TIM For Immersion And Direct-To-Chip Cooling: Compatibility And Selection Guide

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Technology Background and Cooling Objectives

Thermal Interface Materials (TIMs) have evolved significantly over the past decades, transitioning from simple thermal greases to advanced engineered materials designed to address the increasing thermal management challenges in electronic systems. The evolution of TIMs has been driven by the continuous miniaturization of electronic components and the exponential increase in power densities, particularly in high-performance computing, data centers, and power electronics applications.

Initially developed as basic gap fillers, TIMs have transformed into sophisticated materials with tailored thermal, mechanical, and chemical properties. The technology progression has seen the introduction of various material types including thermal greases, phase change materials, thermal pads, gap fillers, and more recently, liquid metal TIMs and carbon-based solutions incorporating graphene and carbon nanotubes.

The fundamental purpose of TIMs remains consistent: to minimize thermal resistance at interfaces between heat-generating components and cooling solutions by filling microscopic air gaps that would otherwise impede heat transfer. However, as cooling technologies advance toward more efficient methods like immersion and direct-to-chip cooling, the requirements for TIMs have become increasingly specialized.

Immersion cooling, which involves submerging electronic components directly in dielectric fluids, presents unique challenges for TIM compatibility. These materials must maintain their thermal performance while being chemically stable in the immersion fluid, preventing degradation or dissolution that could contaminate the cooling system or compromise component reliability.

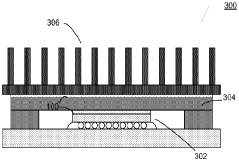

Similarly, direct-to-chip cooling approaches, where coolant flows in close proximity to or directly contacts the chip surface, demand TIMs that can function effectively under these conditions while maintaining long-term reliability. The interface between the cooling solution and the chip becomes critical, requiring TIMs with exceptional thermal conductivity, minimal thickness, and appropriate mechanical properties.

The technical objectives for modern TIMs in these advanced cooling scenarios include achieving thermal conductivity values exceeding 10 W/m·K, maintaining performance stability under thermal cycling, ensuring chemical compatibility with cooling fluids, providing appropriate viscosity for application processes, and delivering long-term reliability without pump-out or dry-out effects.

Future development trajectories point toward nano-engineered materials, hybrid solutions combining multiple TIM technologies, and adaptive materials that can optimize their properties based on operating conditions. The ultimate goal remains reducing the thermal resistance at interfaces to enable more efficient heat dissipation from increasingly powerful electronic components, thereby supporting continued advances in computational performance and system reliability.

Initially developed as basic gap fillers, TIMs have transformed into sophisticated materials with tailored thermal, mechanical, and chemical properties. The technology progression has seen the introduction of various material types including thermal greases, phase change materials, thermal pads, gap fillers, and more recently, liquid metal TIMs and carbon-based solutions incorporating graphene and carbon nanotubes.

The fundamental purpose of TIMs remains consistent: to minimize thermal resistance at interfaces between heat-generating components and cooling solutions by filling microscopic air gaps that would otherwise impede heat transfer. However, as cooling technologies advance toward more efficient methods like immersion and direct-to-chip cooling, the requirements for TIMs have become increasingly specialized.

Immersion cooling, which involves submerging electronic components directly in dielectric fluids, presents unique challenges for TIM compatibility. These materials must maintain their thermal performance while being chemically stable in the immersion fluid, preventing degradation or dissolution that could contaminate the cooling system or compromise component reliability.

Similarly, direct-to-chip cooling approaches, where coolant flows in close proximity to or directly contacts the chip surface, demand TIMs that can function effectively under these conditions while maintaining long-term reliability. The interface between the cooling solution and the chip becomes critical, requiring TIMs with exceptional thermal conductivity, minimal thickness, and appropriate mechanical properties.

The technical objectives for modern TIMs in these advanced cooling scenarios include achieving thermal conductivity values exceeding 10 W/m·K, maintaining performance stability under thermal cycling, ensuring chemical compatibility with cooling fluids, providing appropriate viscosity for application processes, and delivering long-term reliability without pump-out or dry-out effects.

Future development trajectories point toward nano-engineered materials, hybrid solutions combining multiple TIM technologies, and adaptive materials that can optimize their properties based on operating conditions. The ultimate goal remains reducing the thermal resistance at interfaces to enable more efficient heat dissipation from increasingly powerful electronic components, thereby supporting continued advances in computational performance and system reliability.

Market Analysis for Advanced Thermal Management Solutions

The thermal interface materials (TIM) market for advanced cooling solutions is experiencing robust growth, driven by increasing power densities in electronic components across multiple industries. The global TIM market was valued at approximately 3.7 billion USD in 2022 and is projected to reach 6.5 billion USD by 2028, representing a compound annual growth rate of 9.8% during the forecast period.

Data center applications currently dominate the demand for advanced thermal management solutions, accounting for nearly 40% of the total market share. This is primarily due to the rapid expansion of cloud computing infrastructure and the deployment of high-performance computing systems that generate significant heat loads requiring efficient dissipation methods.

The automotive sector represents the fastest-growing segment for advanced TIMs, particularly with the accelerating adoption of electric vehicles. The thermal management requirements for battery systems, power electronics, and motor cooling have created new application scenarios for both immersion and direct-to-chip cooling technologies, with market growth rates exceeding 15% annually in this vertical.

Consumer electronics manufacturers are increasingly exploring advanced cooling solutions to enable higher performance in smaller form factors. This trend is particularly evident in gaming devices, where thermal constraints often limit performance capabilities. The consumer segment currently represents approximately 25% of the advanced TIM market.

Regionally, North America leads in adoption of advanced cooling technologies, holding approximately 35% of the global market share, followed by Asia-Pacific at 32% and Europe at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to the expansion of manufacturing capabilities and increasing technological sophistication in countries like China, South Korea, and Taiwan.

The market is characterized by a price premium for specialized TIMs compatible with immersion and direct-to-chip cooling applications. These advanced materials typically command 30-50% higher prices compared to conventional thermal interface materials, reflecting their enhanced performance characteristics and specialized formulations.

Customer purchasing decisions are increasingly influenced by total cost of ownership considerations rather than initial acquisition costs alone. End users are demonstrating willingness to invest in premium thermal management solutions that offer improved reliability, extended component lifespan, and reduced energy consumption through more efficient heat dissipation.

Data center applications currently dominate the demand for advanced thermal management solutions, accounting for nearly 40% of the total market share. This is primarily due to the rapid expansion of cloud computing infrastructure and the deployment of high-performance computing systems that generate significant heat loads requiring efficient dissipation methods.

The automotive sector represents the fastest-growing segment for advanced TIMs, particularly with the accelerating adoption of electric vehicles. The thermal management requirements for battery systems, power electronics, and motor cooling have created new application scenarios for both immersion and direct-to-chip cooling technologies, with market growth rates exceeding 15% annually in this vertical.

Consumer electronics manufacturers are increasingly exploring advanced cooling solutions to enable higher performance in smaller form factors. This trend is particularly evident in gaming devices, where thermal constraints often limit performance capabilities. The consumer segment currently represents approximately 25% of the advanced TIM market.

Regionally, North America leads in adoption of advanced cooling technologies, holding approximately 35% of the global market share, followed by Asia-Pacific at 32% and Europe at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to the expansion of manufacturing capabilities and increasing technological sophistication in countries like China, South Korea, and Taiwan.

The market is characterized by a price premium for specialized TIMs compatible with immersion and direct-to-chip cooling applications. These advanced materials typically command 30-50% higher prices compared to conventional thermal interface materials, reflecting their enhanced performance characteristics and specialized formulations.

Customer purchasing decisions are increasingly influenced by total cost of ownership considerations rather than initial acquisition costs alone. End users are demonstrating willingness to invest in premium thermal management solutions that offer improved reliability, extended component lifespan, and reduced energy consumption through more efficient heat dissipation.

Current TIM Technologies and Implementation Challenges

Thermal Interface Materials (TIMs) play a critical role in modern cooling solutions, particularly for high-performance computing systems. Current TIM technologies span a diverse range of materials, each with specific thermal conductivity profiles, application methods, and compatibility characteristics. Traditional greases and pastes remain widely used due to their cost-effectiveness and ease of application, offering thermal conductivity values typically between 3-8 W/mK. These materials excel in filling microscopic surface irregularities but face challenges with pump-out effects and dry-out over time, requiring periodic replacement in mission-critical systems.

Phase change materials (PCMs) represent an evolution in TIM technology, transitioning from solid to semi-liquid state at operational temperatures. With thermal conductivity values ranging from 1-5 W/mK, PCMs offer the advantage of minimal bond-line thickness and excellent gap-filling properties. However, they present challenges in high-temperature cycling environments and may experience performance degradation over extended operational periods.

Metal-based TIMs, including liquid metal solutions (primarily gallium alloys), deliver superior thermal conductivity (20-80 W/mK) but introduce significant implementation challenges. Their electrical conductivity creates short-circuit risks, while their corrosive properties with certain metals (particularly aluminum) limit application scenarios. Containment issues and application complexity further restrict their widespread adoption despite thermal performance advantages.

Thermal pads (gap fillers) offer simplified installation and reusability but suffer from higher thermal resistance due to increased thickness requirements. Their conformability to surface irregularities comes at the cost of thermal performance, with conductivity typically ranging from 1-15 W/mK depending on composition.

Carbon-based solutions, particularly graphite sheets and carbon nanotube (CNT) arrays, represent the cutting edge of TIM technology. Graphite sheets offer anisotropic thermal conductivity exceeding 1500 W/mK in-plane but significantly lower through-plane performance. CNT arrays demonstrate promising thermal conductivity (10-200 W/mK) but face manufacturing scalability challenges and high production costs.

Implementation challenges across TIM technologies include reliability concerns in immersion cooling environments, where chemical compatibility with dielectric fluids becomes paramount. Material degradation, delamination, and pump-out effects accelerate in liquid immersion scenarios. For direct-to-chip cooling applications, thermal cycling stress, interface pressure requirements, and long-term reliability present significant engineering hurdles.

The industry continues to struggle with standardized testing methodologies that accurately predict real-world performance, particularly for emerging cooling technologies. The thermal resistance at interfaces remains a complex challenge, with surface roughness, contact pressure, and material wetting characteristics all contributing to overall thermal performance in ways that prove difficult to model consistently across diverse application scenarios.

Phase change materials (PCMs) represent an evolution in TIM technology, transitioning from solid to semi-liquid state at operational temperatures. With thermal conductivity values ranging from 1-5 W/mK, PCMs offer the advantage of minimal bond-line thickness and excellent gap-filling properties. However, they present challenges in high-temperature cycling environments and may experience performance degradation over extended operational periods.

Metal-based TIMs, including liquid metal solutions (primarily gallium alloys), deliver superior thermal conductivity (20-80 W/mK) but introduce significant implementation challenges. Their electrical conductivity creates short-circuit risks, while their corrosive properties with certain metals (particularly aluminum) limit application scenarios. Containment issues and application complexity further restrict their widespread adoption despite thermal performance advantages.

Thermal pads (gap fillers) offer simplified installation and reusability but suffer from higher thermal resistance due to increased thickness requirements. Their conformability to surface irregularities comes at the cost of thermal performance, with conductivity typically ranging from 1-15 W/mK depending on composition.

Carbon-based solutions, particularly graphite sheets and carbon nanotube (CNT) arrays, represent the cutting edge of TIM technology. Graphite sheets offer anisotropic thermal conductivity exceeding 1500 W/mK in-plane but significantly lower through-plane performance. CNT arrays demonstrate promising thermal conductivity (10-200 W/mK) but face manufacturing scalability challenges and high production costs.

Implementation challenges across TIM technologies include reliability concerns in immersion cooling environments, where chemical compatibility with dielectric fluids becomes paramount. Material degradation, delamination, and pump-out effects accelerate in liquid immersion scenarios. For direct-to-chip cooling applications, thermal cycling stress, interface pressure requirements, and long-term reliability present significant engineering hurdles.

The industry continues to struggle with standardized testing methodologies that accurately predict real-world performance, particularly for emerging cooling technologies. The thermal resistance at interfaces remains a complex challenge, with surface roughness, contact pressure, and material wetting characteristics all contributing to overall thermal performance in ways that prove difficult to model consistently across diverse application scenarios.

Comparative Analysis of Immersion vs Direct-to-Chip TIM Solutions

01 Material composition and thermal conductivity

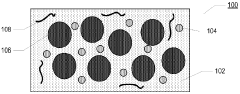

Thermal Interface Materials (TIMs) can be formulated with various compositions to achieve optimal thermal conductivity. These materials often include metal particles, carbon-based fillers, or ceramic components that enhance heat transfer between surfaces. The selection of specific components depends on the application requirements, with higher thermal conductivity materials being preferred for high-power electronic applications. The composition directly impacts the material's ability to fill microscopic air gaps and conduct heat efficiently.- Material composition and thermal conductivity: Thermal Interface Materials (TIMs) can be formulated with various compositions to achieve optimal thermal conductivity. These materials often include metal particles, carbon-based fillers, or ceramic components that enhance heat transfer between surfaces. The selection of specific fillers and base materials significantly impacts the thermal performance of the TIM, with higher thermal conductivity materials being preferred for applications requiring efficient heat dissipation.

- Compatibility with semiconductor devices: When selecting TIMs for semiconductor applications, compatibility with the device materials is crucial. The interface material must not cause degradation or corrosion of semiconductor components while maintaining effective thermal transfer. Considerations include coefficient of thermal expansion matching, chemical stability, and long-term reliability when in contact with silicon, metals, and other semiconductor packaging materials.

- Application methods and interface quality: The method of applying TIMs significantly affects their performance. Techniques include dispensing, screen printing, and pre-applied pads. The quality of the interface formed between the heat source and heat sink is critical, with minimal air gaps and optimal thickness being essential factors. Proper application ensures maximum contact area and minimizes thermal resistance across the interface.

- Testing and performance evaluation: Standardized testing methods are essential for evaluating TIM performance and ensuring proper selection. These include thermal resistance measurements, aging tests, and reliability assessments under various environmental conditions. Advanced characterization techniques help determine the thermal conductivity, viscosity, and other critical properties that influence the material's effectiveness in real-world applications.

- Environmental and reliability considerations: TIM selection must account for environmental factors and long-term reliability requirements. Considerations include operating temperature range, humidity resistance, thermal cycling stability, and pump-out resistance. Materials that maintain performance over time without degradation, delamination, or drying out are preferred for applications requiring long service life and reliability under challenging environmental conditions.

02 Compatibility with substrate materials

When selecting TIMs, compatibility with the substrate materials is crucial to ensure proper adhesion and prevent chemical reactions that could degrade performance. Different electronic components may require specific TIM formulations that won't react with the substrate materials or cause corrosion over time. Factors such as coefficient of thermal expansion matching and chemical stability must be considered to maintain long-term reliability and prevent delamination or interface degradation during thermal cycling.Expand Specific Solutions03 Application methods and processing conditions

The effectiveness of TIMs depends significantly on their application methods and processing conditions. Various techniques such as screen printing, dispensing, and pre-applied pads are used depending on the material type and application requirements. Processing parameters including curing temperature, pressure application, and thickness control are critical for optimal thermal performance. Proper application ensures uniform coverage and minimizes air gaps that could reduce thermal conductivity.Expand Specific Solutions04 Testing and reliability assessment

Comprehensive testing protocols are essential for evaluating TIM performance and reliability. These include thermal resistance measurements, aging tests, thermal cycling, and mechanical stress testing. Advanced characterization techniques help assess material degradation over time and under various operating conditions. Reliability testing ensures that the selected TIM maintains its thermal performance throughout the expected product lifetime and under extreme environmental conditions.Expand Specific Solutions05 Environmental and application-specific considerations

TIM selection must account for specific environmental conditions and application requirements. Factors such as operating temperature range, humidity exposure, and mechanical stress influence material choice. For specialized applications like automotive electronics, aerospace systems, or high-performance computing, custom TIM formulations may be necessary. Additionally, environmental regulations and sustainability considerations are increasingly important in TIM development, with trends toward halogen-free and low-outgassing materials.Expand Specific Solutions

Leading Manufacturers and Suppliers in TIM Industry

The thermal interface materials (TIM) market for immersion and direct-to-chip cooling is currently in a growth phase, with increasing demand driven by high-performance computing and data center applications. The market is expected to reach significant scale as thermal management becomes critical for advanced electronics. Leading semiconductor manufacturers like Intel and IBM are developing specialized solutions, while innovative startups such as JETCOOL Technologies and Arieca are introducing disruptive technologies with novel thermal interface materials. Chinese players including Huawei and research institutions like the Chinese Academy of Sciences are rapidly advancing their capabilities. The technology is approaching maturity for certain applications, with companies like Laird Technologies and Indium Corporation offering commercial solutions, though challenges remain in optimizing performance for next-generation computing systems requiring enhanced thermal dissipation.

Intel Corp.

Technical Solution: Intel has pioneered direct-to-chip cooling solutions through their advanced TIM integration strategies for high-performance computing environments. Their technology focuses on a two-pronged approach: specialized indium-based solder TIMs for critical thermal junctions and engineered polymer TIMs for secondary interfaces. For immersion cooling compatibility, Intel has developed specialized TIM formulations that maintain stability and performance when exposed to dielectric cooling fluids. Their direct-to-chip cooling architecture incorporates precise application methodologies that minimize air gaps and optimize thermal conductivity pathways. Intel's latest innovations include pre-applied TIMs with controlled bond line thickness and specialized edge sealing to prevent coolant infiltration at critical junctions. They've also developed testing protocols specifically for evaluating TIM performance under immersion conditions, ensuring long-term reliability in these specialized cooling environments.

Strengths: Comprehensive integration of TIM solutions with processor design allows for optimized thermal performance; extensive testing and validation processes ensure reliability. Weaknesses: Solutions are primarily optimized for Intel's own processor architectures; implementation complexity requires specialized knowledge and equipment.

Arieca, Inc.

Technical Solution: Arieca has developed Thubber®, a revolutionary thermal interface material that combines the elasticity of soft rubber with the thermal conductivity of metal. This breakthrough material addresses a critical challenge in direct-to-chip cooling: maintaining effective thermal transfer while accommodating the mechanical stresses that occur during thermal cycling. Thubber® utilizes a proprietary network of liquid metal alloy embedded within an elastomeric matrix, creating a compliant material with thermal conductivity exceeding 10 W/m·K. For immersion cooling applications, Arieca has engineered specialized formulations that maintain chemical stability when exposed to dielectric fluids while preserving their unique mechanical properties. Their technology enables conformal contact with irregular surfaces, effectively filling microscopic air gaps that typically impede thermal transfer. Arieca's materials can be applied in various forms including pre-cured pads, dispensable gels, and sprayable coatings, providing flexibility for different integration requirements in advanced cooling systems.

Strengths: Unique combination of high thermal conductivity with mechanical compliance addresses a key limitation of traditional TIMs; versatile application methods for different system requirements. Weaknesses: As a relatively new entrant, less established track record in large-scale deployment; may require specialized application equipment for optimal performance.

Key Patents and Innovations in Advanced Cooling TIMs

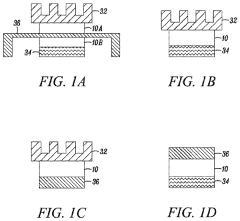

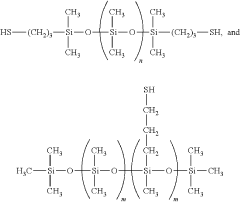

Low melt point metal based thermal interface material

PatentPendingUS20240218228A1

Innovation

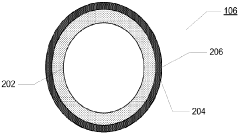

- A thermal interface material composition comprising a low melting point gallium alloy combined with a mercapto-group-containing silicone oil, thermally conductive powder, coupling agent, and emulsifying compound, which improves wettability and compressibility, and is applied using a stencil-printing process.

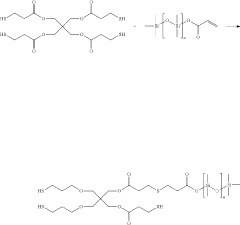

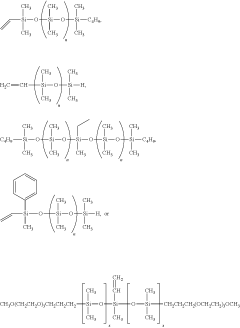

Polymer thermal interface material

PatentActiveGB2508320A

Innovation

- A polymer thermal interface material comprising a silicone-based gel or flexible epoxy polymer matrix, spherical filler material with varying diameters, and fibrous material, such as carbon fibers, to enhance adhesion, flexibility, and thermal conductivity, along with additives like fluxing agents and antioxidants to improve interface properties and thermal stability.

Environmental Impact and Sustainability of Cooling Solutions

The environmental impact of cooling solutions has become increasingly significant as data centers and high-performance computing facilities expand globally. Thermal Interface Materials (TIMs) used in immersion and direct-to-chip cooling systems present both challenges and opportunities for sustainability. Traditional cooling methods often rely on materials with high Global Warming Potential (GWP), while newer TIM solutions can significantly reduce energy consumption and environmental footprint.

When evaluating TIMs for immersion and direct-to-chip cooling, lifecycle assessment reveals that manufacturing processes for advanced thermal compounds often require energy-intensive production methods. However, these initial environmental costs are frequently offset by operational efficiency gains over the system's lifespan. For instance, properly selected TIMs can improve thermal conductivity by 15-30%, reducing the energy required for cooling by up to 25% compared to conventional solutions.

Material composition presents another critical environmental consideration. Silicon-based TIMs typically have lower environmental impact than metal-based alternatives containing gallium or indium, which face resource scarcity and extraction challenges. Biodegradable and bio-based TIMs represent an emerging category with promising sustainability profiles, though their thermal performance currently lags behind synthetic options by approximately 10-15%.

Waste management concerns are particularly relevant for immersion cooling systems, where dielectric fluids must be properly handled at end-of-life. TIMs designed for compatibility with recycling processes can reduce landfill waste by up to 70%. Several manufacturers now offer take-back programs for spent thermal materials, creating closed-loop systems that minimize environmental impact.

Regulatory compliance is evolving rapidly in this space. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly impact TIM formulations. Forward-thinking manufacturers are proactively developing compliant products that eliminate substances of very high concern (SVHCs) while maintaining thermal performance.

Carbon footprint calculations indicate that optimized cooling solutions using appropriate TIMs can reduce data center emissions by 30-40% compared to traditional air cooling. This represents a significant opportunity for organizations pursuing carbon neutrality goals. The embodied carbon in TIM production is typically recovered within 3-6 months of operational efficiency gains.

Water usage represents another sustainability metric, with direct-to-chip cooling solutions generally requiring less water than traditional cooling towers. When paired with appropriate TIMs, these systems can reduce water consumption by up to 80%, addressing growing concerns about water scarcity in many regions where data centers operate.

When evaluating TIMs for immersion and direct-to-chip cooling, lifecycle assessment reveals that manufacturing processes for advanced thermal compounds often require energy-intensive production methods. However, these initial environmental costs are frequently offset by operational efficiency gains over the system's lifespan. For instance, properly selected TIMs can improve thermal conductivity by 15-30%, reducing the energy required for cooling by up to 25% compared to conventional solutions.

Material composition presents another critical environmental consideration. Silicon-based TIMs typically have lower environmental impact than metal-based alternatives containing gallium or indium, which face resource scarcity and extraction challenges. Biodegradable and bio-based TIMs represent an emerging category with promising sustainability profiles, though their thermal performance currently lags behind synthetic options by approximately 10-15%.

Waste management concerns are particularly relevant for immersion cooling systems, where dielectric fluids must be properly handled at end-of-life. TIMs designed for compatibility with recycling processes can reduce landfill waste by up to 70%. Several manufacturers now offer take-back programs for spent thermal materials, creating closed-loop systems that minimize environmental impact.

Regulatory compliance is evolving rapidly in this space. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly impact TIM formulations. Forward-thinking manufacturers are proactively developing compliant products that eliminate substances of very high concern (SVHCs) while maintaining thermal performance.

Carbon footprint calculations indicate that optimized cooling solutions using appropriate TIMs can reduce data center emissions by 30-40% compared to traditional air cooling. This represents a significant opportunity for organizations pursuing carbon neutrality goals. The embodied carbon in TIM production is typically recovered within 3-6 months of operational efficiency gains.

Water usage represents another sustainability metric, with direct-to-chip cooling solutions generally requiring less water than traditional cooling towers. When paired with appropriate TIMs, these systems can reduce water consumption by up to 80%, addressing growing concerns about water scarcity in many regions where data centers operate.

Reliability Testing and Performance Metrics for TIMs

Reliability testing for Thermal Interface Materials (TIMs) in immersion and direct-to-chip cooling applications requires comprehensive evaluation protocols that assess both short-term performance and long-term stability. Standard testing methodologies include thermal cycling tests, which subject TIMs to repeated temperature fluctuations between extreme operating conditions, typically ranging from -40°C to 125°C for several thousand cycles. These tests evaluate the material's resistance to thermal fatigue and mechanical stress induced by coefficient of thermal expansion (CTE) mismatches between different components.

High-temperature storage tests represent another critical evaluation metric, where TIMs are exposed to elevated temperatures (typically 125°C to 150°C) for extended periods (1000+ hours) to accelerate aging effects and assess thermal degradation mechanisms. Similarly, temperature-humidity-bias (THB) tests expose materials to high humidity (85% RH) and elevated temperatures (85°C) while under electrical bias to evaluate potential corrosion or chemical degradation.

Performance metrics for TIMs must be quantified through standardized measurements. Thermal conductivity, measured in W/m·K, remains the primary indicator of a TIM's heat transfer capability, with values ranging from 0.5 W/m·K for basic greases to over 20 W/m·K for advanced metal-based solutions. Thermal resistance (measured in K·mm²/W) provides a more application-specific metric that accounts for both material properties and interface quality.

For immersion cooling applications specifically, chemical compatibility testing becomes paramount. TIMs must maintain performance stability when continuously exposed to dielectric fluids without leaching, swelling, or chemical degradation. Standardized tests measuring weight change, dimensional stability, and thermal performance after fluid exposure for 1000+ hours help quantify compatibility.

Mechanical stability metrics include bond strength measurements (typically 0.3-3 MPa for adhesive TIMs), pump-out resistance testing, and phase separation evaluations. These properties are particularly critical for direct-to-chip cooling where thermal cycling can induce significant mechanical stresses at interfaces.

Reliability prediction models have been developed to correlate accelerated test results with real-world performance expectations. Arrhenius-based models for temperature-induced degradation and Coffin-Manson relationships for thermal cycling fatigue provide mathematical frameworks for estimating TIM lifetime under specific operating conditions. These models typically suggest that every 10°C increase in operating temperature reduces TIM lifetime by approximately 50%.

Industry standards such as JEDEC JESD22-A104 for temperature cycling, ASTM D5470 for thermal performance measurement, and ASTM D5338 for biodegradability assessment provide standardized frameworks for consistent evaluation and comparison of different TIM solutions across immersion and direct-to-chip cooling applications.

High-temperature storage tests represent another critical evaluation metric, where TIMs are exposed to elevated temperatures (typically 125°C to 150°C) for extended periods (1000+ hours) to accelerate aging effects and assess thermal degradation mechanisms. Similarly, temperature-humidity-bias (THB) tests expose materials to high humidity (85% RH) and elevated temperatures (85°C) while under electrical bias to evaluate potential corrosion or chemical degradation.

Performance metrics for TIMs must be quantified through standardized measurements. Thermal conductivity, measured in W/m·K, remains the primary indicator of a TIM's heat transfer capability, with values ranging from 0.5 W/m·K for basic greases to over 20 W/m·K for advanced metal-based solutions. Thermal resistance (measured in K·mm²/W) provides a more application-specific metric that accounts for both material properties and interface quality.

For immersion cooling applications specifically, chemical compatibility testing becomes paramount. TIMs must maintain performance stability when continuously exposed to dielectric fluids without leaching, swelling, or chemical degradation. Standardized tests measuring weight change, dimensional stability, and thermal performance after fluid exposure for 1000+ hours help quantify compatibility.

Mechanical stability metrics include bond strength measurements (typically 0.3-3 MPa for adhesive TIMs), pump-out resistance testing, and phase separation evaluations. These properties are particularly critical for direct-to-chip cooling where thermal cycling can induce significant mechanical stresses at interfaces.

Reliability prediction models have been developed to correlate accelerated test results with real-world performance expectations. Arrhenius-based models for temperature-induced degradation and Coffin-Manson relationships for thermal cycling fatigue provide mathematical frameworks for estimating TIM lifetime under specific operating conditions. These models typically suggest that every 10°C increase in operating temperature reduces TIM lifetime by approximately 50%.

Industry standards such as JEDEC JESD22-A104 for temperature cycling, ASTM D5470 for thermal performance measurement, and ASTM D5338 for biodegradability assessment provide standardized frameworks for consistent evaluation and comparison of different TIM solutions across immersion and direct-to-chip cooling applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!