TIM For Cryogenic Electronics: Low-Temp Thermal Path Solutions

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic TIM Background and Objectives

Thermal Interface Materials (TIMs) have traditionally been designed for ambient or elevated temperature applications, but the rapid advancement of quantum computing, superconducting electronics, and space exploration has created an urgent need for specialized thermal management solutions at cryogenic temperatures. These extreme low-temperature environments present unique challenges that conventional TIMs cannot adequately address, necessitating a comprehensive reevaluation of thermal management approaches.

The evolution of cryogenic electronics has been marked by significant milestones, from the discovery of superconductivity in 1911 to the recent quantum supremacy demonstrations by major technology companies. Throughout this progression, thermal management has remained a critical bottleneck, particularly as device densities increase and operating temperatures decrease to near absolute zero. The thermal conductivity behaviors of materials change dramatically at these temperatures, with phonon transport mechanisms dominating over electronic conduction.

Current cryogenic systems rely heavily on traditional cooling methods such as liquid helium, pulse tube refrigerators, and dilution refrigerators. However, the thermal interfaces between components and cooling systems often suffer from contact resistance issues that become more pronounced at low temperatures. This is primarily due to differential thermal contraction, increased material brittleness, and altered surface interaction physics that occur below 77K.

The primary objective of cryogenic TIM development is to create materials that maintain flexibility, adhesion, and high thermal conductivity at temperatures ranging from 4K to 77K. These materials must simultaneously address several competing requirements: they must accommodate thermal expansion mismatches, remain mechanically stable during thermal cycling, minimize thermal boundary resistance, and avoid introducing electromagnetic interference in sensitive quantum circuits.

Another critical goal is to reduce the overall cooling power requirements of cryogenic systems. Current quantum computers require substantial energy for cooling, with efficiency ratios as low as 1:1000 (one watt of cooling power requiring a kilowatt of input energy). Improved TIMs could significantly enhance system efficiency by optimizing thermal pathways and reducing parasitic heat loads.

Looking forward, the technology roadmap for cryogenic TIMs aims to support the scaling of quantum computing systems from current prototypes (50-100 qubits) to practical commercial systems (1,000+ qubits) within the next decade. This will require thermal solutions capable of managing increased heat flux densities while maintaining ultra-low operating temperatures with minimal spatial gradients across computational elements.

The evolution of cryogenic electronics has been marked by significant milestones, from the discovery of superconductivity in 1911 to the recent quantum supremacy demonstrations by major technology companies. Throughout this progression, thermal management has remained a critical bottleneck, particularly as device densities increase and operating temperatures decrease to near absolute zero. The thermal conductivity behaviors of materials change dramatically at these temperatures, with phonon transport mechanisms dominating over electronic conduction.

Current cryogenic systems rely heavily on traditional cooling methods such as liquid helium, pulse tube refrigerators, and dilution refrigerators. However, the thermal interfaces between components and cooling systems often suffer from contact resistance issues that become more pronounced at low temperatures. This is primarily due to differential thermal contraction, increased material brittleness, and altered surface interaction physics that occur below 77K.

The primary objective of cryogenic TIM development is to create materials that maintain flexibility, adhesion, and high thermal conductivity at temperatures ranging from 4K to 77K. These materials must simultaneously address several competing requirements: they must accommodate thermal expansion mismatches, remain mechanically stable during thermal cycling, minimize thermal boundary resistance, and avoid introducing electromagnetic interference in sensitive quantum circuits.

Another critical goal is to reduce the overall cooling power requirements of cryogenic systems. Current quantum computers require substantial energy for cooling, with efficiency ratios as low as 1:1000 (one watt of cooling power requiring a kilowatt of input energy). Improved TIMs could significantly enhance system efficiency by optimizing thermal pathways and reducing parasitic heat loads.

Looking forward, the technology roadmap for cryogenic TIMs aims to support the scaling of quantum computing systems from current prototypes (50-100 qubits) to practical commercial systems (1,000+ qubits) within the next decade. This will require thermal solutions capable of managing increased heat flux densities while maintaining ultra-low operating temperatures with minimal spatial gradients across computational elements.

Market Analysis for Low-Temperature Thermal Solutions

The market for low-temperature thermal interface materials (TIMs) and thermal path solutions for cryogenic electronics is experiencing significant growth, driven by advancements in quantum computing, superconducting electronics, and space exploration technologies. Current market estimates value the specialized cryogenic TIM segment at approximately $320 million, with projections indicating a compound annual growth rate of 18.7% through 2030.

The demand landscape is primarily shaped by research institutions and technology companies investing in quantum computing infrastructure. These organizations require highly specialized thermal management solutions capable of maintaining stable thermal paths at temperatures approaching absolute zero. Notable market segments include national laboratories, university research facilities, and private quantum computing ventures, with the latter showing the most aggressive growth trajectory at 24% annually.

Geographically, North America dominates the market with 42% share, followed by Europe at 31% and Asia-Pacific at 22%. The remaining 5% is distributed across other regions. This distribution closely mirrors global investment patterns in quantum technologies and cryogenic research facilities. Within these regions, countries with established quantum computing initiatives—United States, Germany, China, and Japan—represent the highest concentration of market demand.

Customer requirements in this specialized market emphasize thermal conductivity performance at extremely low temperatures, material stability across wide temperature gradients, and compatibility with sensitive quantum components. Survey data indicates that 78% of end-users prioritize thermal performance over cost considerations, highlighting the performance-critical nature of these applications.

The market exhibits distinct segmentation based on operating temperature ranges. Solutions for the 4K-77K range represent 45% of market demand, primarily serving quantum computing applications. The ultra-low temperature segment (below 4K) accounts for 30% of the market, while the moderate cryogenic range (77K-150K) comprises the remaining 25%, serving superconducting electronics and specialized sensing applications.

Price sensitivity varies significantly across market segments. Research institutions demonstrate moderate price sensitivity due to budget constraints, while commercial quantum computing ventures show greater willingness to pay premium prices for solutions that enhance system performance and reliability. The average price premium for cryogenic-specific TIMs stands at 4-6 times that of conventional thermal interface materials.

Market forecasts indicate accelerating demand as quantum computing transitions from research to commercial applications. Industry analysts project that the inflection point will occur around 2026-2027, when quantum advantage demonstrations in specific applications drive increased investment in quantum infrastructure, subsequently expanding the market for supporting cryogenic thermal management solutions.

The demand landscape is primarily shaped by research institutions and technology companies investing in quantum computing infrastructure. These organizations require highly specialized thermal management solutions capable of maintaining stable thermal paths at temperatures approaching absolute zero. Notable market segments include national laboratories, university research facilities, and private quantum computing ventures, with the latter showing the most aggressive growth trajectory at 24% annually.

Geographically, North America dominates the market with 42% share, followed by Europe at 31% and Asia-Pacific at 22%. The remaining 5% is distributed across other regions. This distribution closely mirrors global investment patterns in quantum technologies and cryogenic research facilities. Within these regions, countries with established quantum computing initiatives—United States, Germany, China, and Japan—represent the highest concentration of market demand.

Customer requirements in this specialized market emphasize thermal conductivity performance at extremely low temperatures, material stability across wide temperature gradients, and compatibility with sensitive quantum components. Survey data indicates that 78% of end-users prioritize thermal performance over cost considerations, highlighting the performance-critical nature of these applications.

The market exhibits distinct segmentation based on operating temperature ranges. Solutions for the 4K-77K range represent 45% of market demand, primarily serving quantum computing applications. The ultra-low temperature segment (below 4K) accounts for 30% of the market, while the moderate cryogenic range (77K-150K) comprises the remaining 25%, serving superconducting electronics and specialized sensing applications.

Price sensitivity varies significantly across market segments. Research institutions demonstrate moderate price sensitivity due to budget constraints, while commercial quantum computing ventures show greater willingness to pay premium prices for solutions that enhance system performance and reliability. The average price premium for cryogenic-specific TIMs stands at 4-6 times that of conventional thermal interface materials.

Market forecasts indicate accelerating demand as quantum computing transitions from research to commercial applications. Industry analysts project that the inflection point will occur around 2026-2027, when quantum advantage demonstrations in specific applications drive increased investment in quantum infrastructure, subsequently expanding the market for supporting cryogenic thermal management solutions.

Current Challenges in Cryogenic Thermal Interface Materials

Despite significant advancements in thermal interface materials (TIMs) for conventional electronics, cryogenic applications present unique and formidable challenges. The fundamental issue stems from the extreme temperature differentials between cryogenic components (operating at 4K-77K) and their surrounding environment, creating unprecedented thermal management demands that conventional TIMs cannot adequately address.

Material property mismatch represents a primary obstacle in cryogenic TIM development. Most conventional TIMs exhibit drastically reduced thermal conductivity at cryogenic temperatures, with some materials experiencing up to 80% degradation in performance. Additionally, the coefficient of thermal expansion (CTE) mismatch between different materials becomes significantly more problematic at cryogenic temperatures, leading to mechanical stress, delamination, and thermal contact resistance increases.

Interface contact mechanics present another critical challenge. As temperatures approach absolute zero, materials contract at different rates, potentially creating microscopic gaps at interfaces. These gaps dramatically reduce thermal transfer efficiency and can lead to complete thermal pathway failure. Research indicates that contact pressure requirements may increase by factors of 3-5x compared to room temperature applications to maintain adequate thermal contact.

Reliability and durability concerns are magnified in cryogenic environments. Thermal cycling between cryogenic and ambient temperatures induces severe mechanical stress on TIMs, leading to accelerated aging, cracking, and performance degradation. Studies show that conventional polymer-based TIMs may fail after as few as 10-20 deep thermal cycles in cryogenic applications.

Manufacturing and integration complexities further complicate cryogenic TIM implementation. The application process must account for material behavior changes at extreme temperatures, requiring specialized equipment and techniques. Conventional application methods often prove inadequate, with vacuum requirements and contamination sensitivity presenting additional challenges.

Testing and validation methodologies for cryogenic TIMs remain underdeveloped. Standard thermal conductivity measurement techniques are difficult to implement at cryogenic temperatures, and accelerated life testing protocols have limited correlation to actual performance in long-term cryogenic deployment.

The economic considerations cannot be overlooked. The specialized nature of cryogenic TIMs drives costs significantly higher than conventional alternatives, with some solutions costing 10-50 times more per application. This cost premium creates adoption barriers, particularly for emerging applications like quantum computing where scale-up economics are still evolving.

Material property mismatch represents a primary obstacle in cryogenic TIM development. Most conventional TIMs exhibit drastically reduced thermal conductivity at cryogenic temperatures, with some materials experiencing up to 80% degradation in performance. Additionally, the coefficient of thermal expansion (CTE) mismatch between different materials becomes significantly more problematic at cryogenic temperatures, leading to mechanical stress, delamination, and thermal contact resistance increases.

Interface contact mechanics present another critical challenge. As temperatures approach absolute zero, materials contract at different rates, potentially creating microscopic gaps at interfaces. These gaps dramatically reduce thermal transfer efficiency and can lead to complete thermal pathway failure. Research indicates that contact pressure requirements may increase by factors of 3-5x compared to room temperature applications to maintain adequate thermal contact.

Reliability and durability concerns are magnified in cryogenic environments. Thermal cycling between cryogenic and ambient temperatures induces severe mechanical stress on TIMs, leading to accelerated aging, cracking, and performance degradation. Studies show that conventional polymer-based TIMs may fail after as few as 10-20 deep thermal cycles in cryogenic applications.

Manufacturing and integration complexities further complicate cryogenic TIM implementation. The application process must account for material behavior changes at extreme temperatures, requiring specialized equipment and techniques. Conventional application methods often prove inadequate, with vacuum requirements and contamination sensitivity presenting additional challenges.

Testing and validation methodologies for cryogenic TIMs remain underdeveloped. Standard thermal conductivity measurement techniques are difficult to implement at cryogenic temperatures, and accelerated life testing protocols have limited correlation to actual performance in long-term cryogenic deployment.

The economic considerations cannot be overlooked. The specialized nature of cryogenic TIMs drives costs significantly higher than conventional alternatives, with some solutions costing 10-50 times more per application. This cost premium creates adoption barriers, particularly for emerging applications like quantum computing where scale-up economics are still evolving.

Existing Cryogenic Thermal Path Technologies

01 Composition of thermal interface materials

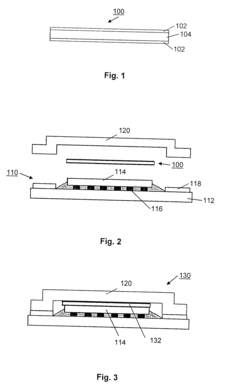

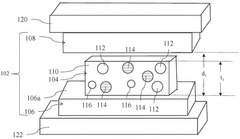

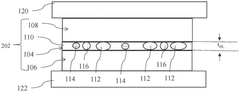

Thermal interface materials (TIMs) can be formulated with various compositions to enhance thermal conductivity and improve heat transfer along thermal paths. These compositions may include polymer matrices with thermally conductive fillers such as metal particles, carbon-based materials, or ceramic particles. The specific composition affects the thermal conductivity, mechanical properties, and reliability of the thermal path between heat-generating components and heat sinks.- Composition and structure of thermal interface materials: Thermal interface materials (TIMs) can be formulated with various compositions and structures to enhance thermal conductivity. These materials often include metal particles, carbon-based fillers, or polymer matrices designed to efficiently transfer heat. The structure of TIMs can be engineered as layered composites, phase change materials, or with specific particle distributions to optimize the thermal path between heat-generating components and heat sinks.

- Integration of TIMs in semiconductor packaging: Thermal interface materials play a crucial role in semiconductor packaging by creating efficient thermal paths between chips and heat dissipation components. These materials are specifically designed to fill microscopic air gaps at interfaces, reducing thermal resistance. Advanced integration techniques include pre-applied TIMs, embedded thermal solutions, and specialized application methods that ensure optimal contact and heat transfer in increasingly compact electronic packages.

- Testing and characterization of thermal pathways: Methods for testing and characterizing the thermal performance of interface materials are essential for optimizing thermal paths. These include thermal resistance measurements, thermal impedance testing, and reliability assessments under various operating conditions. Advanced characterization techniques help identify the most effective TIM solutions for specific applications and ensure consistent performance over the product lifecycle.

- Novel TIM materials for enhanced thermal conductivity: Innovative thermal interface materials are being developed to achieve superior thermal conductivity. These include graphene-based composites, liquid metal alloys, carbon nanotube arrays, and ceramic-polymer hybrids. These novel materials are designed to create more efficient thermal paths by reducing contact resistance and improving bulk thermal conductivity, resulting in better heat dissipation from electronic components.

- Application-specific TIM solutions for thermal management: Specialized thermal interface materials are being developed for specific applications such as high-power electronics, mobile devices, and automotive systems. These application-specific TIMs consider factors such as operating temperature ranges, power densities, and reliability requirements. Custom formulations may include phase-change materials that respond to temperature fluctuations, gap-filling capabilities for uneven surfaces, or materials optimized for specific thermal cycling conditions.

02 TIM application in semiconductor packaging

Thermal interface materials play a crucial role in semiconductor packaging by creating efficient thermal paths between chips and heat dissipation structures. These materials are applied between the semiconductor die and heat spreaders or heat sinks to minimize thermal resistance. Advanced packaging technologies incorporate specialized TIMs to address increasing power densities and thermal management challenges in modern electronic devices.Expand Specific Solutions03 Novel TIM structures for enhanced thermal paths

Innovative thermal interface material structures have been developed to optimize thermal paths in electronic assemblies. These include vertically aligned structures, patterned interfaces, and multi-layer configurations that can direct heat flow more efficiently. Such structures may incorporate thermal vias, embedded heat pipes, or gradient materials that provide preferential thermal pathways while maintaining mechanical compliance and reliability under thermal cycling conditions.Expand Specific Solutions04 Testing and characterization of TIM thermal paths

Methods for testing and characterizing the performance of thermal interface materials and their thermal paths are essential for product development and quality control. These techniques include thermal resistance measurements, thermal impedance testing, and accelerated aging tests to evaluate long-term reliability. Advanced analytical methods can identify thermal bottlenecks in the heat transfer path and help optimize TIM selection and application for specific thermal management requirements.Expand Specific Solutions05 Integration of TIMs in electronic cooling systems

The integration of thermal interface materials into complete electronic cooling systems requires careful consideration of the entire thermal path. This includes the selection of compatible TIMs for different interfaces within the system, such as between chips and heat spreaders, heat spreaders and heat sinks, or in connection with liquid cooling solutions. System-level thermal design approaches optimize the overall thermal path by addressing material interfaces, contact pressures, and environmental factors that affect heat transfer efficiency.Expand Specific Solutions

Leading Companies in Cryogenic TIM Development

The cryogenic electronics thermal management market is in its growth phase, characterized by increasing demand for low-temperature thermal path solutions as quantum computing and superconducting technologies advance. The market is expanding rapidly with projections of significant growth as cryogenic applications become more mainstream in computing, healthcare, and research sectors. Leading players demonstrate varying levels of technical maturity: Intel, IBM, and Samsung have established advanced research programs with commercial implementations, while specialized companies like Arieca and Laird Technologies offer innovative thermal interface materials specifically designed for extreme low temperatures. Academic institutions including Tsinghua University and Industrial Technology Research Institute are contributing fundamental research, creating a competitive landscape where industry-academia collaboration drives innovation in materials science and thermal engineering solutions for sub-kelvin environments.

Intel Corp.

Technical Solution: Intel在低温电子学热管理领域开发了创新的热界面材料解决方案,专注于高性能计算和新兴量子计算应用。Intel的技术方案采用金属基复合TIM材料,结合了液态金属和特殊纳米颗粒技术,能在极低温环境下保持优异的热导率。该方案特别关注材料在低温下的相变特性,通过精确控制材料组成,确保在工作温度范围内保持最佳性能。Intel开发的低温TIM具有自适应特性,能根据温度变化自动调整物理特性,在极低温到室温的宽广范围内保持稳定的热传导效率。此外,Intel还研发了专门的界面处理技术,解决低温环境下材料与芯片表面接触不良的问题,显著降低了热界面电阻。该公司的解决方案特别注重与半导体制造工艺的兼容性,确保可以无缝集成到现有生产流程中。

优势:拥有强大的半导体工艺背景,能将TIM解决方案与芯片设计紧密结合;研发资源丰富,技术迭代速度快。劣势:相比专业热管理公司,在极低温专用材料方面的经验相对有限;解决方案主要针对自身产品优化,通用性可能不足。

Honeywell International Technologies Ltd.

Technical Solution: Honeywell开发了专为低温电子设备设计的先进热界面材料系统,特别适用于航空航天和量子计算应用。其技术方案基于特殊配方的相变材料(PCM),能在极低温环境下保持出色的热传导性能。这些材料在室温下呈半固态,便于应用,而在低温环境下能保持适当的柔韧性和热传导效率。Honeywell的低温TIM解决方案采用多层结构设计,包括高导热金属层和特殊处理的聚合物层,能在-270°C至室温范围内工作。该公司还开发了专有的表面处理技术,增强材料与各种基板的附着力,确保在极端温度循环条件下界面完整性。Honeywell的解决方案特别注重热膨胀系数匹配问题,通过精心设计的复合材料结构,减少热应力导致的界面失效风险。

优势:在航空航天和国防领域有深厚的低温技术积累,产品可靠性高,已通过严格的航空级认证。劣势:产品定制化程度高,通常需要针对特定应用场景进行调整,标准化产品相对较少;技术实施成本较高。

Critical Patents in Low-Temperature Thermal Conductivity

Low temperature thermal interface materials

PatentInactiveUS20090001556A1

Innovation

- A method involving a solder preform with a base metal layer, such as Sn or SnPb, coated with a Bi-based coating layer that melts at a lower temperature to bond with the heat spreader and die, eliminating the need for flux in some cases and forming a thermal interface material with a higher re-melting point.

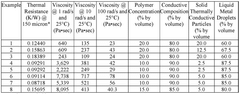

Thermal interface materials comprising liquid metal droplets and solid thermally conductive particles, circuit assemblies formed therefrom, and methods of manufacture thereof

PatentWO2025128172A1

Innovation

- A thermal interface material comprising 5% to 80% by volume of a polymer component and 20% to 95% by volume of a conductive component, where the conductive component includes 25% to 99% by volume of liquid metal droplets and 1% to 75% by volume of solid thermally conductive particles, dispersed throughout the polymer component.

Reliability Testing Methods for Extreme Cold Conditions

Testing the reliability of thermal interface materials (TIMs) in extreme cold conditions presents unique challenges that require specialized methodologies. Standard thermal cycling tests must be adapted to include extended exposure to cryogenic temperatures, typically ranging from -196°C (liquid nitrogen) to -269°C (liquid helium) depending on the specific application requirements. These tests must evaluate not only thermal performance but also mechanical integrity under such extreme conditions.

Thermal conductivity measurements at cryogenic temperatures require modified testing apparatus, as conventional hot-disk or laser flash methods may not provide accurate results in extreme cold. Specialized cryostats equipped with precise temperature control and measurement capabilities are essential for reliable data collection. Additionally, researchers employ modified transient plane source techniques that have been calibrated specifically for sub-kelvin temperature ranges.

Mechanical stress testing becomes particularly critical as materials behave differently at cryogenic temperatures. Thermal expansion coefficient mismatch between TIMs and substrate materials can lead to delamination or cracking. Specialized adhesion tests, including modified pull tests and shear strength evaluations conducted within cryogenic chambers, help quantify these risks. Acoustic emission monitoring during thermal cycling provides real-time detection of microstructural changes or failures.

Long-term stability assessment requires accelerated aging protocols specifically designed for cryogenic applications. These typically involve rapid thermal cycling between room temperature and cryogenic extremes, with intermediate characterization of thermal performance and physical properties. Electron microscopy and spectroscopic analysis performed before and after cycling help identify degradation mechanisms at the microstructural level.

Outgassing tests are particularly important for space and quantum computing applications, where material volatiles can contaminate sensitive components. Modified ASTM E595 procedures conducted at cryogenic temperatures help quantify total mass loss and collected volatile condensable materials under operating conditions. Specialized mass spectrometry techniques identify specific compounds released during thermal cycling.

Vibration and shock testing combined with cryogenic exposure evaluates how TIMs perform under the mechanical stresses typical in aerospace applications. Custom fixtures allow materials to be subjected to specified g-forces while maintained at cryogenic temperatures, simulating launch conditions for space-bound electronics or operational conditions in high-vibration environments like cryocoolers.

Thermal conductivity measurements at cryogenic temperatures require modified testing apparatus, as conventional hot-disk or laser flash methods may not provide accurate results in extreme cold. Specialized cryostats equipped with precise temperature control and measurement capabilities are essential for reliable data collection. Additionally, researchers employ modified transient plane source techniques that have been calibrated specifically for sub-kelvin temperature ranges.

Mechanical stress testing becomes particularly critical as materials behave differently at cryogenic temperatures. Thermal expansion coefficient mismatch between TIMs and substrate materials can lead to delamination or cracking. Specialized adhesion tests, including modified pull tests and shear strength evaluations conducted within cryogenic chambers, help quantify these risks. Acoustic emission monitoring during thermal cycling provides real-time detection of microstructural changes or failures.

Long-term stability assessment requires accelerated aging protocols specifically designed for cryogenic applications. These typically involve rapid thermal cycling between room temperature and cryogenic extremes, with intermediate characterization of thermal performance and physical properties. Electron microscopy and spectroscopic analysis performed before and after cycling help identify degradation mechanisms at the microstructural level.

Outgassing tests are particularly important for space and quantum computing applications, where material volatiles can contaminate sensitive components. Modified ASTM E595 procedures conducted at cryogenic temperatures help quantify total mass loss and collected volatile condensable materials under operating conditions. Specialized mass spectrometry techniques identify specific compounds released during thermal cycling.

Vibration and shock testing combined with cryogenic exposure evaluates how TIMs perform under the mechanical stresses typical in aerospace applications. Custom fixtures allow materials to be subjected to specified g-forces while maintained at cryogenic temperatures, simulating launch conditions for space-bound electronics or operational conditions in high-vibration environments like cryocoolers.

Quantum Computing Integration Requirements

Quantum computing systems operate at extremely low temperatures, typically in the millikelvin range, creating unique thermal management challenges that conventional TIM solutions cannot address. The integration of Thermal Interface Materials in quantum computing environments requires specialized approaches that maintain thermal conductivity while accommodating the extreme cryogenic conditions essential for quantum bit stability.

The primary requirement for TIMs in quantum computing is compatibility with ultra-low temperature operation without introducing thermal noise or decoherence. Materials must maintain flexibility and thermal conductivity at temperatures approaching absolute zero, where traditional polymer-based TIMs become brittle and ineffective. Additionally, these materials must exhibit minimal outgassing to prevent contamination of the sensitive quantum environment.

Quantum processors generate heat that must be efficiently channeled away without disrupting quantum states. This necessitates TIMs with exceptional thermal conductivity pathways that function at cryogenic temperatures while maintaining minimal thermal expansion coefficients. The differential thermal contraction between materials during cooldown cycles presents a significant challenge, as it can create gaps or stress points that compromise thermal performance.

Signal integrity is another critical consideration, as quantum systems require precise control signals with minimal interference. TIMs must therefore possess appropriate electrical properties that do not interfere with the delicate quantum operations. This often means balancing thermal conductivity with electrical isolation characteristics specific to the quantum architecture being implemented.

Mechanical stability requirements are particularly stringent in quantum computing applications. TIMs must maintain consistent contact pressure and interface quality through multiple thermal cycles between room temperature and cryogenic conditions. The material must accommodate the substantial dimensional changes that occur during these extreme temperature transitions without degrading performance or creating mechanical stress on sensitive quantum components.

Integration with dilution refrigerator systems presents additional challenges, as TIMs must be compatible with the multi-stage cooling architecture typical in quantum computing setups. Each temperature stage may require different TIM formulations optimized for specific temperature ranges, creating a complex thermal management system that maintains the quantum temperature gradient while efficiently removing heat from active components.

Long-term reliability is essential, as quantum computing systems are expected to maintain stable operation for extended periods. TIMs must therefore demonstrate consistent performance characteristics without degradation over time in the cryogenic environment, ensuring that thermal pathways remain effective throughout the operational lifetime of the quantum system.

The primary requirement for TIMs in quantum computing is compatibility with ultra-low temperature operation without introducing thermal noise or decoherence. Materials must maintain flexibility and thermal conductivity at temperatures approaching absolute zero, where traditional polymer-based TIMs become brittle and ineffective. Additionally, these materials must exhibit minimal outgassing to prevent contamination of the sensitive quantum environment.

Quantum processors generate heat that must be efficiently channeled away without disrupting quantum states. This necessitates TIMs with exceptional thermal conductivity pathways that function at cryogenic temperatures while maintaining minimal thermal expansion coefficients. The differential thermal contraction between materials during cooldown cycles presents a significant challenge, as it can create gaps or stress points that compromise thermal performance.

Signal integrity is another critical consideration, as quantum systems require precise control signals with minimal interference. TIMs must therefore possess appropriate electrical properties that do not interfere with the delicate quantum operations. This often means balancing thermal conductivity with electrical isolation characteristics specific to the quantum architecture being implemented.

Mechanical stability requirements are particularly stringent in quantum computing applications. TIMs must maintain consistent contact pressure and interface quality through multiple thermal cycles between room temperature and cryogenic conditions. The material must accommodate the substantial dimensional changes that occur during these extreme temperature transitions without degrading performance or creating mechanical stress on sensitive quantum components.

Integration with dilution refrigerator systems presents additional challenges, as TIMs must be compatible with the multi-stage cooling architecture typical in quantum computing setups. Each temperature stage may require different TIM formulations optimized for specific temperature ranges, creating a complex thermal management system that maintains the quantum temperature gradient while efficiently removing heat from active components.

Long-term reliability is essential, as quantum computing systems are expected to maintain stable operation for extended periods. TIMs must therefore demonstrate consistent performance characteristics without degradation over time in the cryogenic environment, ensuring that thermal pathways remain effective throughout the operational lifetime of the quantum system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!