TIM For Automotive ECUs: Thermal Shock, Vibration, And OEM Acceptance Criteria

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Automotive TIM Evolution and Objectives

Thermal Interface Materials (TIMs) have undergone significant evolution in automotive applications since their introduction in the 1970s. Initially, automotive electronic control units (ECUs) utilized simple thermal greases with limited thermal conductivity, typically below 1 W/m·K. These early materials provided basic heat transfer capabilities but struggled to maintain performance under the harsh automotive operating conditions, particularly thermal cycling and vibration stress.

The 1990s marked a pivotal shift with the introduction of silicone-based TIMs specifically engineered for automotive applications. These materials offered improved thermal conductivity (1-3 W/m·K) and better resistance to temperature extremes, addressing the growing thermal management needs as ECU complexity increased. This period also saw the first standardized testing protocols for automotive TIMs, though they remained manufacturer-specific rather than industry-wide.

By the early 2000s, the proliferation of advanced driver assistance systems (ADAS) and more sophisticated powertrain controls drove further TIM innovation. Phase-change materials and thermally conductive adhesives emerged as alternatives to traditional greases, offering improved long-term stability and reliability. Thermal conductivity values reached 3-5 W/m·K, while manufacturers began developing more rigorous qualification standards for thermal shock resistance.

The electrification trend of the 2010s dramatically accelerated TIM development for automotive applications. High-power electronics in hybrid and electric vehicles demanded materials capable of handling significantly greater heat loads while maintaining performance through thousands of thermal cycles. This period saw the introduction of metal-filled composites and novel carbon-based TIMs with conductivity values exceeding 10 W/m·K.

Current automotive TIM technology focuses on meeting increasingly stringent OEM requirements for thermal performance, reliability, and environmental sustainability. Modern automotive TIMs must demonstrate resilience to extreme temperature cycling (-40°C to +150°C), withstand continuous vibration across multiple frequency ranges, and maintain performance for 10+ years or 150,000+ miles of vehicle operation.

The primary objectives for next-generation automotive TIMs include achieving thermal conductivity exceeding 15 W/m·K while maintaining compliance and workability, developing materials that can withstand more extreme thermal shock conditions (particularly for electric vehicle applications), improving long-term stability under constant vibration, and meeting increasingly strict environmental and recyclability requirements from global OEMs. Additionally, there is growing emphasis on developing TIMs that can be efficiently applied in high-volume manufacturing environments while maintaining consistent performance characteristics.

The 1990s marked a pivotal shift with the introduction of silicone-based TIMs specifically engineered for automotive applications. These materials offered improved thermal conductivity (1-3 W/m·K) and better resistance to temperature extremes, addressing the growing thermal management needs as ECU complexity increased. This period also saw the first standardized testing protocols for automotive TIMs, though they remained manufacturer-specific rather than industry-wide.

By the early 2000s, the proliferation of advanced driver assistance systems (ADAS) and more sophisticated powertrain controls drove further TIM innovation. Phase-change materials and thermally conductive adhesives emerged as alternatives to traditional greases, offering improved long-term stability and reliability. Thermal conductivity values reached 3-5 W/m·K, while manufacturers began developing more rigorous qualification standards for thermal shock resistance.

The electrification trend of the 2010s dramatically accelerated TIM development for automotive applications. High-power electronics in hybrid and electric vehicles demanded materials capable of handling significantly greater heat loads while maintaining performance through thousands of thermal cycles. This period saw the introduction of metal-filled composites and novel carbon-based TIMs with conductivity values exceeding 10 W/m·K.

Current automotive TIM technology focuses on meeting increasingly stringent OEM requirements for thermal performance, reliability, and environmental sustainability. Modern automotive TIMs must demonstrate resilience to extreme temperature cycling (-40°C to +150°C), withstand continuous vibration across multiple frequency ranges, and maintain performance for 10+ years or 150,000+ miles of vehicle operation.

The primary objectives for next-generation automotive TIMs include achieving thermal conductivity exceeding 15 W/m·K while maintaining compliance and workability, developing materials that can withstand more extreme thermal shock conditions (particularly for electric vehicle applications), improving long-term stability under constant vibration, and meeting increasingly strict environmental and recyclability requirements from global OEMs. Additionally, there is growing emphasis on developing TIMs that can be efficiently applied in high-volume manufacturing environments while maintaining consistent performance characteristics.

Market Requirements for ECU Thermal Management

The automotive industry is witnessing a significant transformation in electronic control unit (ECU) design and implementation, with thermal management emerging as a critical factor in ensuring reliability and performance. Market requirements for ECU thermal management are increasingly stringent as vehicles incorporate more sophisticated electronic systems, particularly in electric and autonomous vehicles where computational demands are substantially higher.

Original equipment manufacturers (OEMs) have established rigorous thermal specifications that thermal interface materials (TIMs) must meet. These specifications typically demand operational stability across temperature ranges from -40°C to 125°C for standard applications, with even more extreme requirements for specialized applications such as powertrain control modules. The thermal cycling capability has become paramount, with many OEMs requiring TIMs to withstand 1,000 or more thermal cycles without significant degradation in thermal conductivity.

Vibration resistance represents another critical market requirement, as automotive ECUs are subjected to continuous mechanical stress during vehicle operation. OEMs commonly specify vibration testing protocols that simulate real-world conditions, including random vibration profiles that can exceed 10G RMS across frequency ranges of 10Hz to 2000Hz. TIMs must maintain their position and thermal performance characteristics throughout these tests.

Reliability metrics have evolved to include accelerated aging tests that simulate 10-15 years of operational life. These tests evaluate the TIM's resistance to thermal degradation, chemical compatibility with ECU housing materials, and long-term adhesion properties. The market increasingly demands materials that demonstrate less than 10% degradation in thermal performance over the vehicle's expected lifespan.

Cost considerations remain significant, with automotive manufacturers seeking thermal management solutions that balance performance with economic viability. The market shows a preference for TIMs that can be applied through automated processes to reduce assembly costs and ensure consistent application quality. This has driven innovation in pre-applied TIMs and phase-change materials that activate during initial system operation.

Environmental compliance has become a non-negotiable market requirement, with OEMs mandating adherence to regulations such as REACH and RoHS. Additionally, there is growing demand for halogen-free formulations and materials with reduced environmental impact throughout their lifecycle. Some leading manufacturers are now requiring carbon footprint assessments for thermal management components.

The market is also witnessing increased demand for TIMs that can accommodate miniaturization trends in ECU design. As ECUs become more compact and powerful, thermal management solutions must provide higher thermal conductivity in thinner application profiles, typically below 0.5mm thickness while maintaining gap-filling capabilities to accommodate manufacturing tolerances.

Original equipment manufacturers (OEMs) have established rigorous thermal specifications that thermal interface materials (TIMs) must meet. These specifications typically demand operational stability across temperature ranges from -40°C to 125°C for standard applications, with even more extreme requirements for specialized applications such as powertrain control modules. The thermal cycling capability has become paramount, with many OEMs requiring TIMs to withstand 1,000 or more thermal cycles without significant degradation in thermal conductivity.

Vibration resistance represents another critical market requirement, as automotive ECUs are subjected to continuous mechanical stress during vehicle operation. OEMs commonly specify vibration testing protocols that simulate real-world conditions, including random vibration profiles that can exceed 10G RMS across frequency ranges of 10Hz to 2000Hz. TIMs must maintain their position and thermal performance characteristics throughout these tests.

Reliability metrics have evolved to include accelerated aging tests that simulate 10-15 years of operational life. These tests evaluate the TIM's resistance to thermal degradation, chemical compatibility with ECU housing materials, and long-term adhesion properties. The market increasingly demands materials that demonstrate less than 10% degradation in thermal performance over the vehicle's expected lifespan.

Cost considerations remain significant, with automotive manufacturers seeking thermal management solutions that balance performance with economic viability. The market shows a preference for TIMs that can be applied through automated processes to reduce assembly costs and ensure consistent application quality. This has driven innovation in pre-applied TIMs and phase-change materials that activate during initial system operation.

Environmental compliance has become a non-negotiable market requirement, with OEMs mandating adherence to regulations such as REACH and RoHS. Additionally, there is growing demand for halogen-free formulations and materials with reduced environmental impact throughout their lifecycle. Some leading manufacturers are now requiring carbon footprint assessments for thermal management components.

The market is also witnessing increased demand for TIMs that can accommodate miniaturization trends in ECU design. As ECUs become more compact and powerful, thermal management solutions must provide higher thermal conductivity in thinner application profiles, typically below 0.5mm thickness while maintaining gap-filling capabilities to accommodate manufacturing tolerances.

TIM Technical Challenges in Automotive Environments

Thermal Interface Materials (TIMs) in automotive electronic control units (ECUs) face unique and demanding challenges due to the harsh operating environment of vehicles. The automotive industry imposes stringent requirements on all components, with thermal management solutions being particularly critical as ECUs become more powerful and compact.

Temperature cycling represents one of the most significant challenges for TIMs in automotive applications. ECUs must withstand extreme temperature variations ranging from -40°C to 125°C, with rapid transitions between these extremes. This thermal shock creates substantial stress at material interfaces due to coefficient of thermal expansion (CTE) mismatches between different components. Over time, these repeated cycles can lead to pump-out effects, where the TIM material is gradually forced out from between the mating surfaces, significantly reducing thermal performance.

Vibration presents another major technical hurdle for automotive TIMs. Vehicles experience continuous vibration during operation, with frequencies typically ranging from 10Hz to 2000Hz and acceleration forces up to 30G in extreme cases. These mechanical stresses can cause TIM degradation through several mechanisms: physical displacement of the material, breakdown of the internal structure, and separation at interfaces. Traditional TIMs often struggle to maintain performance under these combined thermal and mechanical stresses.

Reliability requirements for automotive-grade TIMs are exceptionally demanding. Components must demonstrate functionality for 10-15 years or 150,000-300,000 miles under varying environmental conditions. This longevity requirement necessitates minimal performance degradation over time, presenting significant materials science challenges in formulating stable compounds that resist aging effects.

Original Equipment Manufacturer (OEM) acceptance criteria add another layer of complexity. Each automotive manufacturer maintains proprietary qualification standards that often exceed industry norms. These typically include accelerated aging tests, thermal cycling protocols, vibration resistance evaluations, and compatibility assessments with specific materials used in their ECU designs. Meeting these diverse requirements across different OEMs requires TIM solutions with exceptional versatility or customization capabilities.

Environmental and safety regulations further constrain TIM development. Automotive components must comply with standards like REACH and RoHS, limiting the use of certain chemicals. Additionally, end-of-life recyclability is becoming increasingly important, requiring TIMs that can be separated from electronic components or that use environmentally friendly materials.

Manufacturing scalability and consistency represent the final major challenge. Automotive production volumes demand TIM solutions that can be applied with high throughput, minimal defects, and consistent performance across millions of units. This necessitates materials and application methods that are robust against manufacturing variations while maintaining precise thermal characteristics.

Temperature cycling represents one of the most significant challenges for TIMs in automotive applications. ECUs must withstand extreme temperature variations ranging from -40°C to 125°C, with rapid transitions between these extremes. This thermal shock creates substantial stress at material interfaces due to coefficient of thermal expansion (CTE) mismatches between different components. Over time, these repeated cycles can lead to pump-out effects, where the TIM material is gradually forced out from between the mating surfaces, significantly reducing thermal performance.

Vibration presents another major technical hurdle for automotive TIMs. Vehicles experience continuous vibration during operation, with frequencies typically ranging from 10Hz to 2000Hz and acceleration forces up to 30G in extreme cases. These mechanical stresses can cause TIM degradation through several mechanisms: physical displacement of the material, breakdown of the internal structure, and separation at interfaces. Traditional TIMs often struggle to maintain performance under these combined thermal and mechanical stresses.

Reliability requirements for automotive-grade TIMs are exceptionally demanding. Components must demonstrate functionality for 10-15 years or 150,000-300,000 miles under varying environmental conditions. This longevity requirement necessitates minimal performance degradation over time, presenting significant materials science challenges in formulating stable compounds that resist aging effects.

Original Equipment Manufacturer (OEM) acceptance criteria add another layer of complexity. Each automotive manufacturer maintains proprietary qualification standards that often exceed industry norms. These typically include accelerated aging tests, thermal cycling protocols, vibration resistance evaluations, and compatibility assessments with specific materials used in their ECU designs. Meeting these diverse requirements across different OEMs requires TIM solutions with exceptional versatility or customization capabilities.

Environmental and safety regulations further constrain TIM development. Automotive components must comply with standards like REACH and RoHS, limiting the use of certain chemicals. Additionally, end-of-life recyclability is becoming increasingly important, requiring TIMs that can be separated from electronic components or that use environmentally friendly materials.

Manufacturing scalability and consistency represent the final major challenge. Automotive production volumes demand TIM solutions that can be applied with high throughput, minimal defects, and consistent performance across millions of units. This necessitates materials and application methods that are robust against manufacturing variations while maintaining precise thermal characteristics.

Current TIM Solutions for ECU Thermal Management

01 Composite materials for enhanced thermal shock resistance

Thermal interface materials can be formulated with composite structures that combine different materials to enhance thermal shock resistance. These composites typically include a matrix material with embedded fillers that can absorb and distribute thermal stress. The combination of flexible polymers with rigid fillers creates a material that can withstand rapid temperature changes without cracking or delaminating, making them suitable for applications with frequent thermal cycling.- Composite materials for enhanced thermal shock resistance: Thermal interface materials can be formulated with composite structures that combine different materials to enhance thermal shock resistance. These composites typically include a matrix material with embedded fillers that can absorb and distribute thermal stress. The combination of materials with different thermal expansion coefficients allows the TIM to maintain integrity during rapid temperature changes. These composites often incorporate elastomeric components that can flex during thermal cycling without losing contact with the mating surfaces.

- Nanostructured TIMs for vibration resistance: Nanostructured thermal interface materials offer superior vibration resistance due to their unique physical properties. These materials incorporate nanoscale particles or structures such as carbon nanotubes, graphene, or metal nanoparticles that create a flexible yet robust network within the TIM. This nanostructure allows the material to absorb vibration energy while maintaining thermal conductivity pathways. The small scale of these structures enables them to fill microscopic gaps between surfaces even under vibration conditions, ensuring consistent thermal contact.

- Phase-change materials for thermal cycling stability: Phase-change thermal interface materials provide excellent performance under thermal shock conditions by utilizing materials that change phase at specific temperatures. These materials can absorb significant thermal energy during phase transitions, helping to buffer temperature spikes. When solid, they provide structural stability, and when softened or melted, they ensure complete surface contact. This dual-state behavior allows them to maintain consistent thermal conductivity even during extreme thermal cycling, making them ideal for applications with frequent temperature fluctuations.

- Reinforced polymer matrices for mechanical stability: Reinforced polymer matrices in thermal interface materials significantly improve both thermal shock and vibration resistance. These TIMs incorporate fibrous or particulate reinforcements within a polymer base to create a mechanically robust structure. The reinforcements can include glass fibers, ceramic particles, or metal meshes that provide structural integrity while allowing some flexibility. This combination prevents cracking or delamination during thermal cycling and maintains performance under vibration conditions, making these materials suitable for high-reliability applications in harsh environments.

- Testing and qualification methods for TIM reliability: Specialized testing and qualification methods have been developed to evaluate the thermal shock and vibration resistance of thermal interface materials. These methods include accelerated aging tests, thermal cycling between extreme temperatures, and combined thermal-mechanical stress testing. Advanced analytical techniques such as acoustic microscopy, thermal impedance measurements, and mechanical shear testing help identify potential failure modes. These testing protocols ensure that TIMs maintain their thermal conductivity and mechanical integrity under the combined stresses of thermal shock and vibration that occur in real-world applications.

02 Elastomeric TIMs for vibration dampening

Elastomeric thermal interface materials provide both thermal conductivity and vibration resistance. These materials typically incorporate silicone or other elastomeric polymers that can absorb mechanical energy and dampen vibrations while maintaining good thermal contact between surfaces. The elasticity allows the material to conform to surface irregularities and maintain contact under vibration conditions, preventing thermal performance degradation in high-vibration environments such as automotive or industrial applications.Expand Specific Solutions03 Phase change materials for thermal stability

Phase change thermal interface materials offer improved thermal shock resistance by changing state at specific temperatures. These materials can absorb thermal energy during phase transitions, helping to buffer temperature spikes and provide more stable thermal performance. When subjected to thermal cycling, the phase change behavior allows the material to accommodate expansion and contraction while maintaining intimate contact with heat-generating components, resulting in consistent thermal performance even under variable conditions.Expand Specific Solutions04 Nanostructured TIMs for mechanical resilience

Thermal interface materials incorporating nanostructures such as carbon nanotubes, graphene, or metal nanowires exhibit enhanced mechanical resilience against thermal shock and vibration. The nanoscale structures create a network that can flex and recover under stress while maintaining thermal pathways. These materials often demonstrate superior thermal conductivity combined with mechanical flexibility, allowing them to withstand physical stresses that would cause conventional TIMs to fail or degrade in performance.Expand Specific Solutions05 Testing and qualification methods for TIM reliability

Specialized testing methodologies have been developed to evaluate thermal interface materials for thermal shock and vibration resistance. These include accelerated aging tests, thermal cycling protocols, and vibration testing under various frequencies and amplitudes. Advanced analytical techniques such as acoustic microscopy and thermal impedance measurements can detect early signs of material degradation or delamination. These testing approaches help in selecting appropriate TIMs for applications with demanding environmental conditions and reliability requirements.Expand Specific Solutions

Leading Automotive TIM Manufacturers and Suppliers

The thermal interface materials (TIM) market for automotive ECUs is in a growth phase, driven by increasing electronic content in vehicles and stringent thermal management requirements. The market is expanding as automotive electronics become more sophisticated, with a projected CAGR of 8-10% through 2028. Major OEMs like Toyota, Honda, and Renault are establishing rigorous acceptance criteria for TIMs that can withstand extreme thermal shock and vibration conditions. Technology leaders include Dow Silicones and 3M with advanced silicone-based solutions, while automotive specialists like DENSO and Astemo are developing application-specific formulations. Tier-1 suppliers such as ZF and Aptiv are integrating these materials into their ECU designs, working closely with semiconductor companies like Intel and QUALCOMM to address thermal challenges in next-generation automotive computing platforms.

TDK Corp.

Technical Solution: TDK has developed advanced ceramic-based TIMs specifically for automotive ECU applications under their TDK-Lambda series. Their technology incorporates aluminum nitride and boron nitride ceramic fillers in a silicone matrix, achieving thermal conductivity values of 3.0-7.0 W/m·K while maintaining flexibility across automotive temperature ranges (-40°C to 150°C). TDK's automotive TIMs feature a unique dual-phase structure that combines solid ceramic particles with phase-change materials, optimizing performance across temperature fluctuations experienced in automotive environments. Their materials undergo comprehensive qualification testing including thermal shock (1000 cycles from -40°C to 125°C), vibration testing (10-2000Hz with acceleration profiles matching specific vehicle mounting locations), and high-temperature/high-humidity storage (85°C/85% RH for 1000 hours). TDK's automotive TIMs are formulated to meet global automotive standards including AEC-Q200, IATF 16949, and specific OEM requirements from Japanese, European, and American manufacturers. Their solutions include both pre-applied options for automated assembly and field-serviceable formats for aftermarket applications.

Strengths: Excellent thermal stability across wide temperature ranges; minimal performance degradation after extended thermal cycling; low outgassing meeting automotive VOC requirements. Weaknesses: Requires higher compression forces than some competing technologies; limited reworkability after initial application; premium pricing compared to basic thermal greases.

Dow Silicones Corp.

Technical Solution: Dow Silicones has pioneered silicone-based TIMs specifically designed for automotive ECU applications with their DOWSIL™ TC series. Their technology employs a two-component silicone elastomer system with thermally conductive fillers that create a compressible interface material capable of withstanding extreme temperature cycling from -55°C to 175°C. The material maintains performance through 3000+ thermal shock cycles while providing thermal conductivity values of 2.5-4.0 W/m·K. Dow's formulations feature controlled volatility with <0.5% weight loss at 150°C/1000hrs, addressing concerns about siloxane contamination of electrical contacts. Their materials undergo comprehensive testing including pressure-cooker tests (121°C/100% RH/2atm) and high-temperature storage (150°C/3000hrs) to validate long-term reliability. Dow's automotive TIMs are engineered with controlled bond-line thickness and minimal pump-out, maintaining thermal performance despite engine vibration and thermal expansion mismatches between components.

Strengths: Exceptional long-term reliability with minimal performance degradation; customizable formulations to meet specific OEM requirements; global manufacturing capabilities ensuring consistent quality and supply chain security. Weaknesses: Requires careful surface preparation for optimal adhesion; some formulations have longer cure times impacting production efficiency; premium pricing compared to conventional thermal greases.

Key Patents in Automotive-Grade TIM Technology

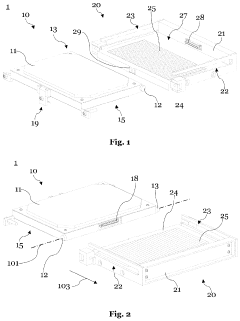

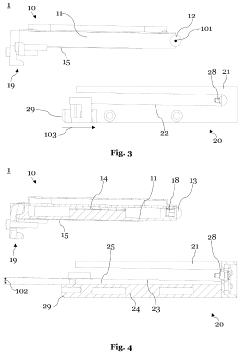

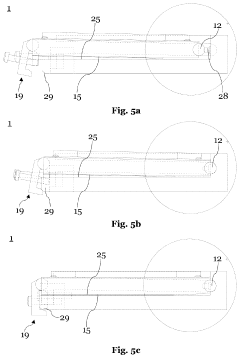

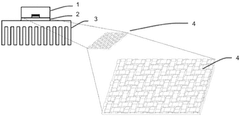

Electric Coupling System

PatentPendingUS20240164067A1

Innovation

- The electric coupling system features a guide element and guide track configuration that allows the ECU to be inserted and rotated relative to the receiving unit, ensuring planar contact and reduced risk of surface damage, with thermal interface materials enhancing heat transfer and providing a secure mechanical and electrical connection through sliding and rotational engagement.

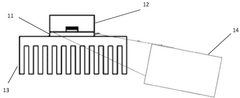

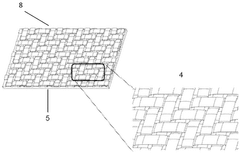

Improved structure of thermal interface material for enhanced heat transfer in electronic components

PatentWO2025004097A1

Innovation

- A thermal interface material sheet with an interwoven mesh structure or twill weave pattern on one side and a standard planar adhesive structure on the other, featuring air gaps to enhance heat transfer and stability during compression, ensuring even distribution of thermally conductive adhesive and increasing the surface area for heat dissipation.

OEM Qualification Standards and Testing Protocols

Automotive OEMs have established rigorous qualification standards and testing protocols for Thermal Interface Materials (TIMs) used in Electronic Control Units (ECUs). These standards vary across manufacturers but generally align with international testing frameworks such as JEDEC, AEC-Q100, and ISO 16750. The qualification process typically encompasses thermal cycling, thermal shock, vibration resistance, and long-term reliability testing.

The thermal shock testing requirements are particularly stringent, with most OEMs mandating that TIMs withstand rapid temperature transitions ranging from -40°C to +125°C for at least 1,000 cycles without significant degradation in thermal performance. This simulates the extreme temperature variations experienced in automotive environments, from cold starts in winter to engine compartment heat during operation.

Vibration testing protocols follow standards such as ISO 16750-3 and SAE J1455, requiring TIMs to maintain their integrity and thermal conductivity under various vibration profiles. These tests typically include random vibration patterns at frequencies between 10Hz and 2000Hz with acceleration forces up to 30G, simulating road conditions and engine vibrations over the vehicle's lifetime.

Mechanical stability testing evaluates the TIM's resistance to pump-out and dry-out phenomena, which can occur due to thermal expansion differences between mating surfaces. OEMs generally require less than 10% degradation in thermal performance after extended thermal cycling and vibration exposure.

Chemical compatibility testing ensures TIMs do not react adversely with common automotive fluids or cause galvanic corrosion between different metals. This includes exposure to oils, coolants, and salt spray testing according to ASTM B117 standards.

Reliability demonstration testing (RDT) represents the final hurdle in OEM acceptance, requiring TIMs to maintain performance through combined stress tests that simulate 10-15 years of vehicle operation. These tests often include power cycling under high humidity and temperature conditions while subjected to vibration.

Documentation requirements for qualification are extensive, with OEMs demanding detailed material composition disclosures, manufacturing process controls, and statistical process control data. Many European and Japanese OEMs have additional requirements regarding environmental compliance, including REACH, RoHS, and end-of-life recyclability documentation.

The trend among OEMs is toward standardization of testing protocols while simultaneously increasing performance requirements, particularly for electric vehicle applications where thermal management is critical for battery longevity and power electronics reliability.

The thermal shock testing requirements are particularly stringent, with most OEMs mandating that TIMs withstand rapid temperature transitions ranging from -40°C to +125°C for at least 1,000 cycles without significant degradation in thermal performance. This simulates the extreme temperature variations experienced in automotive environments, from cold starts in winter to engine compartment heat during operation.

Vibration testing protocols follow standards such as ISO 16750-3 and SAE J1455, requiring TIMs to maintain their integrity and thermal conductivity under various vibration profiles. These tests typically include random vibration patterns at frequencies between 10Hz and 2000Hz with acceleration forces up to 30G, simulating road conditions and engine vibrations over the vehicle's lifetime.

Mechanical stability testing evaluates the TIM's resistance to pump-out and dry-out phenomena, which can occur due to thermal expansion differences between mating surfaces. OEMs generally require less than 10% degradation in thermal performance after extended thermal cycling and vibration exposure.

Chemical compatibility testing ensures TIMs do not react adversely with common automotive fluids or cause galvanic corrosion between different metals. This includes exposure to oils, coolants, and salt spray testing according to ASTM B117 standards.

Reliability demonstration testing (RDT) represents the final hurdle in OEM acceptance, requiring TIMs to maintain performance through combined stress tests that simulate 10-15 years of vehicle operation. These tests often include power cycling under high humidity and temperature conditions while subjected to vibration.

Documentation requirements for qualification are extensive, with OEMs demanding detailed material composition disclosures, manufacturing process controls, and statistical process control data. Many European and Japanese OEMs have additional requirements regarding environmental compliance, including REACH, RoHS, and end-of-life recyclability documentation.

The trend among OEMs is toward standardization of testing protocols while simultaneously increasing performance requirements, particularly for electric vehicle applications where thermal management is critical for battery longevity and power electronics reliability.

Environmental Sustainability in Automotive TIMs

Environmental sustainability has become a critical consideration in the development of Thermal Interface Materials (TIMs) for automotive Electronic Control Units (ECUs). As regulatory frameworks worldwide increasingly emphasize carbon footprint reduction and end-of-life recyclability, TIM manufacturers are pivoting toward more sustainable material compositions and manufacturing processes.

Current automotive TIMs often contain materials that pose environmental challenges, including silicones, metal fillers, and synthetic polymers with high environmental persistence. The industry is witnessing a significant shift toward bio-based alternatives, with research focusing on cellulose-derived compounds and plant-based oils as matrix materials. These alternatives demonstrate promising thermal conductivity while substantially reducing environmental impact throughout their lifecycle.

Manufacturing processes for automotive TIMs are evolving to incorporate principles of green chemistry. Energy-efficient production methods, solvent-free formulations, and reduced waste generation are becoming standard practices among leading manufacturers. Companies like Henkel, Parker Chomerics, and Laird have introduced manufacturing protocols that reduce carbon emissions by 15-30% compared to traditional methods.

End-of-life considerations represent another crucial aspect of environmental sustainability for automotive TIMs. The difficulty in separating TIMs from electronic components has historically complicated recycling efforts. Recent innovations include thermally reversible adhesives and phase-change materials designed specifically for disassembly, enabling more effective component recovery and recycling.

OEMs are increasingly incorporating environmental criteria into their TIM acceptance specifications. BMW, Volkswagen, and Tesla have pioneered sustainability metrics that evaluate not only thermal performance and reliability but also carbon footprint, recyclability percentage, and absence of substances of very high concern (SVHCs). These criteria are driving innovation throughout the supply chain.

The economic implications of sustainable TIMs present both challenges and opportunities. While environmentally friendly formulations may currently carry a 10-20% cost premium, this gap is narrowing as production scales increase and regulatory pressures intensify. Forward-thinking suppliers are finding competitive advantage through early adoption of sustainable practices, particularly as automotive manufacturers commit to carbon neutrality targets.

Looking ahead, the convergence of thermal performance requirements with environmental sustainability will likely accelerate as electric vehicles become dominant in the automotive landscape. The increased thermal management demands of EVs, coupled with their environmental positioning, create a natural incentive for the development of next-generation sustainable TIMs that deliver both performance and reduced ecological impact.

Current automotive TIMs often contain materials that pose environmental challenges, including silicones, metal fillers, and synthetic polymers with high environmental persistence. The industry is witnessing a significant shift toward bio-based alternatives, with research focusing on cellulose-derived compounds and plant-based oils as matrix materials. These alternatives demonstrate promising thermal conductivity while substantially reducing environmental impact throughout their lifecycle.

Manufacturing processes for automotive TIMs are evolving to incorporate principles of green chemistry. Energy-efficient production methods, solvent-free formulations, and reduced waste generation are becoming standard practices among leading manufacturers. Companies like Henkel, Parker Chomerics, and Laird have introduced manufacturing protocols that reduce carbon emissions by 15-30% compared to traditional methods.

End-of-life considerations represent another crucial aspect of environmental sustainability for automotive TIMs. The difficulty in separating TIMs from electronic components has historically complicated recycling efforts. Recent innovations include thermally reversible adhesives and phase-change materials designed specifically for disassembly, enabling more effective component recovery and recycling.

OEMs are increasingly incorporating environmental criteria into their TIM acceptance specifications. BMW, Volkswagen, and Tesla have pioneered sustainability metrics that evaluate not only thermal performance and reliability but also carbon footprint, recyclability percentage, and absence of substances of very high concern (SVHCs). These criteria are driving innovation throughout the supply chain.

The economic implications of sustainable TIMs present both challenges and opportunities. While environmentally friendly formulations may currently carry a 10-20% cost premium, this gap is narrowing as production scales increase and regulatory pressures intensify. Forward-thinking suppliers are finding competitive advantage through early adoption of sustainable practices, particularly as automotive manufacturers commit to carbon neutrality targets.

Looking ahead, the convergence of thermal performance requirements with environmental sustainability will likely accelerate as electric vehicles become dominant in the automotive landscape. The increased thermal management demands of EVs, coupled with their environmental positioning, create a natural incentive for the development of next-generation sustainable TIMs that deliver both performance and reduced ecological impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!