affect TIM performance. Controlled humidity chambers (typically 85% relative humidity at 85°C) reveal potential issues with material degradation or changes in thermal conductivity due to moisture absorption.

Thermal resistance measurement techniques must be standardized across all testing phases. ASTM D5470 provides a common methodology, but laser flash analysis and transient thermal impedance measurements are increasingly utilized for more detailed characterization of thermal performance changes.

Statistical analysis of test results is essential for meaningful conclusions. Multiple samples must be tested under identical conditions to establish confidence intervals and identify outliers. Weibull analysis is commonly employed to predict failure rates and establish reliability metrics that can inform warranty periods and maintenance schedules.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!