TIM For Liquid Immersion: Long-Term Chemistry Compatibility Tests

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Interface Materials for Liquid Immersion: Background and Objectives

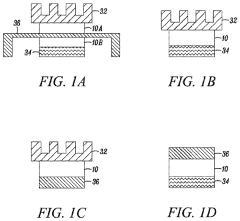

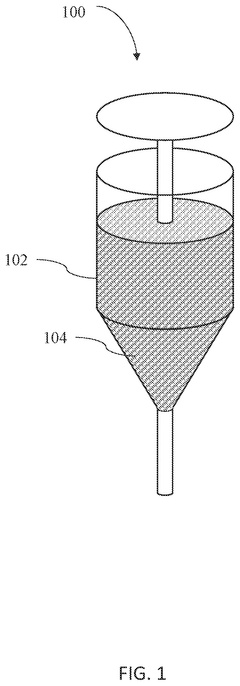

Thermal Interface Materials (TIMs) have emerged as critical components in modern electronics cooling systems, particularly as computing power densities continue to increase exponentially. The evolution of TIMs has been closely tied to the advancement of semiconductor technology, with each generation of processors demanding more efficient heat dissipation solutions. In liquid immersion cooling environments, which represent the cutting edge of thermal management for high-performance computing and data centers, TIMs face unique challenges that traditional air-cooled applications do not encounter.

The historical development of TIMs began with simple thermal greases in the 1980s, progressing through phase-change materials in the 1990s, to today's advanced composites incorporating nanomaterials. This evolution reflects the industry's persistent pursuit of higher thermal conductivity, lower thermal resistance, and greater reliability under increasingly demanding conditions. The introduction of liquid immersion cooling has added another dimension to this development trajectory, requiring TIMs that can maintain performance while submerged in dielectric fluids for extended periods.

Current technological trends point toward the integration of novel materials such as graphene, carbon nanotubes, and metal-matrix composites in TIM formulations. These materials offer promising thermal conductivity values exceeding 20 W/m·K, significantly outperforming traditional silicone-based compounds. However, their long-term chemical compatibility with immersion cooling fluids remains largely unexplored territory.

The primary objective of this research is to systematically evaluate the chemical compatibility of various TIM formulations with common immersion cooling fluids over extended time periods (6-24 months). This investigation aims to identify potential degradation mechanisms, including material breakdown, leaching of components, and changes in thermal performance characteristics. Secondary objectives include quantifying the impact of temperature cycling on TIM stability in immersion environments and developing accelerated testing protocols that can reliably predict long-term performance.

By establishing a comprehensive understanding of TIM behavior in liquid immersion environments, this research seeks to provide critical design guidance for next-generation cooling systems. The findings will enable hardware manufacturers and data center operators to make informed decisions regarding thermal interface material selection, potentially extending equipment lifespan and improving overall system reliability. Additionally, this work aims to establish industry standards for TIM qualification in immersion cooling applications, addressing a significant gap in current specifications.

The historical development of TIMs began with simple thermal greases in the 1980s, progressing through phase-change materials in the 1990s, to today's advanced composites incorporating nanomaterials. This evolution reflects the industry's persistent pursuit of higher thermal conductivity, lower thermal resistance, and greater reliability under increasingly demanding conditions. The introduction of liquid immersion cooling has added another dimension to this development trajectory, requiring TIMs that can maintain performance while submerged in dielectric fluids for extended periods.

Current technological trends point toward the integration of novel materials such as graphene, carbon nanotubes, and metal-matrix composites in TIM formulations. These materials offer promising thermal conductivity values exceeding 20 W/m·K, significantly outperforming traditional silicone-based compounds. However, their long-term chemical compatibility with immersion cooling fluids remains largely unexplored territory.

The primary objective of this research is to systematically evaluate the chemical compatibility of various TIM formulations with common immersion cooling fluids over extended time periods (6-24 months). This investigation aims to identify potential degradation mechanisms, including material breakdown, leaching of components, and changes in thermal performance characteristics. Secondary objectives include quantifying the impact of temperature cycling on TIM stability in immersion environments and developing accelerated testing protocols that can reliably predict long-term performance.

By establishing a comprehensive understanding of TIM behavior in liquid immersion environments, this research seeks to provide critical design guidance for next-generation cooling systems. The findings will enable hardware manufacturers and data center operators to make informed decisions regarding thermal interface material selection, potentially extending equipment lifespan and improving overall system reliability. Additionally, this work aims to establish industry standards for TIM qualification in immersion cooling applications, addressing a significant gap in current specifications.

Market Analysis of Liquid Cooling Solutions

The liquid cooling solutions market has experienced significant growth in recent years, driven primarily by increasing power densities in data centers and the need for more efficient thermal management solutions. The global liquid cooling market was valued at approximately $2.5 billion in 2022 and is projected to reach $7.2 billion by 2028, representing a compound annual growth rate (CAGR) of 19.3% during the forecast period.

Immersion cooling, a subset of this market, is gaining particular attention due to its superior cooling efficiency compared to traditional air cooling methods. This segment is expected to grow at an even higher CAGR of 24.8% through 2028, as data centers seek to accommodate high-performance computing applications, AI workloads, and increasingly powerful processors.

The demand for Thermal Interface Materials (TIMs) specifically designed for liquid immersion environments is closely tied to this market growth. TIMs play a critical role in ensuring efficient heat transfer between electronic components and the cooling medium. The compatibility of these materials with various immersion fluids over extended periods represents a significant concern for end-users, creating a specialized market niche estimated at $340 million in 2022.

Geographically, North America currently leads the liquid cooling market with approximately 38% market share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth due to rapid data center expansion in countries like China, Japan, and Singapore, along with increasing adoption of high-performance computing technologies.

By industry vertical, data centers account for the largest market share (42%), followed by healthcare (18%), telecommunications (15%), and automotive applications (12%). The remaining 13% is distributed across various industries including military, aerospace, and consumer electronics.

Key market drivers include the growing adoption of edge computing, increasing focus on energy efficiency and sustainability, rising deployment of AI and machine learning workloads, and the need to reduce operational costs in data centers. The total cost of ownership (TCO) advantage of liquid immersion cooling systems, which can reduce cooling energy consumption by up to 95% compared to traditional air cooling, remains a compelling factor for market adoption.

Market challenges include high initial implementation costs, concerns about long-term reliability, compatibility issues with existing infrastructure, and the need for specialized expertise for installation and maintenance. The long-term chemical compatibility of TIMs with immersion fluids represents a particular technical challenge that directly impacts product reliability and performance longevity.

Immersion cooling, a subset of this market, is gaining particular attention due to its superior cooling efficiency compared to traditional air cooling methods. This segment is expected to grow at an even higher CAGR of 24.8% through 2028, as data centers seek to accommodate high-performance computing applications, AI workloads, and increasingly powerful processors.

The demand for Thermal Interface Materials (TIMs) specifically designed for liquid immersion environments is closely tied to this market growth. TIMs play a critical role in ensuring efficient heat transfer between electronic components and the cooling medium. The compatibility of these materials with various immersion fluids over extended periods represents a significant concern for end-users, creating a specialized market niche estimated at $340 million in 2022.

Geographically, North America currently leads the liquid cooling market with approximately 38% market share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth due to rapid data center expansion in countries like China, Japan, and Singapore, along with increasing adoption of high-performance computing technologies.

By industry vertical, data centers account for the largest market share (42%), followed by healthcare (18%), telecommunications (15%), and automotive applications (12%). The remaining 13% is distributed across various industries including military, aerospace, and consumer electronics.

Key market drivers include the growing adoption of edge computing, increasing focus on energy efficiency and sustainability, rising deployment of AI and machine learning workloads, and the need to reduce operational costs in data centers. The total cost of ownership (TCO) advantage of liquid immersion cooling systems, which can reduce cooling energy consumption by up to 95% compared to traditional air cooling, remains a compelling factor for market adoption.

Market challenges include high initial implementation costs, concerns about long-term reliability, compatibility issues with existing infrastructure, and the need for specialized expertise for installation and maintenance. The long-term chemical compatibility of TIMs with immersion fluids represents a particular technical challenge that directly impacts product reliability and performance longevity.

Current Challenges in TIM Chemical Compatibility

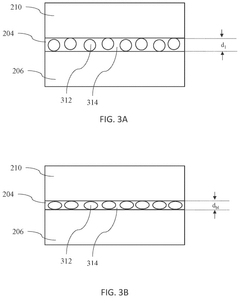

The chemical compatibility of Thermal Interface Materials (TIMs) with liquid immersion cooling fluids presents significant challenges for long-term reliability in data center applications. Current TIMs exhibit varying degrees of degradation when exposed to dielectric fluids over extended periods, compromising their thermal performance and structural integrity. Material swelling, leaching of fillers, and changes in viscosity are commonly observed after prolonged immersion, leading to thermal resistance increases of up to 30-40% in some cases.

Silicone-based TIMs, while offering excellent initial thermal conductivity, demonstrate concerning chemical interactions with hydrocarbon-based dielectric fluids. Studies indicate that after 3000 hours of immersion testing, silicone TIMs can absorb fluid components, resulting in dimensional changes exceeding 15% and significant reductions in adhesive strength at critical thermal interfaces.

Metal-based TIMs face corrosion challenges when trace amounts of water contaminate the immersion environment. Even with moisture levels below 500ppm, galvanic reactions between dissimilar metals in the cooling system can accelerate degradation of aluminum and copper particles commonly used in high-performance TIMs. This corrosion not only reduces thermal conductivity but creates potential particulate contamination in the cooling fluid.

Carbon-based TIMs, including those utilizing graphite and carbon nanotubes, demonstrate better chemical stability but suffer from mechanical interface challenges. Their hydrophobic nature can create micro-voids at material boundaries when immersed, increasing thermal resistance by 20-25% over a 12-month operational period.

Temperature cycling further exacerbates compatibility issues, as differential expansion rates between TIMs and immersion fluids create mechanical stresses at interfaces. Current accelerated testing protocols fail to adequately predict these long-term effects, with laboratory results often underestimating field degradation by factors of 1.5-2x.

Standardization remains problematic, with no universally accepted testing methodology for TIM-fluid compatibility. Different manufacturers employ proprietary testing approaches, making direct comparisons between products difficult for system designers. The industry lacks consensus on acceptable performance degradation thresholds, with some accepting up to 15% thermal performance loss while others require stability within 5% of baseline values.

Emerging high-performance computing applications demanding higher power densities (>100kW per rack) are pushing thermal solutions beyond current compatibility limits. The chemical stability requirements at these elevated thermal loads exceed what current TIM formulations can reliably deliver in immersion environments, creating an urgent need for advanced material development and standardized long-term testing protocols.

Silicone-based TIMs, while offering excellent initial thermal conductivity, demonstrate concerning chemical interactions with hydrocarbon-based dielectric fluids. Studies indicate that after 3000 hours of immersion testing, silicone TIMs can absorb fluid components, resulting in dimensional changes exceeding 15% and significant reductions in adhesive strength at critical thermal interfaces.

Metal-based TIMs face corrosion challenges when trace amounts of water contaminate the immersion environment. Even with moisture levels below 500ppm, galvanic reactions between dissimilar metals in the cooling system can accelerate degradation of aluminum and copper particles commonly used in high-performance TIMs. This corrosion not only reduces thermal conductivity but creates potential particulate contamination in the cooling fluid.

Carbon-based TIMs, including those utilizing graphite and carbon nanotubes, demonstrate better chemical stability but suffer from mechanical interface challenges. Their hydrophobic nature can create micro-voids at material boundaries when immersed, increasing thermal resistance by 20-25% over a 12-month operational period.

Temperature cycling further exacerbates compatibility issues, as differential expansion rates between TIMs and immersion fluids create mechanical stresses at interfaces. Current accelerated testing protocols fail to adequately predict these long-term effects, with laboratory results often underestimating field degradation by factors of 1.5-2x.

Standardization remains problematic, with no universally accepted testing methodology for TIM-fluid compatibility. Different manufacturers employ proprietary testing approaches, making direct comparisons between products difficult for system designers. The industry lacks consensus on acceptable performance degradation thresholds, with some accepting up to 15% thermal performance loss while others require stability within 5% of baseline values.

Emerging high-performance computing applications demanding higher power densities (>100kW per rack) are pushing thermal solutions beyond current compatibility limits. The chemical stability requirements at these elevated thermal loads exceed what current TIM formulations can reliably deliver in immersion environments, creating an urgent need for advanced material development and standardized long-term testing protocols.

Current Testing Methodologies for Long-Term Compatibility

01 Silicone-based TIM compatibility

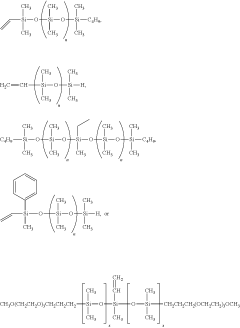

Silicone-based thermal interface materials offer excellent compatibility with various electronic components due to their chemical stability. These materials maintain their thermal conductivity properties over time without degrading or reacting with common substrate materials. Silicone-based TIMs are particularly compatible with metals, ceramics, and most polymers used in electronic packaging, making them versatile for different applications while providing reliable heat transfer performance.- Silicone-based TIM compatibility: Silicone-based thermal interface materials offer excellent compatibility with various electronic components due to their chemical stability and resistance to degradation. These materials maintain their thermal conductivity properties over time and across a wide temperature range. Silicone-based TIMs are particularly compatible with semiconductor materials and metal surfaces, making them suitable for applications in advanced electronic packaging where chemical compatibility is crucial for long-term reliability.

- Metal-based TIM chemical interactions: Metal-based thermal interface materials, including those containing gallium, indium, or other liquid metals, present specific compatibility challenges with certain substrate materials. These TIMs offer superior thermal conductivity but may cause corrosion or amalgamation when in contact with aluminum or certain other metals. Specialized coatings or barrier layers are often required to prevent undesirable chemical reactions while maintaining thermal performance across the interface.

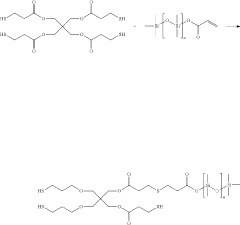

- Polymer-based TIM stability and aging: Polymer-based thermal interface materials must maintain chemical stability when exposed to various environmental conditions including temperature cycling, humidity, and UV radiation. The compatibility of these materials with adjacent components depends on their formulation, with certain additives improving long-term performance and preventing degradation. Cross-linking mechanisms and stabilizers are incorporated to ensure that these TIMs remain chemically compatible with semiconductor packages and heat sinks throughout the device lifetime.

- Testing methods for TIM chemical compatibility: Various testing methodologies have been developed to evaluate the chemical compatibility of thermal interface materials with electronic components. These include accelerated aging tests, chemical resistance evaluations, and interface reaction analyses. Advanced analytical techniques such as spectroscopy and microscopy are employed to detect potential chemical interactions between TIMs and substrate materials, allowing for early identification of compatibility issues before implementation in electronic devices.

- Novel TIM formulations for enhanced compatibility: Recent innovations in thermal interface materials focus on developing formulations with improved chemical compatibility across diverse electronic components. These include hybrid materials combining organic and inorganic components, nanoparticle-enhanced composites, and phase-change materials with tailored chemical properties. Such advanced formulations address specific compatibility challenges while maintaining or enhancing thermal conductivity, allowing for broader application in sensitive electronic assemblies where traditional TIMs might cause degradation or performance issues.

02 Metal-based TIM chemical interactions

Metal-based thermal interface materials, including those containing gallium, indium, or other liquid metals, present specific compatibility challenges. These materials can cause corrosion or amalgamation when in direct contact with certain metals like aluminum. Protective barriers or specialized coatings are often required to prevent unwanted chemical reactions. The high thermal conductivity of metal-based TIMs must be balanced against potential long-term compatibility issues with surrounding materials in the electronic assembly.Expand Specific Solutions03 Polymer-based TIM stability

Polymer-based thermal interface materials offer good chemical compatibility with a wide range of electronic components. These materials, which include epoxy, polyurethane, and acrylic-based formulations, can be engineered to minimize outgassing and prevent contamination of sensitive components. Fillers incorporated into the polymer matrix enhance thermal conductivity while maintaining chemical stability. The curing process and operating temperature range must be carefully controlled to ensure long-term performance without degradation.Expand Specific Solutions04 Carbon-based TIM compatibility solutions

Carbon-based thermal interface materials, including those containing graphene, carbon nanotubes, or graphite, offer excellent thermal conductivity while maintaining good chemical compatibility. These materials are generally inert and do not react with common electronic packaging materials. Surface functionalization can be employed to enhance bonding with specific substrates without compromising thermal performance. Carbon-based TIMs are particularly suitable for applications requiring both high thermal conductivity and chemical stability across a wide temperature range.Expand Specific Solutions05 Testing methods for TIM chemical compatibility

Various testing methodologies have been developed to evaluate the chemical compatibility of thermal interface materials with electronic components. These include accelerated aging tests, thermal cycling, humidity exposure, and chemical resistance evaluations. Advanced analytical techniques such as spectroscopy and microscopy are employed to detect potential degradation or unwanted reactions between TIMs and substrate materials. Standardized testing protocols help ensure that selected thermal interface materials maintain their performance and compatibility throughout the expected lifetime of electronic devices.Expand Specific Solutions

Key Research Findings on TIM-Coolant Interactions

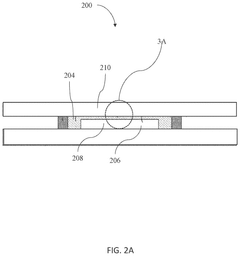

Low melt point metal based thermal interface material

PatentPendingUS20240218228A1

Innovation

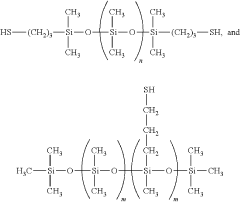

- A thermal interface material composition comprising a low melting point gallium alloy combined with a mercapto-group-containing silicone oil, thermally conductive powder, coupling agent, and emulsifying compound, which improves wettability and compressibility, and is applied using a stencil-printing process.

A thermal interface material, an integrated circuit assembly, and a method for thermally connecting layers

PatentPendingUS20250069987A1

Innovation

- A thermal interface material comprising 8% to 70% by volume of a polymer component and at least 30% by volume of liquid metal droplets, where the polymer component is composed of specific polymers with varying molecular weights and includes polybutadiene, enabling strong adhesion, stretchability, and low thermal resistance.

Environmental Impact and Sustainability Considerations

The environmental implications of Thermal Interface Materials (TIMs) in liquid immersion cooling systems represent a critical dimension of technology assessment that extends beyond performance metrics. Long-term chemistry compatibility testing must consider the full lifecycle environmental impact of these materials. Current TIM formulations often contain metals, silicones, and various synthetic compounds that may pose environmental challenges when disposed of or if they leach into cooling fluids over time.

Sustainability considerations for TIMs in liquid immersion cooling begin with raw material sourcing. Many high-performance thermal interface materials rely on rare earth elements or metals with significant extraction footprints. The mining and processing of these materials contribute to habitat destruction, water pollution, and carbon emissions. Forward-looking compatibility testing must therefore evaluate alternative formulations that utilize more abundant and less environmentally harmful components.

The degradation pathways of TIMs in liquid immersion environments present another environmental concern. Chemical breakdown products may accumulate in cooling fluids, potentially creating hazardous waste streams that require specialized disposal procedures. Long-term compatibility testing protocols should monitor not only performance degradation but also chemical leaching and transformation products that might emerge over extended operational periods.

Energy efficiency represents a positive environmental aspect of effective TIM implementation. By optimizing thermal transfer in immersion cooling systems, properly selected TIMs can significantly reduce the energy consumption of data centers and high-performance computing facilities. This energy reduction translates directly to lower carbon emissions over the system lifecycle, potentially offsetting the environmental costs of TIM production and disposal.

Regulatory compliance frameworks increasingly incorporate environmental standards that affect TIM selection and testing protocols. The European Union's Restriction of Hazardous Substances (RoHS) directive, REACH regulations, and similar global initiatives limit the use of certain compounds commonly found in traditional TIMs. Long-term compatibility testing must therefore verify compliance with current regulations while anticipating future restrictions that may emerge during the operational lifetime of cooling systems.

Recyclability and end-of-life management constitute the final environmental considerations for TIM compatibility testing. Ideal thermal interface materials should maintain their integrity during operation but allow for separation and recycling when systems are decommissioned. Testing protocols should evaluate how TIMs affect the recyclability of other system components and whether the TIMs themselves can be recovered and reprocessed rather than contributing to electronic waste streams.

Sustainability considerations for TIMs in liquid immersion cooling begin with raw material sourcing. Many high-performance thermal interface materials rely on rare earth elements or metals with significant extraction footprints. The mining and processing of these materials contribute to habitat destruction, water pollution, and carbon emissions. Forward-looking compatibility testing must therefore evaluate alternative formulations that utilize more abundant and less environmentally harmful components.

The degradation pathways of TIMs in liquid immersion environments present another environmental concern. Chemical breakdown products may accumulate in cooling fluids, potentially creating hazardous waste streams that require specialized disposal procedures. Long-term compatibility testing protocols should monitor not only performance degradation but also chemical leaching and transformation products that might emerge over extended operational periods.

Energy efficiency represents a positive environmental aspect of effective TIM implementation. By optimizing thermal transfer in immersion cooling systems, properly selected TIMs can significantly reduce the energy consumption of data centers and high-performance computing facilities. This energy reduction translates directly to lower carbon emissions over the system lifecycle, potentially offsetting the environmental costs of TIM production and disposal.

Regulatory compliance frameworks increasingly incorporate environmental standards that affect TIM selection and testing protocols. The European Union's Restriction of Hazardous Substances (RoHS) directive, REACH regulations, and similar global initiatives limit the use of certain compounds commonly found in traditional TIMs. Long-term compatibility testing must therefore verify compliance with current regulations while anticipating future restrictions that may emerge during the operational lifetime of cooling systems.

Recyclability and end-of-life management constitute the final environmental considerations for TIM compatibility testing. Ideal thermal interface materials should maintain their integrity during operation but allow for separation and recycling when systems are decommissioned. Testing protocols should evaluate how TIMs affect the recyclability of other system components and whether the TIMs themselves can be recovered and reprocessed rather than contributing to electronic waste streams.

Standardization and Quality Assurance Protocols

To ensure the reliability and reproducibility of Thermal Interface Materials (TIM) compatibility testing in liquid immersion cooling environments, standardized protocols and quality assurance measures are essential. These protocols must address the unique challenges posed by long-term chemical interactions between TIMs and various immersion fluids.

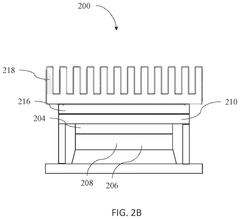

The establishment of standardized testing methodologies begins with sample preparation guidelines that specify precise dimensions, surface treatments, and handling procedures to minimize variability. Testing parameters must be rigorously controlled, including temperature cycling ranges (typically -40°C to 125°C), duration (minimum 1000 hours for long-term tests), and fluid flow conditions that accurately simulate real-world deployment scenarios.

Material characterization before and after immersion testing should follow established industry standards such as ASTM D5470 for thermal conductivity measurements and ASTM D638 for mechanical property evaluation. Documentation requirements must include detailed records of test conditions, measurement uncertainties, and any observed physical or chemical changes throughout the testing period.

Quality assurance measures should incorporate regular calibration of testing equipment, with thermal conductivity measurement devices verified against NIST-traceable standards at minimum quarterly intervals. Statistical analysis methods must be standardized to ensure meaningful interpretation of results, including the use of control samples and appropriate replication to establish statistical significance.

Cross-laboratory validation represents another critical component, requiring interlaboratory comparison studies to verify that testing protocols produce consistent results across different facilities. This validation process should follow guidelines similar to those outlined in ISO/IEC 17043 for proficiency testing in analytical chemistry laboratories.

Accelerated aging protocols must be developed and validated against real-time aging data to provide meaningful predictions of long-term compatibility. These protocols should incorporate multiple stress factors including elevated temperatures, thermal cycling, and mechanical stress under immersion conditions.

Failure analysis procedures need standardization to ensure consistent evaluation of degradation mechanisms. This includes protocols for visual inspection, microscopic examination, chemical analysis of both the TIM and immersion fluid, and correlation of observed changes with thermal performance metrics.

Reporting standards should mandate inclusion of specific data points and observations, ensuring that test results from different sources can be meaningfully compared. These standards must specify minimum requirements for documentation of material compositions, test conditions, measurement methodologies, and statistical analysis of results.

The establishment of standardized testing methodologies begins with sample preparation guidelines that specify precise dimensions, surface treatments, and handling procedures to minimize variability. Testing parameters must be rigorously controlled, including temperature cycling ranges (typically -40°C to 125°C), duration (minimum 1000 hours for long-term tests), and fluid flow conditions that accurately simulate real-world deployment scenarios.

Material characterization before and after immersion testing should follow established industry standards such as ASTM D5470 for thermal conductivity measurements and ASTM D638 for mechanical property evaluation. Documentation requirements must include detailed records of test conditions, measurement uncertainties, and any observed physical or chemical changes throughout the testing period.

Quality assurance measures should incorporate regular calibration of testing equipment, with thermal conductivity measurement devices verified against NIST-traceable standards at minimum quarterly intervals. Statistical analysis methods must be standardized to ensure meaningful interpretation of results, including the use of control samples and appropriate replication to establish statistical significance.

Cross-laboratory validation represents another critical component, requiring interlaboratory comparison studies to verify that testing protocols produce consistent results across different facilities. This validation process should follow guidelines similar to those outlined in ISO/IEC 17043 for proficiency testing in analytical chemistry laboratories.

Accelerated aging protocols must be developed and validated against real-time aging data to provide meaningful predictions of long-term compatibility. These protocols should incorporate multiple stress factors including elevated temperatures, thermal cycling, and mechanical stress under immersion conditions.

Failure analysis procedures need standardization to ensure consistent evaluation of degradation mechanisms. This includes protocols for visual inspection, microscopic examination, chemical analysis of both the TIM and immersion fluid, and correlation of observed changes with thermal performance metrics.

Reporting standards should mandate inclusion of specific data points and observations, ensuring that test results from different sources can be meaningfully compared. These standards must specify minimum requirements for documentation of material compositions, test conditions, measurement methodologies, and statistical analysis of results.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!