TIM Process Capability Study: Cp/Cpk For Dispensing And Compression Steps

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Process Background and Objectives

Thermal Interface Materials (TIM) have emerged as critical components in modern electronics, serving as the essential thermal bridge between heat-generating components and heat dissipation systems. The evolution of TIM technology has been driven by the continuous miniaturization of electronic devices coupled with increasing power densities, creating unprecedented thermal management challenges. From simple thermal greases in early computing systems to advanced phase-change materials and thermal interface pads in today's high-performance electronics, TIM technology has undergone significant transformation to meet escalating thermal requirements.

The current focus on process capability studies for TIM application, particularly examining Cp/Cpk metrics for dispensing and compression steps, represents a critical advancement in manufacturing excellence. These statistical process control measures provide quantitative assessments of how well a process meets specified requirements, with Cp evaluating process potential and Cpk measuring process performance relative to specification limits. In the context of TIM application, these metrics are particularly vital as inconsistent dispensing or compression can lead to thermal interface failures, resulting in device overheating and reliability issues.

The primary objectives of this TIM process capability study are multifaceted. First, to establish baseline process capability metrics for both dispensing and compression steps in TIM application processes. Second, to identify critical process parameters that significantly impact thermal performance and reliability. Third, to optimize process windows that consistently deliver high-quality thermal interfaces across various product configurations. Fourth, to develop robust process control strategies that maintain process stability despite variations in environmental conditions, material properties, and equipment performance.

Industry trends indicate increasing demands for TIM processes that can accommodate higher thermal loads while maintaining reliability under extreme operating conditions. The automotive and aerospace sectors, in particular, require TIM solutions that can withstand severe thermal cycling, vibration, and extended operational lifetimes. Simultaneously, consumer electronics manufacturers seek TIM processes compatible with automated high-volume production while maintaining precise material placement and compression characteristics.

The technological trajectory suggests a convergence toward integrated process monitoring systems that provide real-time feedback on dispensing volume, pattern accuracy, compression force, and final bond line thickness. Advanced manufacturing facilities are increasingly implementing in-line quality verification systems that utilize optical inspection, force measurement, and thermal performance testing to ensure process capability remains within specified limits throughout production runs.

This capability study aims to establish a comprehensive understanding of process variability sources and their impact on thermal performance, ultimately enabling predictive process control strategies that can adapt to changing conditions while maintaining optimal thermal interface quality.

The current focus on process capability studies for TIM application, particularly examining Cp/Cpk metrics for dispensing and compression steps, represents a critical advancement in manufacturing excellence. These statistical process control measures provide quantitative assessments of how well a process meets specified requirements, with Cp evaluating process potential and Cpk measuring process performance relative to specification limits. In the context of TIM application, these metrics are particularly vital as inconsistent dispensing or compression can lead to thermal interface failures, resulting in device overheating and reliability issues.

The primary objectives of this TIM process capability study are multifaceted. First, to establish baseline process capability metrics for both dispensing and compression steps in TIM application processes. Second, to identify critical process parameters that significantly impact thermal performance and reliability. Third, to optimize process windows that consistently deliver high-quality thermal interfaces across various product configurations. Fourth, to develop robust process control strategies that maintain process stability despite variations in environmental conditions, material properties, and equipment performance.

Industry trends indicate increasing demands for TIM processes that can accommodate higher thermal loads while maintaining reliability under extreme operating conditions. The automotive and aerospace sectors, in particular, require TIM solutions that can withstand severe thermal cycling, vibration, and extended operational lifetimes. Simultaneously, consumer electronics manufacturers seek TIM processes compatible with automated high-volume production while maintaining precise material placement and compression characteristics.

The technological trajectory suggests a convergence toward integrated process monitoring systems that provide real-time feedback on dispensing volume, pattern accuracy, compression force, and final bond line thickness. Advanced manufacturing facilities are increasingly implementing in-line quality verification systems that utilize optical inspection, force measurement, and thermal performance testing to ensure process capability remains within specified limits throughout production runs.

This capability study aims to establish a comprehensive understanding of process variability sources and their impact on thermal performance, ultimately enabling predictive process control strategies that can adapt to changing conditions while maintaining optimal thermal interface quality.

Market Requirements for TIM Process Capability

The thermal interface materials (TIM) market is experiencing significant growth driven by increasing demand for efficient heat management solutions across multiple industries. Current market analysis indicates that the global TIM market is projected to grow at a compound annual growth rate of 8-10% through 2028, with particular acceleration in electronics, automotive, and telecommunications sectors. This growth trajectory necessitates stringent process capability requirements for TIM manufacturing processes.

In the semiconductor and electronics manufacturing industry, thermal management has become a critical factor as device miniaturization continues while power densities increase. End users require TIM dispensing processes with Cpk values consistently above 1.33, with industry leaders pushing for 1.67 or higher to ensure reliable thermal performance and minimize defects in high-volume production environments.

The automotive industry, particularly with the rapid expansion of electric vehicles, demands TIM solutions with exceptional reliability under extreme temperature cycling conditions. Market requirements specify compression process capability indices (Cp/Cpk) exceeding 1.5 to ensure consistent bond line thickness and thermal conductivity across production batches, directly impacting battery thermal management system performance and longevity.

Telecommunications infrastructure manufacturers require TIM dispensing processes with demonstrated Cpk values above 1.4 for 5G equipment, where heat dissipation challenges are significantly greater than previous generation technologies. The market increasingly demands statistical evidence of process capability as part of supplier qualification procedures.

Consumer electronics manufacturers have established increasingly stringent specifications for TIM application, with leading smartphone and laptop manufacturers requiring dispensing process Cpk values of 1.6 or higher. This requirement stems from the need to maintain consistent thermal performance while reducing product thickness and weight.

Market feedback indicates that customers are willing to pay premium prices for TIM products with documented process capability studies showing superior consistency in dispensing volume, pattern accuracy, and compression force control. This trend is particularly evident in high-reliability applications such as medical devices, aerospace, and data center infrastructure.

The market increasingly demands real-time process monitoring capabilities integrated with TIM dispensing and compression equipment, allowing for immediate statistical process control and capability analysis. This requirement reflects the growing emphasis on Industry 4.0 principles and the need for manufacturing intelligence to maintain competitive advantage in high-value electronics assembly.

In the semiconductor and electronics manufacturing industry, thermal management has become a critical factor as device miniaturization continues while power densities increase. End users require TIM dispensing processes with Cpk values consistently above 1.33, with industry leaders pushing for 1.67 or higher to ensure reliable thermal performance and minimize defects in high-volume production environments.

The automotive industry, particularly with the rapid expansion of electric vehicles, demands TIM solutions with exceptional reliability under extreme temperature cycling conditions. Market requirements specify compression process capability indices (Cp/Cpk) exceeding 1.5 to ensure consistent bond line thickness and thermal conductivity across production batches, directly impacting battery thermal management system performance and longevity.

Telecommunications infrastructure manufacturers require TIM dispensing processes with demonstrated Cpk values above 1.4 for 5G equipment, where heat dissipation challenges are significantly greater than previous generation technologies. The market increasingly demands statistical evidence of process capability as part of supplier qualification procedures.

Consumer electronics manufacturers have established increasingly stringent specifications for TIM application, with leading smartphone and laptop manufacturers requiring dispensing process Cpk values of 1.6 or higher. This requirement stems from the need to maintain consistent thermal performance while reducing product thickness and weight.

Market feedback indicates that customers are willing to pay premium prices for TIM products with documented process capability studies showing superior consistency in dispensing volume, pattern accuracy, and compression force control. This trend is particularly evident in high-reliability applications such as medical devices, aerospace, and data center infrastructure.

The market increasingly demands real-time process monitoring capabilities integrated with TIM dispensing and compression equipment, allowing for immediate statistical process control and capability analysis. This requirement reflects the growing emphasis on Industry 4.0 principles and the need for manufacturing intelligence to maintain competitive advantage in high-value electronics assembly.

Current Challenges in TIM Dispensing and Compression

The thermal interface material (TIM) dispensing and compression processes face significant challenges in achieving consistent process capability metrics (Cp/Cpk), which directly impact thermal performance and reliability in semiconductor packaging. Current manufacturing processes struggle with several critical issues that affect both quality and production efficiency.

Material viscosity variations represent a primary challenge in TIM dispensing. The rheological properties of thermal interface materials can fluctuate significantly based on temperature, storage conditions, and batch-to-batch inconsistencies. These variations lead to unpredictable flow rates during dispensing, resulting in inconsistent material deposition patterns and volumes that directly impact the Cp/Cpk values.

Dispensing equipment limitations further compound these challenges. Many current dispensing systems lack the precision required for increasingly miniaturized semiconductor packages. Pressure fluctuations, nozzle wear, and calibration drift contribute to dispensing variability that is difficult to control within tight specification limits. These equipment-related factors create systematic errors that negatively affect process capability metrics.

Environmental factors play a crucial role in TIM application consistency. Temperature and humidity variations on the production floor can alter material properties during the dispensing process. These environmental fluctuations are often inadequately controlled in many manufacturing facilities, leading to seasonal or even daily variations in process capability measurements.

In the compression phase, achieving uniform pressure distribution presents significant difficulties. Current compression equipment often fails to deliver consistent pressure across the entire interface surface, particularly for complex package geometries or when multiple dies are present. This non-uniform compression results in variable bond line thickness and potential void formation.

Measurement and monitoring limitations further exacerbate these challenges. Many facilities lack real-time monitoring capabilities for critical parameters during dispensing and compression. The inability to detect and correct process deviations promptly leads to higher rejection rates and reduced Cp/Cpk values. Additionally, measurement systems themselves may introduce variability through gauge repeatability and reproducibility issues.

Integration challenges between dispensing and compression steps create additional complications. The timing between these processes is critical, as material properties can change rapidly after dispensing. Current production lines often struggle with synchronization issues, leading to inconsistent results even when individual process steps appear to be in control.

These challenges collectively contribute to the difficulty in maintaining high and consistent Cp/Cpk values in TIM dispensing and compression processes, necessitating innovative solutions to improve process capability and product reliability.

Material viscosity variations represent a primary challenge in TIM dispensing. The rheological properties of thermal interface materials can fluctuate significantly based on temperature, storage conditions, and batch-to-batch inconsistencies. These variations lead to unpredictable flow rates during dispensing, resulting in inconsistent material deposition patterns and volumes that directly impact the Cp/Cpk values.

Dispensing equipment limitations further compound these challenges. Many current dispensing systems lack the precision required for increasingly miniaturized semiconductor packages. Pressure fluctuations, nozzle wear, and calibration drift contribute to dispensing variability that is difficult to control within tight specification limits. These equipment-related factors create systematic errors that negatively affect process capability metrics.

Environmental factors play a crucial role in TIM application consistency. Temperature and humidity variations on the production floor can alter material properties during the dispensing process. These environmental fluctuations are often inadequately controlled in many manufacturing facilities, leading to seasonal or even daily variations in process capability measurements.

In the compression phase, achieving uniform pressure distribution presents significant difficulties. Current compression equipment often fails to deliver consistent pressure across the entire interface surface, particularly for complex package geometries or when multiple dies are present. This non-uniform compression results in variable bond line thickness and potential void formation.

Measurement and monitoring limitations further exacerbate these challenges. Many facilities lack real-time monitoring capabilities for critical parameters during dispensing and compression. The inability to detect and correct process deviations promptly leads to higher rejection rates and reduced Cp/Cpk values. Additionally, measurement systems themselves may introduce variability through gauge repeatability and reproducibility issues.

Integration challenges between dispensing and compression steps create additional complications. The timing between these processes is critical, as material properties can change rapidly after dispensing. Current production lines often struggle with synchronization issues, leading to inconsistent results even when individual process steps appear to be in control.

These challenges collectively contribute to the difficulty in maintaining high and consistent Cp/Cpk values in TIM dispensing and compression processes, necessitating innovative solutions to improve process capability and product reliability.

Existing Cp/Cpk Measurement Techniques

01 TIM application methods and process control

Various methods for applying thermal interface materials (TIMs) in semiconductor packaging with focus on process control parameters. These methods include dispensing, printing, and pre-application techniques that ensure uniform coverage and thickness. Process capability metrics (Cp/Cpk) are used to monitor and control the application process, ensuring consistent thermal performance across manufactured devices.- TIM application process control and optimization: Thermal Interface Material application processes can be optimized through precise control of parameters such as pressure, temperature, and application time. Process capability indices (Cp/Cpk) are used to measure the consistency and reliability of the TIM application process. Advanced dispensing techniques and automated systems help maintain tight tolerances and reduce variability in TIM thickness and coverage, leading to improved thermal performance and reliability.

- TIM material composition for process capability improvement: The composition of Thermal Interface Materials significantly impacts process capability metrics. Materials with stable viscosity characteristics across temperature ranges enable more consistent application. Fillers, polymers, and phase change materials can be formulated to optimize both thermal conductivity and application properties. Advanced TIM formulations incorporate self-leveling properties and controlled flow characteristics to improve Cp/Cpk values during manufacturing processes.

- Testing and measurement methods for TIM process capability: Various testing methodologies are employed to evaluate TIM process capability, including thermal resistance measurements, bond line thickness analysis, and void detection techniques. Statistical process control methods are applied to monitor Cp/Cpk values in real-time during production. Advanced imaging techniques such as acoustic microscopy and X-ray inspection help identify defects that affect thermal performance. These measurement systems provide data for continuous process improvement and validation.

- TIM process capability in semiconductor packaging applications: In semiconductor packaging, TIM process capability is critical for ensuring reliable thermal management. Specialized application techniques for die-attach materials and interface pads maintain consistent thermal conductivity across high-volume production. Process capability indices are particularly important for advanced packaging technologies where thermal management directly impacts device performance and reliability. Automated dispensing systems with feedback control mechanisms help maintain high Cp/Cpk values in semiconductor assembly processes.

- Environmental factors affecting TIM process capability: Environmental conditions such as humidity, temperature, and cleanliness significantly impact TIM process capability metrics. Controlled manufacturing environments help maintain consistent material properties during application. Storage conditions and shelf life of thermal interface materials can affect their behavior during application processes. Stabilization techniques and environmental monitoring systems are implemented to minimize variations in Cp/Cpk values due to external factors, ensuring consistent thermal performance across production batches.

02 TIM material composition optimization for process capability

Formulation and composition of thermal interface materials specifically designed to improve process capability metrics. These formulations include modified viscosity profiles, controlled filler content, and specialized additives that enhance application consistency. The materials are engineered to maintain stable properties during manufacturing processes, resulting in higher Cp/Cpk values and more reliable thermal performance.Expand Specific Solutions03 Testing and measurement methods for TIM process capability

Advanced testing and measurement techniques for evaluating the process capability of thermal interface material applications. These methods include thermal resistance measurements, thickness uniformity assessments, and void detection technologies. Statistical process control approaches are implemented to calculate and monitor Cp/Cpk values, enabling manufacturers to identify and address process variations that affect thermal performance.Expand Specific Solutions04 Equipment and automation for TIM application with high Cp/Cpk

Specialized equipment and automation systems designed to achieve high process capability in thermal interface material application. These systems incorporate precision dispensing heads, optical alignment features, and real-time monitoring capabilities. Automated process controls adjust parameters during operation to maintain target specifications, resulting in improved Cp/Cpk metrics and reduced variation in thermal performance.Expand Specific Solutions05 TIM integration with semiconductor packaging processes

Methods for integrating thermal interface material application into broader semiconductor packaging processes while maintaining high process capability. These approaches address challenges such as co-planarity, surface preparation, and compatibility with adjacent assembly steps. Process optimization techniques ensure that TIM application achieves consistent Cp/Cpk values even when integrated with complex packaging workflows, resulting in reliable thermal management in the final device.Expand Specific Solutions

Leading Manufacturers and Equipment Suppliers

The TIM (Thermal Interface Material) process capability study for dispensing and compression steps is currently in a growth phase, with the market expanding due to increasing demand for thermal management solutions in electronics. The global TIM market is projected to reach significant scale as electronic devices become more compact and powerful. Technologically, major players like Intel, TSMC, and Samsung are leading innovation with advanced manufacturing processes, while specialized companies such as Arieca and KULR Technology are developing next-generation thermal interface materials. Boeing, IBM, and GlobalFoundries represent the industrial application side, implementing these technologies in high-performance computing and aerospace applications. The industry is moving toward more precise dispensing methods and compression techniques to improve thermal conductivity and reliability in increasingly demanding thermal environments.

Intel Corp.

Technical Solution: Intel has developed a comprehensive TIM (Thermal Interface Material) process capability study focusing on dispensing and compression steps. Their approach utilizes statistical process control (SPC) methodologies to monitor and improve Cp/Cpk values across their semiconductor manufacturing processes. Intel's solution incorporates automated dispensing systems with precision control mechanisms that can achieve ±0.05mm placement accuracy and ±2% volume consistency. For compression, they've implemented force-controlled systems that maintain 0.5-5.0 MPa pressure with ±1% variation tolerance. Their methodology includes real-time monitoring with optical verification systems that capture 30+ frames per second during dispensing to ensure proper material distribution. Intel has established a six-sigma quality target (Cp/Cpk > 1.67) for their TIM processes, with automated statistical analysis tools that process manufacturing data to identify process drift before it impacts yields.

Strengths: Advanced automation integration with real-time process monitoring capabilities; comprehensive statistical analysis framework; established correlation between process parameters and thermal performance. Weaknesses: High implementation cost; requires significant engineering resources for setup and maintenance; system complexity may increase troubleshooting time when issues occur.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has pioneered an advanced TIM process capability framework specifically designed for high-volume semiconductor manufacturing. Their approach combines automated dispensing systems with precision-controlled compression mechanisms to achieve consistent thermal interface quality. TSMC's solution features multi-zone dispensing patterns optimized through computational fluid dynamics simulations, allowing for uniform material distribution even with complex die geometries. Their compression methodology employs dynamic pressure profiling that adjusts in real-time based on material rheology feedback, maintaining Cpk values consistently above 1.5 across production lines. The system incorporates in-line metrology with laser profilometry that measures TIM thickness to ±1μm accuracy, feeding data directly into their statistical process control system. TSMC has implemented machine learning algorithms that analyze historical process data to predict potential Cp/Cpk degradation before it impacts production quality, enabling proactive maintenance and process adjustments.

Strengths: Industry-leading process consistency with documented Cpk values exceeding 1.7 in production environments; sophisticated in-line metrology integration; predictive maintenance capabilities through advanced analytics. Weaknesses: Highly customized systems require specialized training; significant capital investment; system optimization requires extensive process knowledge and engineering resources.

Critical Statistical Analysis Methods for TIM Processes

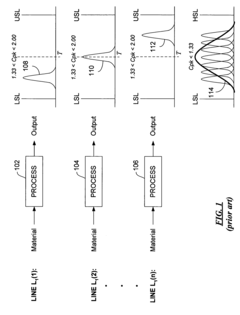

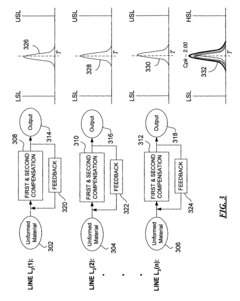

Closed-loop feedback for maximizing Cpk in progressive forming operations

PatentActiveUS7225051B1

Innovation

- A closed-loop feedback control system that detects fiducial features on incoming components, calculates compensation values to adjust forming positions, and continuously updates these values using algorithms to minimize deviations introduced by both components and forming tools, thereby maintaining precise alignment and tool calibration.

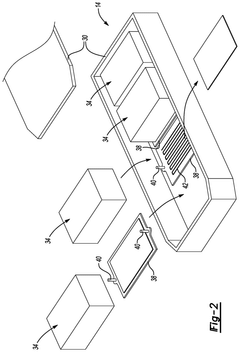

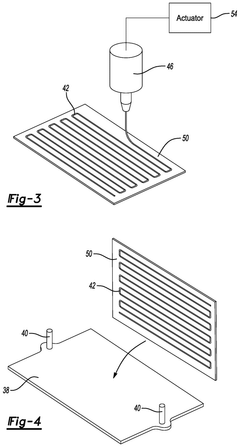

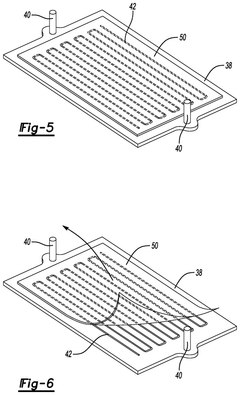

Thermal interface material installation within a traction battery pack

PatentPendingUS20250260085A1

Innovation

- Dispensing TIM onto a release sheet, applying it to a component, and then separating the release sheet while the TIM remains bonded to the component, allowing for automated transfer and compression, thereby reducing cycle times.

Quality Control Standards and Compliance

The implementation of TIM (Thermal Interface Material) process capability studies must adhere to rigorous quality control standards and compliance frameworks to ensure consistent manufacturing outcomes. Industry standards such as ISO 9001:2015 provide the foundational quality management system requirements, while specialized standards like JEDEC JESD22-A121 offer specific guidelines for thermal performance testing of TIMs in semiconductor applications.

For dispensing and compression steps in TIM application, statistical process control metrics like Cp and Cpk must meet minimum thresholds established by industry benchmarks. Typically, a Cpk value of 1.33 or greater is considered acceptable for non-critical parameters, while critical parameters often require Cpk values of 1.67 or higher to ensure robust process capability.

Regulatory bodies including the FDA for medical devices and automotive standards like IATF 16949 impose additional compliance requirements when TIMs are used in these specialized applications. These standards mandate documented process validation protocols, including Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) for dispensing and compression equipment.

Statistical methods for process capability studies must follow guidelines established in reference documents such as the AIAG Statistical Process Control (SPC) manual. These guidelines specify appropriate sampling methods, data collection frequencies, and statistical analysis techniques to ensure valid Cp/Cpk calculations. For TIM dispensing, weight or volume measurements typically require at least 30 consecutive samples under stable process conditions.

Measurement system analysis (MSA) standards, particularly gauge R&R (Repeatability and Reproducibility) studies, must be conducted prior to process capability assessments to validate that measurement systems can adequately discriminate between acceptable and unacceptable product. For TIM applications, measurement systems should typically contribute less than 10% of the total observed process variation.

Documentation requirements for process capability studies include detailed process maps, control plans, and failure mode and effects analysis (FMEA) as prescribed by quality standards. These documents must identify critical process parameters, specification limits, and measurement methods for dispensing volume/weight and compression force/distance parameters.

Continuous monitoring protocols must be established to detect process shifts that might impact Cp/Cpk values over time. Statistical techniques such as control charts (X-bar and R charts) provide real-time monitoring capabilities to maintain process stability and compliance with established quality standards.

For dispensing and compression steps in TIM application, statistical process control metrics like Cp and Cpk must meet minimum thresholds established by industry benchmarks. Typically, a Cpk value of 1.33 or greater is considered acceptable for non-critical parameters, while critical parameters often require Cpk values of 1.67 or higher to ensure robust process capability.

Regulatory bodies including the FDA for medical devices and automotive standards like IATF 16949 impose additional compliance requirements when TIMs are used in these specialized applications. These standards mandate documented process validation protocols, including Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) for dispensing and compression equipment.

Statistical methods for process capability studies must follow guidelines established in reference documents such as the AIAG Statistical Process Control (SPC) manual. These guidelines specify appropriate sampling methods, data collection frequencies, and statistical analysis techniques to ensure valid Cp/Cpk calculations. For TIM dispensing, weight or volume measurements typically require at least 30 consecutive samples under stable process conditions.

Measurement system analysis (MSA) standards, particularly gauge R&R (Repeatability and Reproducibility) studies, must be conducted prior to process capability assessments to validate that measurement systems can adequately discriminate between acceptable and unacceptable product. For TIM applications, measurement systems should typically contribute less than 10% of the total observed process variation.

Documentation requirements for process capability studies include detailed process maps, control plans, and failure mode and effects analysis (FMEA) as prescribed by quality standards. These documents must identify critical process parameters, specification limits, and measurement methods for dispensing volume/weight and compression force/distance parameters.

Continuous monitoring protocols must be established to detect process shifts that might impact Cp/Cpk values over time. Statistical techniques such as control charts (X-bar and R charts) provide real-time monitoring capabilities to maintain process stability and compliance with established quality standards.

Cost-Benefit Analysis of Process Improvements

Implementing process improvements in TIM (Thermal Interface Material) dispensing and compression steps requires careful cost-benefit analysis to justify investments. The financial implications of enhancing process capability metrics (Cp/Cpk) must be quantified against both immediate costs and long-term returns.

Initial investment costs for improving TIM dispensing and compression processes typically include equipment upgrades ($50,000-$150,000), calibration systems ($15,000-$30,000), and advanced measurement tools ($20,000-$45,000). Additionally, staff training programs ($5,000-$10,000) and potential production downtime during implementation (estimated at 24-48 hours) represent significant considerations.

Operational costs encompass increased maintenance requirements (approximately $8,000-$15,000 annually), potential material waste during adjustment periods (3-5% increase initially), and ongoing calibration expenses ($3,000-$6,000 quarterly). These recurring costs must be factored into the total cost of ownership calculation.

The benefits side presents compelling financial advantages. Improved Cp/Cpk values (target: >1.33 for dispensing, >1.67 for compression) directly correlate with reduced scrap rates, typically decreasing by 15-25% within six months of implementation. This translates to material savings of $30,000-$60,000 annually for medium-volume production facilities.

Quality-related cost reductions represent another significant benefit. Field failures attributed to TIM application issues decrease by 30-40% with optimized processes, reducing warranty claims by $50,000-$100,000 annually. Internal quality costs also decline as inspection requirements can be strategically reduced once process capability demonstrates sustained improvement.

Production efficiency gains emerge as processes stabilize, with cycle time reductions of 5-8% achievable through more consistent TIM application. This capacity increase represents $40,000-$70,000 in additional production value annually without capital expansion.

Return on investment analysis indicates most TIM process capability improvement initiatives achieve payback within 12-18 months, with IRR typically ranging from 25-40% depending on production volumes. Sensitivity analysis suggests that even with conservative estimates, these improvements remain financially viable across various production scenarios.

Initial investment costs for improving TIM dispensing and compression processes typically include equipment upgrades ($50,000-$150,000), calibration systems ($15,000-$30,000), and advanced measurement tools ($20,000-$45,000). Additionally, staff training programs ($5,000-$10,000) and potential production downtime during implementation (estimated at 24-48 hours) represent significant considerations.

Operational costs encompass increased maintenance requirements (approximately $8,000-$15,000 annually), potential material waste during adjustment periods (3-5% increase initially), and ongoing calibration expenses ($3,000-$6,000 quarterly). These recurring costs must be factored into the total cost of ownership calculation.

The benefits side presents compelling financial advantages. Improved Cp/Cpk values (target: >1.33 for dispensing, >1.67 for compression) directly correlate with reduced scrap rates, typically decreasing by 15-25% within six months of implementation. This translates to material savings of $30,000-$60,000 annually for medium-volume production facilities.

Quality-related cost reductions represent another significant benefit. Field failures attributed to TIM application issues decrease by 30-40% with optimized processes, reducing warranty claims by $50,000-$100,000 annually. Internal quality costs also decline as inspection requirements can be strategically reduced once process capability demonstrates sustained improvement.

Production efficiency gains emerge as processes stabilize, with cycle time reductions of 5-8% achievable through more consistent TIM application. This capacity increase represents $40,000-$70,000 in additional production value annually without capital expansion.

Return on investment analysis indicates most TIM process capability improvement initiatives achieve payback within 12-18 months, with IRR typically ranging from 25-40% depending on production volumes. Sensitivity analysis suggests that even with conservative estimates, these improvements remain financially viable across various production scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!